If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab P1S vs the Bambu Lab A1

Bambu Lab P1S

(~10.25 x 10.25 x 10.25 in)

Vs.

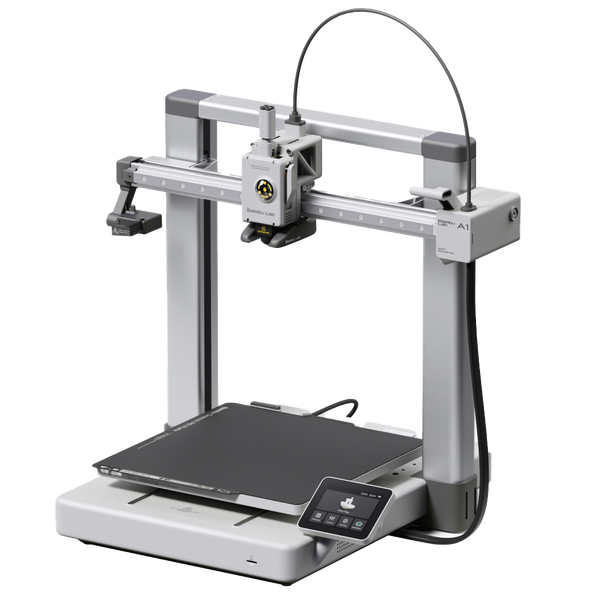

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

The Bambu Lab P1S and A1 are two of Bambu’s most popular 3D printers. With the two machines having several key features in common, it can be difficult to decide which of these printers is the right choice for you and what the important differences are. We’ve tested both of these 3D printers hands-on, so we’ll go through each of the major features and point out the differences between the machines that you might want to consider, and give our recommendations about which of these printers is the best choice.

The Bambu Lab P1S is an upgraded version of the Bambu P1P, which was an extremely popular 3D printer that helped put Bambu Lab on the map in the 3D printing world. The P1S is a fully enclosed machine with a CoreXY motion system, giving it a sleek, modern appearance. Along with the Bambu P1P and X1C, it’s compatible with the Bambu AMS multi-material add-on, which allows the P1S to print with multiple colors or materials. This is one of the big features that has set Bambu Lab’s printers apart from the competition.

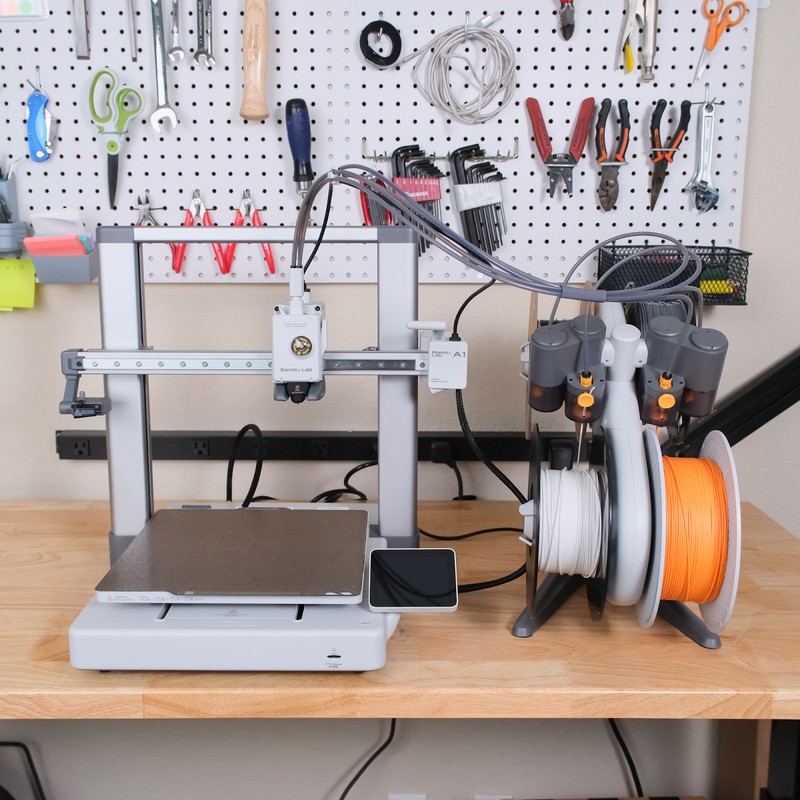

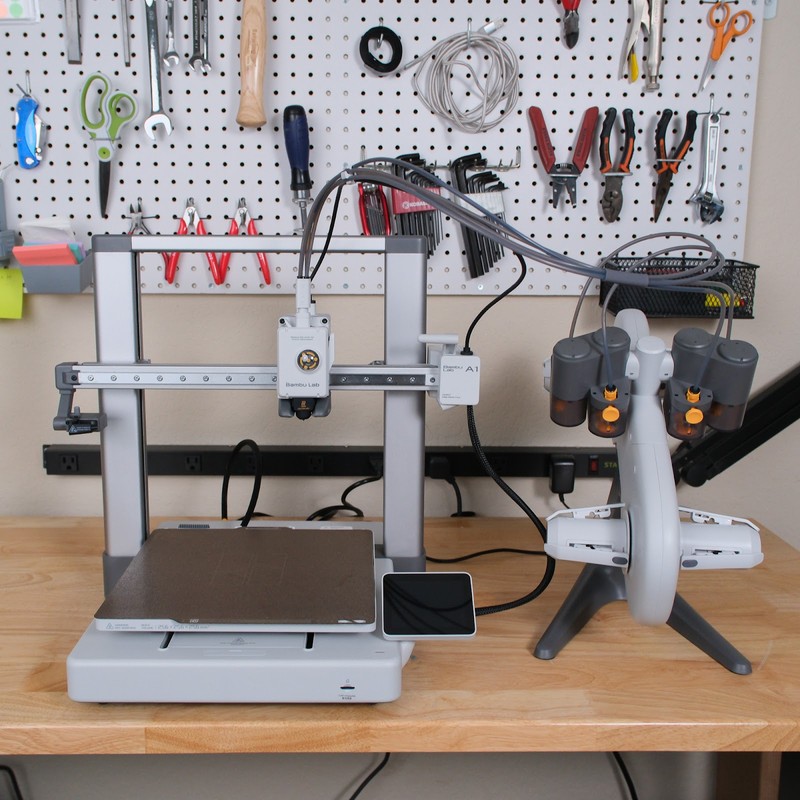

The Bambu Lab A1 is a newer model from Bambu that is aimed at a lower price point. Similar to many other 3D printers in the market, it’s a Cartesian “bedslinger” design in which the bed moves back and forth in an open-air chassis. It’s also capable of multi-material printing with the newer Bambu AMS Lite, giving it many of the same capabilities as the P1S. Since its release, the A1 has become extremely popular among hobbyists, and has also seen extensive adoption in schools and universities due to its more affordable price.

For this article, we’ll be covering the similarities and differences between the two machines to help you clearly see how the P1S and A1 compare. We’ll start with the similarities between the machines.

Similarities Between the Bambu Lab P1S and Bambu Lab A1

The two 3D printers have many features in common, but even among the common features, the two printers sometimes implement them differently. We’ll cover the major differences in this section.

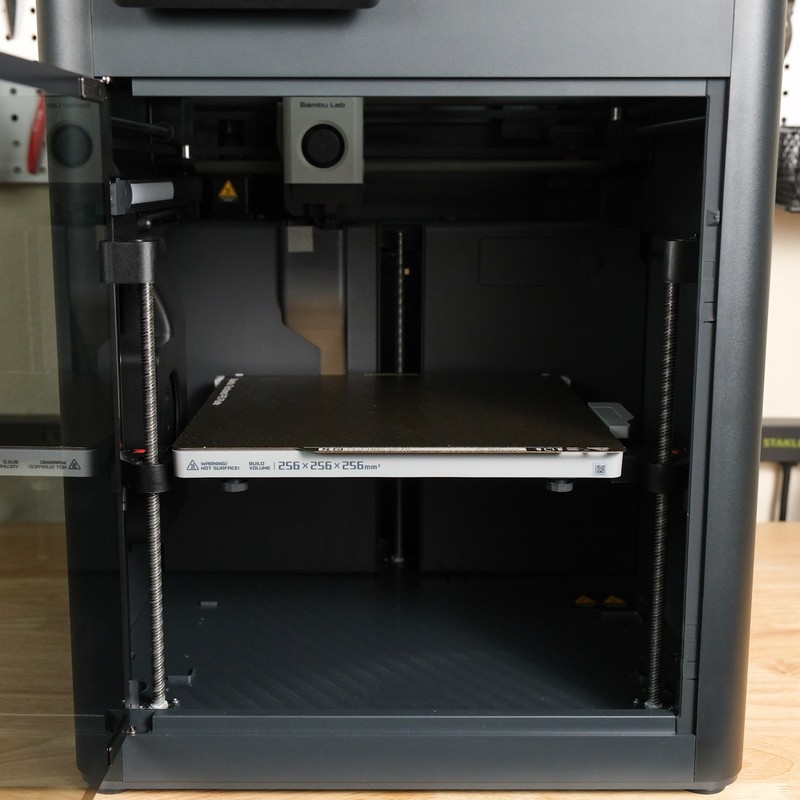

Build Volume

The Bambu P1S and A1 both have a build volume of 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”). This is slightly larger than the average for 3D printers at this price point, with many other machines having a slightly smaller 220 mm x 220 mm x 250 mm volume. In our opinion, this is a good balance of size that allows you to print many functional or decorative parts as a single piece, while still keeping the overall size of the printer small enough to reasonably fit in your workspace.

Print Quality

Both 3D printers are capable of excellent print quality. Bambu’s printers are some of the best machines you can buy in terms of overall print quality, and although the P1S and A1 have a few differences that should theoretically impact print quality, the reality is that there is very little difference in the print quality you’ll see from either machine. The best way to describe the print quality from Bambu’s printers is that out of the box, it’s as good or better than what you can achieve by fine-tuning or upgrading a printer from most other consumer 3D printer brands.

The two printers do have different motion systems, with the P1S using a CoreXY motion system and the A1 using a Cartesian motion system. This difference should theoretically result in slightly better print quality from the P1S due to its more rigid design and the fact that the bed does not move back and forth during the print. In practice, though, we don’t notice a difference at all between the machines in this respect. We’re really pleased with the print quality from both machines.

Print Speed

The P1S and A1 both advertise a maximum print speed of 500 mm/s, but the printers do differ in their advertised maximum acceleration. The P1S’s maximum acceleration is 20,000 mm/s2, while the A1 tops out at 10,000 mm/s2.

In practice, it’s rare for any 3D printer to hit their maximum speed and acceleration during a print. The actual speeds you see will depend on the quality settings you choose, as well as the model geometry. The printer simply can’t move as quickly when it’s printing intricate details. Therefore, while the P1S is theoretically slightly faster than the A1 due to its higher maximum acceleration, we don’t notice any real-world print speed differences between the two machines.

Print Bed

Both machines have a magnetic print bed with a thin, flexible bed surface that can be easily pulled off the bed for part removal or if you want to replace the bed surface. Both machines include a textured PEI bed surface by default, which is one of our favorite bed surface options for modern 3D printers. We find this material, and Bambu’s beds in particular, to offer excellent print adhesion while still allowing you to easily remove the printed part once the bed cools down.

If you want to replace the bed surface with a smooth bed to get a smooth surface finish on the bottom of your prints, there are alternatives available from Bambu Lab as well as third-party manufacturers.

Material Compatibility

For the most part, the P1S and A1 can print the same set of 3D printing filament types. Both machines have a direct-drive extruder and a hot end that can heat to 300 degrees C, which is sufficient to print all common 3D printing materials, including flexible materials such as TPU.

The only difference is that the enclosure on the P1S makes it better suited for printing a few specific materials, including ABS and ASA. These materials tend to print better in an enclosed environment because they are sensitive to air drafts during printing. They also tend to produce an unpleasant smell during printing, which the enclosure and air filter on the P1S will help take care of. The A1 is technically capable of printing those materials, but the P1S would be a better choice if you envision yourself printing with ABS or ASA often.

For the standard 3D printing materials such as PLA, PETG, and TPU, both machines offer the same level of capability and can easily print these materials.

Automatic Bed Leveling and Calibration

Both printers include automatic bed leveling, using a strain sensor system where the nozzle gently touches the print bed in several locations to accurately set the nozzle height for printing. Of the automatic bed leveling systems we’ve used, we find strain sensors to be the most reliable approach, and the bed leveling on both machines is consistent from print to print.

The P1S and A1 both include an automatic calibration feature which runs through several calibration steps when you first power on the printer. You can also run the calibration manually later if you change something about the hardware configuration of the printer or if you move it to a new location. This process takes 15-20 minutes but fully calibrates the machine, including leveling the print bed, measuring the resonance of the frame for vibration compensation, and adjusting the motor drivers to reduce noise. These are all steps that used to be manual processes on older 3D printers, but modern machines are able to do them automatically. We’ve found this calibration to work well on both printers.

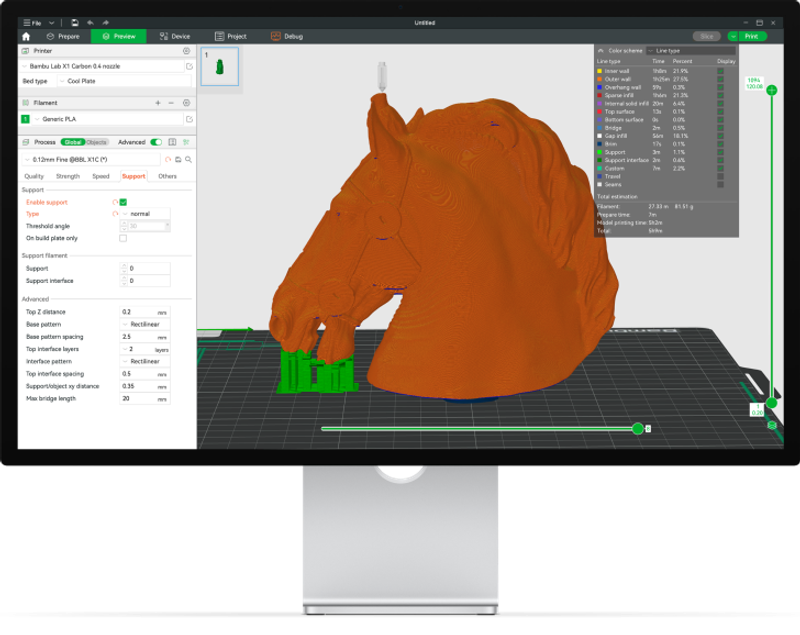

Wireless 3D Printing and App

The Bambu P1S and A1 both support the Bambu Handy smartphone app and Bambu Studio computer application, and both machines allow you to connect over WiFi to monitor and control the printer. In our experience, Bambu’s software is more polished and easy to use than many other brands in 3D printing, and the P1S and A1 offer identical software and app support.

With either the smartphone app or computer program, you can send files to the printer to be printed, load or unload filament, and monitor the progress of ongoing prints. You can browse Bambu’s MakerWorld 3D model website and select and print a model directly from the Bambu Handy app on your phone, but if you want to print a custom model or change the slicer settings, you’ll need to use the Bambu Studio app on a computer.

As a side note, Bambu does support other slicer software, but if you want to wirelessly transfer the file to the printer, you’ll have to use Bambu’s own software. Otherwise, you’ll need to use the microSD slot on the machine.

Differences Between the Bambu Lab P1S and Bambu Lab A1

Although the P1S and A1 share some of the primary 3D printer specs, they do have a few important differences, especially in the way they implement some features that seem similar on the surface. We’ll cover each one in this section and give you our personal experiences with using both printers.

Physical Design

One immediately-apparent difference between the two printers is that the Bambu P1S is fully enclosed while the Bambu A1 is a much more open design. There are pros and cons to each design.

The enclosure on the P1S enables it to print materials such as ABS and ASA which are sensitive to air drafts and produce unpleasant smells during printing. The enclosure also keeps the print bed from getting dusty and might discourage a curious child or pet from interfering with ongoing prints. Finally, the enclosed design makes the P1S look more like a sleek appliance than a hobby tool, and the CoreXY motion system means that no part of the printer ever protrudes outside the enclosed area, which might be appealing depending on your workspace.

On the other hand, the open design of the A1 makes that printer much easier to service than the P1S. If you ever need to repair the extruder or hotend, the A1 offers much easier access to these components than the P1S since you don’t have to reach into an enclosure. It’s lighter weight and easier to pick up and carry than the P1S as well. However, the open design means that the A1 has more exposed moving parts. The bedslinger design also results in the bed protruding from the printer’s footprint during the printing process, so the A1 effectively takes up a little more desk space than the P1S.

Among the 3DPros team, we’re divided on which of these designs we prefer. I personally appreciate the clean design of the P1S, but one of our other writers prefers the A1’s design for how easy it is to service. Our recommendation is that if you want to print ABS or ASA, or if you have kids or pets who are often in your workspace, the P1S is probably a better choice in this regard. Otherwise, it’s a matter of personal preference.

Multicolor 3D Printing

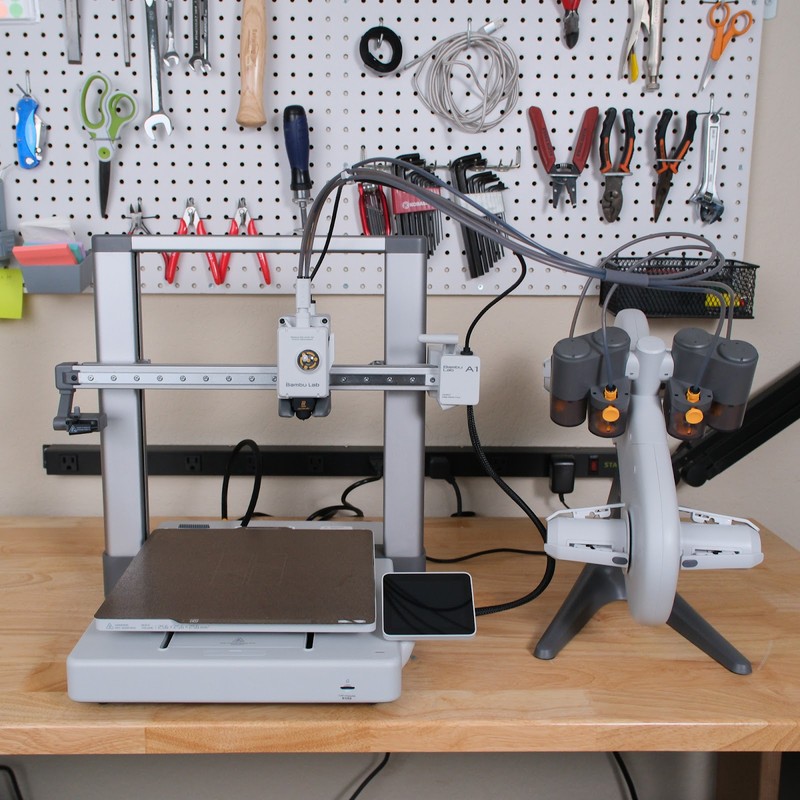

Although the Bambu P1S and A1 both support multicolor and multi-material 3D printing, the experience of printing with multiple materials on each printer is a bit different. This is because the P1S supports the Bambu AMS add-on, while the A1 supports the Bambu AMS Lite add-on. These two versions of the AMS have several differences.

We’ve written a detailed article on the differences between the AMS and AMS Lite, but to summarize, the AMS for the P1S has a cleaner design and can automatically load and unload filament spools, as well as supporting up to 4 AMS units chained together to enable printing with 16 colors or materials. However, it has a more complicated filament path that can make clearing jams more time-consuming, and it’s more sensitive to the physical size of your filament spools.

On the other hand, the AMS Lite for the A1 requires you to push the filament through a long tube to the extruder when loading it, and you can only use a single AMS Lite for up to 4 colors or materials, but it’s an overall simpler design that makes it much easier to clear a jam. The AMS Lite also has some considerations for filament spool size, but it is more forgiving than the AMS, and you can even mount a spool separately and still feed it into the AMS Lite.

The other downside to the AMS Lite on the A1 is that it’s more limited on mounting options. Bambu Lab does actually provide a 3D-printable model that you can use to clamp the unit to the top of the A1, but otherwise you’ll need to set it on the table next to the printer, and it results in a fairly bulky setup. We think the AMS results in a much cleaner work area, especially with the P1S where you can easily set it on top of the machine.

With their respective multi-material add-ons, both printers have the same set of capabilities. They can print a model in multiple colors, with the Bambu Studio program allowing you to easily specify which parts of the model you want to be in which color. You can also use multiple materials, such as if you want to print support material using a special “breakaway” filament that is easier to remove. Both the AMS and AMS Lite support a “failover” feature, where the unit can automatically switch to a second spool of the same color when one runs out.

The one factor to keep in mind is that if you’re printing with either the AMS or AMS Lite, you’ll need to use either Bambu Lab’s own Bambu Studio slicer, or the open-source OrcaSlicer software. You also generally cannot print with flexible filament such as TPU using either of the units.

Overall, we think both of these systems have advantages and disadvantages. If you place a lot of value on having a clean setup, and want it to be as easy as possible to load filament, the Bambu P1S with AMS is certainly the better solution for those needs. But when it comes to clearing jams or if you want to use a wider range of filament spools, the A1 with the AMS Lite may be the better choice for you.

And for what it’s worth, with either of these machines we highly recommend getting the AMS or AMS Lite as appropriate. Even for single-color printing, we find these add-ons to greatly improve the usability of the printer, and multi-color prints can add a fun element to 3D printing that you may not have been able to experience yet.

Screen and Controls

Both the P1S and A1 include a screen and controls for operating the printer, but the screen and controls for each printer are very different. In most cases we find ourselves using the Bambu Handy app to control the printer, but we still find physical screens and controls useful for quickly checking on the status of the printer or changing a setting while you’re standing next to the machine.

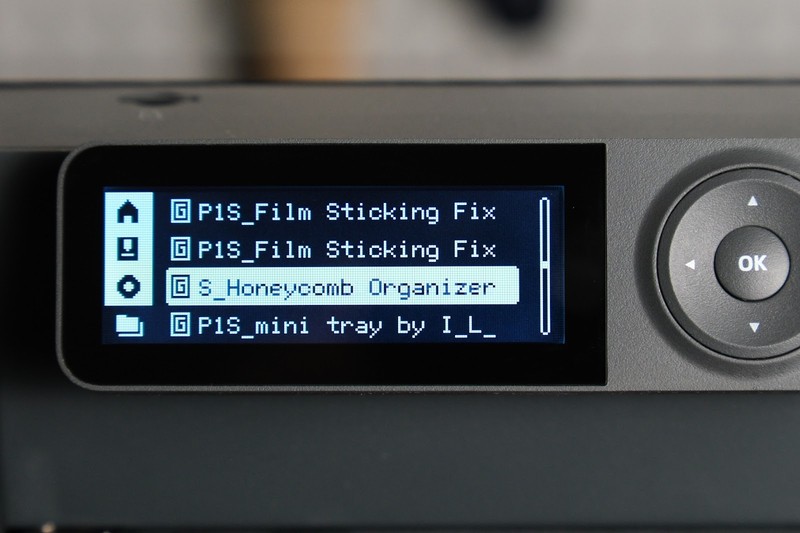

The Bambu P1S uses a monochrome LCD screen which can only display text and icons, and a set of physical buttons for navigating menus and selecting options. While we don’t have any issues with the buttons, the LCD screen feels antiquated compared to every other aspect of the printer. It’s much harder to read than a modern display, and is very limited in functionality. For example, the screen on the P1S is unable to show a preview of the models loaded on the printer, while this is a common feature of printers with full-color displays.

On the other hand, the Bambu A1 includes a full-color touchscreen display. While the display is smaller than what we’ve seen on some other printers, it’s very easy to read and makes the experience of using it much more pleasant than on the P1S. This feels like a substantially better controller, and is one large benefit to the A1 over the P1S.

Flow Rate Compensation Sensor

The Bambu A1 contains an interesting feature that isn’t found on the P1S–a flow rate sensor in the hotend that allows the printer to automatically calibrate the flow rate of the filament. The flow rate is a setting that allows you to adjust how much filament is extruded by the printer. Because each brand or type of filament can be slightly different, this is one way to further improve print quality.

Flow rate has typically been a setting that you would need to calibrate manually, but the A1 has a sensor built into the hotend to measure the flow rate of the filament. You can optionally enable the printer to adjust this setting before each print, using the information it gathers from the sensor. We haven’t really noticed cases where this made a notable difference in print quality, but it might be helpful if you find yourself using different filament brands or material types often.

Overall, this is a nice bonus on the A1 that we hope to see on future Bambu Lab 3D printers. It’s not necessarily a major point in favor of the A1 over the P1S, but it is a small advantage.

Which Printer Should You Choose?

Overall, the Bambu Lab P1S and A1 are surprisingly similar 3D printers, especially considering their difference in price. However, they do also have some key differences, and we think that depending on what you’re looking for, one of these two machines will likely stick out to you as being the better fit for your needs.

The Bambu Lab P1S is the right choice for you if you’re looking for a 3D printer that feels more like an appliance than a hobby tool. Its enclosed design and clean appearance make it an unobtrusive addition to your workspace. We like that the AMS can automatically feed in a spool of filament and that it has the option of chaining multiple AMS units together to print with even more colors. Finally, the P1S is capable of printing with more materials, such as ABS or ASA, which give it some increased capability compared to the A1.

The Bambu Lab A1 is the right choice if price is important to you and you value ease of maintenance over appearance. Although its open-frame design isn’t as tidy as the P1S, the design makes it much easier to access the major components of the printer for maintenance and repair. This is even more true with the AMS Lite add-on, which has the filament path almost completely within easily-accessible tubing, making it trivial to clear jams. The A1 also has a much better display and includes touchscreen controls, which feel more modern than the LCD display on the P1S.

While we think these are two distinctly different printers that each fit a different set of needs, we’ll close with this thought. We’ve tested both the P1S and A1, and are currently using both printers as some of our primary machines for our own 3D printing. We’ve been very pleased with both machines, and honestly, it’s hard to go wrong with either choice.

You can use the links below to view the P1S and A1 on Bambu Lab’s website, or keep scrolling to see a table comparing the specs of both machines.

Click here to view the Bambu Lab P1S on the Bambu Lab website.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: