If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab A1 vs the Anycubic Kobra 3 Combo

In this article, we'll compare the Bambu Lab A1 and Anycubic Kobra 3 Combo to help you understand the differences between these 3D printers and help you determine which one is the better choice for you.

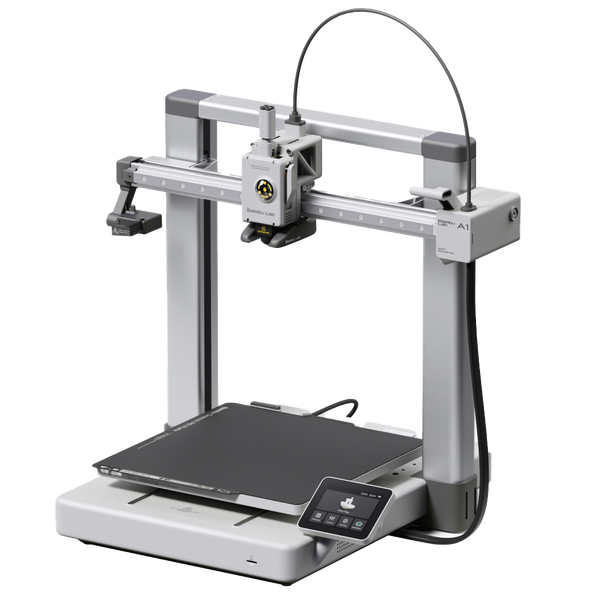

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

Vs.

Anycubic Kobra 3 Combo

(~10 x 10 x 10.25 in)

When the Bambu Lab A1 was announced in the fall of 2023, it made an immediate splash as an affordable 3D printer with the quality and performance we’ve come to expect from Bambu’s machines. It was also one of the lowest-cost printers with true multicolor 3D printing capability thanks to Bambu’s AMS Lite add-on. We’ve tested the A1 and have been very impressed—it’s one of our top recommended 3D printers, especially for new users.

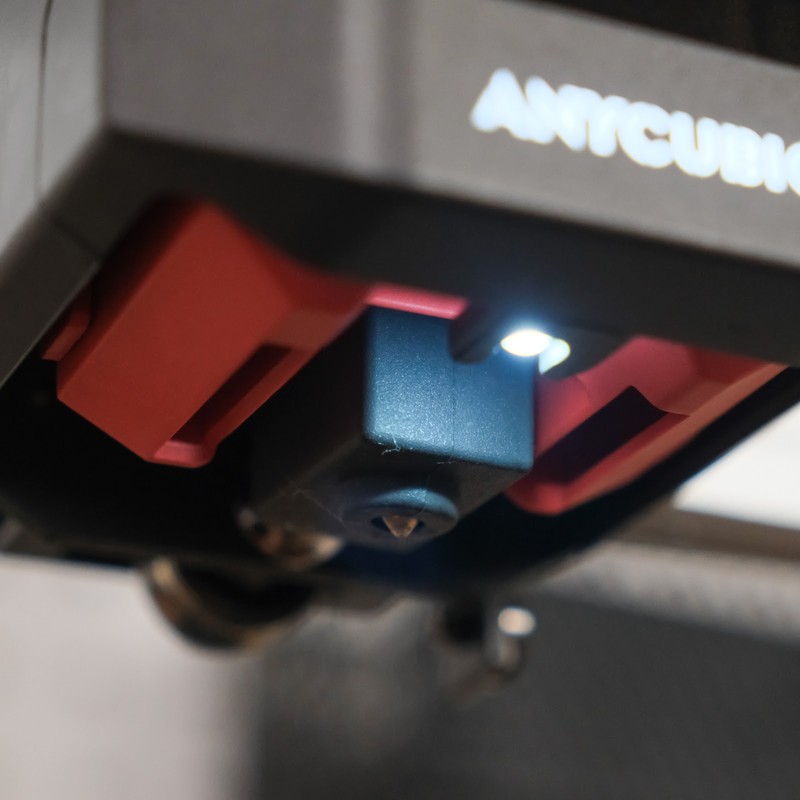

But it was only a matter of time before another company would step up to challenge Bambu Lab’s dominance in the low-cost multicolor 3D printing space, and Anycubic has emerged as one of the first true competitors to the A1 with the Anycubic Kobra 3 Combo. With a similar bedslinger design and their “ACE” multi-color add-on that looks suspiciously similar to a Bambu Lab AMS unit, the Kobra 3 Combo is a clear attempt by Anycubic to take on Bambu.

But how does the Anycubic Kobra 3 Combo measure up to the Bambu A1 Combo? And if you’re looking to purchase a multicolor 3D printer, how should you choose between these two options? We set out to test the Kobra 3 Combo to find out.

One quick note: Both of these 3D printers are available in a “combo” kit which includes their respective multicolor 3D printing units. For the purpose of this comparison, we’re comparing the combo kit for both printers.

We’re going to start by covering the similarities between the printers before looking at the bigger differences. Don’t skip over the similar features! Although these printers look the same on the outside, the way they implement these features does differ in some important ways.

Similarities Between the Bambu Lab A1 and Anycubic Kobra 3 Combo

The A1 and Kobra 3 share many similar features, which is why the comparison between them is interesting to dig into. We’ll cover each similarity here, and explain how the two printers implement similar-sounding features differently in ways that might matter to you.

Size and Build Volume

The Bambu Lab A1 and Anycubic Kobra 3 share an almost identical build volume:

- Bambu Lab A1: 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”)

- Anycubic Kobra 3: 250 x 250 x 260mm (9.8” x 9.8” x 10.2”)

Although there is a minor difference in build volume here, it’s not likely to be significant for most uses. Both machines can print parts a little larger than what the average FDM 3D printer is capable of.

Because the printers are both bedslinger designs, they’re similarly sized. Keep in mind that for this style of printer, you will need a bit of extra space in front of and behind the machine since the bed moves forward and backward while printing.

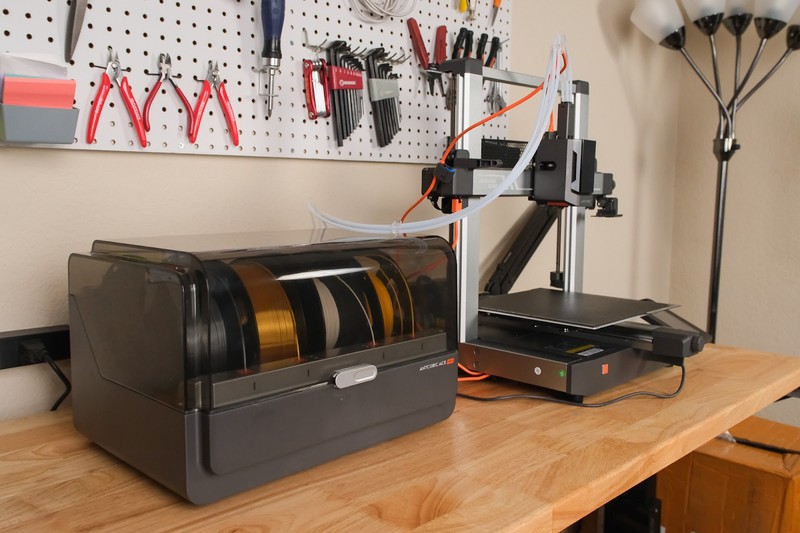

One difference to note here is that the multi-color add-ons for each machine will take up space in different ways. The AMS Lite on the Bambu A1 can be mounted next to or on top of the printer (with an optional 3D printed bracket). If your work area has limited desk space, but plenty of vertical space, stacking the AMS Lite on top of the A1 allows you to add multi-color capability without taking up any more room on the desk. On the other hand, the box-style multi-color unit for the Kobra 3 Combo can’t be mounted on top of the printer, meaning you will need extra room on your desk to use it.

Print Speed and Motion System

Both the A1 and Kobra 3 advertise a maximum print speed of 600 mm/s, which makes them some of the fastest 3D printers available. These speeds are far beyond what was possible for standard consumer-level FDM 3D printers just a few years ago, and it’s impressive to see such speeds in printers at this price point.

However, it’s important to note that you won’t always attain the full 600 mm/s speed during printing. Due to the geometry of parts and the specific slicer settings you choose, the printer may only spend a small amount of time printing at the maximum speed. This is the case for both printers. Regardless, the fast maximum speed does generally mean your 3D prints will finish faster than they would on a slower machine.

Print Quality

We’ve found both the Bambu Lab A1 and Anycubic Kobra 3 to have excellent print quality, and while they aren’t identical in all cases, we feel that the quality is largely similar between the machines.

Both printers include advanced firmware features such as input shaping and vibration compensation that are proven to improve print quality, and our experience with both machines has been that they produce higher quality 3D prints than most older printers. Bambu Lab arguably has more experience with this type of firmware and with extremely high speed 3D printing than Anycubic, but we haven’t found this to result in a major difference in print quality.

One thing that does differentiate the two printers in this regard is the Bambu A1’s flow calibration sensor, which allows that printer to automatically calibrate the optimal flow rate for the filament at the beginning of the print. This feature does make a notable difference in print quality, especially if you frequently switch to different brands of filament. That said, this is a setting you can calibrate manually, so you can determine an appropriate value to use on the Anycubic Kobra 3 to improve that printer’s quality to a similar degree.

Supported 3D Printing Material Types

The Bambu A1 and Anycubic Kobra 3 can print most of the same materials, including the most common material types such as PLA, PETG, and TPU. Both machines are able to heat the hot end to 300 degrees C and the bed to at least 100 degrees C, so those will not be limitations for most standard materials.

These printers will not be the best choice for materials that require extremely high temperatures, such as nylon, and aren’t ideal for materials that benefit from an enclosure, such as ABS or ASA.

There are some notable limitations, and differences, with both printers when using the multicolor printing capabilities. On both machines, you generally will not have much success printing with flexible filament such as TPU in multi-color mode, due to the much longer distance the filament has to travel between the multi-color unit and the extruded.

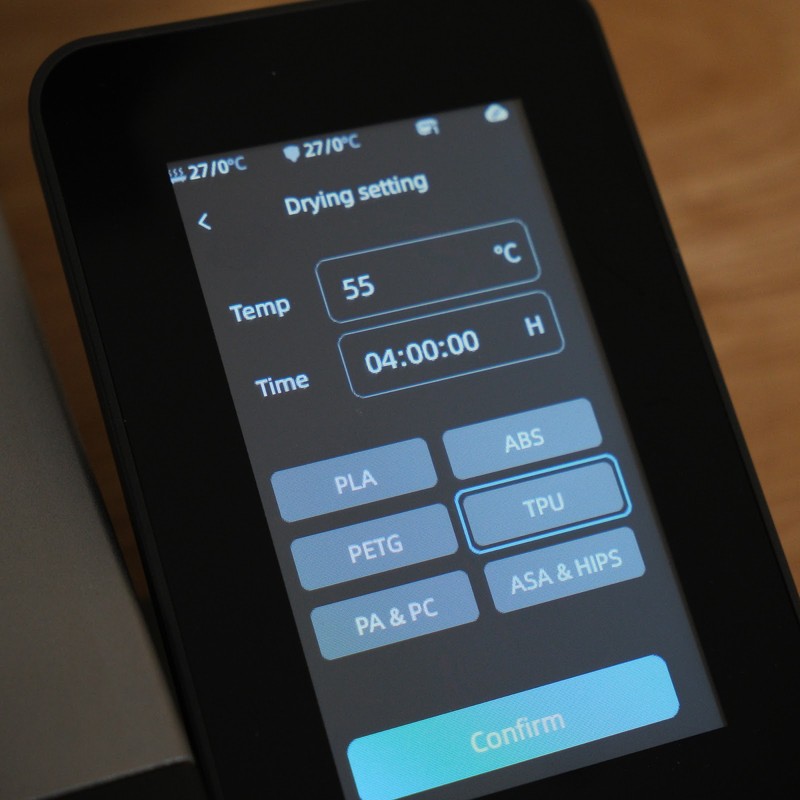

On the Kobra 3 Combo, the ACE Pro multi-color unit also acts as a filament drybox, and includes a heater to dry out the filament. This makes it a better choice for materials that are sensitive to humidity. Unfortunately, one such material is TPU, which makes it unfortunate that you can’t effectively print TPU from the ACE Pro unit. However, you do gain the interesting option of using the ACE Pro to keep your TPU dry, but then feeding the filament directly into the printer from its spool holder rather than using the ACE Pro during printing.

Controls and Display

The A1 and Kobra 3 both include a color touchscreen display for controlling the printer and monitoring the status of ongoing prints. Between the two, the Kobra 3’s display is larger, but a bit harder to use compared to the A1–there were a few times where we thought we had pressed a button, but realized we needed to press harder to trigger the action.

Both user interfaces allow you to perform basic operations on the printer, and although we might slightly prefer the user interface on the A1, we don’t think the differences here are significant.

We expect that most users will end up using either the smartphone app or computer-based slicer software to control either of these machines, and there are more significant differences there which will cover later in this article.

Nozzle Wiper and Purge Area

Both printers include a nozzle wiper and purge area, two mechanical features that reduce some print imperfections and enable the machine to purge filament when changing colors in a multi-color print.

These features are implemented similarly on both machines. The nozzle wiper is a small rubber strip on the edge of the print bed, and the printer uses it by dragging the nozzle across it immediately before printing. The purge area is mounted on the X axis gantry, allowing the printer to move the print head off of the printable bed area and purge filament into a small catch area. When the print head moves away from the purge area, a simple mechanical system ejects the purged filament away from the printer. This system works as intended on both machines.

An annoyance we have with both printers in this regard is that they don’t include a container to catch the purged filament. By default, when you use either the A1 or Kobra 3 out of the box, they’ll eject hot purged filament across your work area periodically, which is certainly not desirable. For most users, one of their first prints will be a small purge bucket to set next to the printer to catch the discarded filament. We’d love to see this part either included with the printer, or at least have a 3D model loaded on the printer so the user can more easily print this necessary upgrade.

Assembly Required

The Bambu Lab A1 and Anycubic Kobra 3 Combo both require some assembly. The assembly process is simple for both machines, and doesn’t require any tools other than the ones included with the printers. Between the two, we found that the Kobra 3 was faster to assemble and required fewer steps, but the steps were generally a little more difficult than on the A1. For example, there were fewer screws required for the installation, but the screws tended to be in harder-to-reach places than on the A1.

We don’t feel that this is a significant difference between the machines and isn’t something you should base your decision on. With either machine, you should expect to spend 15-30 minutes on unpacking and assembly, but both printers come with easy-to-follow instructions and the assembly process is not challenging.

Differences Between the Bambu Lab A1 and Anycubic Kobra 3

Although the Bambu A1 and Anycubic Kobra 3 are similar in many ways, there are some key differences that you should be aware of when deciding between these printers. We’ll cover each difference in detail here.

Multicolor 3D Printing

One of the headline features of both printers is their ability to print in multiple colors at once. This is particularly true for the Kobra 3 Combo since it’s Anycubic’s first multicolor printer, but Bambu has always stood out as well for their multicolor capability.

On either machine, you can load up to 4 filament spools and use all of them during a print. This could be four different colors for a multi-color print, different materials for purposes such as water-soluble support material, or even multiple spools of the same material and color so the printer can automatically switch to a new spool when one runs out of filament. However, the two printers implement the multi-color feature in substantially different ways.

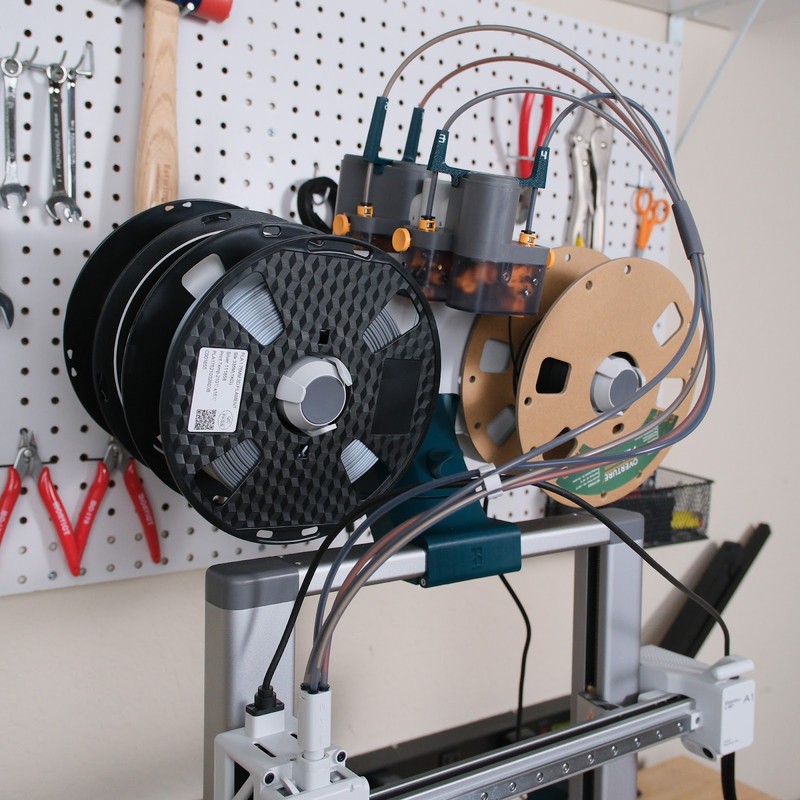

On the Bambu A1, the AMS Lite holds onto each spool from the center using a large spring-loaded peg. The unit itself is freestanding and sits next to the printer by default, but can be mounted on top of the printer with an optional 3D printed bracket. Four long Bowden tubes run from the AMS Lite to the extruder. The unit is connected to the A1 via a single cable that plugs into the back of the printer. This cable both powers and controls the AMS Lite. The A1 actually has two of these connectors, but the printer only supports a single AMS Lite, and Bambu has not announced any plans to expand the number of AMS Lites that can be used at once.

One thing we like about the Bambu AMS Lite over other systems, such as the Anycubic ACE Pro or even Bambu’s own AMS, is that the filament path is almost entirely through exposed tubing. If you need to clear a jam due to the filament breaking in the tube, you can easily disconnect the tubing and access the filament. On the other hand, with the box-style units such as the original AMS, some of the filament path is inside the unit, requiring you to remove a few screws and partially disassemble the unit to clear certain types of jams.

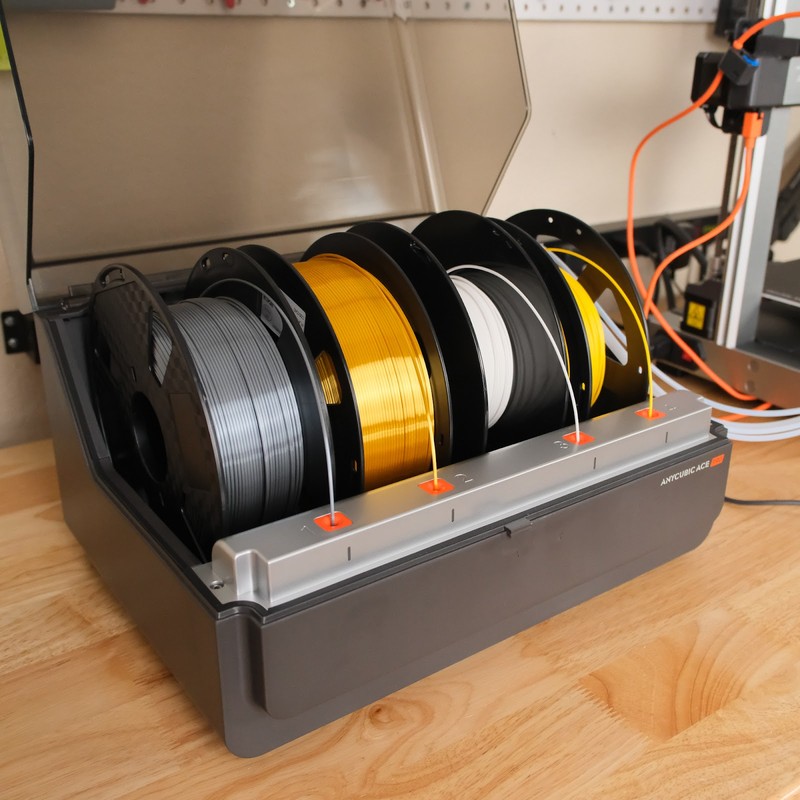

On the Anycubic Kobra 3 Combo, the ACE Pro is a box with a flip-up lid. You set each spool inside on a set of motorized rollers which allow it to extrude or retract the filament as needed. The unit is freestanding and must sit next to the printer; there is no easy way to mount it on top. Similar to the AMS Lite, four Bowden tubes run from the ACE Pro to the extruder.

One difference is that unlike the AMS Lite, the ACE Pro has a separate power cable in addition to the control cable that connects to the printer. This is likely due to the ACE Pro’s additional power needs, which we’ll discuss momentarily, but the one slight inconvenience here is that the ACE Pro has a separate power switch as well, requiring you to toggle two switches to turn everything on. We also wish the control cable plugged into the back of the Kobra 3 instead of the front—this is an accessory we’d want to keep plugged in continuously, and it looks messy to have the cable plugged into the front of the printer.

The ACE Pro on the Anycubic Kobra 3 Combo does offer one notable feature that is missing from the Bambu AMS Lite, which is the ability to act as a drybox and actively dry the filament stored inside. Due to its enclosed design, the unit naturally shields the filament from humidity. But additionally, it contains a heater, and you can optionally activate the heater to further dehumidify the filament. Most 3D printed materials can benefit from a filament dryer, and certain filament types practically require it, so this is definitely a nice addition to the ACE Pro.

It’s worth noting that Anycubic has indicated that the Kobra 3 Combo will support up to two ACE Pro units, for a total of 8 colors, while the AMS Lite on the Bambu A1 is limited to a single unit for a total of 4 colors.

Between these two systems, we feel that both have pros and cons and there isn’t a clear winner between the two. The Bambu Lab A1’s AMS Lite is a slightly simpler design and has the ability to be mounted on top of the printer, which we prefer for our workspace. On the other hand, the Anycubic Kobra 3’s ACE Pro includes drybox functionality and is arguably easier to load, since you can simply drop filament spools into its bays.

The more substantial difference between the multicolor capabilities of the two machines is in the software, which we’ll discuss next.

Software and Wireless Printing

Bambu Lab and Anycubic both provide their own smartphone app for controlling their printers, and their own slicer software for preparing prints and printing wirelessly from a computer. With either 3D printer, you need to use the manufacturer’s software or app to wirelessly send files to the printer or control it remotely. You’ll also need to use their software to use the multicolor printing capabilities.

For this reason, the software is a major factor to consider when deciding between these printers, and this is an area where we found significant differences between the two.

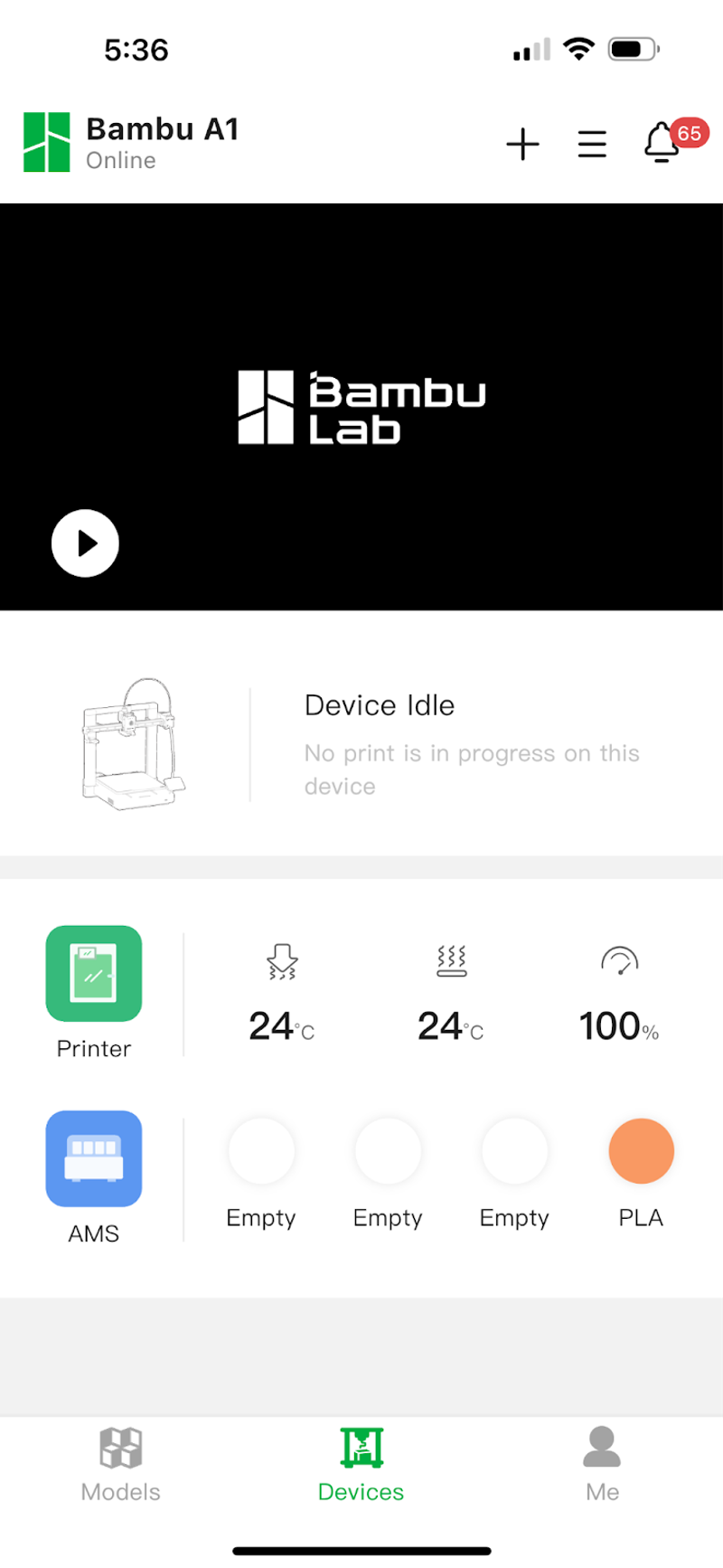

On the smartphone side of things, we’ve found the Bambu Handy app to be well-designed and easy to use. The UI is clean and simple, and it’s generally very reliable for controlling the printer and starting prints. There are a few exceptions. For example, the camera display doesn’t always load and sometimes requires us to restart the app, and we’ve found it annoying that there’s no easy way to “bookmark” a model from the built-in MakerWorld browsing feature. But overall, the Bambu Handy app feels like a polished and modern way to interact with the A1.

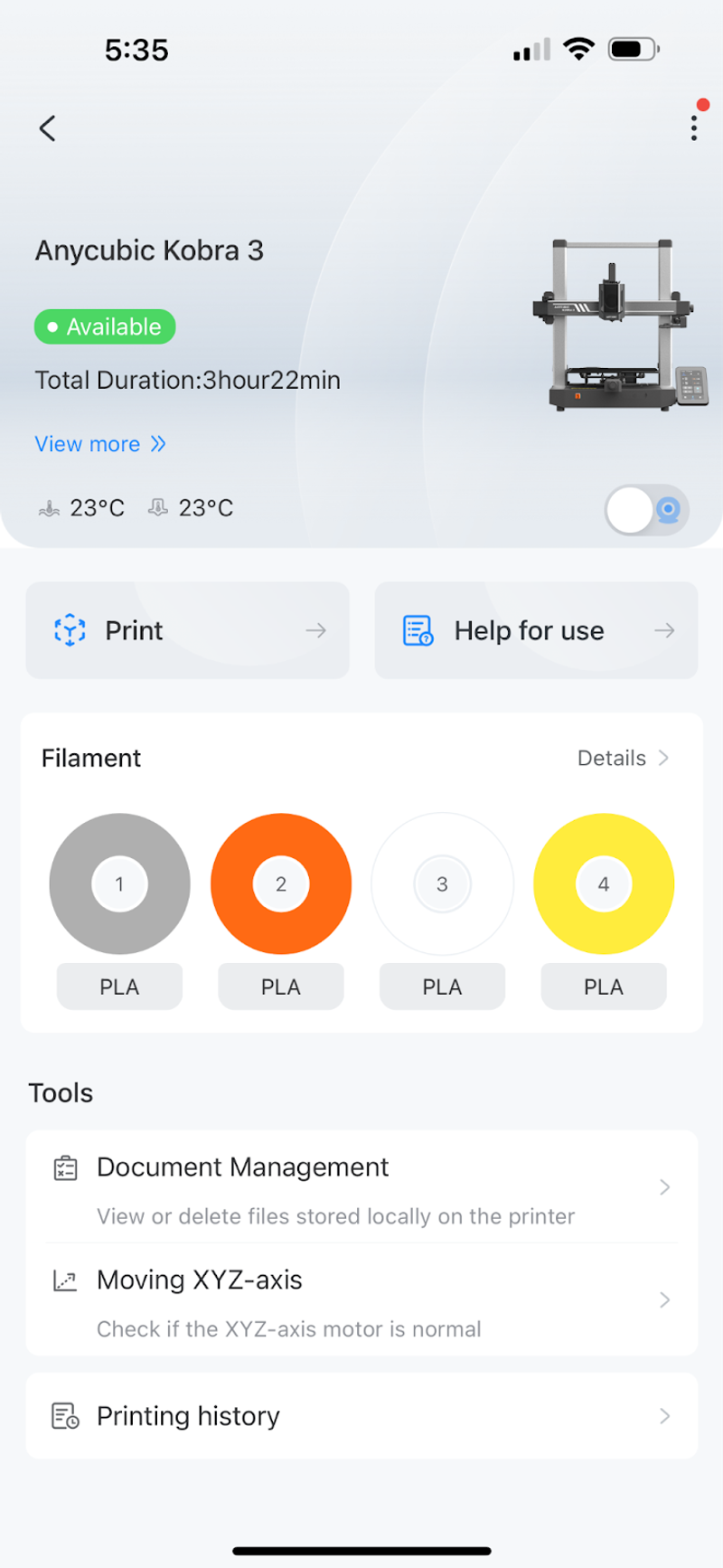

On the other hand, the Anycubic app feels slightly rough around the edges and generally unfinished, although we’ve seen worse. It provides the core functionality that is needed for interacting with the Kobra 3, but the user interface itself is not quite as efficient to use. Overall, we found the Anycubic app to be usable, but not pleasant.

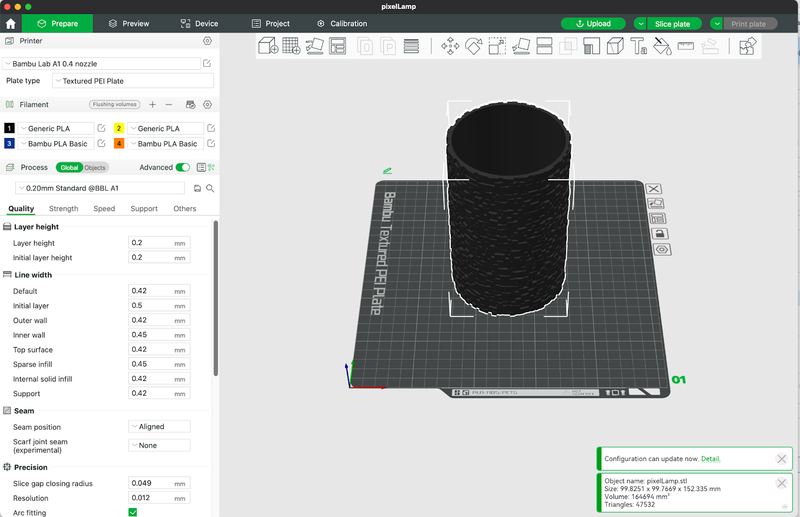

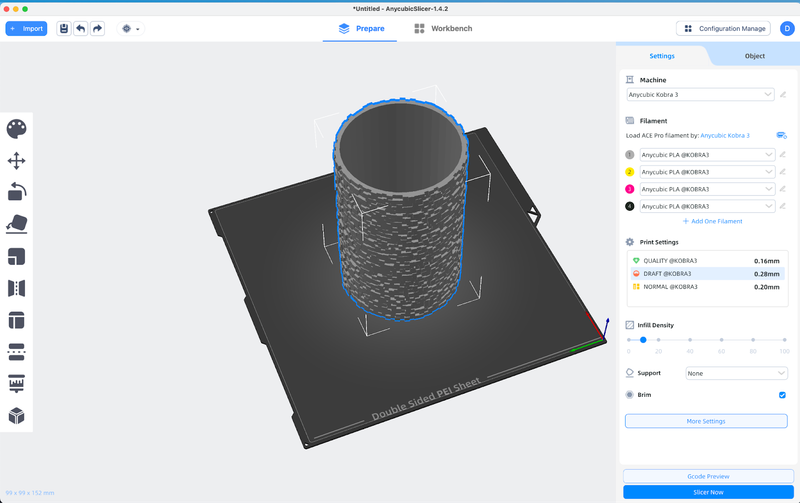

This contrast is similar with the computer programs, but perhaps to a greater degree. Both the Bambu and Anycubic slicers are based on PrusaSlicer, but we have found the Bambu Studio software to be simpler to use and more polished than the AnycubicSlicer program. It gives you faster access to the settings and makes it easy to see which ones you’ve changed from the defaults.

We encountered a few annoying bugs with the Anycubic software–for example, at one point when switching between the “Draft” and “Normal” quality presets, the program was inexplicably also switching from the PLA to ABS filament preset, which we didn’t immediately notice. We also encountered a few confusing error messages when sending files to the printer wirelessly. In most cases, we haven’t encountered these types of issues with the Bambu Studio software.

However, the computer programs for both printers do ultimately function as expected and allow us to prepare and print models wirelessly. The workflow for these machines is so much easier than older non-wireless 3D printers that we have a hard time complaining about the experience in either case, but we did find the Bambu software to be easier to use.

There’s an upshot here for Anycubic: software can be updated, and they can easily update both their app and slicer to address these issues. You should never buy products based on the promise or hope of future updates, but it seems likely to us that the Anycubic software will improve over time.

Camera

The Bambu Lab A1 includes a built-in camera, while the Anycubic Kobra 3 requires you to purchase and install a camera separately. We enjoy having the camera so we can quickly check the status of an ongoing print from another room, so this is a feature we were happy to see built-in on the A1.

One caveat is that the camera on the A1 isn’t particularly good–it’s aimed poorly, so it’s hard to monitor the first few layers of the print, and it’s such a low framerate camera that watching the feed feels more like watching a slideshow than a video. But it does the job, and does allow you to check on a long print to make sure things are still going well.

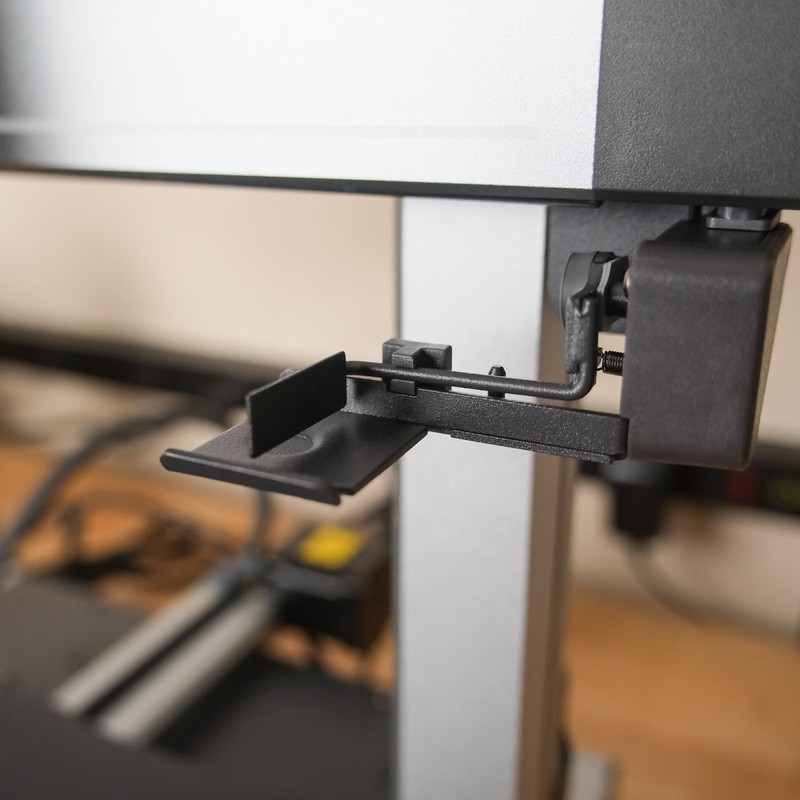

If you want to add a camera to the Anycubic Kobra 3, you can purchase the camera from Anycubic and 3D print a bracket to mount it on the printer. The camera plugs into a USB port on the front of the printer–we’d have preferred to see it connect at the back for a cleaner installation, but we’re glad there is an option to add a camera to the printer.

—-

Should You Choose the Bambu Lab A1 or the Anycubic Kobra 3 Combo?

Overall, the Bambu Lab A1 and Anycubic Kobra 3 Combo share many of the same core features, but there are many nuances in how those features are implemented on each machine. They exist in the same rough price bracket and both offer the exciting possibility of multicolor 3D printing, but we found the difference between the two 3D printers to be larger than what it initially appeared.

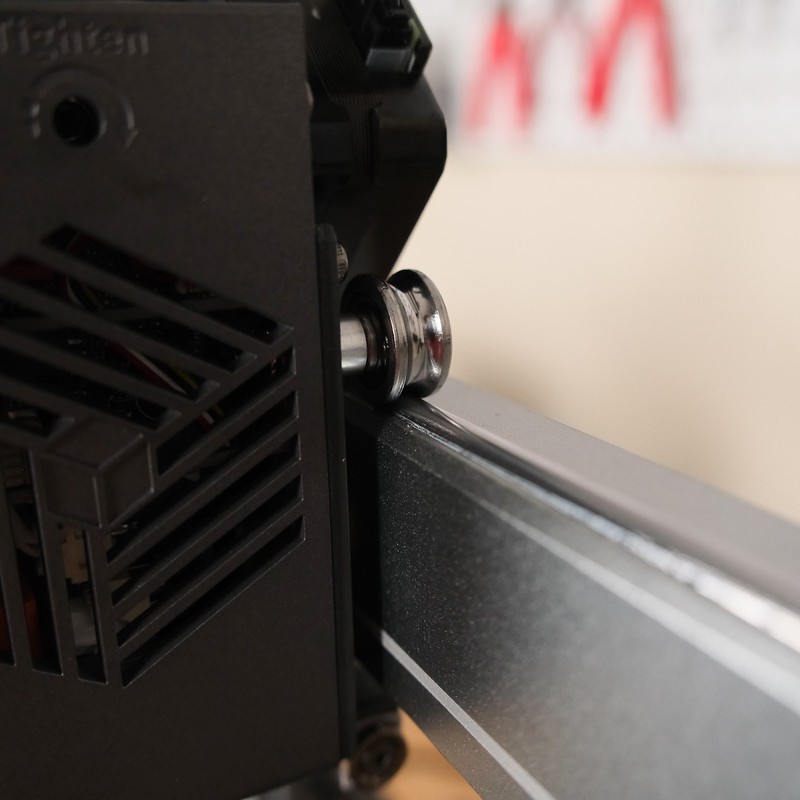

In our opinion, the Bambu Lab A1 is more refined and generally higher quality than the Anycubic Kobra 3. The physical build is a bit better, with more premium motion system components and an integrated camera. On the software side, the Bambu smartphone app and slicer are clean, professional, and reliable in a way that the Anycubic software is not. The A1 comes in at a higher price than the Kobra 3, but we think it justifies its higher price.

On the other hand, the Anycubic Kobra 3 has all of the core features to compete with the A1, and can essentially match its print quality and speed, but is missing some of the polish of the A1. This is especially true on the software side–we came away with the impression that the smartphone app and slicer for the Kobra 3 are a bit unfinished in a way that left us both disappointed in the current state and yet hopeful that Anycubic will improve this side of their experience.

Speaking about the multicolor features specifically, we think the A1 and Kobra 3 are fairly evenly matched. The Kobra 3 has an edge on the hardware side, since their ACE Pro add-on can also act as a heated filament drybox. The Kobra 3 also has the ability to use two ACE Pro units for a total of 8 colors, while the AMS Lite on the A1 is limited to a single unit with only 4 colors. But on the other hand, the AMS Lite can be mounted on top of the A1, while the ACE Pro must be placed next to the Kobra 3. Depending on your workspace, this might make the A1 and AMS Lite a more palatable setup.

It’s also worth noting that both machines offer the multicolor printing capability as an optional add-on or as a combo with the 3D printer itself–make sure you buy the combo if you want the multicolor capability.

You can view the Bambu Lab A1 and Anycubic Kobra 3 product listings using the links below, or continue scrolling to see a side-by-side comparison of each printer’s key specs.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

Click here to view the Anycubic Kobra 3 Combo.

You can find a side-by-side comparison of the specifications for these two printers in the table below: