If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Bambu’s Bedslingers: the Bambu Lab A1 Compared to the Bambu Lab A1 mini

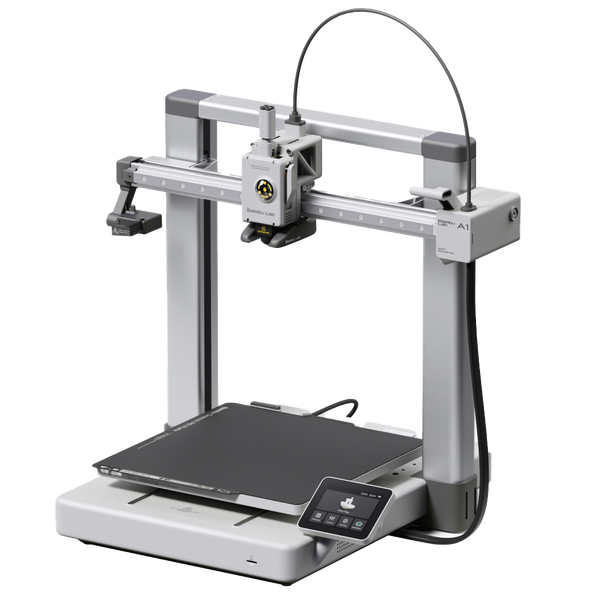

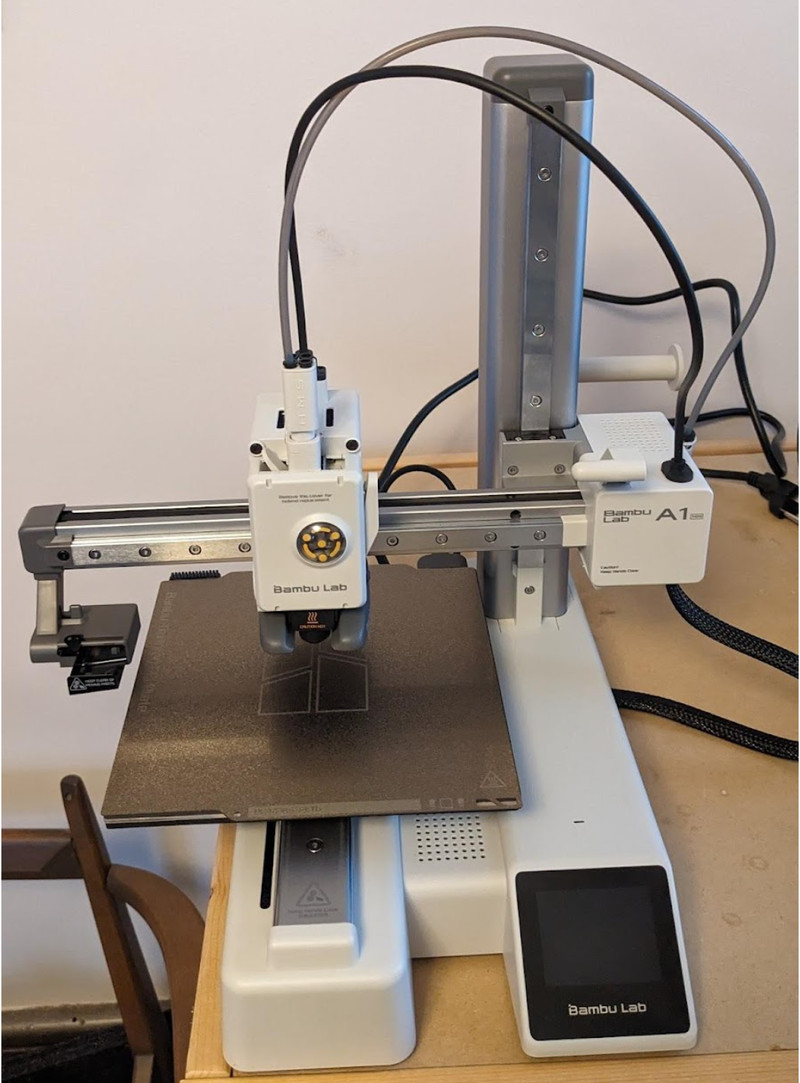

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

Vs.

Bambu Lab A1 Mini

(~7.25 x 7.25 x 7.25 in)

Bambu’s Bedslingers: the Bambu Lab A1 Compared to the Bambu Lab A1 mini

Startup Bambu Lab’s now infamous early marketing text for their flagship X1 printer reads “no more bed-slingers”. So they shocked the 3D printing world by releasing the A1 mini in September 2023 - their first bedslinger, where the bed moves backwards and forwards. Besides its high speed and automation typically associated with Bambu Lab, it’s also optionally equipped with 4-filament printing using a new variant of Bambu Lab’s Automatic Material System, the AMS lite.

In another surprise announcement, on December 9th, 2023, Bambu Lab announced the A1. Full size, as the lack of the “mini” moniker would imply. It’s also available with the AMS lite.

Is the only difference between the two the bed size?

Shared Features

The printers have almost the same name and seem to be part of a series. They share more than a few features.

Extruder

The first shared feature seems obvious just from looking at photos - both the A1 and the A1 mini use the same extruder. It’s a tall direct extruder with a large wraparound part cooling fan duct. The specifications are further proof that both extruders are identical: this is an all-metal hot end with hardened steel gears, capable of 300°C. The nozzle is a tool-less quick swap design, with the heatsink, heartbreak and nozzle integrated, held in place with a magnet and secured with a latch and buckle. It is equipped with a filament cutter and an AMS hub which accepts 4 filaments. At the left end of the X axis arm is a purge tray.

Speed

Despite their size difference, Bambu Lab has designed each printer to print at 500mm/s with 10,000mm/s2 acceleration. These are peak speeds, typical speed is around 300mm/s.

This is very impressive for a bedslinger (Cartesian) 3D printer and other manufacturers are just catching up to it with these types of designs now. But Bambu Lab’s other 3D printers are of the Core XY design, where the bed only moves up and down. This allows for higher acceleration - 20,000mm/s2 in the case of the P1 and X1 series. So there are some limitations.

User Interface

Both printers use the same user interface on a touchscreen. The touchscreens may not be the same size (2.4” for the A1 mini and a more comfortable 3.5” for the A1) but every icon, every color, every menu and every bit of text is identical.

Mechanics

Both printers use linear rails on all axes. Bambu Lab did not want to deal with the wear of POM wheels at high speed and the instability that develops as they wear and change shape. So they went for linear rails everywhere.

Camera and LED

At the right of the X axis beam on both printers is the same LED and camera. The low framerate camera has 1920 X 1080 resolution and supports timelapse. A frosted cover over the LED can be rotated to act as a privacy cover for the camera.

Control Technologies

These printers are identical in regards to the technologies on board. There’s flow compensation, active motor noise cancellation, strain gauge bed leveling, automatic Z offset, a filament detector and filament tangle detection. All fans are temperature controlled to keep noise down to the bare minimum. The series also has power loss recovery.

Bed

Both printers are equipped with a removable textured PEI steel bed on a magnetic surface. This offers the best balance of adhesion, durability, and easy part removability. It will accommodate a wide variety of filaments.

Nozzle Wiper

Contributing to the excellent performance of both printers is the nozzle wiper pad mounted behind the heatbed. Before each print, the nozzle is wiped through this pad in order to remove any filament stuck to the nozzle. This ensures consistent, accurate bed leveling and Z axis offset since the nozzle is used to measure distance to the bed. Also, filament flows out of the nozzle freely and does not stick to the nozzle.

Multicolor/Multifilament

Both printers are compatible with the Bambu Lab AMS lite. This is a multicolor/multifilament filament changer that allows the printer to select between 4 spools. Each printer handles this add-on component in exactly the same way.

Connectivity

The printer series has identical connectivity - 2.4 GHz WiFi and two Bambu Bus ports. Since the AMS lite is the only currently available accessory that uses the Bambu Bus port, the other port must be for future expansion. The possibilities are intriguing.

Interestingly, earlier photos of the A1 show 3 Bambu Bus ports, but the actual printer has two with a center port covered up.

Cosmetics

It’s obvious that both printers have the same styling. All components are shrouded in the same gray plastic with rounded corners, and a few darker gray plastic parts. Vents are the same in both printers - a grid of identically-sized small holes with the same spacing. Text is in a darker gray in the same font as seen on all Bambu Lab printers. Cables are in the same black rubber. Both printers have a minimalist footprint and shape - there’s nothing extraneous or unnecessary. You can definitely tell the printers are from the same manufacturer and in the same series.

Differences

Are these really the same printer, with the A1 mini just larger? Almost.

Print Volume

The A1 mini is the smaller of the two printers. Its print volume is 180mm X 180mm X 180mm. The A1’s print volume is considerably larger, at 256mm X 256mm X 256mm.

The Creality Ender 3 established the defacto standard size of a 3D printer at 220mm X 220mm X 250mm, so the A1 mini is a bit smaller than average while the A1 is a bit larger than average.

Construction

The A1 mini’s small size makes the use of its cantilevered design possible. The X axis beam is cantilevered off the single Z axis upright. This is a rare design that reduces cost.

The A1’s construction is more conventional and uses two Z axis uprights and a horizontal gantry beam connecting the two uprights like the Creality Ender 3 and its many variants and clones. This is necessary to support the longer X axis beam and ensures greater stability since the beam is held at two points which minimizes flex and deflection of the beam.

AMS lite Mounting

The AMS lite is not small and pairing it with the A1 mini effectively doubles its footprint, turning a small 3D printer into a large one. To save space, the community has designed wall mounts, vertical stands and even top mounts, which balance the considerable weight and size of the AMS lite off the small Z axis upright. Bambu Lab does not endorse these methods and insists on the stand which comes with the AMS lite. Since they use substantial bracing with the A1 top mounting method (see below) they seem to be concerned about instability and stress on components. But this is probably the least space efficient method.

With the A1, there’s the option of the officially-sanctioned method of top mounting in addition to the stand. This is a fairly intensive modification involving 14 screws and many 3D printed parts including two large stiffeners for the Z axis uprights, but it allows the AMS lite to be mounted on the top gantry. This does not alter the footprint at all and uses the only space often available - the space above the printer. It does not make the printer any larger but it does make it considerably taller.

Bed Temperature

The bed heater on the A1 mini’s smaller bed is capable of heating the bed to 80°C.

The bed heater on the A1 is more powerful and can heat the bed to 100°C.

Without an enclosure, the printer is not capable of printing the advanced filament types that require such a temperature (like ABS), but it should still be noted.

First Party Build Plates

Bambu Lab sells two build plates for the A1 mini: a textured PEI build plate that comes with the printer and a smooth PEI build plate.

The A1 uses the same build plates as the P1 and X1 printers so more build plate types are available. In addition to the included textured PEI build plate, a smooth PEI plate is available as

well as a dual sided high temperature plate and engineering plate. The high temperature plate is a smooth PEI sheet adhered to an engineering coating on steel. The engineering plate is a special very tough coating on steel. It is suitable for most advanced filaments but (oddly) not PLA.

Heatbed Cable

Though both printers seem to have identical heatbed cables, there have been no problems reported with the A1 mini’s heatbed cable.

Unfortunately there have been a few issues reported with the A1 heatbed cable - some broken connections and a few short circuits. Out of an abundance of caution, Bambu Lab recalled all A1 printers and spent months working on a fix. A1 owners who opted to keep the printer were given replacement heatbeds, and current A1s have a reinforced heatbed cable to prevent this problem from occurring.

Conclusion

If you need the print volume, the choice is clear, you should get the A1.

Beyond size, the differences between the A1 and the A1 mini are minor. The A1 has two Z axis uprights to support the longer X axis beam, there’s the official method for top mounting the AMS lite, the A1 has a higher bed temperature which you can’t really take advantage of, and there’s a third official build plate. Finally, the heatbed cable is different but after Bambu Lab’s redesign, it’s just as reliable. So if you don’t need the print volume and want to save some money, the A1 mini is just as capable. In many ways, they are the same printer, only different sizes.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

Click here to view the Bambu Lab A1 Mini on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: