If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab A1 vs the Bambu Lab X1 Carbon

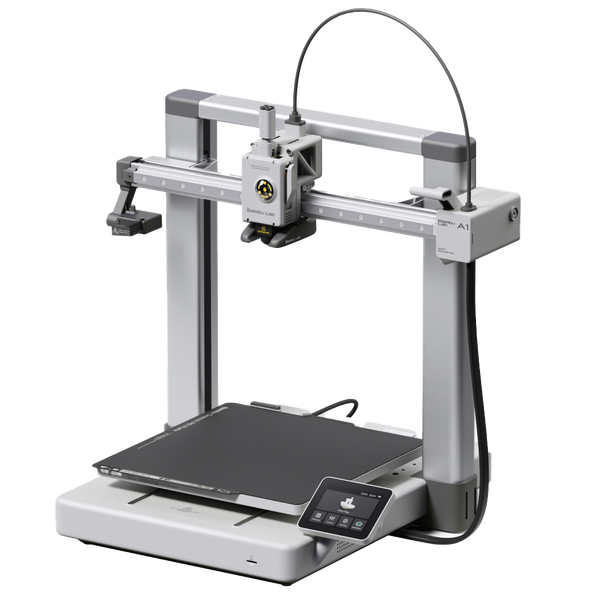

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

The A1 is Bambu Lab’s first full-size “bedslinger” 3D printer, released in 2023, with a standard build volume and feature set that makes it a very appealing option to anyone looking for a mid-range printer.The X1 Carbon, the first printer Bambu Lab released back in 2022, has kept up surprisingly well with the ever-evolving competition. How does it stack up against one of Bambu Lab’s more recent printers, the A1?

In this article, we will be comparing both of these machines, going over their similarities and differences to help you decide which 3D printer is right for you.

Similarities Between the Bambu Lab A1 and X1 Carbon

Coming from the same manufacturer, you can expect much of the same specs from these printers.

Hot End and Extruder

Both the Bambu Lab A1 and X1 Carbon are equipped with all-metal hotends that are capable of heating up to 300°C, making them compatible with a wide range of filament types, including PLA, PETG, ABS, TPU, and nylon. Both printers use dual-gear extruders that provide consistent extrusion, especially when printing with TPU.

Print Speed

The Bambu Lab X1C was praised on its release for its remarkable maximum print speed of 500 mm/s. While still impressive today, many printers are beginning to catch up to this speed, including the A1. The A1 also has a maximum print speed of 500 mm/s, meaning you can expect very similar print times between these two machines.

The X1C does pull ahead on acceleration, with a maximum acceleration of 20,000 mm/s, double that of the A1’s 10,000 mm/s. You can expect the X1C to deliver faster results when many print head travels are present in your print jobs.

Overall, you can expect to find similar performance between these printers in terms of speed, which is surprising given the more efficient motion system of the X1C.

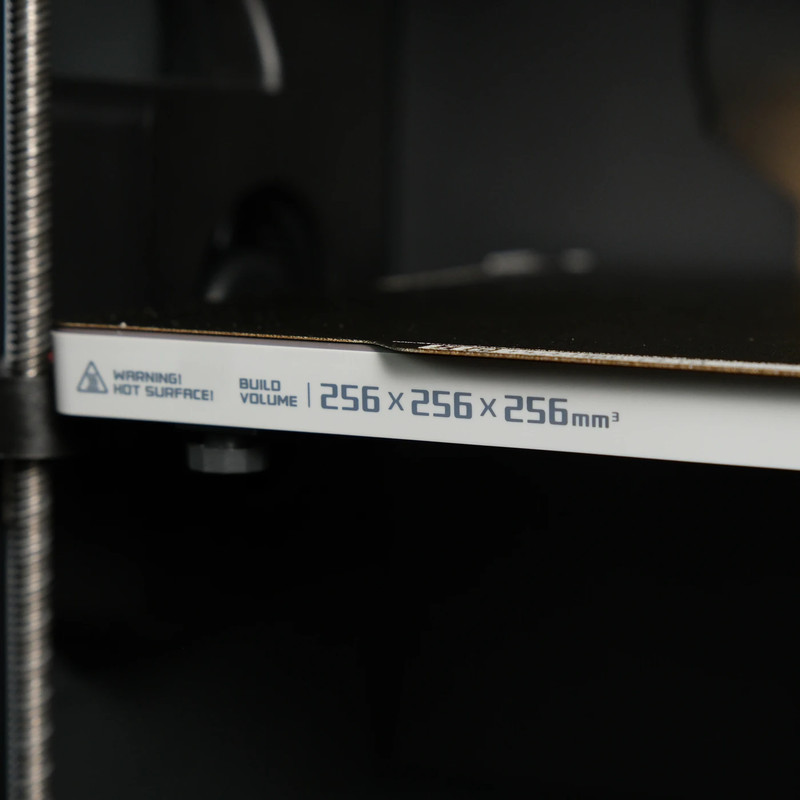

Build Volume

The Bambu Lab A1 has a build volume of 256 x 256 x 256 mm (10.25 x 10.25 x 10.25 in). This is the same build volume found on Bambu Lab X1C, as well as the P1 series of 3D printers, and provides plenty of space for the average user. You should have no issues fitting almost any 3D print on this print bed.

Print Surface

The A1 and the X1C come with a textured PEI print surface. This is our favorite print surface as it provides excellent print adhesion. The flexibility of this surface makes part removal simple and it requires little cleaning or maintenance.

Automatic Leveling

The X1C was one of the first printers to fully integrate a reliable automatic bed leveling system that required little to no user input. This same system can now be found on the A1, making both printers generally easier to use and great beginner machines as you won’t have to manually adjust your bed once it is calibrated.

Display and Connectivity

Both the A1 and the X1C utilize full-color touchscreen displays for menu navigation and print job control. These touchscreen displays are a nice addition that gives these machines a premium feel during operation. You can fully control your A1 or X1C over your local Wi-Fi network using the Bambu Handy app. This app also allows you to monitor your prints using the built-in cameras that are present on both of these machines. Both printers are capable of offline printing using the included SD cards.

Multicolor Printing

The X1 Carbon was the trailblazer for multi-color 3D printing, with the AMS unit designed specifically for it. The AMS unit allows you to run four different colors of filament to your X1 Carbon that it can then use to automatically swap colors mid-print. With an AMS hub, you can connect up to four different AMS units for a total of 16 different colors per print.

The A1, while not compatible with the original AMS unit, got its own variation with the AMS Lite. Rather than sit on top of the printer, the AMS Lite stands next to your A1 and feeds up to four different spools of filament into the nozzle for automatic color swaps. This version of the AMS is compatible with all types of spools, including cardboard spools, which were previously very difficult to use on the original AMS unit.

No matter which of these printers you choose, you will have access to multicolor printing.

Differences Between the Bambu Lab A1 and X1 Carbon

Now that you see how similar these 3D printers are, let’s go over what makes them different to help you better determine which is right for you.

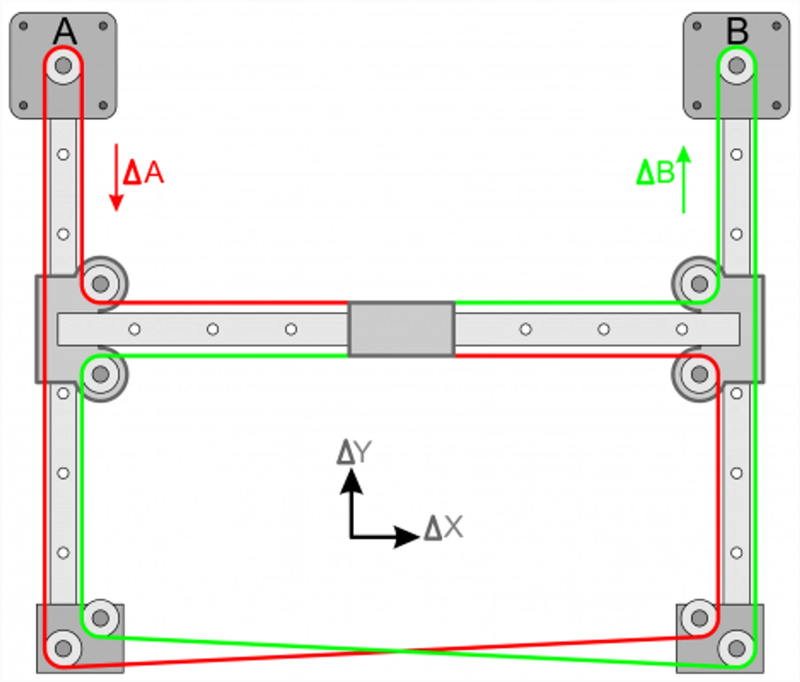

Motion System and Frame

The X1 Carbon takes advantage of the CoreXY motion system, moving the nozzle along the X and Y axes while the print bed is lowered along the Z-axis during printing. This type of motion system is very efficient and is currently one of the fastest motion systems there is. As the print bed is not moving back and forth, as it would in a traditional Cartesian design, the prints are much more stable and will experience fewer artifacts in the print surfaces from movements in the print bed.

The X1C opts for carbon-fiber rods along the X and Y axes while using standard lead screws for the Z-axis movements.

The Bambu Lab A1 returns to the “bedslinger” design. The print head is moved along the X-axis and raised along the Z-axis, while the print bed is moved along the Y-axis during printing. To combat the issues found in these print bed movements, the A1 uses vibration compensation to help reduce the amount of wobble experienced when moving the print bed. Linear rails are used along the X and Y axes, while lead screws are again found on the Z-axis.

Both printers use robust motion systems that are designed with speed and durability in mind.

The X1C comes with a fully enclosed frame. This not only protects the motion system from dust and debris but also keeps heat trapped inside the chamber. A heated chamber means the X1C will have no issues with materials that require heated enclosures, such as ABS and ASA.

The A1 has an open-frame design that will give you issues when trying to print materials that need consistent ambient heat, though will perform better when printing materials that benefit from passive cooling, such as PLA.

Material Compatibility

The X1 Carbon is designed to print all kinds of exotic and rough materials, including PC, carbon fiber, and glass-reinforced materials using its hardened steel nozzle.

The A1, while equipped with an all-metal hot end, comes stock with a brass nozzle that is not capable of printing these more exotic materials.

Physical Size

The A1 has a compact size of 385 x 410 x 430 mm, which is on par with other bedslingers. The AMS Lite takes up a considerable amount of space beside this printer unless you mount it on top of or above the A1.

The X1 Carbon has a size of 389 x 389 x 457 mm. CoreXY 3D printers are able to keep their movement confined in their frame, making the most efficient use of their space. You can expect both of these machines to take up roughly the same amount of space, with the A1 requiring a bit more space along the Y-axis for bed movements

Sensors

While there are a few sensors that the A1 and X1C have in common, there are a couple of noticeable exceptions that you may want to consider. They both come with a filament run-out sensor, a filament odometry sensor, and power loss recovery.

The X1C comes with a Micro Lidar sensor that is used to ensure the consistency of filament flow between prints. This means that you will not have to manually adjust flow for different types of materials and colors, as your printer will do it all automatically.

The A1 comes with a filament tangle sensor that monitors the flow of material and will pause the print if the filament gets stuck in the extruder or tangled in the spool.

Additionally, both printers come with a 1080p built-in camera that is capable of monitoring your prints and streaming to the Bambu Handy app, though the X1C’s camera is of noticeably higher quality.

Should You Buy the Bambu Lab A1 or the Bambu Lab X1 Carbon?

You can find a lot of the same core design principles within these two machines, with ease of use, durability, speed, and multicolor printing being the key factors here. With that in mind, it is actually fairly easy to pick between these two machines.

If you need to print with materials that require an enclosure or a hardened steel nozzle, then go with the X1 Carbon. You will be paying a much higher premium but will be getting a fairly future-proof printer that is capable of printing just about anything you need.

If you don’t see yourself printing in exotic materials, have a mid-range budget, or are looking for a good printer to get started in the hobby, then go with the A1. It provides you with a slew of nice-to-have sensors that will make it much easier for those newer to 3D printing to get successful prints and is an overall workhorse when it comes to printing PLA, PETG, or TPU.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: