If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab A1 vs the Creality Ender 3 V3

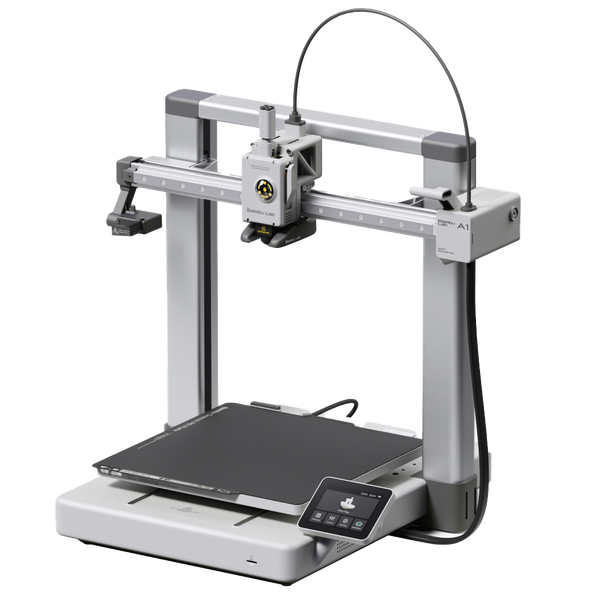

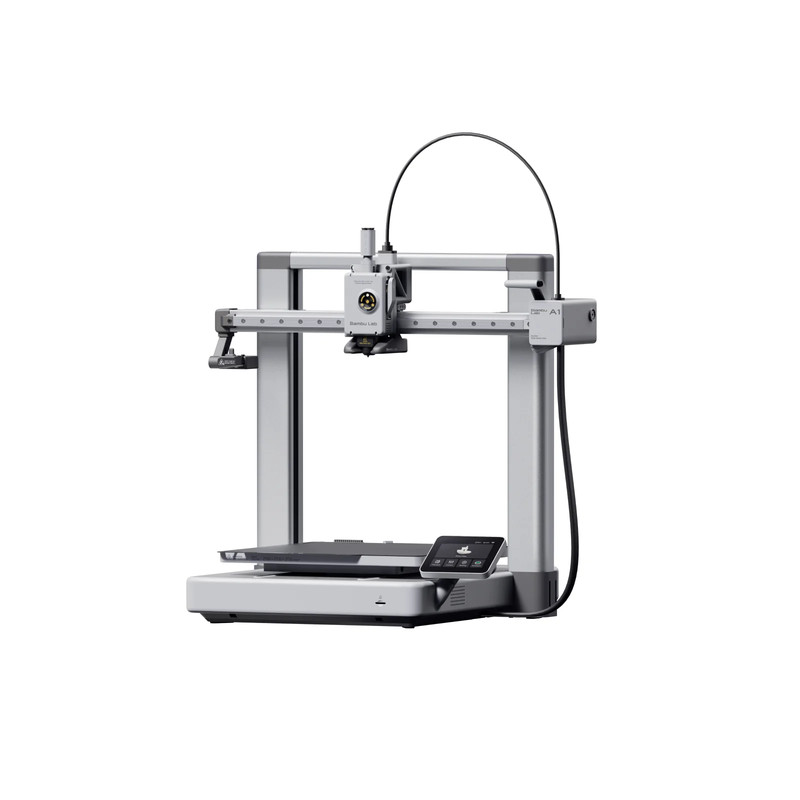

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

Vs.

Creality Ender 3 V3

(~8.75 x 8.75 x 10 in)

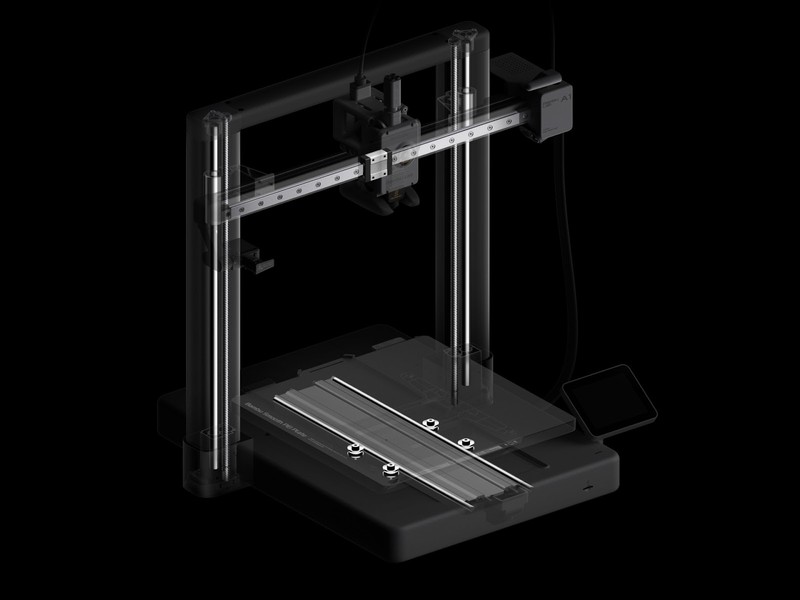

The Bambu Lab A1 is Bambu Lab’s second “bedslinger” 3D printer, released shortly after the A1 Mini in the Fall of 2023. It includes a larger build volume than the A1 Mini as well as a familiar frame to the 3D printing community. The A1 looks to take over the low-to-mid range budget of the 3D printing market with its advanced features and reasonable pricing.

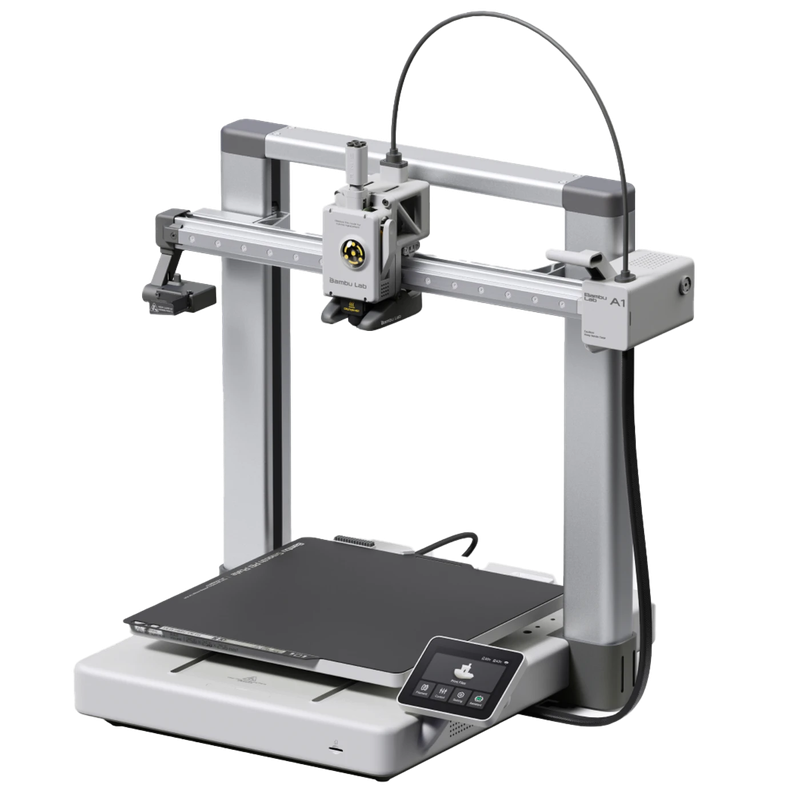

Released only a month after the A1, the Ender 3 V3 is the latest addition to the Ender lineup, featuring a unique, if not novel, CoreXZ design that attempts to innovate in ways we haven’t seen on many 3D printers. The V3 is aiming to find a spot in the same budget high-speed tier that the A1 fills, making this a very close comparison.

In this article, we will be comparing both of these machines, going over their similarities and differences to help you decide which 3D printer is right for you.

Similarities Between the Bambu Lab A1 and Ender 3 V3

As these machines are directly competing with each other, you can expect a lot of similarities.

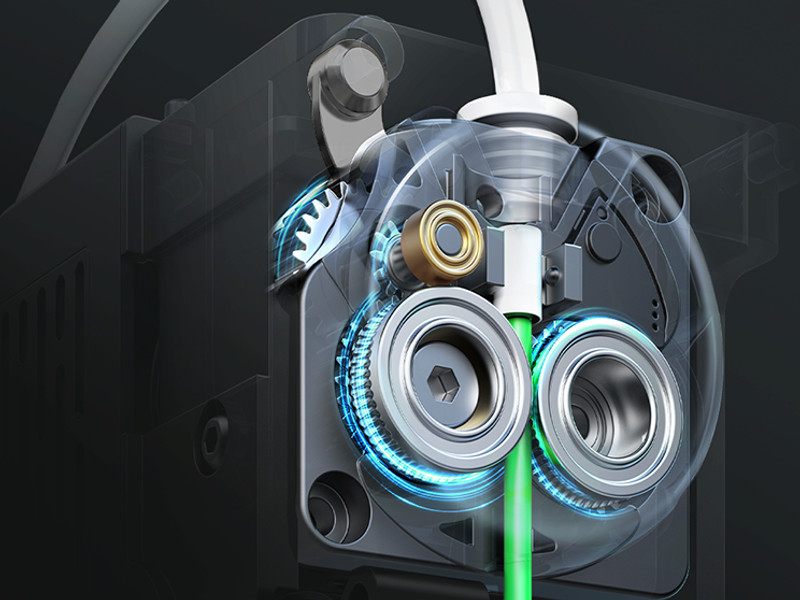

Hot End, Extruder, and Filament Compatability

Both Bambu Lab A1 and the Ender 3 V3 are equipped with all-metal hotends that are capable of heating up to 300°C, making them compatible with a wide range of filament types, including PLA, PETG, ABS, TPU, and nylon. Both printers use dual-gear extruders that provide a good grip on the filament for consistent extrusion. This design is especially noticeable when printing with TPU, as the extra gears will ensure the TPU does not bind up and jam your extruder.

The A1 has an additional flow rate sensor installed in its hotend. This sensor tracks your filament flow rate in real-time and makes adjustments when necessary to maintain a consistent flow of material. This takes some of the work off your shoulders when swapping between many different kinds of filaments, as you won’t have to fine-tune your slicer settings as much to get consistent results.

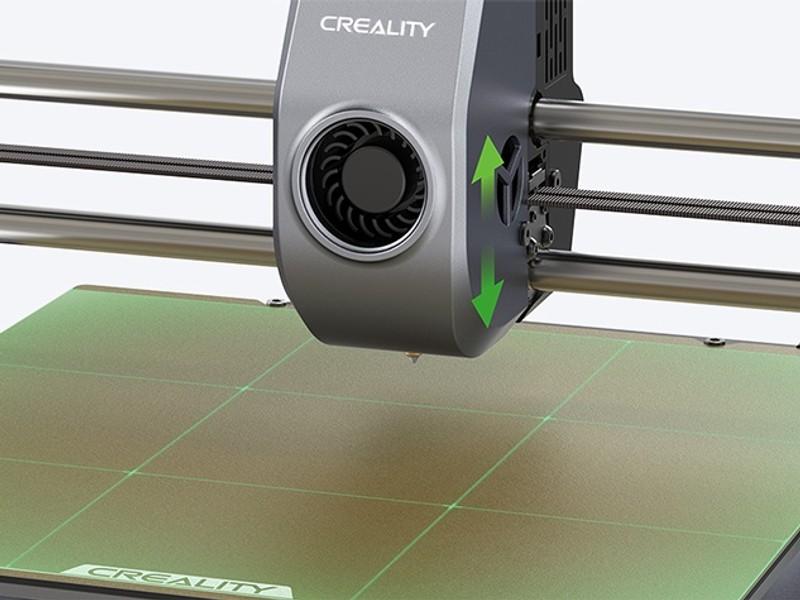

Print Surface

The A1 and the V3 come stock with a textured PEI print surface. This is our favorite print surface as it provides excellent print adhesion. The flexibility of the print surface makes part removal very easy once the bed has cooled down. We are seeing many modern 3D printers swapping to this print surface and are happy to find it on both of these machines.

Automatic Leveling

Ease of use is a major factor for many modern 3D printers, especially when the target audience is beginners and those looking to expand their print farms. Printers at this price point are expected to “just work” and neither of these machines disappoint.

The A1 and the V3 both use a variety of smart sensors to probe the bed, creating a bed mesh and automatically adjusting movements during printing to compensate for any variations in the height of your print surface. The most important of which is the strain-based sensors used to gauge the distance of the nozzle from the bed and automatically set the optimal Z-offset. We prefer strain-based sensors over bed probes as they are much more accurate, and consistent, and maintain their reliability over time. You can expect a similar hands-free approach to bed leveling when working with either of these printers.

Display and Connectivity

Many higher-end 3D printers utilize touchscreen displays as they look and feel more premium than the traditional LCD screen with scroll wheel input. While not necessary by any means, touchscreens are nice to have and are a welcome addition to both of these printers. Full-color touchscreen displays make it easy to navigate menus and quickly check on the status of your prints at a glance.

If you prefer wirelessly controlling your 3D printers, you won’t be disappointed with either choice here. The A1 connects to your local WiFi network and can be controlled remotely using the Bambu Handy app on your phone or through Bambu Studio on your PC. You can send print files over WiFi, pause prints, and perform other basic commands without having to be near your printer. This is one of the cleanest 3D printer apps we have used.

The Ender 3 V3 uses the Creality Print app to control your printer over the WiFi with either your phone or PC. While you will find similar controls as the Bambu Handy app, we prefer the look and overall design of the Bambu Handy app over Creality Print.

Should you wish to keep your 3D print files offline, both printers are capable of storing files locally, allowing you to use the touchscreen to begin print jobs.

Differences Between the Bambu Lab A1 and Ender 3 V3

Now that you see how similar these 3D printers are, let’s go over what makes them different to help you better determine which is right for you.

Motion System

An obvious place to start is with the motion systems, as this is a core factor in the design philosophy of the Ender 3 V3. It utilizes a CoreXZ motion system, pairing the X-axis and the Z-axis together with timing belts that run alongside linear rods inside the frame of the machine. This results in a lightweight gantry and print head that can maneuver much faster than the normal print head. The Z-axis uses linear rods in place of lead screws, with the timing belts used to position the Z-axis. This leads to faster movements along the Z-axis, though this is not something that contributes to any real-world improvements in print speed or quality and we find it to be mostly unnecessary. The only improvement brought with this motion system is the removal of lead screws from the Z-axis. This means the V3 is less likely to experience Z-banding. Otherwise, the CoreXZ design of the V3 does not provide many benefits over traditional Cartesian printer designs.

The Bambu Lab A1 sticks to simple linear rails along the X and Y axes, along with lead screws for the Z-axis. This is quickly becoming the standard for modern 3D printers and is practically necessary for high-speed 3D printing as linear rails are very durable.

You can expect similar performance between these two motion systems, though the unfamiliar design of the V3’s CoreXZ motion system may be difficult to maintain should anything go wrong with the timing belts, especially for a beginner.

Print Speed

The Bambu Lab A1 is marketed with a maximum print speed of 500 mm/s and a maximum acceleration of about 10,000 mm/s, keeping it competitive with some of the fastest bedslingers around. It is important to keep in mind that maximum speed values are rarely achieved in real-world print jobs. The average user can expect to achieve a reasonable 250 mm/s print speed with the A1, with max acceleration speeds only coming into play when printing multiple parts along the print bed.

The Ender 3 V3 is rated for a maximum print speed of 600 mm/s, along with a maximum acceleration of 20,000 mm/s. This makes it Creality’s fastest bedslinger to date and possibly the fastest bedslinger on the market. Again, the actual maximum print speed you can expect from a V3 is about 250-300 mm/s, slightly faster than the A1 though still an improvement that can be seen in the faster print times of the V3. The max acceleration speed makes the V3 a much more appealing option should you wish to print many parts at the same time, reducing the travel time of the print head significantly over the A1.

Overall, you can expect to find similar performance between these printers in terms of speed, with the V3 pulling ahead slightly for those who need the absolute fastest machines around.

Multicolor Printing

The Bambu Lab A1 is compatible with the AMS Lite unit that was originally shipped with the A1 Mini. This allows for printing with up to four different colors or materials of filament at the same time, using the included purge wiper for automatic filament swaps. This can be purchased as a separate add-on or as a combo for a cheaper price. Either way, it will significantly increase the price of the A1.

The Ender 3 V3 is not compatible with the AMS Lite unit. Outside of third-party DIY alternatives, the V3 is stuck with single-color printing for now.

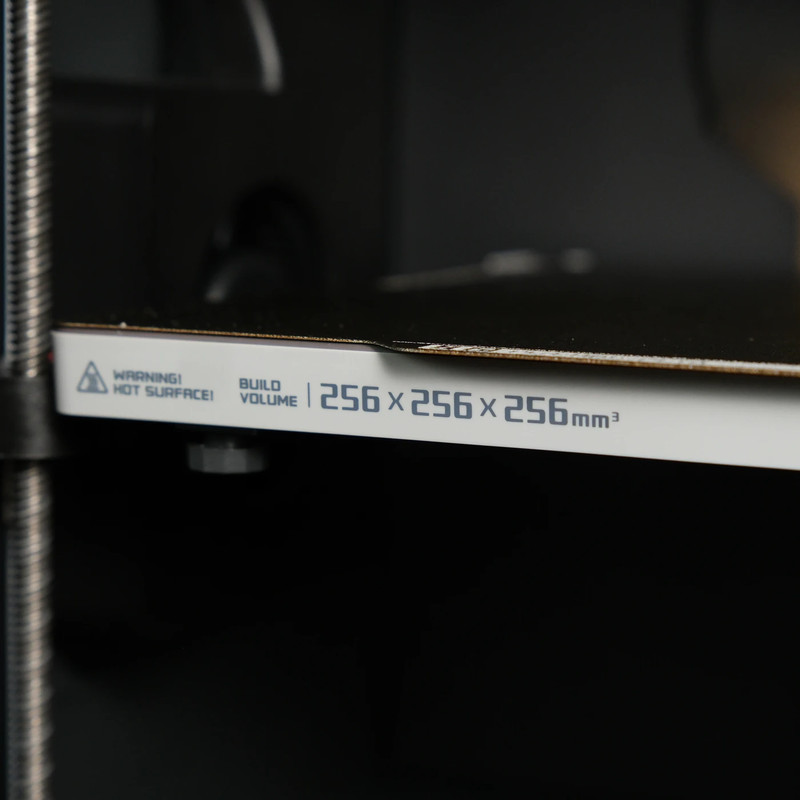

Build Volume and Physical Size

The Bambu Lab A1 has a noticeably larger build volume than the A1 Mini before it, with a build volume of 256 x 256 x 256 mm (10.25 x 10.25 x 10.25 in). This is the same build volume found on Bambu Lab’s X1 and P1 series of 3D printers and provides plenty of space for the average user. You will be able to fit medium to large prints or multiple smaller prints on the bed with ease.

The A1 has a compact size of 385 x 410 x 430 mm (15 x 16 x 16.9 in), fairly average for printers of this form factor. If you plan on using the AMS Lite unit alongside the A1, you will need a much larger space for this combo.

The Ender 3 V3 has a build volume of 220 x 220 x 250 mm (8.75 x 8.75 x 10 in). This is average for an Ender 3 and is plenty of space for most print jobs though it is noticeably smaller than the sizable A1.

The total size of the Ender 3 V3 is 358 x 374 x 498 (14 x 14.7 x 19.6 in), slightly slimmer than the A1 thanks to the V3’s frame design, though noticeably taller than the A1 as well.

The extra 36 mm on the X and Y axes of the A1 may be a deal breaker for those looking for the absolute largest build volume, though the V3 will still provide the average user with more than enough space.

Remote Monitoring

The Bambu Lab A1 comes with a built-in camera that allows you to remotely monitor your prints using the Bambu Handy app. This is a nice addition if you plan on putting your printer in a far room in the home, as you won’t have to get up to check if your print is done. The camera is capable of recording timelapses of your prints as well.

The Ender 3 V3 does not come with a built-in camera, though Creality offers AI camera add-ons for an additional cost.

Should You Buy the Bambu Lab A1 and Ender 3 V3?

With these two printers directly competing for the same spot in the market, you can expect it to be a tough choice. Ultimately, we think that the majority of users will prefer the Bambu Lab A1 over the Crealtiy Ender 3 V3. With the inclusion of remote print monitoring, a flow sensor for consistent print results when using different material types, a large build volume, and the option to upgrade to multicolor printing later on, the A1 makes for a very compelling option at this price point.

If you are strictly after the fastest bedslinger 3D printer and want to stick with a brand that encourages open-source hardware and firmware, then the Ender 3 V3 is for you.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

Click here to view the Creality Ender 3 V3 on Amazon.

You can find a side-by-side comparison of the specifications for these two printers in the table below: