If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab A1 vs the Creality Ender 3 V3 KE

In this article, we’ll compare the Bambu Lab A1 to the Creality Ender 3 V3 KE to help you determine which of these 3D printers is the better choice for you.

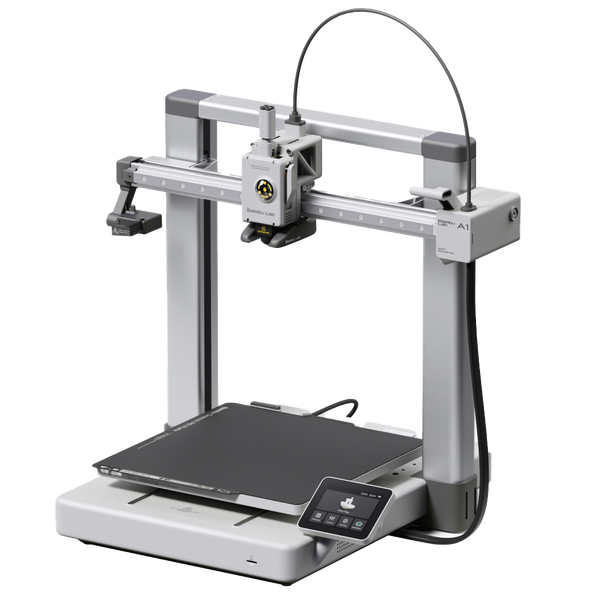

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

Vs.

Creality Ender 3 V3 KE

(~8.75 x 8.75 x 9.5 in)

The Bambu Lab A1 series, beginning with the A1 Mini in September 2023 and followed by the larger A1 in December 2023, marks Bambu Lab’s first foray into the standard Cartesian “bedslinger” design favored by most other 3D printer manufacturers. In particular, the Bambu A1 shares a lot of design similarities with machines from Creality, Prusa, and other brands. This raises an obvious question: is the Bambu A1 worth buying over some of these other similar machines, especially if it comes at a higher price?

The Creality Ender 3 V3 KE is a particularly interesting competitor to the Bambu Lab A1. It was announced in September 2023 but started shipping in November 2023, and uses the same bedslinger design as the A1. The KE also includes WiFi connectivity along with firmware features such as pressure advance and vibration compensation, matching several of the A1’s headlining features. At first glance, these two 3D printers are very similar, which may make it hard to decide which one is a better choice.

We’re going to take a closer look at both machines and help you analyze the differences. Although they seem similar on the surface, they are different in a few important ways, and we think you’ll be able to decide which one is better for you based on this comparison.

We’ll start by covering the similarities between the Bambu Lab A1 and the Creality Ender 3 V3 KE.

Bambu Lab A1 and Creality Ender 3 V3 KE Similarities

As two midrange FDM 3D printers at similar price points, the Bambu A1 and Creality Ender 3 V3 KE have several common features. We’ll discuss each one here.

Physical Design and Motion System

It’s immediately apparent from looking at the A1 and Ender 3 V3 KE that the two machines use the same motion system and have a similar physical design. These printers are both “bedslingers” with a Cartesian motion system, where the print head moves left and right along an X axis gantry as the bed moves forward and backward in the Y axis. The X axis gantry raises upward on the Z axis, lifted evenly by two leadscrews. This is the most common motion system for FDM 3D printers, although the A1 is Bambu Lab’s first machine to use this specific configuration.

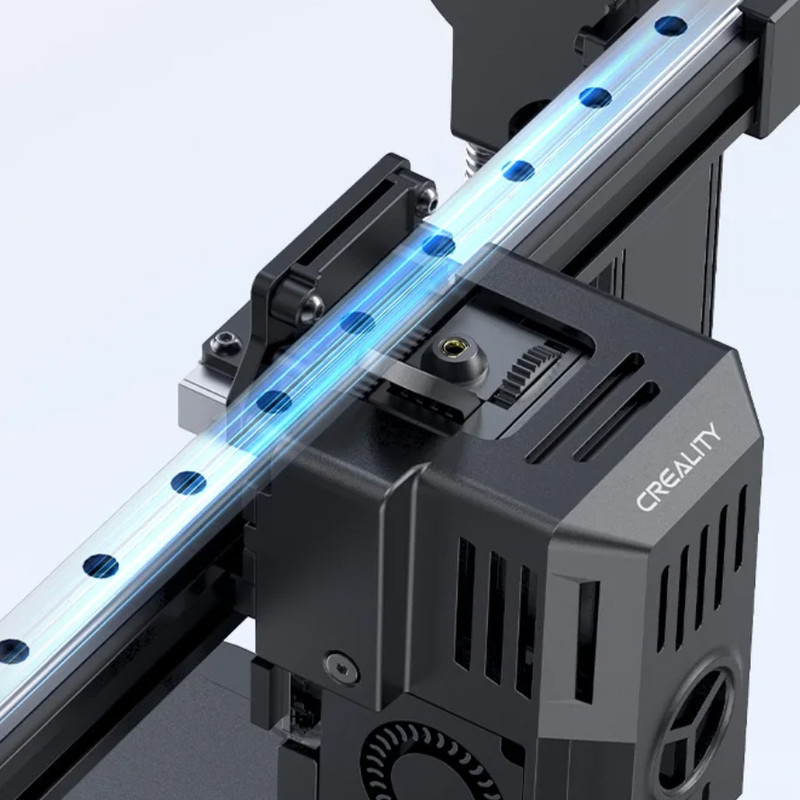

The two printers do both improve on this common design by using a linear rail on the X axis and linear rods on the Y axis. Compared to older and cheaper 3D printers that use rubber wheels running along a track, the higher-quality motion components on these printers cause less vibration, allowing them to attain higher print speeds than most other 3D printers.

Although the bedslinger design tends to look less polished and has more exposed moving parts than other 3D printer designs, the A1 and Ender 3 V3 KE both use smooth casings to enclose most of the cables and mechanisms, resulting in a clean appearance. Besides one printer being black and the other being white, there are no major differences in appearance between the two.

Print Speed

Both the A1 and Ender 3 V3 KE advertise a maximum print speed of 500 mm/s. They do differ slightly in maximum acceleration, with the A1 advertising a maximum of 10,000 mm/s2 and the Ender 3 V3 KE advertising 8,000 mm/s2. In real usage, we expect these printers to offer similar speeds, since the ability of any 3D printer to reach or maintain its maximum speed is highly dependent on the model being printed.

To put these numbers in context, these are some of the fastest FDM 3D printers you can buy–while a few machines have advertised a faster 600 mm/s speed, most printers either match this speed or are significantly slower. Many older 3D printers could only maintain speeds of 60-100 mm/s.

Supported Filament Types

The Bambu A1 and Creality Ender 3 V3 KE include a direct drive extruder and have an all-metal hot end capable of heating to 300°C. This allows both machines to print with most standard filament types, including PLA, PETG, TPU, PA, nylon, and more. The print bed on both machines can heat up to 100°C, which is more than sufficient for all of these materials.

Some other materials, such as ABS and ASA, require an enclosed build chamber to print larger parts successfully. Since neither of these printers include an enclosure, you’re likely to have more trouble printing those filament types. If ABS or ASA are important for your needs, you could purchase or build your own enclosure for either printer, but you may wish to consider a different model that includes an enclosure, such as the Bambu Lab P1S or the Creality K1.

Display and Physical Controls

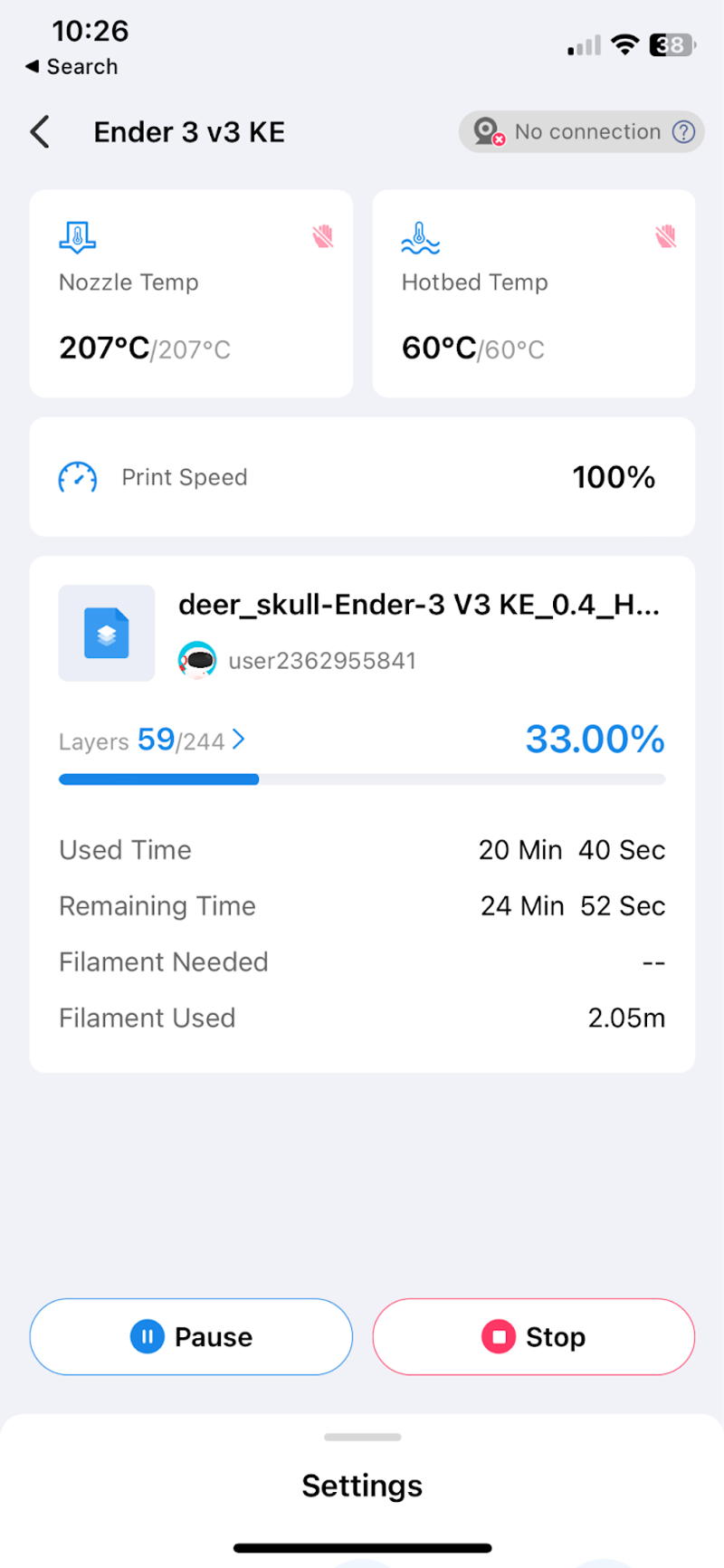

The A1 and Ender 3 V3 KE both have full-color graphical touchscreen controllers, a feature we’re happy to see. Although both printers provide a smartphone app, the physical screen and controls are more convenient for quickly checking on the printer status when you’re near the machine. And while a full-color display and touchscreen are not strictly necessary, we’ve found this control scheme to be the easiest and fastest way to control a printer.

The two 3D printers have different user interfaces, but in our opinion, the differences between them are not meaningful. Both interfaces give you access to the important controls and printer status information you’ll want to see.

WiFi Connectivity and App Control

We’re starting to see more 3D printers include WiFi to allow you to control and monitor your printer remotely, and both of these machines include that capability. Unfortunately, there is no standardized way to control a 3D printer over WiFi, so each manufacturer has its own app for communicating with their printers.

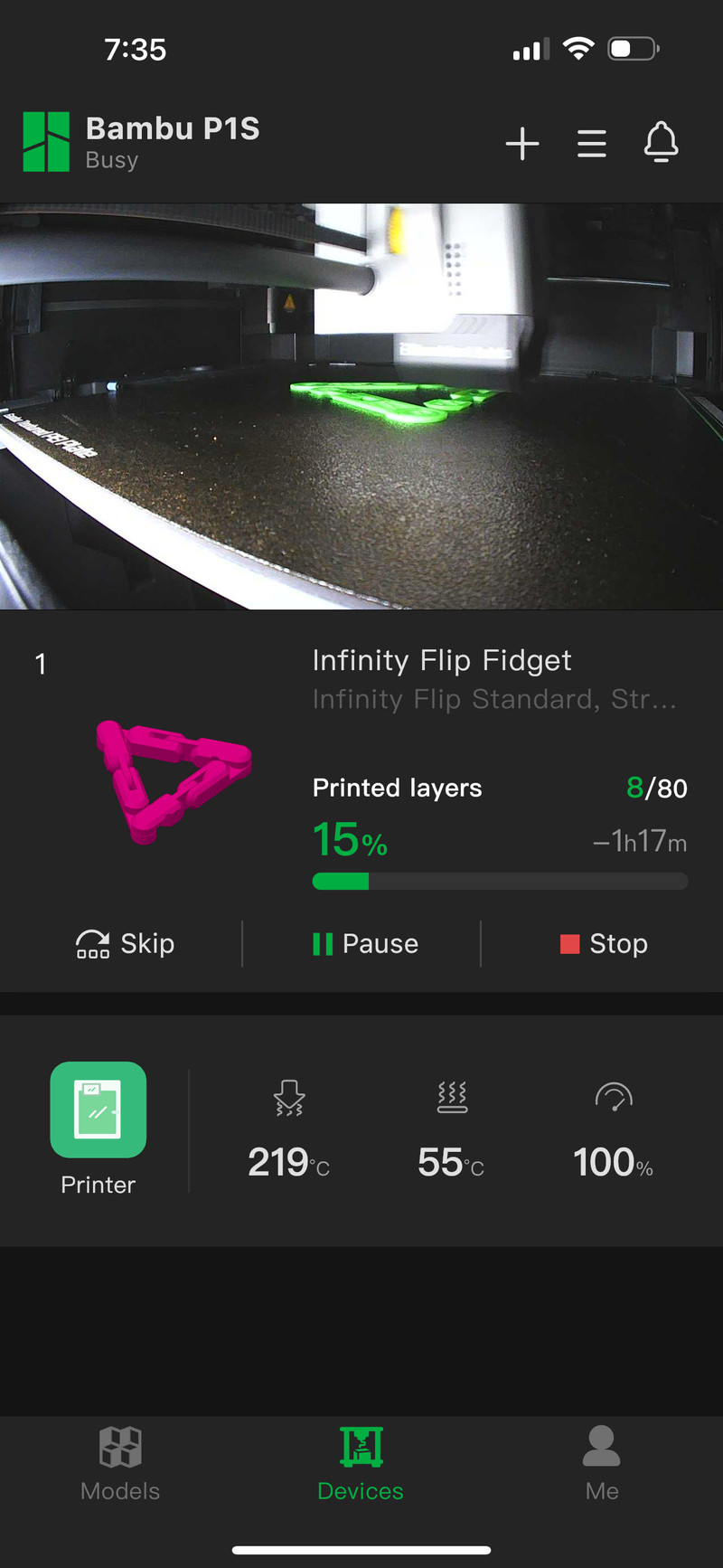

On the Bambu A1, you can use the Bambu Studio application to control the printer from your computer, and can also view the printer’s integrated camera. The Bambu Studio app also includes a slicer for preparing 3D models. You don’t have to use the Bambu Studio slicer if you prefer a third-party option such as Cura, but Bambu does caution that you can’t take advantage of all of the features of the A1 (such as the optional multi-material capability, discussed later) without using Bambu Studio.

You can also use the Bambu Handy smartphone app to control the printer from your phone, which is a convenient feature for checking on an ongoing print.

On the Creality Ender 3 V3 KE, you can use the Creality Print computer application and the Creality Cloud web app and smartphone app to control the printer similarly to what Bambu offers with their software. Similarly, the Creality Print computer application does include an easy-to-use slicer for preparing models. But unlike Bambu, Creality doesn’t make any claims that you need to use their slicer to use all of the features of the Ender 3 V3 KE.

We’ve tested both the computer application and smartphone app for both Bambu and Creality, and we’ve found both companies’ software easy enough to use. We really like having WiFi on these newer 3D printers, and feel that it’s a feature worth paying extra for if you’re considering a different model that doesn’t offer it.

Firmware Features to Improve Print Quality

The Bambu A1 and Creality Ender 3 V3 KE both include several firmware features to improve print quality beyond what we’ve seen on many older 3D printers. These features, such as pressure advance, vibration compensation, and input shaping, first appeared in open-source projects and higher-end consumer 3D printers, but are starting to make their way down to lower-cost machines. From our testing, these features really do improve print quality, especially at the higher print speeds these printers are capable of.

Because the A1 and Ender 3 V3 KE are made by different manufacturers, their firmware isn’t exactly the same and there will be differences in how each one handles specific details on printed models. Between the two, Bambu Lab arguably has more experience here, since all of their 3D printers have included these features. However, we don’t have any reason to doubt Creality’s implementation of the firmware–the KE isn’t their first printer to include these features, and Creality’s firmware is based on the open-source Klipper project, which has received years of development and improvement from the 3D printing community.

Overall, both of these 3D printers should be capable of similarly-high print quality, and you’re likely to be impressed with the results from either machine. As we’ll discuss later in this article, the Bambu A1 includes a few automatic calibration features that may get you closer to its maximum quality out of the box, whereas the Creality Ender 3 V3 KE may require more experimentation to reach its maximum quality. Both machines will have better print quality out of the box than most older 3D printers.

Automatic Bed Leveling

Both the Bambu A1 and Creality Ender 3 V3 KE include automatic bed leveling and automatic Z offset calibration, which eliminates one of the most annoying and time-consuming calibration steps on older 3D printers.

The two machines implement the automatic leveling slightly differently. The Bambu A1 uses a strain-based leveling system, where the printer touches the nozzle to the bed and detects the exact moment the nozzle makes contact. This allows the A1 to measure the exact bed height from the perspective of the nozzle, which is a very precise form of calibration that also precisely sets the Z offset of the nozzle.

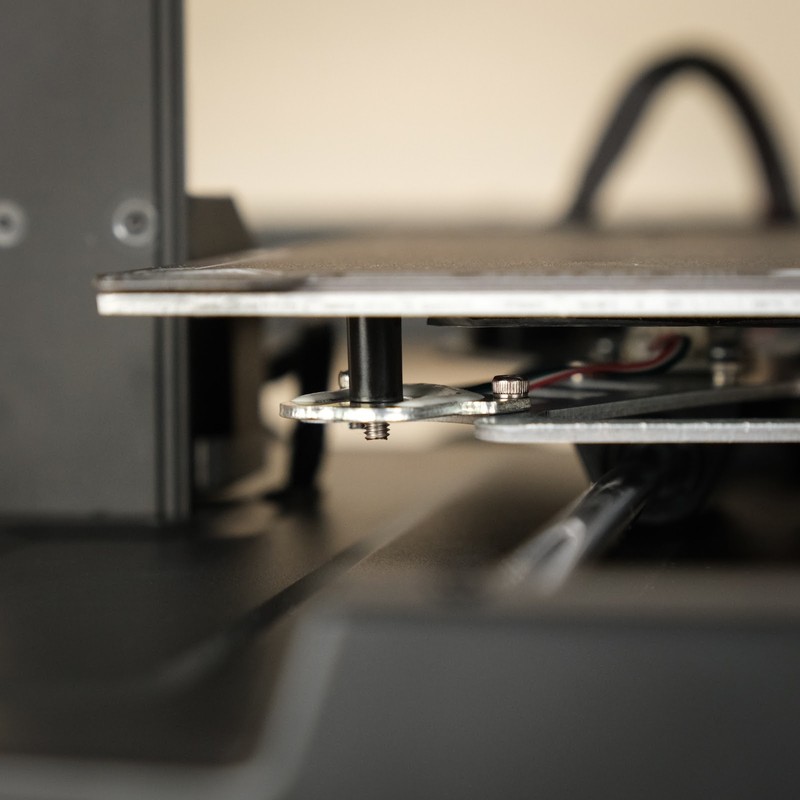

On the other hand, the Creality Ender 3 V3 KE uses a separate CR-Touch probe to detect the bed height. During the automatic leveling process, the probe automatically extends, touches the bed in several locations, and then retracts. Because the probe does not set the Z offset, the Ender 3 V3 KE also includes a separate strain gauge sensor which allows the printer to set the Z offset automatically.

Between these two approaches, we prefer the strain-based leveling on the Bambu A1. It’s a simpler system with fewer moving parts and fewer points of failure. However, we’ve seen great results from both printers’ automatic bed leveling systems, and from your perspective as a user, both of these systems achieve the same result of eliminating the manual process of bed leveling.

Print Bed Surface

The Bambu A1 and Creality Ender 3 V3 SE both include a flexible PEI bed surface, which is our favorite print bed material. PEI provides great layer adhesion during the print, but easily releases the finished model once the bed cools down after a print. It’s a durable material that can be easily cleaned, and has few downsides.

The only difference between the machines is that the A1 includes a textured PEI surface with an orange peel-like texture, while the Ender 3 V3 KE includes a smooth PEI surface with a glass-like texture. We’ve found both textures to work reliably, and the only difference is in the texture that each material leaves on the bottom surface of printed models.

The bed surface attaches to the print bed magnetically on both machines, and it’s a flexible material that can easily be removed from the print bed and flexed to aid in part removal. This also means you can easily replace the bed surface if desired. For example, you can purchase a smooth or textured PEI bed for either printer, or replace it with another material such as PC-coated steel if you prefer.

Bambu Lab A1 and Creality Ender 3 V3 KE Differences

The A1 and Ender 3 V3 KE have a few important differences that you’ll want to keep in mind if you’re deciding between these two 3D printers. We’ll discuss each difference in this section.

Build Volume

The Bambu A1 can print slightly larger objects than the Creality Ender 3 V3 KE:

- Bambu Lab A1: 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”)

- Creality Ender 3 V3 KE: 220 x 220 x 240 mm (8.7” x 8.7” x 9.4”)

This isn’t a major difference, but if you’re printing functional parts or models that must be a certain size, you should verify whether you’ll need the extra printable area that the A1 provides.

If neither of these machines provides a large enough build volume for your needs, there are other FDM 3D printers with much larger build volumes. The A1 matches Bambu’s largest machines, but Creality offers printers such as the CR-M4, which has a massive 450 x 450 x 470 mm (17.7” x 17.7” x 18.5”) build volume. Of course, the trade-off is the physical size of the machines–a nice aspect of both the A1 and the Ender 3 V3 KE is that they won’t take up too much of your work area.

Flow Rate Sensor

The Bambu Lab A1 includes a new flow rate sensor that allows the printer to automatically calibrate the flow rate of the filament. This sensor is located in the hot end and uses eddy currents to precisely measure the flow of the filament, which lets the printer compensate for slight differences between filament types or brands.

This is a setting that we’ve typically had to set manually, and the idea of the A1 setting it automatically is exciting. This flow rate sensor was first introduced on the Bambu A1 Mini and hasn’t appeared on any other machines yet, so we have limited information on how effective it is, but this sensor seems like a compelling feature for the A1.

We expect it to result in a slight improvement to print quality on the A1, although it’s worth noting that you can manually tweak this setting on any 3D printer to maximize print quality.

Multi-Material Support

One of the biggest headlining features of the Bambu A1 is its compatibility with the Bambu Lab Automatic Material System (AMS) Lite, a multi-material system that allows the A1 to feed from up to four filament spools during a print. This means you can print models in multiple colors, or can use different materials, such as breakaway support material. You can even configure the AMS Lite to switch to a different spool when one runs out, allowing you to use the last remaining filament on each of your spools.

The AMS Lite is a unique capability that is only available on Bambu Lab’s printers. Creality doesn’t have a comparable system. There are a few third-party options such as the Mosaic Palette, but in our testing, these systems tend to have a lot of reliability issues since they aren’t directly integrated with the printer software and firmware. Bambu Lab controls the entire software stack, including the slicer–you’re required to use the Bambu Studio slicer when using the AMS Lite–which makes it much more reliable and easy to use than the third-party alternatives.

The AMS Lite is designed to sit on the table next to the A1, so you’ll need a larger desk footprint to use it. However, Bambu has also shown a printable top mount for the AMS Lite, which allows you to mount it on top of the A1. This reduces the footprint needed for the setup, but does increase the overall height of the printer.

You can purchase a combo kit from Bambu Lab that includes the A1 and the AMS Lite, and it’s a surprisingly inexpensive addon when purchased with the printer. You can also buy the AMS Lite separately from Bambu Lab’s store.

This is a key differentiator for the Bambu A1, and if you’re interested in multi-material or multi-color 3D printing, the A1 is a better choice than the Ender 3 V3 KE.

Repair and Upgrade Parts

The Creality Ender 3 V3 KE is similar to other Creality 3D printers in that it’s compatible with many third-party repair and upgrade parts, in addition to Creality’s own parts. In most cases, if something breaks on the Ender 3 V3 KE or if you want to upgrade a part such as the hotend, you can easily purchase a part on Amazon from Creality or another brand and install it on the printer.

Creality also has historically released their own upgrades for their printers, such as improved hot ends, extruders, and displays. This gives you an easy path to upgrade your printer as 3D printing technology improves, and is something we’ve taken advantage of on many of our Creality 3D printers. Creality printers are also compatible with open-source firmware, so if you want to install a more significant upgrade that changes the electrical or mechanical characteristics of the machine, you have the ability to modify the firmware to support these larger upgrades.

Bambu Lab has taken a different approach with their 3D printers, and the Bambu A1 generally only supports Bambu Lab’s own repair parts. They do offer a full range of parts on their site, but you’ll lose the ability to purchase repair parts on Amazon and are reliant on Bambu Lab to continue stocking repair parts for the machine.

Similarly, there aren’t many hardware upgrade options for the A1. It only supports Bambu’s proprietary firmware, so you’re unable to make any major changes to the machine’s functionality, and any repair parts you use will need to be a direct match to the original design of the printer. There are a few exceptions to this, and we’re seeing some early signs that Bambu Lab is open to working with other manufacturers to produce upgrades for their machines, but at this point, we don’t feel comfortable claiming that you have much hardware upgrade potential on any Bambu 3D printer.

One specific difference in the repairability of the two machines is in the nozzle. On the Creality Ender 3 V3 KE, the nozzle unscrews from the hotend and can be replaced with any standard “volcano style” 3D printer nozzle on Amazon, allowing you to easily swap to a different size or replace a clogged nozzle. On the other hand, the Bambu A1 integrates the nozzle and hotend heatsink into a single part, requiring you to replace a larger and more expensive part even if you only want to change to a different nozzle size. While Bambu has made this replacement simple on the A1, and it’s not a particularly expensive part, it’s more expensive than replacement nozzles for the Ender 3 V3 KE.

Overall, it’s hard to say how you should feel about the repairability differences between the machines. There’s no doubt that the Creality Ender 3 V3 KE is a more open design that you’ll be able to continue to repair with parts from a variety of manufacturers, and if you’re into the idea of upgrading your printer, it will support a wide range of upgrades. But if you think you’d only ever want to replace parts as they break, and don’t mind paying slightly more to buy the OEM part from Bambu Lab, you should be able to keep the Bambu A1 running as long as Bambu Lab continues to support the machine.

One other note is that while users have had mixed experience with both companies’ customer support, Bambu Lab’s customer support is more responsive than Creality’s. Our general experience with Creality support has been that it’s typically more effective to search online for help from other users, except in cases where there is an obvious manufacturing defect with the printer. Both companies do have large, thriving online communities, so help from other users is readily available.

Camera

The Bambu A1 includes an integrated camera which allows you to visually monitor ongoing prints from your computer or phone using Bambu’s apps. You can also use the camera to create a timelapse of a print, which can be fun. This is a feature we appreciate having on the A1, since it allows you to periodically check on the status of the print even when you’re not in the room.

The A1’s camera is a “low framerate” 1080p camera. The framerate ends up being around 0.5 frames per second, meaning you won’t see a smooth continuous video when you’re monitoring the print in the app. Instead, you’ll see a static image that updates every few seconds. We don’t find this problematic, but some users have been frustrated by not being able to see a smooth video feed from the printer.

The Creality Ender 3 V3 KE doesn’t include a camera by default, although it does support Creality’s AI Camera addon [Amazon], which you can add to the printer if you want similar functionality.

Nozzle Wiper

The Bambu A1 includes a nozzle wiper, which is a small rubber piece that the printer runs the nozzle across before a print to clear off any hanging plastic strings. This is a minor feature, but it is a small quality-of-life improvement that ensures your prints don’t have a stray plastic string attached to the first layer.

Which 3D Printer Is Better?

The Bambu Lab A1 and Creality Ender 3 V3 KE offer an impressive set of features, making both 3D printers compelling options. Here’s how we’d decide between the two:

If you prioritize ease of use and are interested in multi-material 3D printing, the Bambu Lab A1 is likely the right choice for you. Bambu Lab’s 3D printers are extremely easy to set up and use, and the A1 supports the Bambu Lab AMS Lite for multi-material or multi-color 3D printing. It also includes sensors and features not found on the Ender 3 V3 KE, such as the new flow rate sensor and the integrated camera. Bambu Lab’s printers are known to be well-built and reliable, and the A1 is no exception.

If you prioritize repair and upgrade potential, the Creality Ender 3 V3 KE offers more in that regard. Unlike the A1, the Ender 3 V3 KE is compatible with a wide range of third-party repair parts, and it’s likely that Creality or other manufacturers will release upgrade kits for the KE as 3D printing technology improves. The Ender 3 V3 KE’s build quality does not quite reach that of the A1, but it comes close, and we’ve generally seen great reliability from Creality’s printers. The Ender 3 V3 KE also comes in at a lower price than the Bambu Lab A1.

You can check out each printer using the links below, or continue scrolling to see a side-by-side comparison of each printer’s specs.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

Click here to view the Creality Ender 3 V3 KE on Amazon.

You can find a side-by-side comparison of the specifications for these two printers in the table below: