If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab H2D vs the Bambu Lab X1C

Bambu Lab H2D

(~14 x 12.75 x 13 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

The Bambu Lab X1 Carbon, or X1C, has been the company’s flagship consumer 3D printer since its introduction in late 2022. With a premium feature set, excellent print quality, and unprecedented ease of use, it’s been a go-to choice for a multitude of 3D printing hobbyists, print farm operators, and businesses. Since its release, other 3D printer brands have released competing models, and some have come close to unseating the X1C from its place at the top, but in many users’ opinion, none have yet surpassed it.

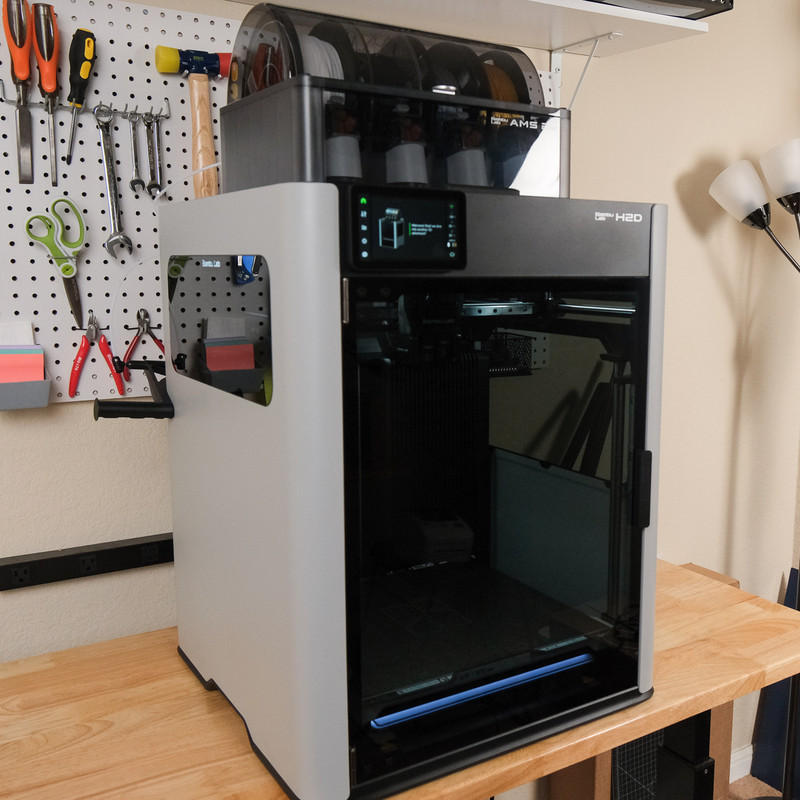

In March 2025, Bambu Lab finally released a new high end machine. Occupying a higher position in their lineup, the Bambu Lab H2D offers a bigger print volume and more features than the X1C, but also has a higher price to match. The question is, does the Bambu H2D fully replace the X1C as the premium Bambu Lab 3D printer to own, or does it instead offer a different set of trade-offs that may not fit your needs? And even if the H2D is better, is it worth the rather substantial price premium over the X1C? We’re going to try to answer those questions in this article.

Note that while the H2D is offered in a 3D printer-only version as well as a combo unit that adds a laser cutter and vinyl cutter, we are going to focus on the 3D printer aspects of the H2D for this comparison.

We’ll start by covering the similarities between the printers, and then cover the key differences, to help you determine which of these 3D printers is the better choice for you.

Similarities Between the Bambu Lab H2D and X1C

Since the H2C and X1C are both Bambu Lab 3D printers, they share many common features.

Physical Design and Motion System

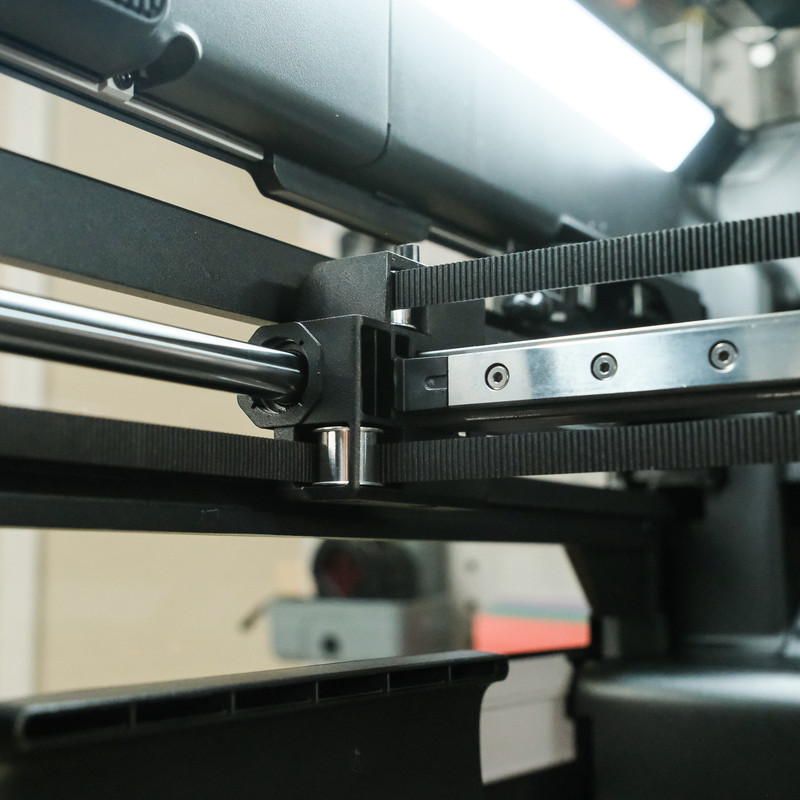

The Bambu H2D and X1C both use a CoreXY motion system, where the print head moves in the X and Y axis and the bed moves up and down in the Z axis. At the beginning of a print, the bed will be raised completely to the top of the printer, and will slowly lower during the printing process. CoreXY is known for being a fast and accurate motion system, and has the advantage of not moving the bed in the X or Y axes, which can reduce the tendency of a large model to shift during printing.

CoreXY printers tend to be cube-shaped and are typically self-contained, with no protruding moving parts. The H2D and X1C are no exception, and both printers are fully enclosed. One thing we like about this design is that it’s easy to set the printer on a workbench or desk and know exactly how much space you need. The enclosed nature of the printers offers some other advantages, such as the ability to print certain materials such as ABS and ASA which require an enclosure. However, there are a few important differences in each printer’s enclosure, which we’ll cover later in this article.

There are two notable differences between the machines in this regard. The H2D gets points for including a nice molded inset grip at the bottom on each side of the machine, making it easy to lift (with a friend; it’s a heavy printer). The X1C offers no such affordance for lifting. On the other hand, the side panels on the X1C are made of aluminum, which feels more premium than the plastic side panels on the H2D. This material choice doesn’t affect the functionality of the machine, and both machines feel well-built.

Print Quality and Speed

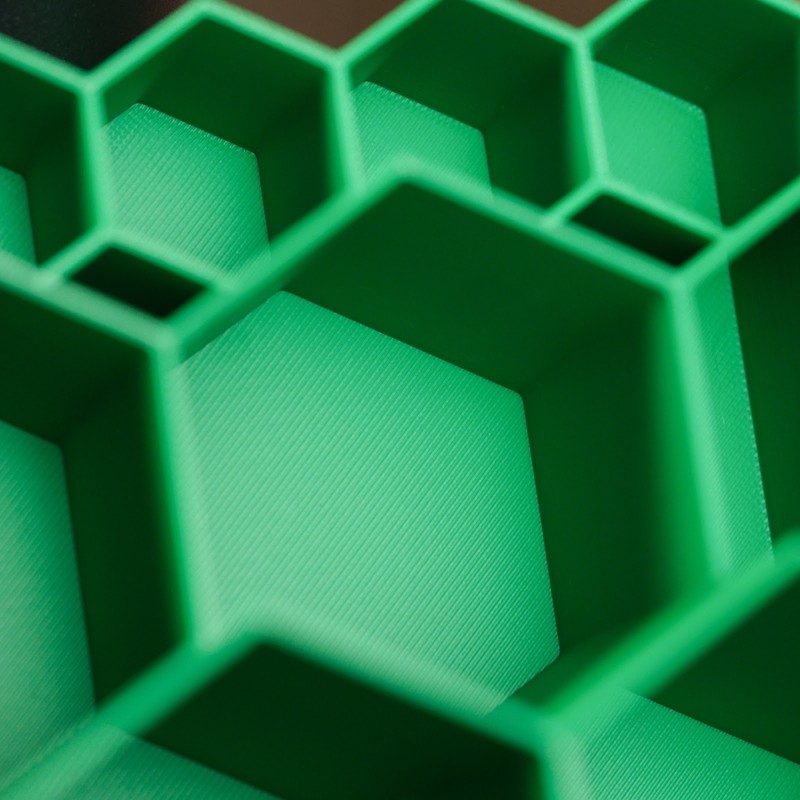

Both the H2D and X1C are capable of extremely impressive print quality with little to no manual calibration needed. This is an area where Bambu Lab 3D printers have excelled since the X1C was released, and we’re seeing no different with the new H2D. Thanks to the build quality, sensors, and firmware features on both printers, you’ll see class-leading print quality from both of these machines. These machines are extremely consistent, and you’ll see very few of the issues that plagued older 3D printers, such as inconsistent extrusion or layer shifting.

Both printers are also very fast, with up to 600 mm/s print speed and 20,000 mm/s acceleration. In practice, you won’t see these speeds for the entire print, but either machine will produce printed parts much faster than older 3D printers.

There’s not much else to say here other than that we don’t think you can get better print quality in an FDM 3D printer than what you’ll see from either of these machines, and their print speed is similarly impressive. This isn’t to say either printer produces flawless prints in all cases, but you’re likely to get a great result on most 3D printable models with little to no manual adjustments needed.

We haven’t noticed any particular improvements in the H2D’s print quality compared to the X1C and other Bambu 3D printers, but we’ll continue to update here as our testing continues.

Supported 3D Printing Materials

The H2D and X1C support the same set of 3D printing materials, which includes common materials such as PLA and PETG, temperature-sensitive materials such as ABS and ASA, and higher-end materials such as PA, PC, and carbon fiber-infused filament. You can also print flexible materials such as TPU, although you won’t be able to use the AMS multi-material system with flexible filament. Both printers ship with a hardened steel nozzle, which will lengthen life when printing abrasive materials as compared to a printer with a standard steel nozzle.

The H2D does have a few advantages with regards to material choice. For one, its heated enclosure will likely result in improved print quality for materials that are particularly sensitive to ambient printing temperature, such as ABS. And two, since the H2D includes two nozzles that can independently feed filament, it’s more capable than the X1C when it comes to mixing filament types that have different melting points and material characteristics. We’ll discuss this more later in the article.

Automatic Calibration

The Bambu H2D and X1C both feature a full suite of sensors to enable automated calibration, removing one of the most annoying aspects of using older 3D printers. Both printers use a strain gauge-based bed leveling system which uses the nozzle to probe the bed to ensure a consistent first layer. We’ve found this system to be reliable on all of the Bambu Lab 3D printers we’ve used.

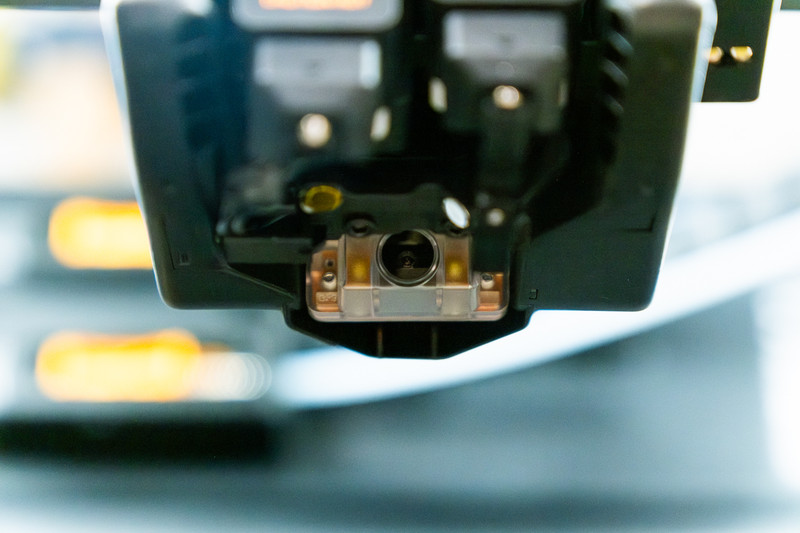

Both printers also include a sensor for detecting the flow rate and consistency of the first layer, although they do so differently. The H2D includes a camera mounted on the print head which watches the extrusion and adjusts parameters as needed to ensure consistent flow and a smooth first layer. On the other hand, the X1C uses a Lidar sensor for the same purpose. It’s hard for us to say which of these approaches is better; from what we’ve seen, both printers do a good job of calibrating the flow rate and we haven’t noticed any major shortcomings to either system.

The only downside to the automated calibration features is that both printers execute a rather long calibration procedure at the beginning of each print. This is probably one of the keys to the excellent print quality we see from these machines, but it does mean every print takes about 5 minutes longer. You can disable some of the pre-print calibration steps, but on a long enough print job, it’s not too big of a deal.

Controls and Display

Both 3D printers include a color touchscreen controller, allowing you to monitor or control the printer directly without needing to use the app. This is a feature we appreciate, and one that not every Bambu 3D printer has–the P1P and P1S have a small, text and icon-only LCD screen which isn’t nearly as usable. The displays on the H2D and X1C are large, easy to read, and easy to interact with. On both printers, the screen is mounted on a tilt bracket.

The user interface on the two printers is extremely similar and allows you to perform common operations such as starting a print, configuring filament settings for the external spools or AMS, starting the calibration routine, and monitoring or stopping an ongoing print. We found all of the settings to be easy to access and understand, and the interface responds quickly.

Bambu Software Ecosystem

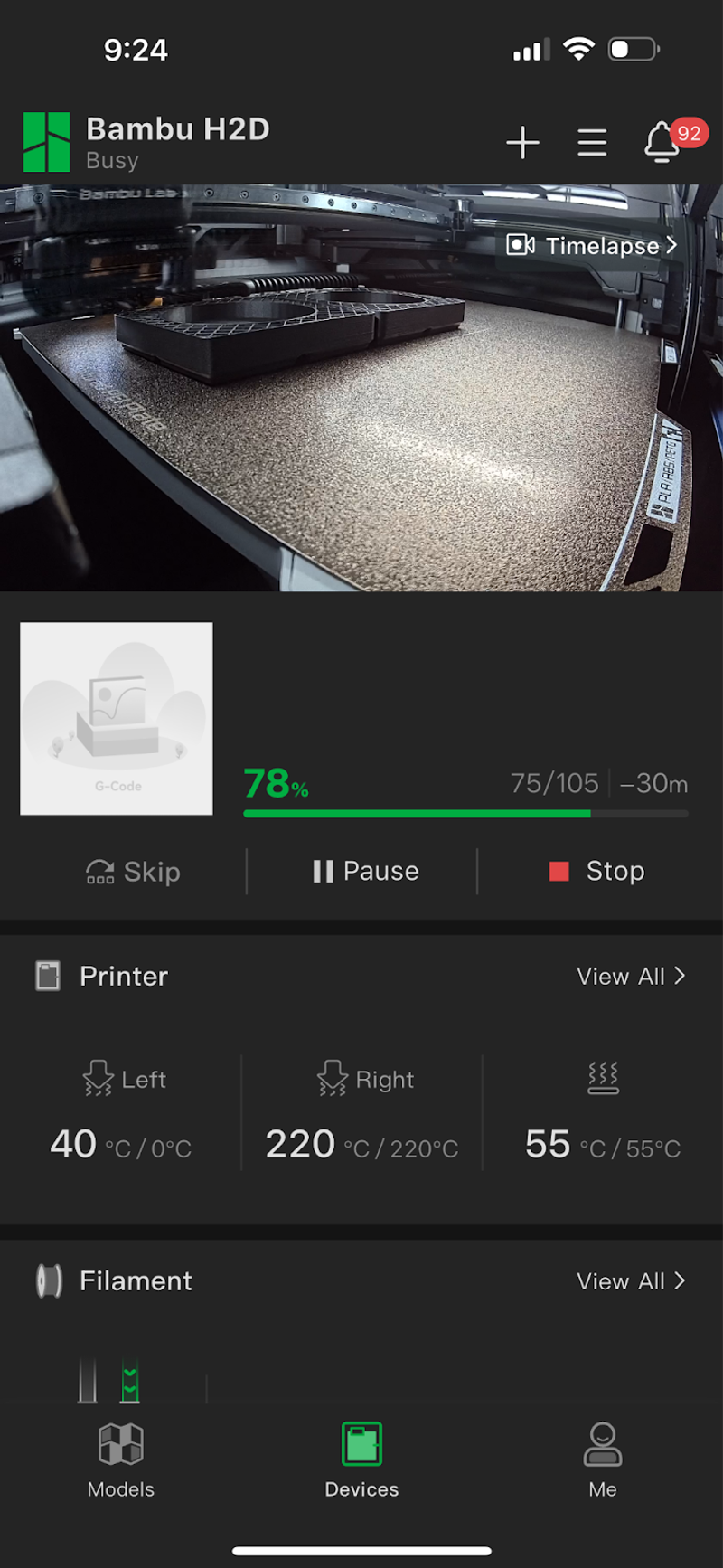

The H2D and X1C both work with Bambu Lab’s full software ecosystem, including the Bambu Handy smartphone app and Bambu Studio slicer software. From either of these tools, as well as from a web browser, you can also access MakerWorld, Bambu’s online model repository which includes many models with preconfigured print profiles for the H2D and X1C.

One of the ways Bambu Lab has approached 3D printing differently from other companies is by focusing on ease of use in the software, and we’ve definitely seen the advantage of this when using their printers. It’s easy to open the app on your phone, browse for a model to print, and begin printing it in only a few moments. From the computer, you can use the Bambu Studio application to prepare and print your own 3D models, or adjust all of the slicer settings if you want. With either the app or computer application, you can wirelessly transfer files for printing and monitor an ongoing print, including viewing the build chamber camera. It’s all a very easy-to-use system and something that we’ve found to be very enjoyable with both machines.

Bambu Lab has recently come under fire for taking steps to limit the access that third-party applications have to control their printers wirelessly. Their stated reason is security, but users have complained that after the latest X1C firmware update, they can no longer use open-source applications such as OrcaSlicer to wirelessly send prints to the printer, and can’t use third-party software such as Home Assistant to monitor the printer status.

Bambu Lab has never been quite as “open” as other manufacturers in the 3D printing market, and this has felt like a further step away from embracing the open source roots of 3D printing. Notably, the H2D does allow you to enable a “developer mode” which opens up access for third-party software and accessories, so hopefully this will continue to be offered as a router for users who want these features.

Personally, this doesn’t worry us too much. Would it be better if Bambu Lab offered a fully open system, with full access for third parties to plug in new functionality and do everything their official apps can do? Almost certainly. But in our experience using the printers, the official apps offer everything that most users would need, and this seems to be the tradeoff Bambu Lab is asking you to make in exchange for the ease-of-use you get with their printers. For us, it’s a tradeoff we’re willing to make, but you’ll have to determine whether this is a concern for you.

Camera

The Bambu H2D and X1C both include a build chamber camera which allows you to monitor ongoing prints from the Bambu Handy app or Bambu Studio computer program. Unlike some of Bambu’s other models, the camera in both of these printers offers a smooth framerate and relatively high resolution, which makes for a good experience when watching prints remotely.

The H2D includes an additional nozzle camera which it uses for some of its print quality detection features, but you can’t monitor this camera in the app.

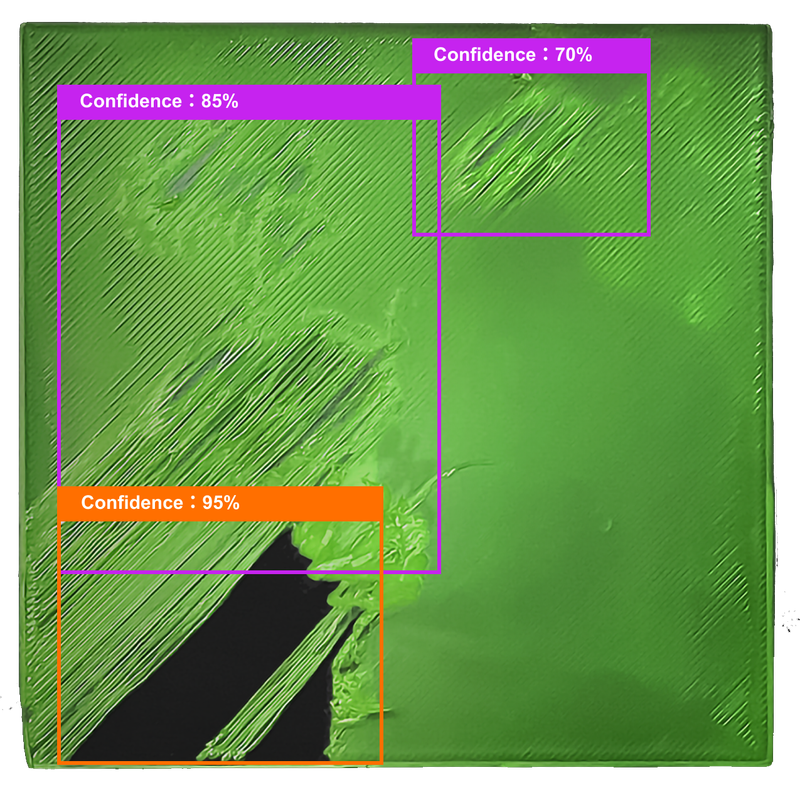

Both 3D printers offer some AI-powered features for detecting print failures such as “spaghetti”, nozzle clumping, or a jammed extruder. We’ve had mixed results with these features. In some cases it can catch a print problem before it becomes a mess (or at worst, breaks something in the machine), but we’ve also had a few false alarms where the printer reported a problem that didn’t exist. Overall, we’re glad to have the features–when there is a false alarm, you can simply open the app, observe whether there is a real failure, and stop or resume the print as appropriate.

Differences Between the Bambu Lab H2D and X1C

Next, we’ll look at the differences between these two 3D printers.

Build Volume

The H2D and X1C differ in build volume, with the H2D offering a notably larger print area:

- Bambu Lab H2D: 300 x 320 x 325 mm (11.8” x 12.6” x 12.8”) for dual nozzle prints, or 325 x 320 x 325 mm (12.8” x 12.6” x 12.8”) for single nozzle prints

- Bambu Lab X1C: 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”)

The H2D can definitely print larger objects in all dimensions, but the maximum build volume is complicated by the dual nozzles. For a dual-nozzle print, the printer can’t use the extreme left or right sides of the print bed because one or the other nozzle won’t be able to reach, so the X dimension is slightly reduced for dual-nozzle prints. If you’re only using a single nozzle, you can stretch the X dimension a bit farther since the other nozzle won’t need to print on that part of the bed. And if you’re willing to load two spools of filament and use both nozzles for the same color, you can stretch the total X size up to 350 mm (13.8”)! It’s a bit confusing.

Physical Size

The tradeoff for the H2D’s larger build volume is that it’s also a physically larger printer:

- Bambu Lab H2D: 492 x 514 x 626 mm (19.4” x 20.3” x 24.7”)

- Bambu Lab X1C: 389 x 389 x 457 mm (15.3” x 15.3” x 18.0”)

The printers also differ in weight, with the H2D weighing 31 kg (68 lbs) and the X1C weighing 14 kg (31 lbs), so the H2D is more than twice as heavy as the X1C. As a point of reference for both the size and weight, most people should be able to easily pick up and move the X1C themselves, but the H2D will probably require two people to pick up and reposition safely.

This is not a small difference and you’ll definitely notice the extra bulk of the H2D. The printer will dominate most standard workbenches and desks, and its weight means you’ll need to make sure you’re using something sturdy to support the printer. Keep in mind that many users also like to mount the AMS unit on top of the printer, so if you plan to use the AMS you’ll need additional vertical clearance. The H2D is not a small machine.

Multi-Color and Multi-Material 3D Printing

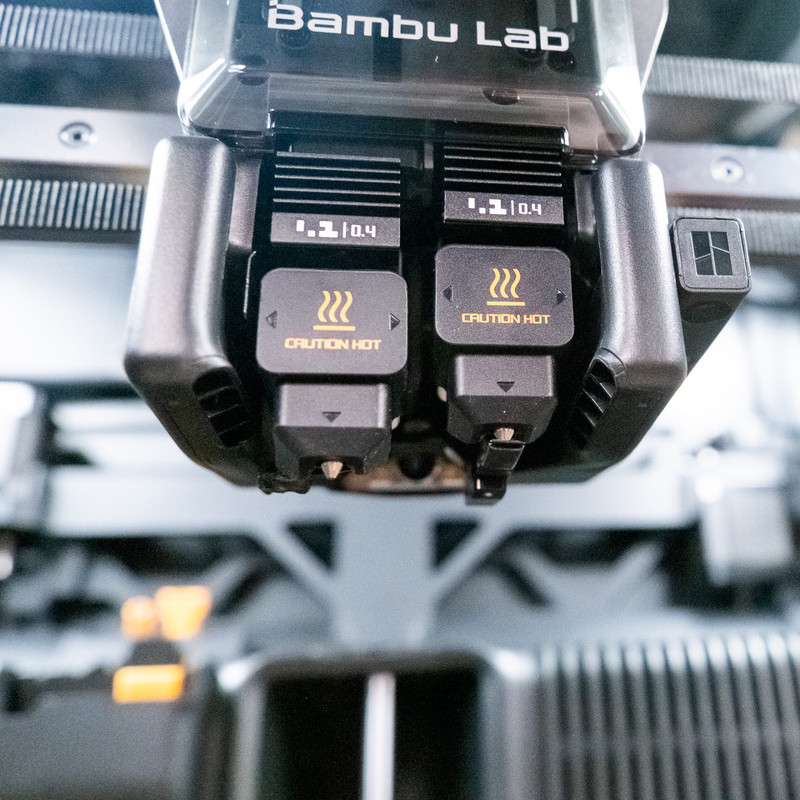

The biggest headline feature of the Bambu H2D is its dual hotends, which has a significant effect on the H2D’s capabilities for multi-material printing.

Unlike the Bambu X1C, which has a single hotend and nozzle, the H2D has two hotends and nozzles located within a single print head. This means that the hotends move as one unit, and only one will be active at a time. The H2D has a mechanism which physically lifts one hotend and lowers the other, keeping the inactive hotend out of the way. A small paddle actually covers the nozzle of the inactive hotend, preventing any plastic from oozing out of the nozzle and potentially fouling the printed model.

If that sounds complicated, it is, and that does present one downside of this system. Not only do you have to maintain and replace two hotends instead of one, but the overall print head is a complex mechanism that may prove to be difficult and expensive to repair. We haven’t needed to repair ours yet (and probably most users haven’t; the H2D is still a new printer), so we’ll update here once we have more hands-on experience with this part, but it’s something to keep in mind.

By comparison, the X1C’s print head is a very straightforward design that doesn’t really have any moving parts and will be simpler to repair. The H2D does use a newer quick-swap hotend design which will make it easier to change hotends, but the overall mechanism is far more complex.

However, there are some major advantages to the dual hotend configuration in the H2D. Each hotend feeds separately from the outside of the printer, from either an external spool or an AMS unit. This allows you to print with material combinations that you can’t do on an X1C. For example, you can load TPU into one hotend and a standard plastic such as PLA or PETG into the other, a combination that isn’t possible on the X1C because the AMS can’t feed standard TPU filament.

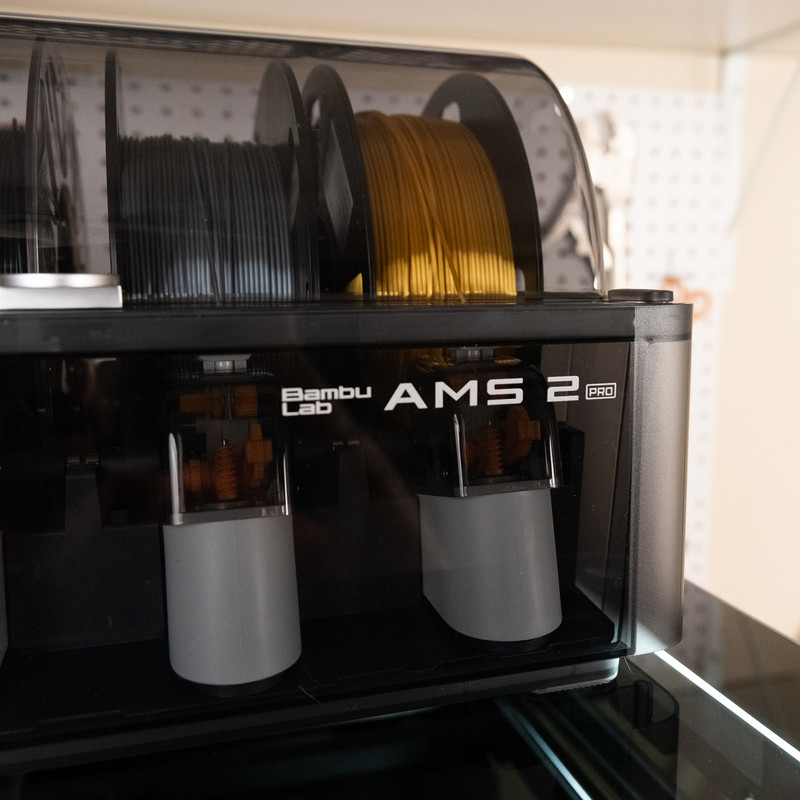

It also means that if you have one AMS, you can actually print in five colors/materials on the H2D (four in the AMS and one on the external spool holder), compared to four colors on the X1C (all in the AMS). Both the H2D and X1C support up to four AMS or AMS 2 Pro units, for a total of 16-color printing. For more colors, you can incorporate the Bambu AMS HT single-spool filament dryer, adding up to 8 AMT HTs to the H2D for a total of 24 colors, or 4 AMS HTs to the X1C for a total of 20 colors.

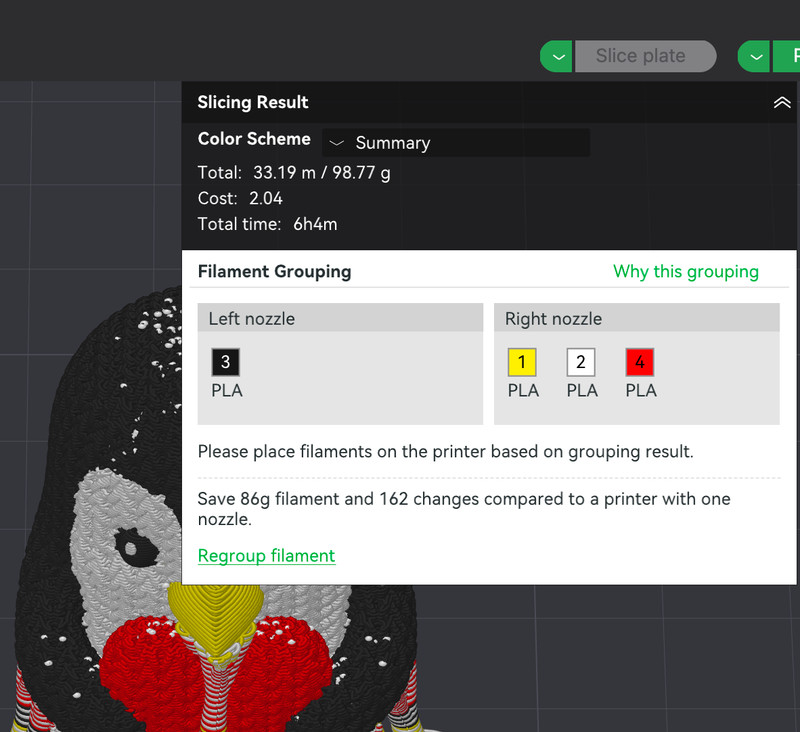

The H2D’s dual hotend configuration can also significantly reduce printing time and waste filament for multicolor or multi-material 3D prints. Because the printer doesn’t need to purge the old filament color when switching hotends, two-color prints will generate almost no waste, and prints with more colors will often generate less waste than they would on a single-nozzle X1C. Purging all of that filament takes time, so you’ll see significant time savings in these cases as well.

When you configure the settings for the H2D, you specify whether each hotend is connected to one or more AMS units or is using its external spool holder. Then, when you want to print a multicolor or multi-material model, the software will analyze the print and suggest the best spool configuration to use between the two hotends.

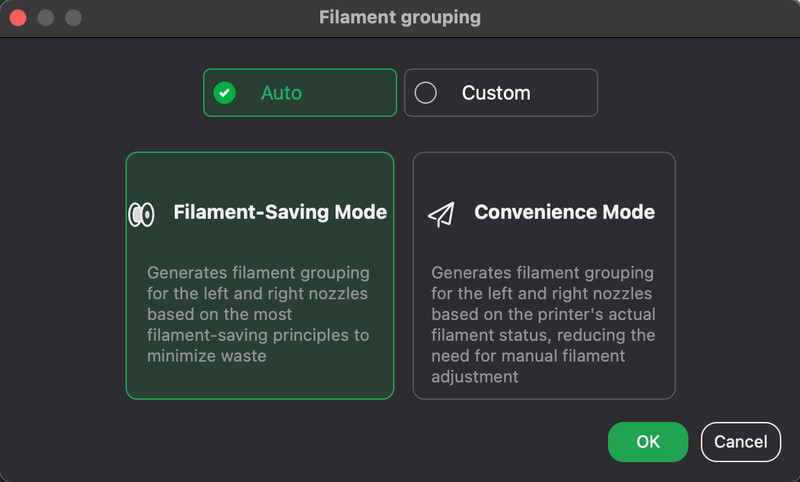

You can pick between “filament saving” and “convenience” modes, depending on whether you would prefer to use the two hotends in the most efficient way, or instead save yourself the effort of possibly rearranging how the filament spools are distributed between the hotends. We really appreciate having both of these options, and can imagine cases where we’d use each. The software makes it clear where each spool is being loaded from, but we still feel like we have to think a little more about the filament configuration of the H2D before printing, just because it’s not quite as easy to tell at a glance whether everything is set up properly. This is probably something that will become more intuitive over time.

Bambu Lab has offered multicolor and multi-material support on all of their 3D printers, and the outcome is excellent on both machines. The X1C offers the ability to easily produce multicolor prints, albeit with quite a bit of waste depending on the model. The H2D takes the multicolor and multi-material capabilities to the next level with its dual hotend design, and can often produce multicolor prints more quickly and with less waste. It also allows for some multi-material prints that aren’t possible on the X1C. But in exchange, its design is more complicated and expensive. It’s obvious that some of the added cost of the H2D is accounted for in the dual hotend mechanism and the associated engineering that went into its design.

Enclosure and Build Chamber

Although both the Bambu H2D and X1C include a fully enclosed build chamber, there are some notable differences between them. The most notable difference is that the H2D’s chamber is actively heated and includes more ventilation capabilities.

The Bambu X1C’s build chamber heats up passively as a result of the waste heat from the heated print bed and hotend, which is sufficient for printing most materials that require a higher ambient printing temperature such as ABS and ASA. The X1C also includes an exhaust fan to ventilate the chamber if the ambient temperature gets too high. However, the temperature isn’t controlled precisely and it’s also possible for the chamber to get too hot for materials such as PLA. When this happens, you can experience print issues such as drooping overhangs. To combat this, many users of the X1C end up propping open the enclosure door or top glass panel during PLA prints.

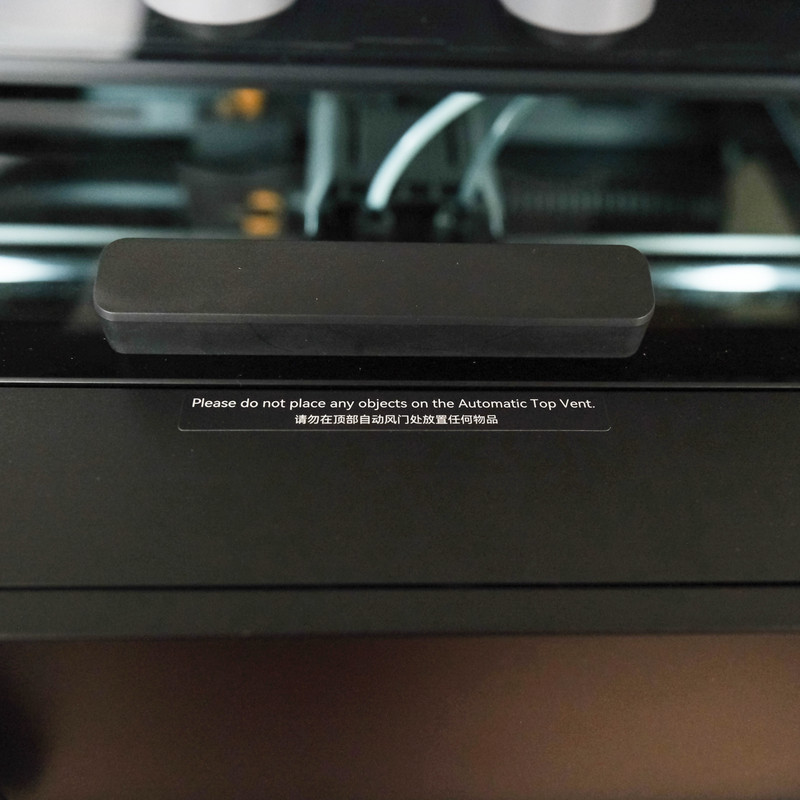

In contrast, the H2D includes more direct solutions to both of these issues. It can actively heat the build chamber up to 65 degrees C for precise control of the ambient printing temperature. This may improve the consistency of prints with materials such as ABS and ASA. And for other materials such as PLA which need a lower ambient temperature, the H2D’s enclosure includes motorized vents that automatically open when needed, further ventilating the chamber and helping to efficiently remove heat. This system, while more complex than the X1C’s simple chamber, allows the H2D to control the printing environment appropriately for any material.

Should You Buy the Bambu Lab H2D or the Bambu Lab X1C?

Both the Bambu H2D and X1C offer impressive print quality, fast print speeds, and are extremely easy to use no matter how much experience you have with 3D printing. We’ve continually been impressed by the results we get from Bambu Lab’s 3D printers, and their multicolor capabilities add a fun element to 3D printing that other manufacturers are only just now starting to match. Bambu’s machines are some of our top-recommended 3D printers, and until the release of the H2D, the Bambu X1C has been an easy recommendation for users in search of the absolute top-of-the-line Bambu 3D printer.

After doing our testing and evaluating the differences between the printers, our feeling is that it’s best to look at the Bambu H2D as another option in Bambu Lab’s lineup alongside the X1C, rather than a direct replacement to it. If you’re looking for better multi-material printing support, less purge waste, and a larger print volume, the H2D is undeniably more capable than the X1C. Bambu has definitely pushed their overall printer design forward with this machine, and it’s superior to the X1C in a lot of small ways–the hotends are easier to swap, the build chamber lighting is better, and the machine is quieter during printing, to name a few of the little improvements we didn’t cover in detail.

But all of those improvements certainly come at a high price. Not only is the H2D significantly more expensive than the X1C, but it also weighs more and takes up more desk space, making its placement in your workspace more of a consideration. And the dual hotend design, for all of its added capabilities, also increases the complexity of the machine and introduces more possible points of failure. These downsides are worth keeping in mind, and you’ll need to evaluate your 3D printing needs against the H2D’s benefits to determine whether these drawbacks are an acceptable compromise.

Overall, we think both of these 3D printers are excellent and we’re looking forward to doing additional testing on the Bambu H2D. We’ll update this article as we learn more. Whether you’re willing to spend big to get the new highest-end Bambu printer with the H2D, or prefer to stick with the more compact and proven X1C, we think either 3D printer is a great choice.

Click here to view the Bambu Lab H2D.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: