If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab X1-Carbon vs the Prusa MK4

In this article, we’ll compare the Bambu Lab X1 Carbon and Prusa MK4 to see which of these premium 3D printers is the better choice for you. We’ll look at the similarities and differences between the machines, and give our recommendation for how to choose between these two 3D printers.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

Vs.

Prusa MK4

(~10 x 8.25 x 8.75 in)

Bambu Lab is a newer 3D printer manufacturer that surprised the market in 2022 with the Bambu X1 Carbon (also known as the X1C), which demonstrated impressive capabilities and performance that surpassed most other consumer FDM 3D printers. Although they’ve released other models since, the X1C continues to be their highest-end 3D printer and is a popular choice for users who are willing to pay the price for a premium machine.

Prusa was one of the first companies to make consumer 3D printers and started in 2012. Most of their machines have used the same basic design, which has since been copied by many other manufacturers. Despite the competition, Prusa has continued to be seen as a more premium printer manufacturer and continues to be successful. Their latest model, the Prusa MK4, is a further refinement of this design and adds some modern features that were conspicuously missing from their older machines.

Both companies have a reputation for making premium 3D printers, but whose flagship model is better? We’ll start by taking a look at the similarities between them.

Similarities Between the Bambu Lab X1 Carbon and Prusa MK4

The two printers share many similarities. We’ll describe each one in this section.

Extruder and Hotend

The Bambu X1C and Prusa MK4 both include a direct drive extruder and an all-metal hotend, which makes them capable of printing all standard 3D printing filament types.

Direct drive extruders are becoming more common, and we prefer this type of extruder over Bowden extruders. They’re more reliable and less prone to jamming, as well as making it easier to print flexible filament such as TPU. The two machines use different extruders, but both designs are known to be reliable, and both are direct drive.

The all-metal hotend on both printers enables printing high-temperature materials. They have similar specifications, with the Bambu X1C advertising a maximum temperature of 300°C and the Prusa MK4 advertising 290°C. This is enough to print all standard materials, although if you want to print ABS or ASA, the Prusa’s lack of an enclosure may be an issue–we’ll discuss that more in the Differences section below.

Print Speed

Both printers advertise high maximum print speeds–500mm/s for the Bambu X1C and 600 mm/s for the Prusa MK4. These are some of the fastest consumer 3D printers on the market, and if you’ve used an older 3D printer, either of these machines will be significantly faster.

Although the 500mm/s and 600mm/s specs would make you think the Prusa MK4 is notably faster than the Bambu X1C, in actual use the printers are likely to take approximately the same amount of time to print the same object. As a model is printed, the machine has to slow down for certain parts of the print, and it’s not common for any 3D printer to stay at its maximum speed for very long.

It’s worth noting that the Prusa MK4 was not originally capable of hitting these speeds, and only recently gained that capability through a major firmware update. It’s possible this was in response to the threat of other companies like Bambu who have been releasing printers with higher print speeds that exceeded the MK4’s original specs. In our opinion, the hardware design of the Bambu X1C is more able to support high print speeds, with a robust CoreXY motion system and a welded steel frame. The Prusa’s more traditional “bed slinger” design is less common for high speed printers, but we haven’t heard of any problems resulting from Prusa pushing the MK4 to these faster speeds.

Print Quality

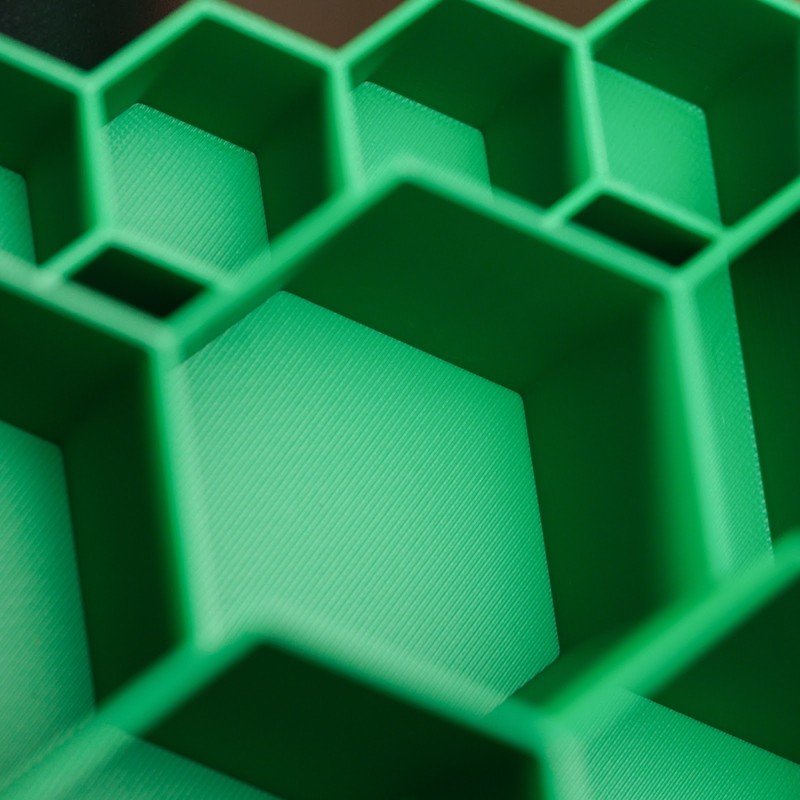

Both the X1C and MK4 use a combination of hardware design and firmware features to produce excellent print quality.

Although the printers use different motion systems, both designs use quality components such as linear rods and bearings to reduce vibrations during high-speed printing. In firmware, the X1C and MK4 use newer algorithms to control the extrusion, with features such as pressure advance and input shaping that allow the printer to more precisely print objects and reduce artifacts and other imperfections.

In general, we don’t think print quality is a great way to compare 3D printers; almost all modern FDM 3D printers are capable of printing in very high quality. However, what sets the Bambu X1C and Prusa MK4 apart from most other 3D printers is that they can maintain this high print quality at much faster speeds. With most other printers, you would either need to print more slowly or accept lower print quality.

Display and Controls

The Bambu Lab X1C and Prusa MK4 both include a full-color graphical display, which is a welcome feature on any 3D printer to make it easier to monitor the status of the printer and navigate the menus. There are some slight differences between them, the biggest being that the X1C’s display is a touchscreen while the MK4 uses a separate knob controller to navigate the display. The X1C’s display is also slightly larger, at 5” versus 3.5” on the MK4.

Between the two control schemes, we prefer the touchscreen on the Bambu X1C, but the knob controller on the Prusa is a familiar design that we’ve never had trouble using. We’re just happy to see a graphical color display on the MK4–previous Prusa machines used a monochromatic text display that has been outclassed by most other 3D printers. Even though many printers support wireless control with an app and some printers don’t include a display at all, we’re happy to see a large graphical display on both machines.

Connectivity and Wireless Printing

Both printers include WiFi connectivity and allow you to remotely control and monitor the printer from a computer or smartphone.

On the Bambu X1C, you can use the Bambu Studio application on a computer to slice 3D models and upload the gcode to the printer. You can also use the Bambu Handy smartphone app to monitor prints and control the printer, in addition to selecting and printing models from Bambu’s online library. Both apps also let you view the camera in the X1C’s build chamber to visually monitor your prints.

On the Prusa MK4, you can use the Prusa Connect cloud app on either a phone or computer to control and monitor the printer. This web-based application also works with the PrusaSlicer slicing software, allowing you to slice 3D models and directly upload the gcode to your printer. The Prusa MK4 supports Ethernet in addition to WiFi, allowing you to hardwire the printer to your network if desired. The X1C only has WiFi.

On either printer, you can load gcode files directly onto the machine for printing if you don’t want to use the wireless connectivity. The Bambu X1C supports a microSD card, similar to many older 3D printers, while the Prusa MK4 has a USB-A port for USB flash drives.\

Multi-Material Support

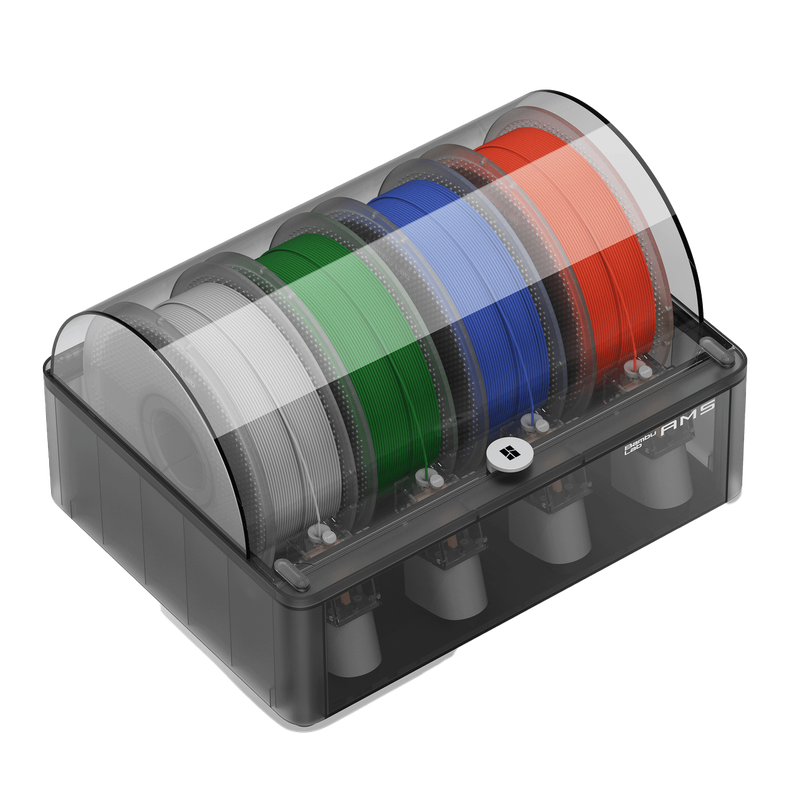

The Bambu X1C and Prusa MK4 both support multi-material 3D printing as an add-on component, although Prusa’s multi-material add-on is not yet shipping as of this writing.

The Bambu X1C supports Bambu Lab’s Automatic Material System (AMS), which is an add-on that allows you to feed up to four different types or colors of filament during a print. This enables you to print in multiple colors, as well as switch over to a new spool when one runs out of plastic, or print with soluble support material to make post-processing easier. However, to use the AMS you’ll need to use the Bambu Studio slicer software, as it’s not supported with third-party slicer applications.

Bambu Lab sells the AMS separately on their site, or you can buy a combo kit that includes the X1 Carbon and the AMS.

The Prusa MK4 supports the Multi-Material Unit 3, or MMU3, which supports up to five different types or colors of filament. It functions similarly to the Bambu AMS, but one difference is that while the AMS is self-contained and can sit on top of the printer, the Prusa MMU3 separates the filament spool holders from the filament feeder, requiring you to mount the spools separately or store them on the desk next to the printer. Similar to the Bambu AMS, you’ll need to use Prusa’s own PrusaSlicer software to slice models when using the MMU3.

Prusa sells the MMU3 separately on their site, although it’s not yet shipping as of this writing.

Although these systems are implemented slightly differently, they provide similar functionality at a similar price. Between the two, we prefer the design of the Bambu AMS since it can fit neatly on top of the printer. But since most other 3D printers don’t offer this capability at all, it’s a point in favor of both machines that you can add multi-material support.

Automatic Bed Leveling

Both the Bambu X1C and Prusa MK4 include automatic bed leveling. This feature has become common on 3D printers at all price points (finally!) so it’s unsurprising to see on these premium machines. The printers both use a strain gauge sensor for the automatic leveling, where the printer moves the nozzle toward the bed and detects the moment it touches the bed. We’ve found this to be the fastest and most reliable automatic bed leveling system, so you’ll see great results here from either machine.

The Bambu X1C additionally uses its Lidar sensor to verify the bed leveling. We’ll discuss that later in the Differences section, since it’s unique to the X1C.

Differences Between the Bambu Lab X1 Carbon and Prusa MK4

While they share some similarities, the Bambu Lab X1C and Prusa MK4 are different in several important ways. We’ll discuss each difference in this section and explain how they may affect your experience with each printer.

Build Volume

The printers differ in build volume, which is the maximum model size you can print on the machine:

- Bambu Lab X1C: 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”)

- Prusa MK4: 250 x 210 x 220 mm (9.8” x 8.3” x 8.6”)

The X1C can print objects that are slightly larger in all dimensions than the MK4. If you’re interested in printing functional parts or large models, you may appreciate the larger build volume on the X1C.

Physical Size

Surprisingly, given its smaller build volume, the Prusa MK4 is a bit larger in length and width than the X1C:

- Bambu Lab X1C: 389 x 389 x 457 mm (15.3” x 15.3” x 18.0”)

- Prusa MK4: 500 x 550 x 400 mm (19.7” x 21.7” x 15.7”)

If you have limited desk space, the X1C will fit into a smaller space than the MK4. However, it is a bit taller than the MK4, which may be a consideration if you’re limited on vertical space.

As we mentioned in the multi-material printing section above, the printers’ multi-material add-ons also differ in physical size requirements. The Bambu AMS can either sit on top of the X1C or next to it, while the Prusa MMU3 requires the filament spools to be located next to the printer, or mounted with a custom solution. Therefore, the MMU3 is likely to require even more desk space.

Repairs and Upgrades

One of the most significant differences between the Bambu X1C and Prusa MK4 is their repair and upgrade potential. In short, Bambu Lab requires you to use their parts and isn’t very open to hardware upgrades, while Prusa is compatible with many third-party parts and has more upgrade potential.

Bambu Lab’s approach to 3D printers is to provide a machine that is fully assembled and calibrated, and that handles almost all of the complexity of 3D printing for you. However, the trade-off is that their firmware is closed-source and only works with the specific hardware configuration that they’ve defined for each of their printers. This means you can’t meaningfully change the hardware or electronics on the X1C, and you’ll need to use Bambu Lab’s own parts for most repairs. Bambu Lab does sell a full range of repair parts on their site, so the machine is still user-serviceable.

On the other hand, Prusa fully embraces the open-source roots of 3D printing and the MK4 is much more accessible for upgrades than the Bambu X1C. The firmware for the MK4 is open-source, which means you can update the printer firmware to support any hardware or electronics upgrades you choose to add. The MK4 is also compatible with many third-party repair parts, giving you more options for buying any parts you may need.

Whether this difference matters to you comes down to whether you want to deeply understand the hardware of your 3D printer and upgrade your machine. If you enjoy working on electronics and mechanical systems, and like the idea of continually improving your printer, the Prusa MK4 offers much more potential and flexibility than the Bambu X1C. But if you don’t have the desire to modify the printer hardware, and want to focus only on 3D printing models, you can still easily maintain and repair the Bambu X1C using Bambu Lab’s selection of repair parts.

Print Bed Surface

The Prusa MK4 comes with a smooth PEI print bed, which is one of our favorite bed surfaces. We have a slight preference for textured PEI, but smooth PEI offers nearly the same first-layer adhesion and leaves a smooth, glasslike finish on the bottom of the print. You don’t have to use any coatings on this surface, and it can be easily cleaned as needed.

The Bambu X1C comes with two bed surfaces, a “cool plate” and an “engineering plate”. The cool plate is designed for printing PLA, TPU, and PVA filament at a low bed temperature of 35-45℃, while the engineering plate is designed for filament types that require a higher bed temperature. Both of these build plates have a smooth surface that will result in a glasslike surface finish similar to the smooth PEI on the MK4, but both plates require you to coat the plate with a glue stick to aid in part adhesion, which is a bit annoying.

On both machines, the bed surface attaches magnetically to the bed, making it simple to replace. You can purchase a wide range of bed surface options for either machine, including smooth PEI, textured PEI, and more. But from the factory, we prefer the smooth PEI bed on the Prusa MK4 because of its low maintenance and excellent adhesion.

Enclosure

The Bambu X1C has an enclosed build chamber, while the Prusa MK4 does not. The enclosure seals the build chamber during printing, which allows the X1C to maintain a higher ambient temperature and limits the smell associated with 3D printing.

Some materials, such as ABS and ASA, require an enclosure because they need a higher ambient temperature during printing. The enclosure helps the printed parts maintain a consistent temperature, which prevents them from warping or delaminating along layer lines. The X1C includes a temperature sensor inside the build chamber and circulates air as needed to maintain a consistent temperature.

The enclosure also reduces the smell that sometimes occurs during 3D printing. While FDM 3D printing does not typically cause a strong smell, certain materials such as ABS can give off an odor that some users find unpleasant. The X1C incorporates an activated carbon filter on the exhaust fan to filter out these odors, which may make it a desirable choice if you’re sensitive to these smells or share your printing space with someone who is sensitive to it.

Finally, the enclosure provides a degree of protection from curious children or pets. Although the Bambu X1C doesn’t stop printing when the door is open, and the door doesn’t have a lock, the enclosure itself can prevent accidental or intentional interference with an ongoing print.

Although the Prusa MK4 doesn’t include an enclosure, Prusa does sell an enclosure kit to fully enclose the MK4. However, the enclosure makes the printer much larger than the X1C:

- Prusa MK4 with Enclosure: 530 x 640 x 545 mm (20.9” x 25.2” x 21.5”)

- Bambu Lab X1C: 389 x 389 x 457 mm (15.3” x 15.3” x 18”)

The Prusa enclosure is also quite expensive, making an enclosed MK4 notably more expensive than the Bambu Lab X1C.

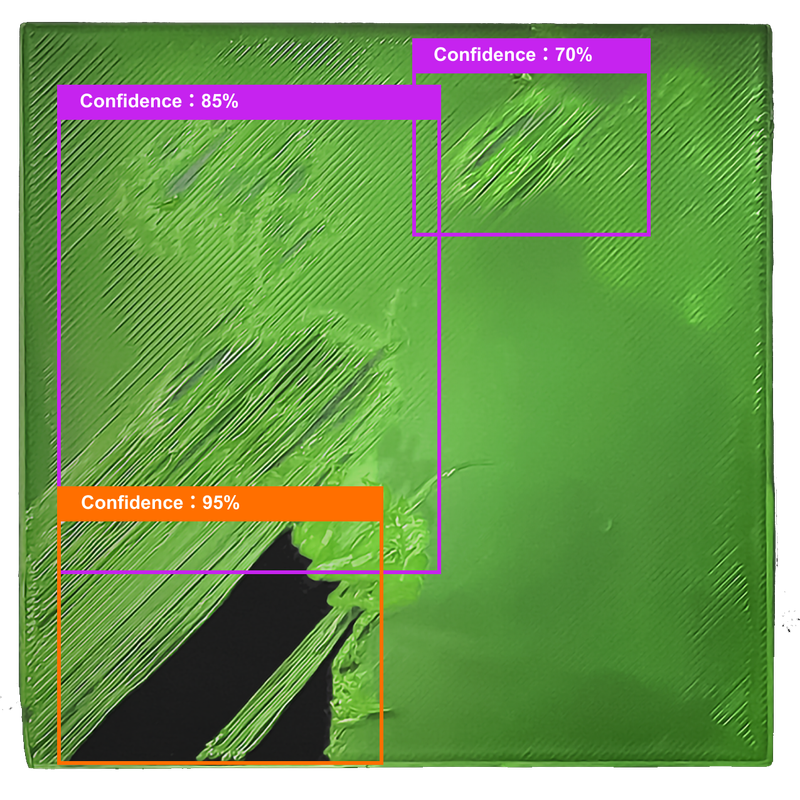

Lidar Sensor

The Bambu Lab X1C includes an optical Lidar sensor, which it uses in a few ways to improve the printer’s automatic calibration and fault detection.

As the first layer prints, the Lidar sensor scans the extruded filament and precisely measures its height and width. The X1C is able to use this information to calculate the flow rate of the filament, which allows it to automatically configure the flow rate. Since this is normally a calibration setting you’d have to set yourself for new brands or types of filament, the sensor makes things easier. It can also detect some issues with the first layer, such as peeling or inconsistent extrusion, potentially stopping a failed print early.

Additionally, the Lidar sensor measures the bed height during bed leveling, acting as a second check for the X1C’s strain-based automatic leveling system. We’ve seen very consistent results from Bambu’s strain-based leveling on the P1S (and we’d expect the X1C to be similar), but this is an added measurement that can help the machine level its bed more precisely.

While these features aren’t necessary, they fit in well with the X1C’s promise of a more automated 3D printing experience. The Prusa MK4 doesn’t have this sensor.

Camera

The Bambu X1C includes a camera in the build chamber, allowing you to watch an ongoing print from the computer or phone app. This is a convenient feature for cases where you don’t want to stay in the same room as the printer, and we like having this built into the machine.

In addition to live monitoring, you can also use the camera to create a timelapse of a print. The camera on the X1C is substantially better than the one Bambu uses on its lower end machines–it’s higher resolution, and updates at 30 frames per second rather than the 0.5 frames per second of Bambu’s other models.

The Prusa MK4 does not include a camera, so if you want to watch prints remotely, you’ll need to purchase a WiFi camera separately.

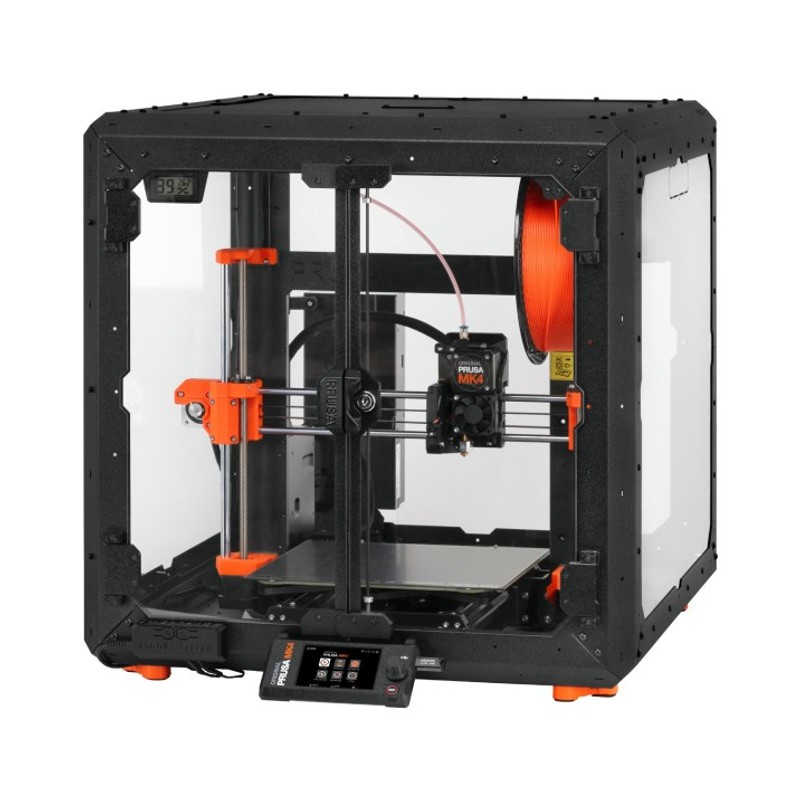

Assembly

The Prusa MK4 is offered as either a kit or a fully assembled printer (both links go to Prusa’s site). While the assembled printer is probably the right choice for many users, the kit is an interesting option–you save some money on the printer and shipping, and get to learn the details of how the printer works. The assembly process is rather involved, and you should set aside several hours for it, although no soldering is required. The biggest advantage to assembling the printer yourself is that you’ll have a better understanding of the printer’s components, which may come in handy if you end up modifying or repairing the machine later.

On the other hand, the assembled version of the Prusa MK4, as well as the Bambu X1C, arrive fully assembled and ready to use. You’ll need to remove some packing material, but both printers provide automated calibration processes to prepare them for printing after that.

Should You Choose the Bambu Lab X1 Carbon or the Prusa MK4?

The Bambu Lab X1 Carbon and Prusa MK4 are both premium 3D printers from well-known brands. They’re some of the best machines you can currently buy–both printers are fast, reliable, and capable of extremely high print quality. But we think you’ll have an easy time deciding between the X1C and MK4 depending on what you’re looking for in a 3D printer.

The Bambu Lab X1 Carbon prioritizes ease of use above all else, and sometimes feels more like an appliance than a tool. This is good and bad–the X1C is very easy to use, but it’s less customizable than the MK4. Bambu Lab has done an excellent job of polishing the rough edges of 3D printing, and we’ve found their machines to be very simple to use with essentially zero manual adjustment or tinkering required. Despite that, their printers offer some of the fastest print speeds and highest print quality you can find. If your goals with 3D printing are to focus on printing models without needing to adjust or upgrade the machine, the Bambu X1C is an excellent choice.

The Prusa MK4 prioritizes openness and modification potential, but maintains print speeds and print quality that match the Bambu X1C. Prusa prides itself on all aspects of the MK4 being open-source, and you have almost limitless possibilities when it comes to repairing or improving the printer. The MK4 is a more polished 3D printer than a home-built variant (or even many budget 3D printer manufacturers), and Prusa’s quality control and customer service is some of the best you can find in 3D printing. However, the experience of using a Prusa 3D printer isn’t as smooth and easy as the Bambu X1C. If you’re interested in the inner workings of 3D printers and want to modify and tinker with your machine, the Prusa MK4 is a much better choice for you than the Bambu X1C.

If you’d like to check out these 3D printers in more detail, you can use the links below to view them on the manufacturers’ websites, or continue down to see a side-by-side spec comparison.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

Click here to view the Prusa MK4 on Prusa3d.com.

You can find a side-by-side comparison of the specifications for these two printers in the table below: