If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Creality K2 Plus and the Bambu X1C

Creality K2 Plus

(~14 x 14 x 14 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

In this article, we’re going to compare the Creality K2 Plus and Bambu Lab X1C to help you determine which of these 3D printers is the better choice for you. Based on our hands-on testing experience, we’ll give you our informed opinion about the features of both machines, and importantly, how easy each one is to use and whether the results live up to the manufacturers’ promise.

Since the release of their Bambu X1C printer in 2022, Bambu Lab has been a dominant player in the world of high-end consumer 3D printers with multicolor 3D printing capability. While other companies offered some multicolor-capable machines, Bambu Lab quickly gained a reputation for the ease of use and performance of their AMS multicolor add-on. In addition, the X1C’s clean, enclosed design and the printer’s overall high level of performance and speed stood out among the competition. In all respects, the Bambu Lab X1C has been a top-tier 3D printer since its release, and one of our most recommended machines.

But now, other brands are starting to catch up and offer machines with similar capabilities. One of the recent competitors to appear on the market is the Creality K2 Plus, which is also available in a combo kit with Creality’s CFS (Creality Filament System), which holds 4 rolls of filament and can switch between them during a print. Sound familiar?

We’ll start by looking at the similarities between the two 3D printers, and then look at the differences. Finally, we’ll give you our conclusions about which printer might be a better fit for your needs.

Similarities Between the Creality K2 Plus and Bambu Lab X1C

The Creality K2 Plus and Bambu Lab X1C have several similarities, including their physical design, automated calibration systems, and overall printing capability. We’ll look at each major similarity in this section and point out the places where the machines implement these features in different ways.

Enclosed Build Chamber

Both the K2 Plus and X1C have an enclosed build chamber, which enables the printers to print materials which are sensitive to air drafts, such as ABS and ASA. The enclosure has other benefits, such as slightly reducing noise, keeping dust out of the machine, and limiting the spread of odors generated by printing certain types of plastic. On both machines, the enclosure door only opens one way and can’t be flipped, but both doors are made of glass and open and close nicely.

One slight difference is that the Creality K2 Plus’s build chamber includes an active heater that can heat the chamber to a maximum of 60 degrees C. On the other hand, the Bambu X1C doesn’t include a build chamber heater, although it will try to maintain a desired temperature by turning on its chamber exhaust fan as needed. The heated chamber isn’t required for many materials, but it can be helpful for materials such as ABS which benefit from being printed in a warmer environment.

The enclosed design also makes the overall machines look clean and sleek, and more like high-end appliances than a hobby project. Both machines are incredibly well-built, with a silver/gray metal frame and glass top. These printers look and feel much higher-end than almost all consumer 3D printers we’ve used.

Supported 3D Printing Materials

The two 3D printers support the same set of materials, and are capable of printing nearly all 3D printing filament types. This includes common materials such as PLA and PETG, as well as higher-end materials including carbon fiber-infused plastics. Due to the enclosed build chamber, both printers can print materials such as ABS and ASA, which require a warm, still environment for printing. And due to their direct-drive extruders, both 3D printers can print flexible materials such as TPU, although you won’t be able to print TPU while using the multicolor add-on for either machine.

The only limitation you might encounter on either machine is with the maximum nozzle temperature, which is around 300 degrees C for both machines. This is more than sufficient for all common materials, but some speciality materials such as nylon can require higher temperatures which these machines do not support.

One thing to note is that while both Creality and Bambu Lab produce their own filament which has convenient RFID tags for the printer to auto-detect the filament type, it’s not necessary to use the brand’s own filament. In fact, some of our favorite filament options are produced by third-party companies and all common brands of filament work properly in both of these 3D printers.

Print Speed and Quality

The Creality K2 Plus and Bambu X1C are both capable of extremely fast print speeds of up to 600 mm/s. Their maximum acceleration differs slightly, with the K2 Plus’s 30,000 mm/s edging out the X1C’s 20,000 mm/s, but this should be a minor difference in practice. For most 3D prints, the machine will spend a fairly low percentage of its time at its top speed or acceleration. However, these machines are both very fast, putting them at the top of the pack for speed in FDM 3D printers.

We’ve seen firsthand that these features do result in improved print quality. Both the K2 Plus and X1C produce some of the best-quality 3D prints we’ve ever seen, and far surpass older printers. In many cases, you’ll be able to get a very high-quality result with little to no adjustment of settings, making these printers fun to use and requiring fewer reprints than what we’ve seen with older machines. Between the two printers, we really don’t see much difference in the print quality—at this level, any differences would be so minor as to not be worth factoring into your decision, given the larger differences between these printers that we’ll discuss later in the article.

Print Bed Surface

Both printers include a magnetic print bed that supports a variety of bed surfaces which are magnetically attached to the bed, making it easy to remove the bed surface to swap it out or just to make prints easier to remove. Both machines include a textured PEI bed surface, which is one of our favorite materials and has excellent print adhesion while also being easy to remove once the bed has cooled. However, if you want to change it to a different material such as smooth PEI, you can easily do so.

Wireless 3D Printing and App Control

The Creality K2 Plus and Bambu Lab X1C both include WiFi capability (as well as Ethernet, on the K2 Plus) and can be controlled via WiFi using the manufacturer’s smartphone app or computer-based slicing software. This is an excellent feature that has transformed the ease-of-use of 3D printers—now you can easily start prints wirelessly, and no longer need to load files on an SD card and walk it over to the printer.

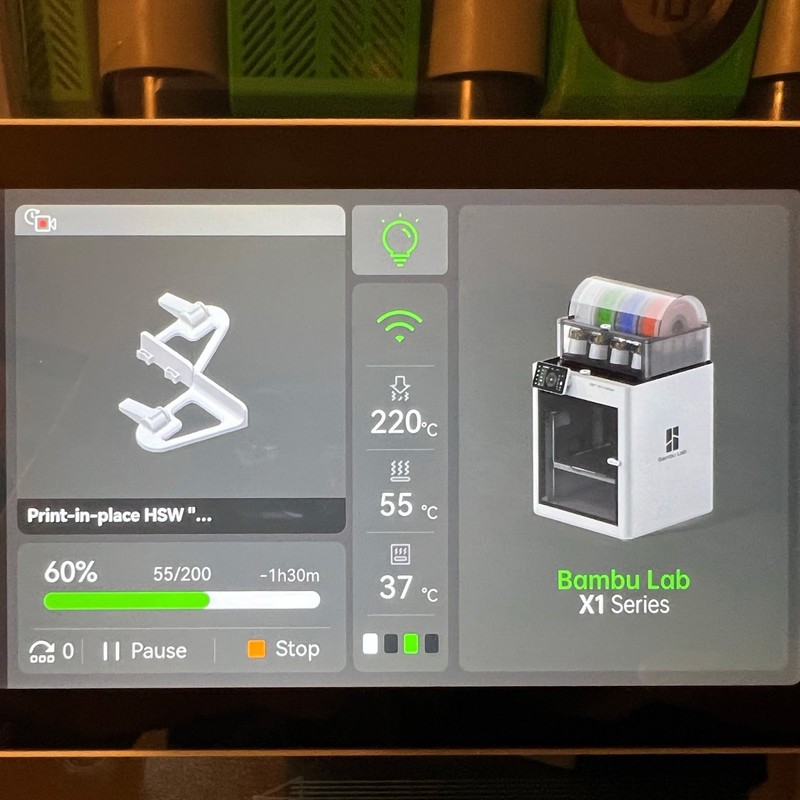

You also have the ability to monitor an ongoing print using the app for either 3D printer. This lets you view the live camera feed from the built-in camera as well as seeing the time remaining and the current status of the printer. You can pause or stop the print remotely if desired. While it’s not recommended to leave a 3D printer completely unattended during a print, we’ve found these features to be extremely useful for monitoring the machine while we’re in another part of the house.

Both manufacturers’ apps are easy to use and fairly well-designed, although we prefer the Bambu app—we’ll discuss the differences in the apps and online communities later in this article. But in terms of functionality, both apps let you do everything you’d need to do to monitor and control the printer remotely.

One downside that is apparent with both the K2 Plus and X1C is that there isn’t a standard in the market for wireless control of 3D printers. What that means is that you have to use each manufacturer’s own app and software to wireless send prints to their printer—you can’t use any third-party applications to control the printers as of this writing. However, if you want to use a third-party or open source slicer, you are able to use that to slice a model, and then either transfer the .gcode printing file to the machine using either a USB drive or by using the manufacturer’s software to send the gcode to the printer.

There have been some attempts to support third-party wireless control, but Bambu Lab in particular has recently restricted some of these efforts in the name of security. This is an ongoing situation and we don’t know yet what the long-term story will be for third-party access to Bambu’s printers. On the Creality side, while there isn’t currently any third-party software that can communicate with the K2 Plus, our expectation would be that Creality will be more open to allowing this. In our opinion, for most users, this isn’t worth worrying about—the manufacturers’ own apps are perfectly sufficient for controlling the machines, and the improvements you get from being able control the printer wirelessly more than offset any platform lock-in you might experience.

Camera

Both printers include a camera mounted inside the build chamber, allowing you to monitor prints remotely and create timelapse videos of your prints. While it’s not recommended to run a 3D printer while you aren’t home, the camera is useful for checking on the printing progress periodically if you aren’t in the same room. This used to be a common 3D printer modification, and it’s great to have it built-in on these machines.

We’ve seen a wide range of quality on built-in cameras, with Bambu’s lower-end printers being some of the worst offenders (on some of their machines, the camera provides more of a slideshow rather than a smooth video) but the cameras on both the Creality K2 Plus and Bambu X1C are reasonably high quality and provide a smooth video feed.

Controls and Display

The K2 Plus and X1C both provide a color touchscreen for directly controlling the printer. The X1C’s is slightly bigger, at 5 inches vs. 4.3 inches on the K2 Plus, but this is a minor difference. Both touchscreens are responsive and easy to use, giving you access to all of the controls you need to control the printer and start prints. During a print, the screen shows you the progress of the print at a glance, and gives you the ability to pause or stop the print if needed.

Automated Calibration

Both printers include a full suite of automated calibration features, including automatic bed leveling, resonance compensation, and belt tension detection. Additionally, each printer includes a sensor which detects the flow rate of the filament and adjusts the extrusion parameters accordingly to optimize the flow rate–the Creality K2 Plus uses a camera for this purpose, while the Bambu X1C uses a Lidar sensor.

We’ve found the automated calibration to work well on both machines. When you first power up either printer, it will go through a calibration process that takes approximately 15-20 minutes. The printer will also do a limited amount of calibration before each print, and if you ever want to repeat the full calibration process (such as if you move the machine to a new location) you can easily initiate the full process using either the controller or the app.

Once calibrated, both printers performed very well, with consistent first layers and overall very consistent extrusion and quality. This calibration process used to involve a lot of manual work on older 3D printers, so we’re happy to see these new automated systems.

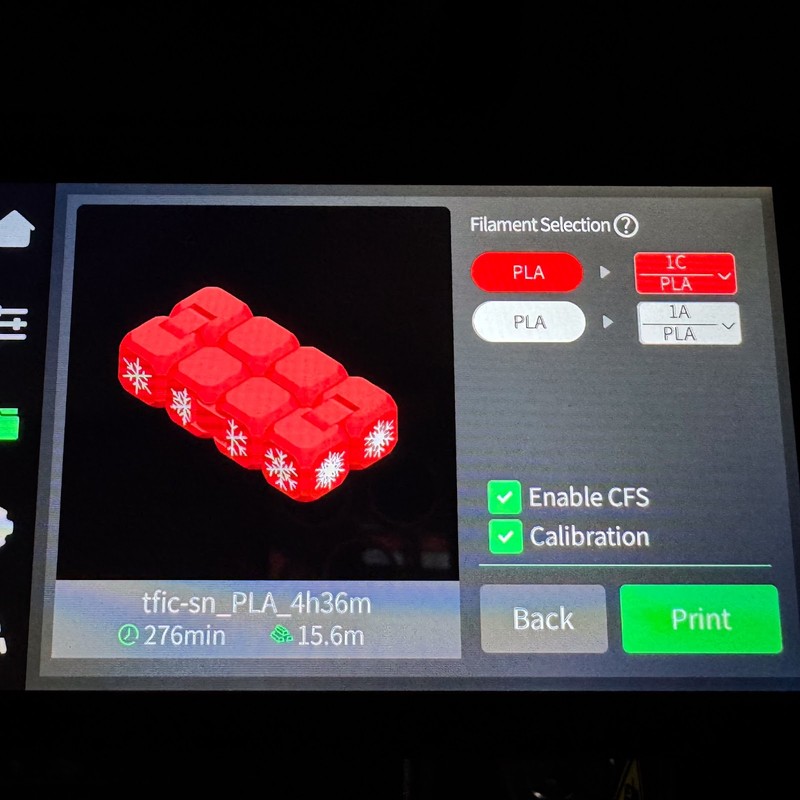

Multicolor 3D Printing

The Creality K2 Plus and Bambu X1C both offer multicolor and multi-material 3D printing using an optional add-on–the Creality CFS for the K2 Plus, and the Bambu AMS for the X1C. Both systems allow you to load up to 4 spools of filament, and both allow you to connect up to 4 units for a maximum of 16 colors/materials for a single print.

Both systems are reliable and work very well for multicolor prints, with the main downsides being printing time and filament waste. When the printer changes from one spool to another, it purges filament through a waste chute to ensure the new spool is flowing cleanly through the nozzle before resuming the print. This process takes time and results in a notable amount of filament waste, which is essentially an added cost of multicolor printing.

The Creality CFS has a few minor improvements over the Bambu AMS. One minor improvement is that it includes a display that shows the humidity level inside the unit, although it doesn’t include an active heater or dehumidifier which would make this display more useful. But more importantly, the CFS is designed to make it easier to clear jams or broken filament. Unlike the Bambu AMS, which requires you to remove a few screws and partially disassemble the unit to access the internal Bowden tubing, the Creality CFS has cutouts on the bottom case which allow you to access these tubes. This should make it much easier to clear jams.

Assembly and Setup

In part due to their enclosed design, both the K2 Plus and X1C ship completely assembled. This results in a large shipping box–particularly for the K2 Plus–but simplifies the setup process as compared to many other 3D printers we’ve used. For either printer, you’ll need to remove packaging material and will need to remove a few screws that secure parts of the motion system during shipping. Fortunately, both machines include a clear set of instructions that guide you through the process of preparing the printer for use.

Once these simple steps are complete, you can simply plug the printer in and power it on. The user interface on the display will guide you through the process of pairing the 3D printer with the smartphone app and starting the automated calibration process. Once that process is complete, which takes approximately 20 minutes, you’ll be ready to load a filament spool and can immediately print one of the models stored in the printer’s internal memory.

This process really couldn’t be much easier, and for new users, it’s a big benefit over older 3D printers which sometimes required extensive assembly and calibration work prior to starting the first print. We didn’t feel that the process was any easier or more difficult for either machine, and felt that both printers provided a good first-use experience in this regard.

Differences Between the Creality K2 Plus and Bambu Lab X1C

Although the Creality K2 Plus and Bambu Lab X1C share many similarities, there are some key differences between the printers such as their build volume and size, software ecosystem, and brand identity. We’ll take a closer look at each difference in this section.

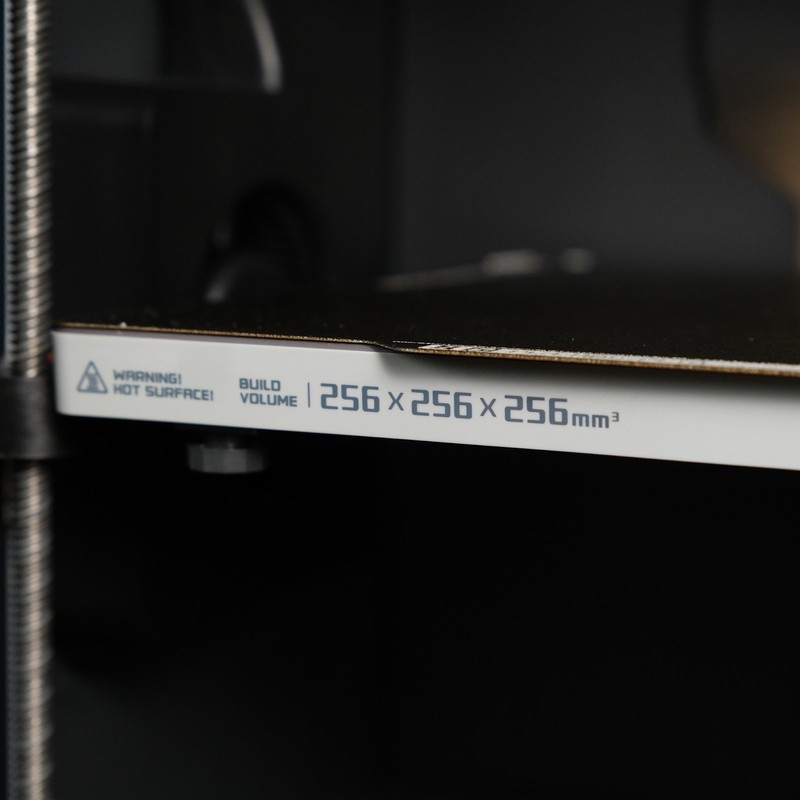

Build Volume

Possibly the most important difference between the K2 Plus and X1C is their difference in build volume:

- Creality K2 Plus: 350 x 350 x 350 mm (13.78” x 13.78” x 13.78”)

- Bambu Lab X1C: 256 x 256 x 256 mm (10.08” x 10.08” x 10.08”)

If you need to print large models, the Creality K2 Plus is clearly more able to meet that need than the Bambu X1C. Its 350 x 350 mm print bed is substantially larger than what is provided with most standard-size 3D printers, and is one of the largest available build volumes in a fully enclosed printer of its type. Since a large 3D printer can still print small models when needed, this is an exciting aspect of the K2 Plus that makes it a more capable machine for large prints.

Physical Size

Fully-enclosed CoreXY 3D printers such as the K2 Plus and X1C tend to take up a smaller desk footprint than their bedslinger competitors. Both printers are on the larger size, but the Creality K2 Plus is particularly massive due to its larger-than-average build volume.

- Creality K2 Plus: 495 x 515 x 640 mm (19.5” x 20.3” x 25.5”)

- Bambu Lab X1C: 389 x 389 x 457 mm (15.3” x 15.3” x 18”)

These numbers may not make the K2 Plus sound much larger than the X1C, but in person it feels like a notable difference. The K2 Plus is a huge machine that will dominate any normal-sized workbench, which is a factor you should consider when deciding if it will fit into your space. It’s also a very heavy machine due to its extremely sturdy metal construction–you’ll certainly want to enlist the help of someone else to lift or move the printer.

Keep in mind, too, that with either of these machines you may need additional space if you want to use their multicolor printing capabilities. With fully-enclosed 3D printers like these, the cleanest way to mount the Creality CFS or Bambu AMS is to place it on top of the printer, although you can easily place it next to the machine if you’re limited on vertical space.

Overall, with the Creality K2 Plus you may have a hard time fitting it into your workspace, especially if you’re using it with the CFS. That’s the trade-off for its impressively large build volume.

App and Ecosystem

As we discussed previously in the section on wireless 3D printing, one unfortunate reality of modern 3D printers is that you’re often limited to the manufacturer’s own smartphone app for wireless control of the machine. To be clear, you aren’t limited on where you can download 3D models from, and you can even use any slicer software you want (although you’re more limited for multicolor prints). But for the fully-integrated experience of wirelessly controlling the printer and transferring print files to it, you’ll need to use the manufacturer’s own app.

Additionally, we’re seeing that most manufacturers have created an online repository and marketplace for 3D models. This allows you to browse for models directly in the printer app, and in many cases, you can download a model with preset settings for your 3D printer model, allowing you to immediately print the model without having to worry about tweaking settings for a high-quality print. We really enjoy the ease of use that comes with this integration, but it does mean that you’ll get a different experience with each manufacturer if you want to find and print models directly from their app.

Both Creality and Bambu provide apps and online model repositories for this purpose, and while we haven’t found any major deficiencies in either, we have generally preferred the experience of using the Bambu app, and especially their model website, MakerWorld.

The apps feel fairly closely matched, with both offering all of the key functions you need to control the printer and start prints. In some ways, we found the Creality app to be slightly more reliable, especially when viewing the live camera feed from the printer. On the Bambu app, we often have to close and reopen the app to get the camera feed to quickly load. However, we did also have an occasional issue with the Creality app where it would forget that we had paired a 3D printer to our account. In short, both apps work fairly well, but aren’t bug-free.

Creality offers 3D models through their “Creality Cloud” website, which is also accessible within the app for the printer. There are plenty of models to choose from, but one of our biggest frustrations with this platform was that many of the models require payment to download and print. While we’re in full support of creators being paid for their work, and like the idea of a site offering premium models, it feels like the majority of the models on Creality Cloud are in the premium category. If you’ve just spent over a thousand dollars on a 3D printer, we could imagine it being hard to want to pay for models to print, at least for casual experimentation.

We also found that it was hard to find good multicolor models on Creality Cloud, which made it harder to take advantage of the CFS when searching for prints within Creality’s ecosystem. This is probably partially due to the CFS being fairly new and only supported by a few of Creality’s machines–the rest of their lineup only supports a single color, so it makes sense that most models would be designed for single-color 3D printing.

In contrast, Bambu Lab’s MakerWorld site does not offer premium models at all, meaning anything you find on the site can be printed free of charge. The site also offers many multicolor models, probably in part due to all of Bambu Lab’s machines supporting multicolor printing through their AMS (or AMS Lite, for A-series machines) add-on. As a user, this is a much more satisfying experience–you can browse around and find a model you like, and immediately print it without needing to pay.

We’re not completely sure why the economics of these two model websites are so different, but it’s undeniable that MakerWorld is a bit more friendly to a casual user due to the lack of paywall. We hope to see Creality Cloud offer more and more free models in the future.

Brand

It’s no secret that Creality and Bambu Lab are very different brands, and although the brand isn’t the biggest consideration in choosing between these machines, we think there are a few differences worth discussing. In some ways, each of these machines reinforces its brand’s stereotypes, while in other ways you might be surprised.

Creality has always been a great value in 3D printing, offering impressive specs (such as large build volume) at a low price that makes their machines very competitive in the market. We’ve generally felt that their machines are decently well-built, although they have typically fallen short of the more premium construction we see from higher-end brands. On the other hand, they have offset that by charging a lower price for their machines, as well as offering printers that are very upgradable and repairable. We have some Creality printers that have had basically every part replaced except the frame.

With the K2 Plus, Creality has taken some steps away from this operating model into a more premium space, with all of the pros and cons that come with that. We are very, very impressed with the build quality and overall performance of the K2 Plus. It’s by far the most premium and best-performing Creality 3D printer we’ve ever used, and in our judgement, the build quality and printing experience with the K2 Plus rival what we’ve seen from any other consumer 3D printer, including Bambu Lab’s machines. But along with that, the K2 Plus is one of Creality’s most expensive consumer machines, and isn’t any cheaper than the Bambu X1C.

We generally would expect any Creality 3D printer to be open to repairs and upgrades from third party manufacturers, but there is currently limited information about how the K2 Plus will fare in this area. There aren’t too many repair parts available currently for the custom aspects of the K2 Plus’s motion system, and the overall design of the printer with its automated calibration systems might make it a little less open to repairs and upgrades than the rest of Creality’s lineup. We’ll have to see how things go in this regard, but we’re hopeful that Creality will be as open with the K2 Plus as they have been with their previous machines.

On the other hand, Bambu Lab has always presented an image of being premium and offering turn-key, easy-to-use 3D printers since their first entry in the market. While they do offer repair parts and support some third-party upgrades, their machines are undoubtedly less open to customization than most other manufacturers in the 3D printing space. In return, they offer machines that are high-quality and easy to use. You might be able to think of comparisons to brands in other categories of technology that are similar to this.

Bambu Lab has recently come under fire for a decision they made to further lock down the X1C from being controlled by third-party software. While this particular change is unlikely to be a large impact to most users, it does indicate that their company prioritizes their own end-to-end software and hardware experience over providing openness and options to their users. If open-source and third-party customization are important factors for you in your 3D printing choice, Creality will be more appealing to you than Bambu Lab.

Should You Buy the Creality K2 Plus or Bambu Lab X1C?

As you can see, the Creality K2 Plus and Bambu Lab X1C are surprisingly similar in some ways and clearly different in others. We think the choice between these two machines might be more obvious to you than some of our other comparisons depending on what you’re looking for in your next 3D printer, but we’ll summarize some of the reasons we think you might prefer one of these printers over the other.

If you really need a large build volume and also want high print quality as well as the ability to print with multiple colors or materials, the Creality K2 Plus will meet your needs better than most other 3D printers on the market. There are other large-format 3D printers, but the K2 Plus is the first of its kind by combining that large build volume with the premium build, excellent print quality, and multicolor printing capability that we’ve started seeing on smaller machines. We’re very impressed with the build quality, performance, and ease-of-use of the Creality K2 Plus, and will be maintaining the printer as part of our own lineup for our printing needs. If you can get over the massive size and high price tag, it’s an excellent 3D printer.

On the other hand, if you aren’t in need of the K2 Plus’s build volume, the Bambu Lab X1C offers a nicer user experience with the Bambu app and ecosystem, and is a more compact printer that might fit into your workspace more easily. While Bambu’s focus on end-to-end user experience over third-party openness will be off-putting to some users, we can’t deny that it makes for a very pleasant experience of using the machine and we’ve overall been extremely pleased with all of the Bambu 3D printers we’ve used. We maintain a number of Bambu machines and still think they’re some of the best options available today. As their most premium consumer 3D printer, the X1C is undoubtedly a great choice.

Overall, we think build volume is the biggest reason to decide between the machines, and we’re impressed with what Creality has done with the K2 Plus–this is really an entry into a more premium space for them, and they’ve managed to create a very competitive machine. We honestly think either of these printers would be a great choice, so it’s up to you to decide which one is the best fit for you.

Click here to view the Creality K2 Plus.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: