If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Ender 3 V3 vs Prusa MK4

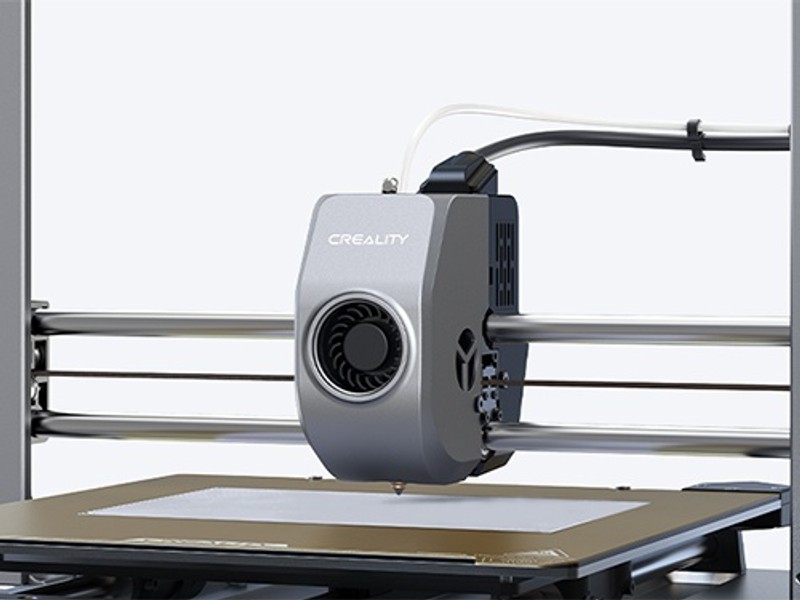

Creality Ender 3 V3

(~8.75 x 8.75 x 10 in)

Vs.

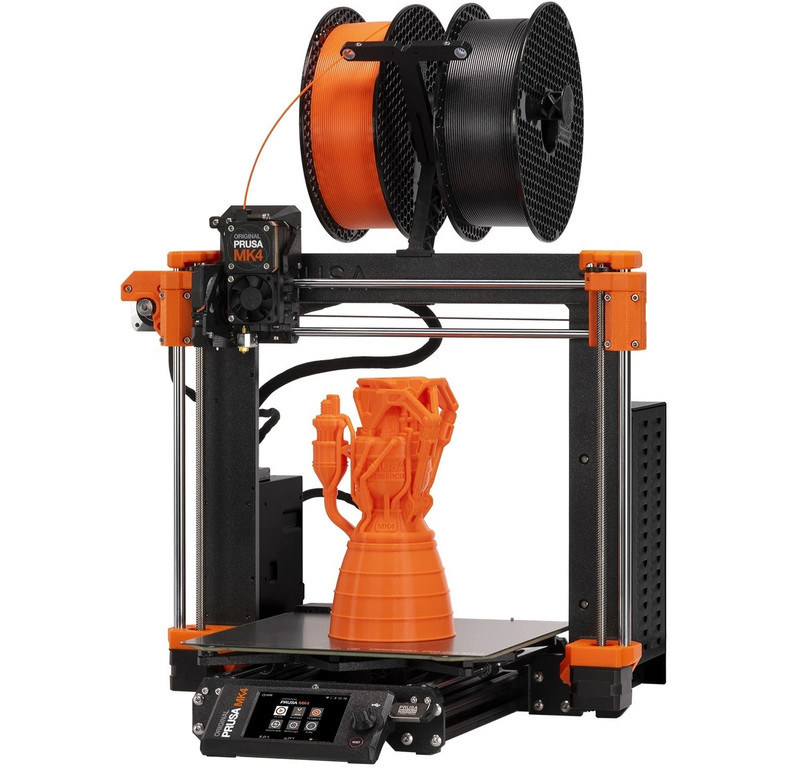

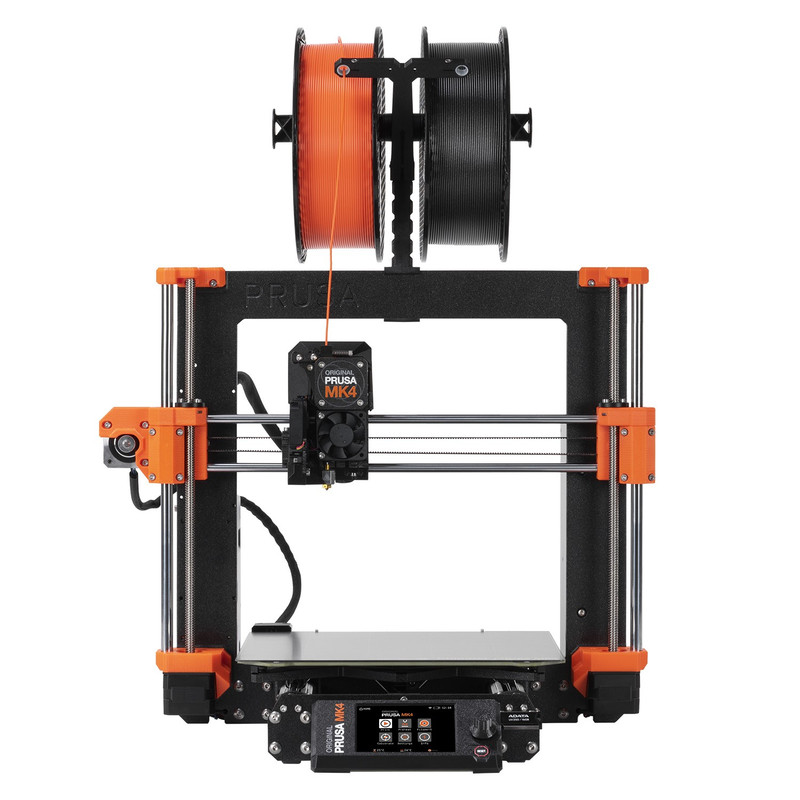

Prusa MK4

(~10 x 8.25 x 8.75 in)

Prusa has been a household name in the 3D printing community since 2012 when they began creating consumer-grade 3D printers with quality components that weren’t found in their competitors’ machines. They have always been known as the premium choice when it comes to 3D printing. The Prusa MK3 was the inspiration for many of today’s cheaper Cartesian-style 3D printers. The MK4 is Prusa’s newest rendition, with firmware and hardware updates that modernize the tried-and-true design of the Mk3.

The Ender 3 V3 CoreXZ is Creality’s newest addition to their V3 lineup, further innovating with hardware and firmware that continues to push for faster print speeds and increased reliability. While similar in appearance to the MK4, the V3 uses a unique CoreXZ design for significantly improved performance along the X and Z axes.

This article will help you determine which of these two printers is the right choice for you. We will go over all of the differences, as well as the similarities, between these two 3D printers before summarizing everything at the end of this article.

Let’s begin with what makes these printers similar

Similarities Between the Prusa MK4 and Ender 3 V3

Both the Prusa MK4 and the Ender 3 V3 share some common traits that are found on many 3D printers that follow the I3 design.

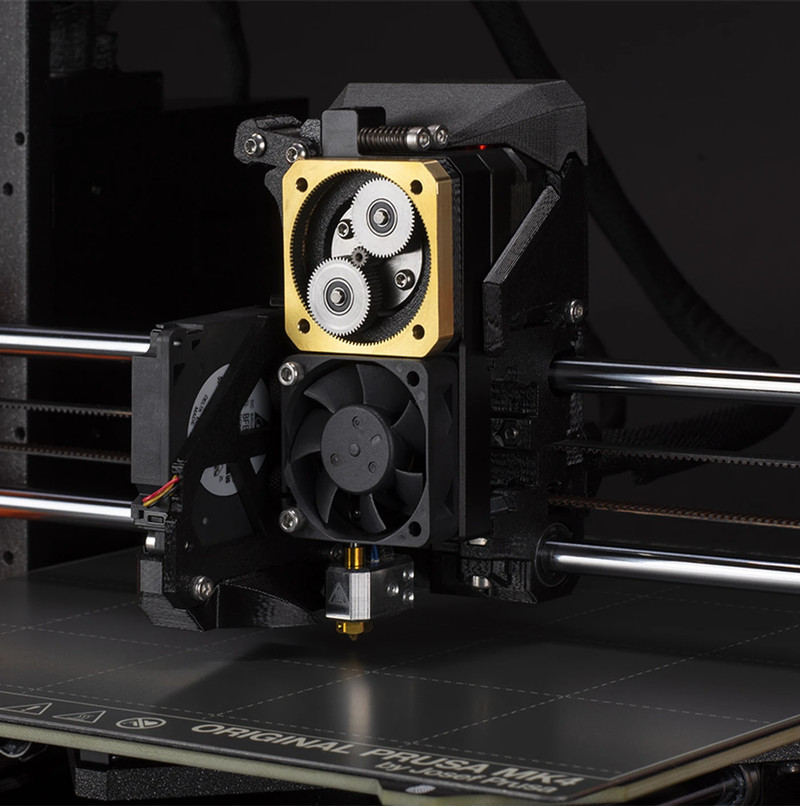

Extruder and Hotend

Both the Prusa MK4 and the Ender 3 V3 use a direct drive extruder, with the MK4 opting for a planetary gear design while the V3 sticks with a simple but effective gear ratio to increase extrusion force. You can expect similar extrusion performance from both of these machines. Direct drive extruders are our preferred extrusion method as they are much easier to work with than Bowden-style printers. These extruders are mounted directly to the print head and move along the X and Z axes during printing. Each of the print heads has a break-out board that makes it easy to swap between hot ends, fans, and nozzles.

Both printers are equipped with all-metal hot ends that are capable of achieving temperatures of around 300°C. This makes them both capable of printing all of the hobby-grade filament types such as PLA, PETG, TPU, ABS, and ASA, as well as some of the engineering-grade materials like Polycarbonate and carbon fiber blends, though an enclosure would be required.

Print Speed

The Prusa MK4 and the Ender 3 V3 are both marketed with a print speed of 600mm/s, impressive speeds for bedslinger-style 3D printers. The Ender 3 V3 makes this possible with the use of a lightweight print head and linear rods for the motion system, similar to the MK4, with spring-mounted bearings to help reduce vibrations. While the CoreXZ design also helps reduce vibrations, we don’t expect it to affect the overall print speed as much as Creality would claim. This is made evident by the fact that the MK4 can still reach the same print speeds.

The PrusaMK4 uses advanced firmware iterations to achieve these print speeds, with every update improving the capabilities of the machine. Input Shaping and Pressure Advanced play a large role here. While you may not realistically print at 600mm/s with these printers, you can expect solid print times from either of these machines.

Build Quality

The Prusa MK4 is constructed out of a die-cast aluminum frame and 3D-printed components that hold the machine together. Prusa prints all of its parts in-house using their own print farm. The 3D-printed parts have little to no impact on the rigidity or quality of the machine. The Mk4 still maintains that hobbyist look that the Prusa machines have pioneered.

The Ender 3 V3 frame is also made of die-cast aluminum, though there are only two pieces to the frame and no 3D-printed parts are used to connect them. This gives the Ender 3 V3 a more streamlined appearance when compared to the MK4, though it still lacks the luxury look and feel that some of the other mid-to-high-end 3D printers have achieved. This is partly due to the open-air design.

Neither printer will suffer from print quality issues due to their build quality. You can expect a solid and durable frame on both of these machines.

Auto Leveling

The Prusa MK4 and Ender 3 V3 both utilize many of the same components, sensors, and firmware features to automatically level the print bed and give you a good first layer on your prints. They both use load cells to detect the nozzle distance from the print bed, with the MK4 mounting the load cell to the print head while the V3 uses four load cells on the print bed. These sensors also automatically set the correct Z-offset for a completely automatic bed leveling experience. This is becoming standard for just about every 3D printer released today and is expected on printers at this price point.

You can expect similar performance in regard to bed leveling and bed mesh compensation from these two 3D printers.

Connectivity

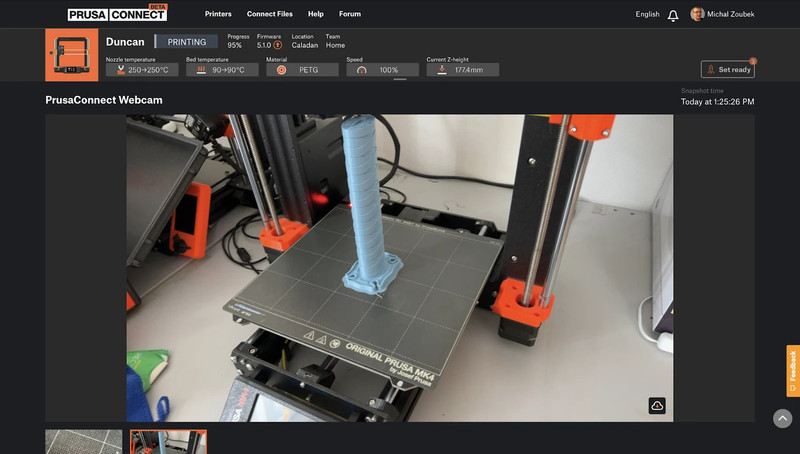

Both the Prusa MK4 and the Ender 3 V3 are capable of connecting to your local network using WiFi. This allows you to wirelessly send print jobs to the machine and monitor it while you are away from the room.

The Prusa MK4 uses the Prusa Connect app to monitor everything from machine temperatures to print time remaining. The Ender 3 V3 uses the Creality Cloud app to send print jobs to the printer, though you will have slightly fewer options in regards to monitoring your prints.

Both printers are shipped with USB thumb drives that can be used to store your favorite prints for offline use. Some Mk4 owners have complained about the USB thumb drive being of poor quality and recommend a replacement as soon as possible.

Firmware

Both the Prusa MK4 and the Ender 3 V3 use variations of the Klipper firmware, each with its own version that is custom-tuned for the best results. This leads to increased print quality and speed from both of these machines, along with Input Shaping and Linear Advanced for further quality tuning. The MK4 uses Prusa’s own iteration on Klipper, giving you less customizability when it comes to adding new firmware features.

The Ender 3 V3 comes with Creality OS installed, which is Creality’s variation of Klipper. It is completely open-source, following the tradition set by Klipper, allowing you to customize and add to the project however you see fit. It similarly enables the use of Input Shaping and Linear Advanced on this machine for improved print speed and quality tuning.

Differences Between the Prusa MK4 and Ender 3 V3

While these printers may seem very similar at first glance, it is the way they function and the day-to-day user experience that will set them apart from each other.

Motion System

The biggest difference between the Prusa MK4 and the Ender 3 V3 is obviously the different motion systems. While both printers are still considered bedslingers, the PrusaMK4 continues to use the tried-and-true motion system found on the MK3, with linear rods and timing belts controlled by a stepper motor mounted alongside the gantry. This design, found on both the MK4 and the V3, is favored over the V-slot rollers found on many 3D printers, as the wheels will wear down and will require replacement over time.

The Ender 3 V3 looks to innovate from the traditional Cartesian-style 3D printer by including a CoreXZ design, pairing the X and Z axes together with timing belts that run along the inner frame of the machine. Both the X-axis and the Z-axis are controlled by two high-torque stepper motors that are mounted on the base of the printer, rather than the gantry. This reduces the overall weight of the gantry and allows for faster movements in the Z-axis. We have yet to find a good use for the increase in Z-axis speed and have found it to be negligible for this type of machine. The use of timing belts as opposed to lead screws for the Z-axis does make some improvements in print quality, specifically with Z-banding.

Build Volume and Size

The Prusa MK4 comes with a build volume of 250 x 210 x 210 mm (10” x 8.2” x 8.2”, the same print volume as the MK3 before it. This is plenty of space for most users, though you may run out of space with this machine if you intend to print larger models.

The Ender 3 V3 comes with a build volume of 250 x 220 x 220 mm (10” x 8.75” x 8.75”), slightly larger in the X-axis and Y-axis than the MK4. Even with the added space, you may run into issues printing large models on this machine.

The total space that the MK4 makes up is 500 x 550 x 400 mm (19.7” x 21.7” x 15.7”), a decently compact design. The Ender 3 V3 takes up 358 x 498 x 374 mm (14” x 19.6” x 14.3”). This is thanks to the slim design of the frame and the decision to house all of the electronics inside the base of the machine. Keep in mind that additional space is required for the bed to move along the Y-axis for both of these machines.

If saving space is a big factor for you, the Ender 3 V3 takes up less space than the Mk4 while providing you with 10 additional millimeters of space along the X and Y axes.

Print Surface

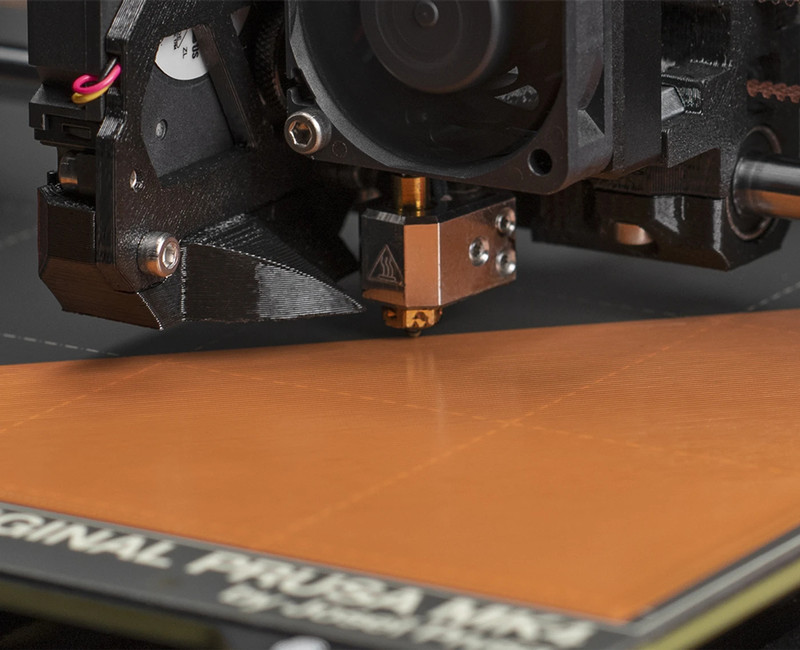

The Prusa Mk4 is shipped with a smooth PEI sheet for the print surface. This print surface leaves a smooth, glass-like appearance on the bottom of your prints, making it preferred by some. We still prefer the textured PEI sheet as it offers slight improvements to bed adhesion. You can purchase a textured PEI print surface as well as a satin PEI print surface directly from Prusa’s website should you prefer one or the other.

The Ender 3 V3 comes with the standard textured PEI print surface that is becoming the new normal for just about every printer today. This print surface provides great print adhesion and part removal once the bed has cooled down. Additional print surfaces are not yet available from Creality’s website.

Both of these machines utilize magnetic print surfaces, making it very easy to remove the print surface for part removal or replacement when needed. We recommend regular cleaning of your print surfaces using isopropyl alcohol to remove any dust, debris, or oils from your hands after handling the print surfaces.

Display and Controls

The Ender 3 V3 has a 4.3” HD full-color display that is navigated with the touchscreen. This is a feature that is normally only found on higher-end 3D printers and really adds to the user experience. Menu navigation is simple with no settings being hidden behind random menus. The definition of the screen is a noticeable improvement over the competition.

The Prusa MK4 comes with a 3.5” full-color display that is navigated using the scrolling knob to the right of the screen. This same design can be found in earlier iterations of Prusa’s machines. Even though the screen looks nice on this machine, you would expect it to have touchscreen functionality, especially when considering the price point. We have had no issues navigating the MK4 menus using the scroll knob, though the inclusion of a touchscreen would have been a welcome addition. The MK4 screen comes with LEDs that are mounted just below the display. These LEDs will change color depending on the status of the print, with a green glow indicating that your print is done. Those who plan on adding this machine to their print farm will find this feature very useful for monitoring print status at a glance.

Assembly

Assembly of the Prusa MK4 will depend heavily on which option you purchase, as Prusa offers two different variations. One variation comes completely assembled. All you have to do is mount the spool holder and turn the machine on for calibrations to begin. This process should take you less than 5 minutes to unbox and power on the machine.

The other variation is a kit version that comes with all of the parts you need to build your MK4 machine from scratch. This kit is offered at a discount and is preferred by those who are experienced with building 3D printers and want to save as much as possible when purchasing a new machine. The entire assembly process will take the average user a full day to ensure that all components are correctly installed. Prusa does include a very detailed instruction manual to give you a step-by-step experience. This kit is not recommended for those looking to purchase their first 3D printer, as it can easily overwhelm a beginner who has little to no experience building these machines.

The Ender 3 V3 comes mostly preassembled, with the gantry and the base of the machine separated. All of your electronics, including the power supply and the mainboard, are housed inside the base of the printer. The gantry frame is a single solid piece that comes with your print head and timing belts preinstalled. Only eight screws are required to attach the gantry to the base. After ensuring that all of the motors, sensors, and print head are connected to the mainboard, you are ready for start-up calibrations. The entire unboxing and assembly process shouldn’t take you longer than 15 minutes.

Modification Capabilities

The original Ender 3 has long been considered one of the best 3D printers for tinkering and modifications. It was used as a canvas that the community could customize however they saw fit. The Ender 3 V3 CoreXZ, along with many of the newer generation of Ender 3 V3 printers, has stepped away from its roots, opting for a more closed ecosystem of parts that are not widely used. This makes the Ender 3 V3 a challenge to modify. Even the nozzle on the Ender 3 V3 is not a traditional nozzle, with replacements only available from Creality’s store.

The Prusa MK4 retains the same modification capabilities as the MK3 and other Prusa machines before it, with a completely open-source design that allows anyone the chance to customize just about anything they want on the machine. If you enjoy making any type of modifications to your 3D printers, the MK4 is the better option here.

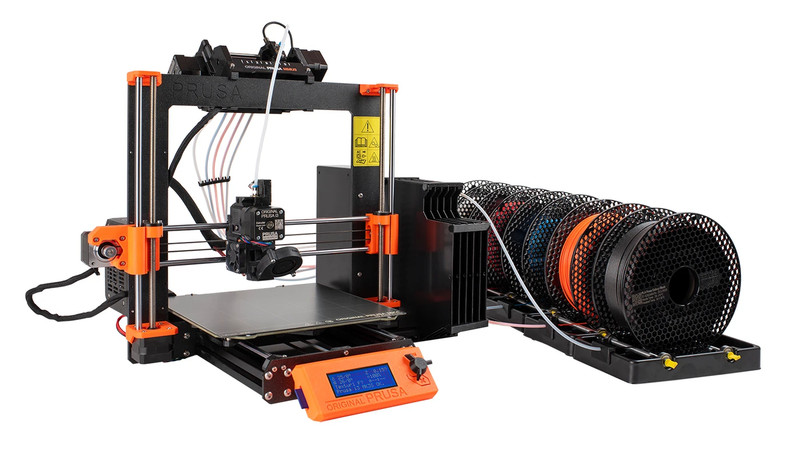

Multi-Material Compatability

The Prusa MK4 is compatible with Prusa’s Multi-Material Unit 3 (MMU3), allowing it to swap between up to five different colors or filament types during a single print job. The MMU3 is a separate add-on that you will need to purchase if you plan on printing in multiple colors with the MK4 and you will need a significant amount of space beside the printer to use the MMU3.

The Ender 3 V3 is not compatible with the MMU3 and Creality has yet to make their own multi-material system for their printers. While there are third-party options, such as the Palette 3 Pro, these options are much more expensive than the MMU3 or even Bambu Lab’s AMS.

While it is hard to justify the cost of both the MK4 and the MMU3 for multi-color printing, this type of future upgradability is something that not a lot of printers on the market have going for them, outside of Bambu Labs machines.

Should You Buy the Prusa MK4 or Ender 3 V3?

When deciding which of these 3D printers to get, it is important to first think about what you want out of your 3D printer. These machines are very similar in what they have to offer. Both of these printers will produce similar quality prints at similar speeds. With this being the case, why would anyone choose the $1,100 MK4 over the $400 Ender 3 V3?

Prusa is known for their reliability. When you are buying a Prusa machine, you are paying for their reputation as a brand. Prusa has one of the best customer service experiences around and has shown that they are very capable of handling any issues that you might run into with your machine. Many of those who have purchased a Prusa 3D printer are still using it today, speaking to their quality and longevity.

While Creality as a brand is well-known in the 3D printing community, the Ender 3 V3 is a newer 3D printer and has yet to show whether or not it can compete with the reliability of Prusa machines.

We believe that the majority of users will be satisfied with the Ender 3 V3, as it offers very similar performance to the MK4 at almost a third of the price. If you are interested in multi-material 3D printing, heavily modifying your 3D printer, or want to purchase a machine that you know has a proven track record, then you will not be disappointed with the Prusa MK4 either.

Click here to view the Creality Ender 3 V3 on Amazon.

Click here to view the Prusa MK4 on Prusa3d.com.

You can find a side-by-side comparison of the specifications for these two printers in the table below: