If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Creality K1 vs Creality Ender 3 V3 KE

Creality K1

(~8.75 x 8.75 x 10 in)

Vs.

Creality Ender 3 V3 KE

(~8.75 x 8.75 x 9.5 in)

The K1 is one of Creality’s most complete 3D printers, with a feature set that is often found on many higher-end machines and a focus on high-speed 3D printing, all while maintaining the budget-consciousness that Crealtiy is known for in their printers.

The Creality Ender 3 V3 KE is an upgraded version of the Ender 3 V3 SE, with a slightly increased price that is offset by its many new features, including more durable parts and a focus on higher-speed printing. This it a more compelling option by today’s standards.

In this article, we will be comparing both of these machines, going over their similarities and differences to help you decide which 3D printer is right for you.

Similarities Between the Creality K1 and Creality Ender 3 V3 KE

Coming from the same manufacturer, you can expect much of the same specs from these printers.

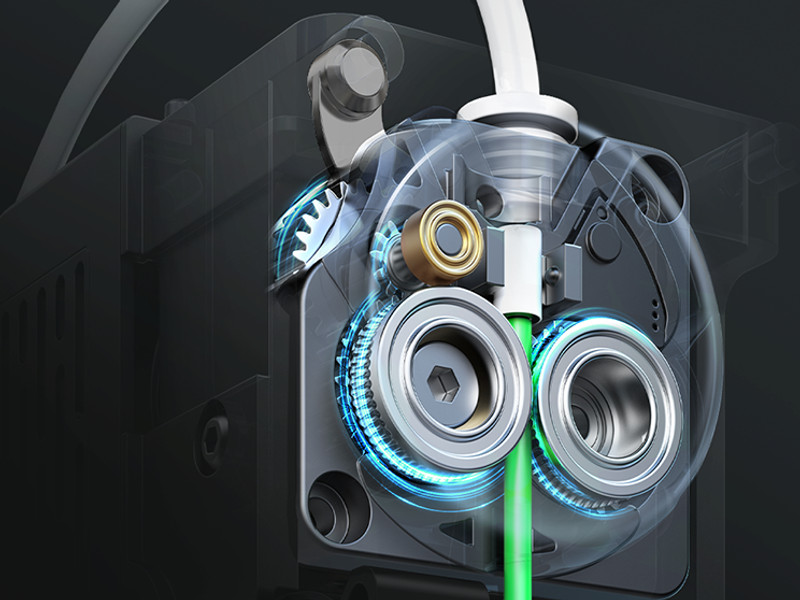

Hot End and Extruder

Both the K1 and the Ender 3 V3 KE are equipped with all-metal hotends reaching up to 300°C, making them compatible with a wide range of filament types, including PLA, PETG, ABS, TPU, and nylon. Both machines use dual-gear extruders, with the Ender 3 V3 KE using an upgraded all-metal Sprite extruder, each providing consistent extrusion, especially when printing with TPU.

Build Volume

The Ender 3 V3 KE has a build volume of 220 x 220 x 240 mm (8.75 x 8.75 x 9.5 in), which is standard for most of Creality’s 3D printers. The K1 has a similar build volume of 220 x 220 x 250 mm (8.75 x 8.75 x 10 in), giving you slightly more space in the Z-axis for taller prints. For the average user who isn’t maxing out the height of these build volumes, they should feel very similar.

Print Surface

The K1 and the Ender 3 V3 KE come with a textured PEI print surface. PEI print surfaces are one of our favorite materials, providing excellent print adhesion. This flexible surface is very durable and easy to maintain.

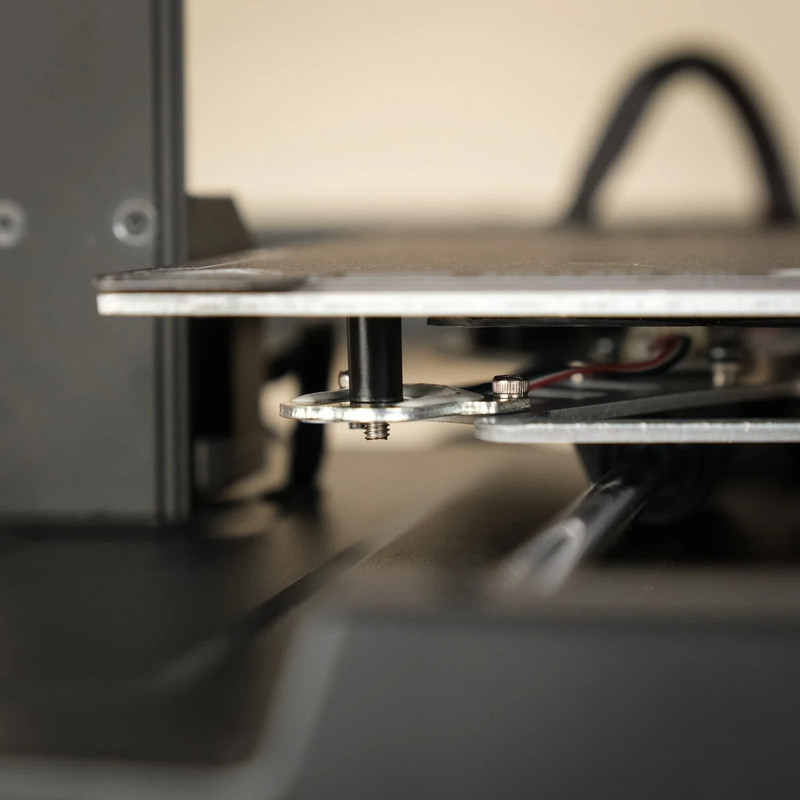

Automatic Leveling

The K1 uses a strain gauge inside of the hot end to probe the bed, creating a bed mesh and automatically setting the Z-offset. This is a completely hands-free approach that should provide you with consistent bed leveling.

The Ender 3 V3 KE uses a strain gauge underneath the print bed, combined with a CR-Touch bed probe, to gauge nozzle distance from the print bed and automatically set your Z-offset. While this system is still fully automatic, we prefer the strain gauge to be inside of the hot end as this will provide more consistent results. Beginners should still have little to no issues keeping the bed level with these two printers.

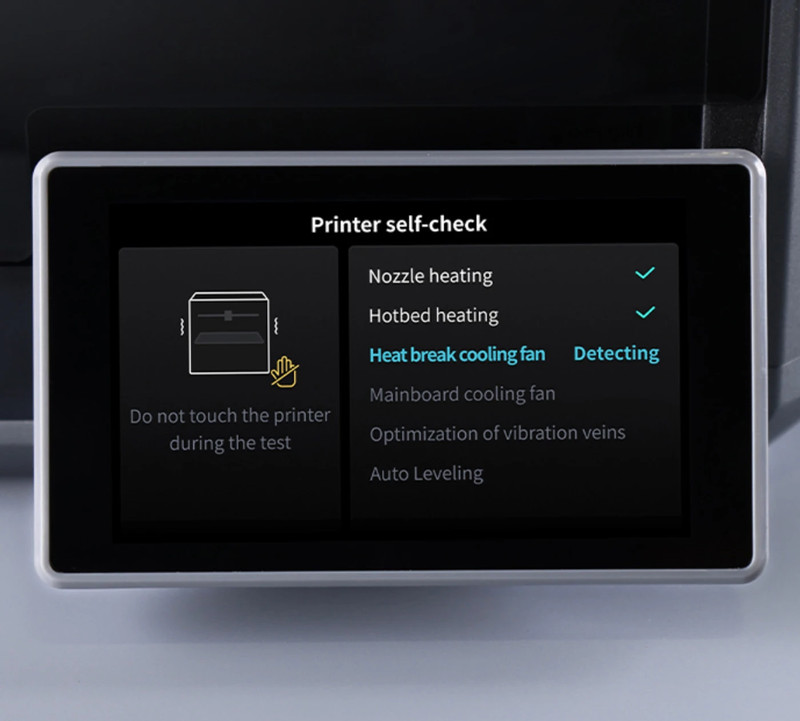

Display and Firmware

Both the K1 and the Ender 3 V3 KE come with full-color touchscreen displays. These displays make menu navigation easy and are much more premium-feeling than the traditional scroll knobs. Both machines are running on Creality’s variation of Klipper, which provides a solid foundation for users to customize.

Differences Between the Creality K1 and the Crealtiy Ender 3 V3 KE

Now onto the more important part of this comparison, the differences.

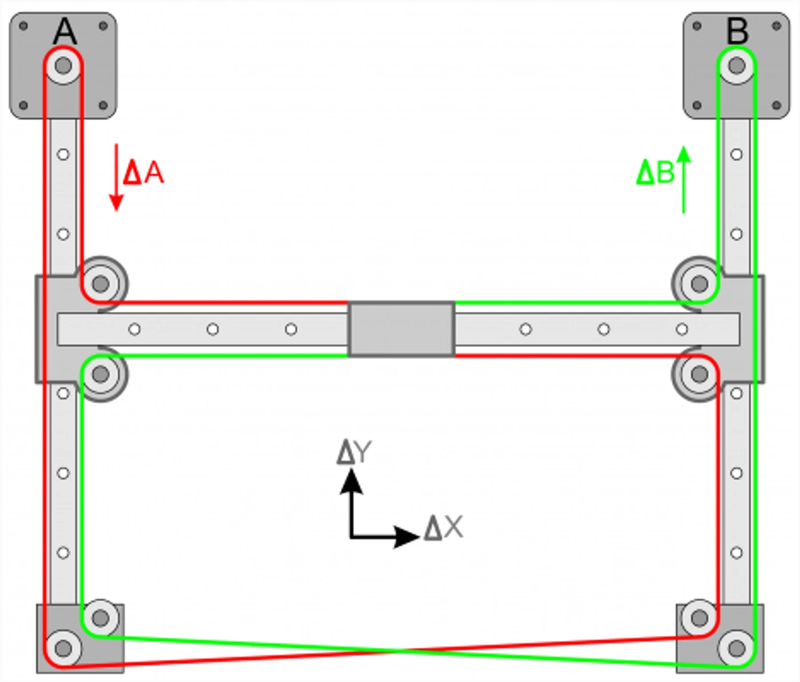

Motion System and Frame

The K1 is a CoreXY 3D printer. This means the X and Y axes are connected through a series of timing belts. These belts are connected to two high-power stepper motors that control both axes at the same time, resulting in fast, precise movements. The print bed is moved along the Z-axis, providing a more stable printing experience than Cartesian-style printers. The print head glides across two durable linear rods, while the print bed is raised and lowered with multiple lead screws.

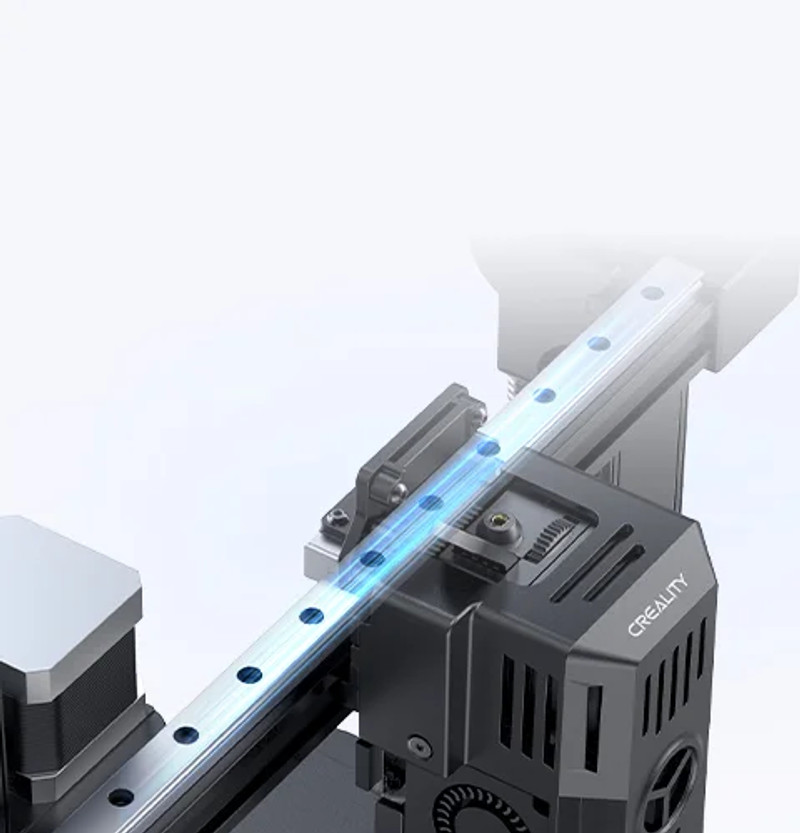

The Ender 3 V3 KE is a Cartesian 3D printer, with the print head attached to an X-axis gantry that is raised in the Z-axis with lead screws. This leaves the print bed to move along the Y-axis, which sometimes results in surface inconsistencies in taller prints as the bed movements cause the print to wobble slightly. The print head uses linear rails for fast movement. Linear rails are much more durable than V-wheel rollers.

The K1 has a fully enclosed frame, making it ideal for printing materials that require a consistent ambient temperature such as ABS and ASA.

The Ender 3 V3 KE has an open-frame design that is ideal for hobby-grade materials such as PLA, PETG, and TPU. This style of frame will give you issues when trying to print materials that need consistent ambient heat.

Print Speed

The Creality K1 is listed with a maximum print speed of 600mm/s, which puts it at the top with many of the most popular CoreXY 3D printers in terms of speed. The Ender 3 V3 KE has a maximum print speed of 500mm/s, impressive for a bedslinger. You can expect similar enough results in speed when comparing these two machines, with the K1 pulling ahead slightly.

Where the K1 does win out is in acceleration. The maximum acceleration of the K1 is listed at 20,000mm/s, more than double that of the Ender 3 V3 KE’s 8,000mm/s. This makes a noticeable difference when printing multiple objects at the same time, as travel times make up a large sum of the total print time.

Material Compatibility

The K1 has a hardened steel nozzle that is capable of printing many engineering-grade materials, including nylon and polycarbonate blends. The enclosed frame makes the K1 a good printer for ABS and ASA as well.

The Ender 3 V3 KE is not capable of printing these more demanding materials. An upgraded hardened steel nozzle kit is available as an additional purchase, though you will still need an enclosure for many of these materials. The stock Ender 3 V3 KE will be able to print PLA, PETG, and TPU just fine.

Physical Size

The Ender 3 V3 KE comes in at 433 x 366 x 490 mm in size, which is on par with other bedslingers. The K1 has a size of 435 x 462 x 526 mm, making it slightly larger than the Ender 3 V3 KE, though still fairly similar in size. Keep in mind that bedslingers, like the Ender 3 V3 KE, require additional space in front of and behind the printer for Y-axis print bed movements.

Sensors and Extra Features

The K1, being one of Creality’s more feature-rich printers, comes with a few smart sensors that make day-to-day printing much easier. It has a filament run-out sensor to pause prints when at the end of a spool of filament, a sensor for Input Shaping and Vibration Compensation calibration, and an auxiliary cooling fan mounted inside of the chamber that makes printing at high speeds more attainable. An AI-assisted camera is also available as a future upgrade for the K1.

The Ender 3 V3 KE comes with a filament runout sensor, though the Vibration Compensation sensor will need to be purchased separately as an upgrade. The Ender 3 V3 KE lacks many of the more modern smart features, requiring a little more attention from the user.

Should You Buy the Creality K1 or the Creality Ender 3 V3 KE?

Both of these machines were revolutionary upon release, with the V3 KE offering a high-speed, hands-free bedslinger option and the K1 being Creality’s first real entry to the appliance-like printer category. You won’t be disappointed with either of these two printers. Picking which one is right for you will come down to a few key factors.

If you are looking for a budget-friendly 3D printer that can print fast and you do not care to stick with PLA, PETG, and TPU, then the Ender 3 V3 KE is a fine choice. It has enough smart features to make it a compelling option for a beginner and a solid foundation that would allow experienced users to upgrade it to suit their needs.

If you need a printer that is able to print ABS, ASA, and other more advanced materials and you do not care to spend a bit more, the Crealtiy K1 would be the better option for you. The enclosure and hardened steel nozzle make it compatible with a wide range of materials, while the auxiliary fans will help keep print quality at its finest even when printing at higher speeds.

Click here to view the Creality K1 on Amazon.

Click here to view the Creality Ender 3 V3 KE on Amazon.

You can find a side-by-side comparison of the specifications for these two printers in the table below: