If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Creality K1C vs the Bambu P1S

Creality K1C

(~8.75 x 8.75 x 10 in)

Vs.

Bambu Lab P1S

(~10.25 x 10.25 x 10.25 in)

After the partial success and plentiful issues with the original 2023 release of the Crealty K1 to the high-speed CoreXY printing scene, Creality looked to address all of the issues the community had with the machine by releasing its successor. Eight months later, in 2024, the Creality K1C was born and users were very happy with all of the fixes and improvements made in this iteration, including carbon fiber printing capabilities and additional smart features.

Similarly, Bambu Labs had come out with their new iteration of the P1P with the 2023 release of the P1S, addressing most of the issues that were found with the original while maintaining a competitive price for such a high-speed machine. Notable upgrades include an enclosure and a better part cooling system to allow for a wider range of materials when using this machine.

In this article, we will cover all of the similarities and differences between the Creality K1C and the Bambu Lab P1S to help you decide which of these high-speed CoreXY printers is the right choice for you.

Similarities Between Creality K1C and Bambu Lab P1S

With both of these machines competing for the same spot in the market, you can expect them to have much of the same feature set. Here are the similarities that you will find between these two printers.

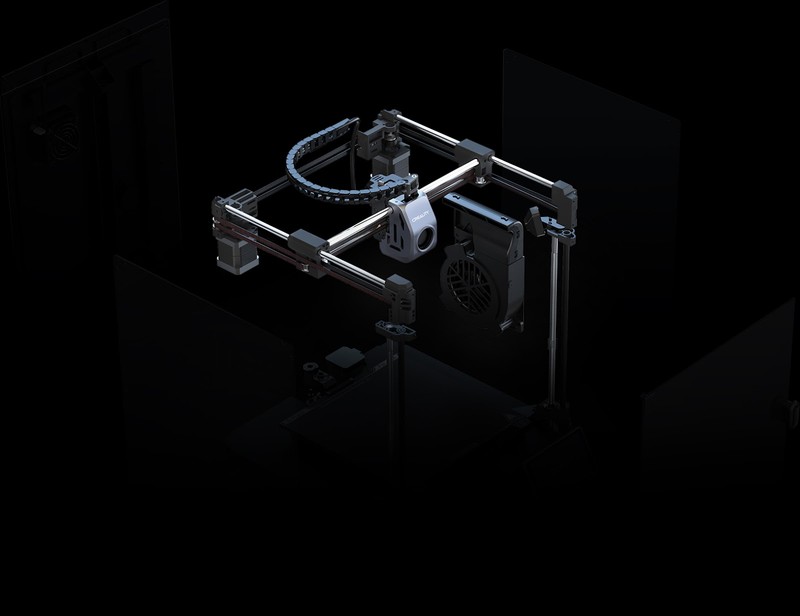

Motion System

Both the Creality K1C and the Bambu Lab P1S use a CoreXY kinematic motion system that pairs the X and Y axes together to be controlled by two stepper motors that are in sync, while the Z-axis is controlled by three lead screws for stability. This has quickly become the preferred motion system for high-speed 3D printing, as the removal of print bed movements along the Y-axis makes for a very stable printing experience. Parts will only move vertically along the Z-axis during printing, virtually eliminating any wobble that would be present when printing large objects and moving them along the Y-axis of a bedslinger.

This motion system is currently the most efficient in terms of raw speed, as the print head is the only part that has to move at high speed. The K1C uses linear rods for smooth movement, while the P1S opts for carbon fiber rods that perform similarly. The use of these rods in the motion system also plays a major role in the increased performance and reliability of these motion systems.

While some members of the P1S community have voiced their concerns about the durability of the carbon fiber rods, asking for standard linear rods instead, we have not found a significant impact on performance or longevity using carbon fiber rods as long as they are properly maintained.

Enclosure and Air Filter

Both the Creality K1C and the Bambu Lab P1S ship with a prebuilt enclosure that protects the motion system and allows for easy printing of engineering-grade materials that are not possible to print on open-frame machines, such as ABS, and ASA. Both machines have glass doors that swing open for access to your prints, as well as removable top covers for additional ventilation when printing with PLA or PETG.

A nice inclusion found on both printers is an air filter attached to the chamber exhaust that keeps foul and harmful odors from leaking into your home when printing with harsher materials.

While these enclosures do make the Creality K1C and the Bambu Lab P1S larger in size, CoreXY 3D printers are much more efficient with the space that they take up when compared to traditional bedslingers.

Extruder

You will find a very similar extrusion system found on both of these printers. CoreXY machines favor the use of direct-drive extruders as they provide more consistent extrusion than typical Bowden-style extruders. Direct-drive extruders are also much more capable of printing flexible materials such as TPU. You will find that both extruders utilized a dual-gear system that grips filament on both sides for increased extrusion force and reliability. You can expect very similar performance between the extruders on these two printers.

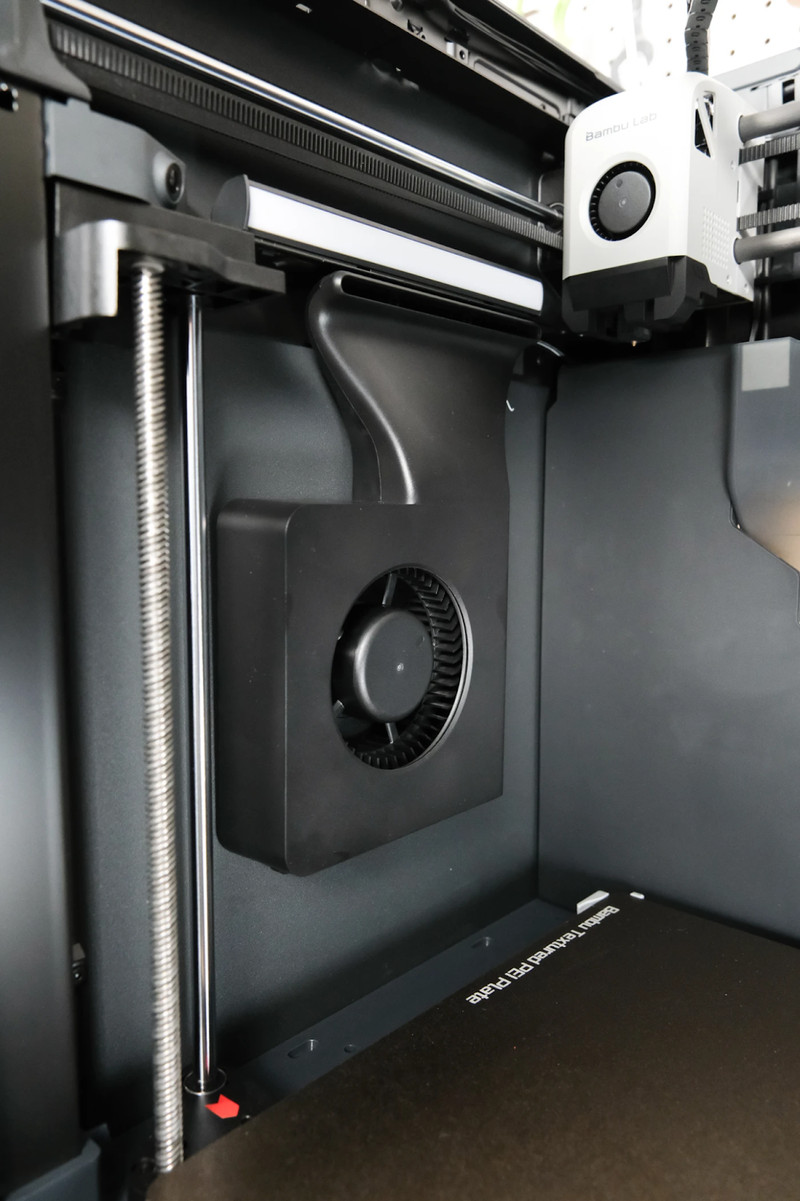

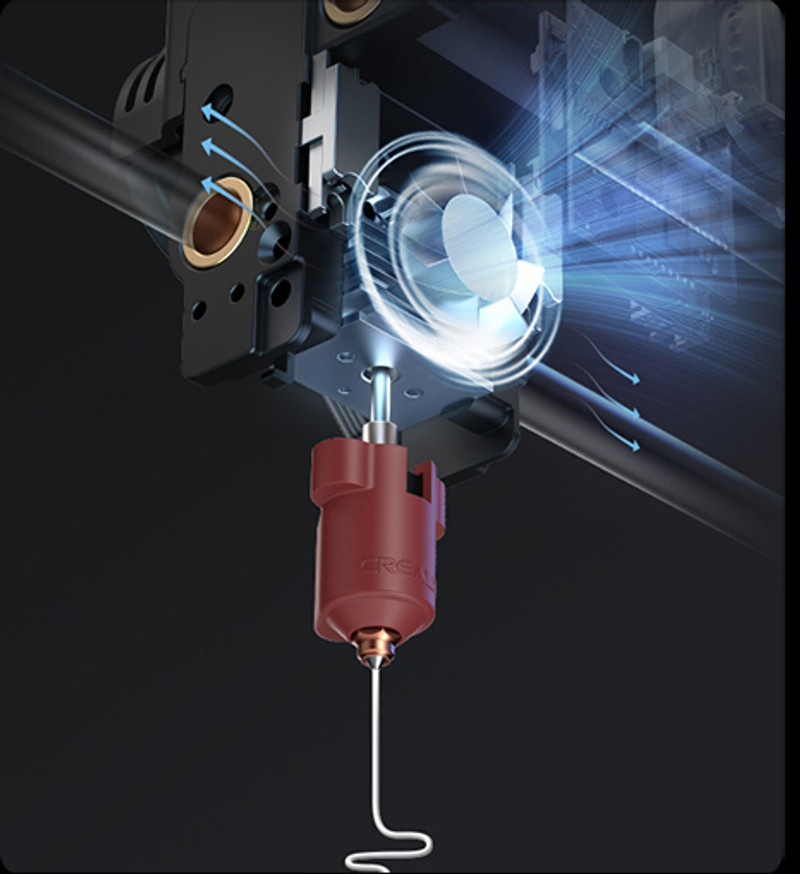

Part Cooling

Both the Creality K1C and the Bambu Lab P1S have a single-part cooling fan on the print head that spreads air evenly around printed parts for efficient cooling. When printing at high speeds, these print head cooling fans alone usually are not enough to keep up with the high flow rate of these machines. This is why the inclusion of a separate, much larger chamber-cooling fan is a welcome addition to both of these printers. This fan blasts printed parts with a powerful stream of air that massively increases cooling performance when printing at higher speeds. This chamber fan does increase the overall sound levels of the machine when printing, though that is a sacrifice you will have to be willing to make if you want appropriate cooling for your prints when using these machines.

Automatic Leveling

You will find very similar automatic leveling systems on both the Creality K1C and the Bambu Lab P1S. Each uses strain gauges on the nozzle paired with load cells on the print bed to gauge distance and set Z-offset accordingly. Just about every printer at this price range is expected to have a fully automatic bed leveling experience and neither of these machines disappoints. You can expect very similar performance when it comes to first layers and bed adhesion from these leveling systems, with little-to-no user input.

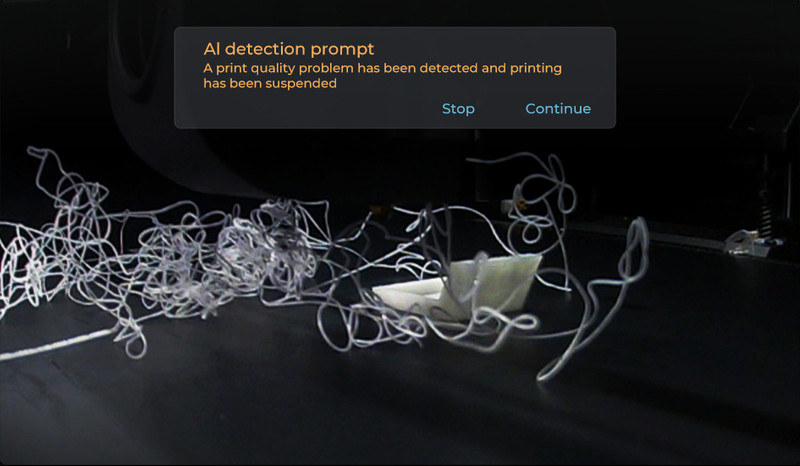

Camera

Both the Creality K1C and the Bambu Lab P1S come with a built-in camera that will allow you to monitor your prints and record a time-lapse of the entire print job. These cameras are great if you plan on putting your printer in a separate room in your home. You will always be able to check up on your prints using your phone or computer. While these cameras are very low frame rate lenses, they are perfectly capable of everything you need them to do.

The K1C comes with a slightly-improved AI camera that will automatically monitor your prints and attempt to detect any issues mid-print. Should an issue be spotted, the camera will pause the print and alert you. It is also capable of detecting foreign objects left on the print bed and will not allow you to start a print until the bed is clear. This is a very nice feature for those who are new to 3D printing, as it will prevent a lot of wasted filament on failed print jobs.

Connectivity

Both the Creality K1C and the Bambu Lab P1S are capable of connecting to your local home WiFi network, allowing you to control the printers wirelessly using each printer’s respective app.

The K1C uses the Creality Connect app to send files over your local network and begin print jobs without having to be near your 3D printer. It is also the app you will use to remotely monitor your printer.

The P1S uses Bambu Lab’s Bambu Handy app. It offers similar functionality to the Creality Connect app, allowing you to remotely send print jobs to your P1S and monitor prints using the camera. The Bambu Handy app provides a few more features that you can use to directly control your P1S printer and is the main form of interaction for many users, for better or worse. More on this in the Display section.

Assembly

You’d be hard-pressed to say that you have to assemble either of these printers. Due to the complex motion system and inclusion of an enclosure, both the Creality K1C and the Bambu Lab P1S are shipped almost completely assembled straight out of the box. You will need to remove all of the protective packaging and mount the spool holders and screens to either machine. After that, you are ready to begin first-time calibrations. The entire unboxing process for the Creality K1C or the Bambu Lab P1S should take you about 5 minutes and an additional 10 minutes to finish calibrations. You will be printing your first model in about 15-20 minutes.

These are among the most user-friendly 3D printers out of the box. Even someone who is completely new to 3D printing should have no issues getting either of these machines up and running in no time.

Differences Between Creality K1C and Bambu Lab P1S

Now that we have covered the similarities between these two printers, let’s go over what makes each of them different. These will be important points for many as you may have a strong preference for some of them.

Print Speed

The Bambu Lab P1S is rated for a maximum print speed of 500 mm/s, the same print speed found on the P1P before it. This is a very respectable print speed that will result in fast print completion and is ideal for quick design drafting. For the most optimal speed-to-quality ratio, the average user will most likely use a print speed of around 250 mm/s with this machine, which is still much faster than the average bedslinger.

The Creality K1C is rated for a maximum print speed of 600 mm/s, 100 mm/s faster than the P1S. This speed can be seen when comparing how long similar models will take on each machine. You can expect the K1C to outperform the P1S in this regard, if only slightly. Again, the average user will opt for a print speed of around 300 mm/s for optimal quality when using the K1C.

While both the Creality K1C and the Bambu Lab P1S are among some of the fastest 3D printers available, the K1C wins in overall speed performance.

Nozzle and Hotend

The Bambu Lab P1S comes with a stainless-steel nozzle, providing better performance than a standard brass nozzle. The hotend and nozzle are a single piece on the P1S, making them quick-swappable. The print head is attached using magnets, making it very easy to move out of the way during maintenance. To replace the hotend, you will only need to remove two screws and unplug a couple of wires. This makes maintenance and swapping between different nozzle sizes very easy on the P1S. These nozzles and hotends are proprietary and only available from the Bambu Lab online store.

The Creality K1C comes with Creality’s Unicorn tri-metal nozzle, which uses hardened steel in place of stainless steel. This makes the K1C able to print abrasive materials such as carbon fiber blends and glow-in-the-dark filaments that could potentially wear down a stainless steel nozzle and completely destroy a brass nozzle. The nozzle requires a bit more work to replace than the P1S. You will need to first remove two screws to gain access behind the print head. From here, the process is very similar to Ender 3 variants, requiring you to completely unscrew the nozzle from the hotend. This will take slightly more time and energy than the P1S. Again, the Unicorn tri-metal nozzle is only available from Crealty’s website, should you need replacements or different nozzle sizes.

Size and Build Volume

The Creality K1C has a standard build volume of 220 x 220 x 250 mm(8.6” x 8.6” x 9.8”), this is about average for Creality’s 3D printers and is on par with most Ender 3 variants. The total size of the machine is 428 x 428 x 527 mm (16.8” x 16.8” x 20.7”).

The Bambu Lab P1S has a square build volume of 256 x 256 x 256 mm (10” x 10” x 10”), noticeably larger than the K1C. Surprisingly, the Bambu Lab P1S is not larger in size than the K1C, measuring about 389 x 389 x 457 mm(15.3” x 15.3” x 17.9”) in total size. This makes the P1S more space-efficient in both footprint and build volume when compared to the K1C. The extra build volume will definitely be appreciated when attempting to print larger objects or multiple objects at once.

Filament Compatability

The Bambu Lab P1S is capable of printing all of the most common 3D printing materials, such as:

- PLA

- PETG

- TPU

- ABS

- ASA

- PC

The stainless-steel nozzle makes this printer better suited for some of these harsher materials that a brass nozzle would not be able to print.

The Creality K1C comes with a hardened steel nozzle that is much more abrasion-resistant than a stainless steel nozzle. This allows the K1C to print a larger variety of materials, such as PA and carbon fiber blends. However, nozzles are easy to replace, so this isn’t a compelling reason to choose one printer over the other.

If you plan on printing PLA or PETG with either of these machines, be sure to leave the door of the printer open and remove the top cover to allow for optimal airflow. If you plan on printing with any engineering-grade materials then the K1C is the better option.

Multi-Material Compatibility

The Bambu Lab P1S is fully compatible with Bambu Lab’s AMS unit, allowing for multi-color 3D printing and multi-material prints. The AMS automatically changes filament colors mid-print, removing the need for you to monitor your prints and swap colors accordingly. You can even load the same colors into the AMS unit and have it swap between spools once one of them runs out, ensuring you do not come back to a failed print due to a lack of material.

The AMS unit can be purchased alongside the P1S for a discount or as an upgrade later on should you choose to purchase the P1S alone first.

The Creality K1C is not compatible with the Bambu Lab AMS unit. Creality does not yet have its own multi-color printing solution, meaning the K1C is not able to perform multi-color printing at this time. While there are third-party solutions, such as the Palette 3 Pro, they are far from beginner-friendly and may cause more trouble than they are worth.

If you want to create multi-color prints, the P1S paired with the AMS unit is the obvious choice here.

Display and File Storage

The Bambu Lab P1S comes with the same monochrome LCD screen found on the P1P, using a D-pad for menu navigation and selection. This screen was a major point of contention for the P1P and we were surprised to find it on the P1S as well. The D-pad does not make for a great user experience, especially when trying to make simple changes to the printer such as heating the nozzle or unloading filament. We would have liked to have seen an upgrade for the display on this machine, something similar to the touchscreen display on the X1C.

Many P1S users opt to solely interact with their printers using the Bambu Handy app, forgoing the LCD screen entirely. This gives you all of the basic controls you need in day-to-day use and is a compromise you will have to make when using this machine.

Finally, the Bambu Lab P1S still uses a micro-SD card for local file storage and offline printing. This has been the standard for a while, though more and more printers are moving away from SD cards in favor of USB storage for convenience.

The Creality K1C comes with the same full-color touchscreen found on the original K1. The screen looks nice and is very easy to navigate, making for a great user experience. This is more in line with what we expect from higher-end 3D printers at this price point. New users should have no issues finding all of the controls they need when using this screen.

The K1C uses a USB device for local file storage. This is preferred, as someone new to the hobby may already have additional USB drives, while micro-SD cards are not as common.

Firmware

The firmware on the Creality K1C and the Bambu Lab P1S will provide you with a very similar experience in most regards. Both printers are running on a variation of the Klipper firmware, enabling Input Shaping and Linear Advance to assist with high-speed printing.

The major difference between the firmware on these two machines is the fact that Creality OS, the firmware used by the K1C, is open-source. This allows experienced users to go into the firmware and make any changes they want with their 3D printers, testing new features or completely modifying the printer. This is ideal for printers running on Klipper firmware, as Klipper itself is open-source.

The P1S does not run on open-source firmware. You will not be able to easily make changes to this machine or modify it. In this regard, we give a win to the K1C.

Should You Buy the Creality K1C or the Bambu Lab P1S?

Both of these machines are competing for exactly the same spot in the market as CoreXY 3D printer appliances. They are both successors to very popular machines and promise an even better experience than the previous generation of printers. So the question is, which printer has made the most amount of improvements?

While both of these printers offer very similar spec sheets, the K1C is our overall choice between these two. The K1C is compatible with a wider range of filaments, has a much better AI camera, is faster than the P1S, and provides a much more user-friendly experience out of the box. To top it off, the K1C is a fair bit cheaper than the P1S, making it more appealing to those looking for a higher-end 3D printer on a budget.

If you want a printer with a larger build volume and smaller footprint than the K1C, multi-material compatibility, and an easy-to-swap nozzle, then the P1S would be a better choice for you, for a slight increase in price.

Both the Creality K1C and the Bambu Lab P1S are the most appliance-like 3D printers on the market, working straight out of the box and automatically handling everything from leveling to print monitoring. You can’t go wrong with either machine.

Click here to view the Creality K1C on Amazon.

Click here to view the Bambu Lab P1S on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: