If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

K1C vs Bambu X1C

Creality K1C

(~8.75 x 8.75 x 10 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

The K1C was released in early 2024 as Creality’s improved version of the original K1 3D printer, complete with upgraded parts and solutions to many of the issues that were found in their initial K1 release, for a slight increase in price. This has made the K1C a very appealing 3D printer, with a competitive price point for what it offers. It is directly competing with Bambu Lab’s lineup of CoreXY printers and seems to be keeping up just fine.

The Bambu X1 Carbon (or X1C) was one of Bambu Lab’s first 3D printers to hit the market and really make a splash. The introduction of quality components and a much more efficient motion system than the typical bedslinger design made the X1C the single most sought-after 3D printer at the time. This release proved that the community was willing to pay an extra premium for a quality feature set and high-speed capabilities. The race to see who could make the most competitive CoreXY 3D printer has begun. Two years after its release, does the X1C still hold up to a printer released in 2024?

We will be going over everything that these two 3D printers have in common, as well as the key differences that make them each unique, before summarizing which printer we believe is right for you.

Similarities Between the Creality K1C and the Bambu Lab X1C

Aesthetics included, the Creality K1C and the Bambu Lab X1C have quite a few things in common.

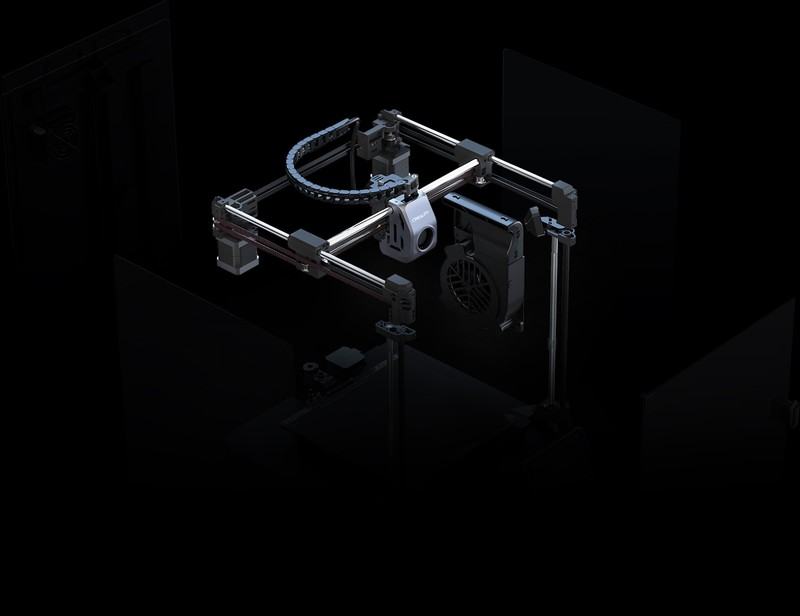

Motion System

Both printers are built with a CoreXY motion system, pairing the X-axis and the Y-axis movements together using two stepper motors that are in sync along with timing belts. The print head is moved along the X and Y axes, as opposed to moving along the X and Z axes on traditional bedslinger 3D printers. This change in the print head movement allows for an overall speed increase for the print head, as the printer is no longer moving the large print bed along the Y-axis. Instead, the print bed is only moved along the Z-axis. This design results in improved print quality and part stability while printing, as large prints no longer have the potential of being wobbled or knocked over by Y-axis print bed movements.

While Bambu Lab wasn’t the first company to create a 3D printer with this motion system, they were definitely the company to bring it to the mainstream 3D printing community and have spawned many clones as a result. We are happy to see more 3D printers moving towards CoreXY motion systems, as they offer many benefits over Cartesian designs.

Enclosure, Air Filter, and Build Quality

Both the Creality K1C and the Bambu Lab X1 Carbon come with a fully enclosed frame, glass door, and a removable top cover. While the enclosure keeps the motion system hidden and safe, its main purpose is in printing engineering-grade materials that require a consistent ambient temperature during printing to prevent warping, layer separation, and poor adhesion. Both of these enclosures are capable of keeping ambient temperatures around 40°C during printing, making them compatible with a wider range of materials than open-air frames. Enclosures give 3D printers a more appliance-like appearance and provide an extra layer of protection for your machine, making it safer to have around children and pets.

Both machines come with a carbon-activated air filter built into the enclosure that filters out foul odors and harmful fumes that are produced when printing some of the higher-grade materials. This is a necessity for many materials and is very nice to see included on both of these machines.

Finally, the build quality on both of these printers is great. The frame frame on the Creality K1C is made from a one-piece die-cast aluminum, while the Bambu Lab X1C uses stamped metal and aluminum side panels. This creates a very durable frame that will help dampen vibrations made by the motion system. The use of linear rods in the motion system will provide it with much-needed durability. While some users have criticized the choice to use carbon-fiber rods on the X1C, we have not found any discernible difference in print quality or durability when compared to traditional linear rods.

Extruder and Hotend

Both The Creality K1C and the Bambu Lab X1C use very similar all-metal direct-drive extruders. The dual-gear design gives these extruders additional grip on the material and increased extrusion force and speed for a higher flow rate. Removing the use of any plastic parts means these extruders will last you a long time even when printing with abrasive filaments. We much prefer direct-drive extruders over Bowden-style extrusion systems as they are much easier to work with, and maintain, and provide better results when it comes to stringing and printing with flexible materials.

The hotends on the Creality K1C and the Bambu Lab X1C also use all-metal designs that are capable of reaching temperatures around 300°C, making them compatible with a much larger range of materials than much of the competition.

Part Cooling

Both printers are equipped with a single-part cooling fan on the print head that shoves air through a duct and is spread evenly toward the printed part for better overhang performance. When printing at high speeds, a single printhead fan is not enough to sufficiently cool printed parts. To combat this, these printers also include a large chamber fan that blasts cool air toward the printed part, massively increasing the machine’s cooling capabilities and making for a very noticeable improvement in print quality and overhang performance when printing at high speeds. These chamber cooling fans are noticeably louder than normal cooling fans and make up the bulk of the noise produced by these printers. You will want to keep this in mind should you be looking for a printer that doesn’t make a lot of noise, as these machines are not the type to go unnoticed in the same room as you.

Automatic Leveling

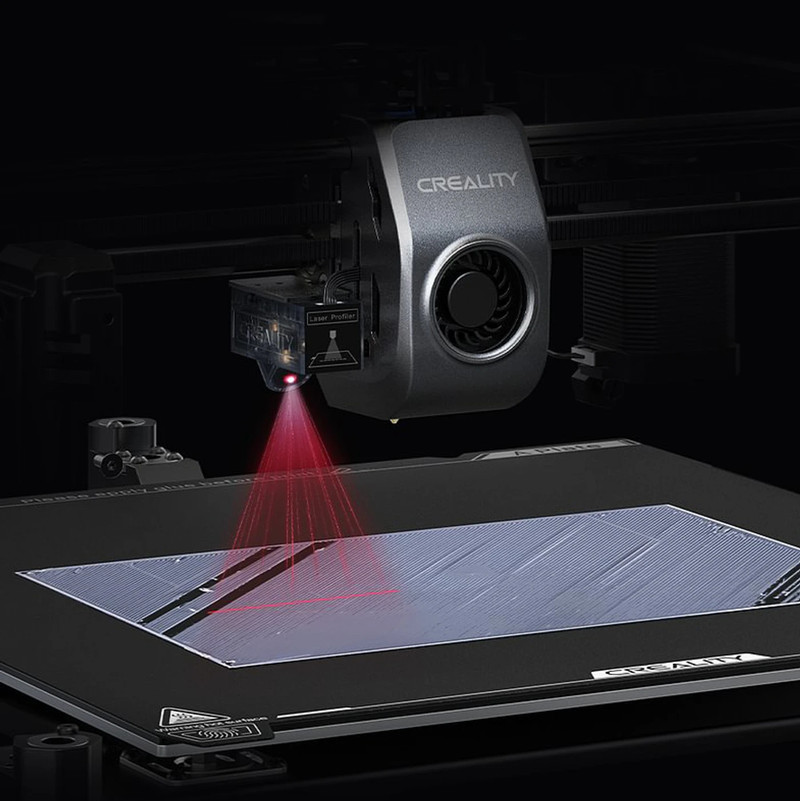

One of the biggest appeals of the Bambu Lab X1C on its release was the inclusion of several smart sensors to make homing, Z-offset, bed mesh leveling, and consistent material feeding all automatic. These were features that were previously seen on high-end 3D printers. Now, even many of the recent budget 3D printers include automatic bed leveling sensors and auto Z-offset capabilities, eliminating much of the frustration that comes with troubleshooting an uneven bed.

Both the Creality K1C and the Bambu Lab X1C feature a full set of auto-leveling sensors, with a mix of strain gauges and load cells to tell the machine where the nozzle is and offset it from the print bed accordingly. This makes for near-perfect first layers and improved bed adhesion for all of your prints.

The X1C takes this a step further than the K1C with the inclusion of a Lidar sensor. This sensor is used before every print to check for inconsistencies in extrusion width and force and compensates accordingly to provide very consistent print results. The Lidar sensor was met with a lot of hype in the community, with many praising its inclusion. Some users have reported no discernable difference in print quality when disabling the Lidar sensor or comparing prints between the X1C and similar machines that do not use the Lidar sensor. This has been the case in our tests as well. While this sensor does provide some peace of mind, it is a nice-to-have and not a necessity.

Display and File Storage

Both the Creality K1C and the Bambu Lab X1C come with full-color touchscreen displays that are used to control the printers. These displays are much larger than the average LCD display, with the K1C equipped with a 4.3” screen while the X1C has a slightly larger 5” inch display. Touchscreen displays are far from necessary for day-to-day printer operations, though they do make the user experience much easier and more enjoyable.

Both machines are capable of offline printing using local storage devices. The Bambu Lab X1C still uses the traditional micro-SD card for file storage, while the Crealtiy K1C has moved on to the more modern approach of using USB devices. While there is no discernable difference in performance between the two devices, USB storage is preferred as new users are more likely to own additional USB storage devices and are less likely to lose them over tiny SD cards.

Connectivity and Camera Monitoring

Being able to wirelessly connect to your 3D printer over your local home network and begin print jobs without having to physically be near your printer is a very nice feature that more and more printers today are implementing. This was another key feature for the X1C on its release and has been applied to the K1C as well. Both printers connect to your home WiFi and allow for wireless access to controls and print jobs.

Both printers are also shipped with built-in AI cameras that allow you to remotely monitor your printer’s progress. These cameras also come with smart AI print failure detection that will notify should your print begin to fail, pausing the print for you to inspect. This is a very nice feature to have that will save you from wasting filament on failed prints, especially if you are new to 3D printing.

Both cameras are capable of recording your print jobs and creating a time-lapse for you to view and share later on. It is worth mentioning that the camera on the K1C uses a very low frame rate of about 5 fps, while the camera on the X1C is capable of recording at 30 fps for a smoother viewing experience. If built-in time-lapses are an important feature for you, the X1C will deliver a better overall experience with quality recordings.

Firmware

Both the Creality K1C and the Bambu Lab X1C are running off of variations of the Klipper firmware, an open-source project that is specifically tuned for high-speed 3D printing while maintaining as much print quality as possible.

The K1C uses the Crealtiy OS firmware, Creality’s in-house variation on Klipper. Crealtiy has maintained the open-source nature of Klipper by allowing its users access to the source of their firmware. This means that those who like to mod their printers and add new software features can do so with the K1C.

Bambu Lab, though they use Klipper variations inside of their printers, has not made their firmware open-source. This makes it nearly impossible to modify or make changes to the X1C software. You will be stuck with using the machine however Bambu Lab intended. This is not a concern for the average 3D printer owner and should not be taken into consideration at all by a beginner. Only experienced 3D printer owners may prefer the K1C for its modding capabilities and open-source firmware.

Filament Compatibility

Both the Creality K1C and the Bambu Lab X1C are compatible with most 3D printing materials on the market. They are of course capable of printing many of the most popular materials, such as PLA, PETG, and TPU. The enclosures and use of a 300°C hotend make them both the perfect machine for printing ABS and ASA. The all-metal hotend and inclusion of an air filter allow these printers to confidently print with polycarbonate and carbon-fiber filament blends. If you are looking for a printer that is capable of printing just about any material you want, you can not go wrong with either of these choices.

Assembly

Most CoreXY 3D printers are shipped preassembled, making them very beginner-friendly and a good choice for print farms that do not want to spend additional time setting up printers before putting them to work. Both the Crealtiy K1C and the Bambu Lab X1C share this trait. Little actual assembly is required after unboxing these machines. You will need to remove any protective packaging surrounding the motion system and install that spool holder and screen to the front of the printers. After that, you are free to begin first-time calibrations. You should be starting your first print out of the box after only 10-15 minutes of setup.

Many higher-end 3D printers, especially CoreXY printers, are moving towards an appliance-like user experience, working straight out of the box and removing much of the headache that comes with assembling and manually calibrating lower-end machines. These two printers are among the easiest 3D printers to set up.

Differences Between the Creality K1C and the Bambu Lab X1C

You may notice that these printers have a lot in common, making it tough to see why you would choose one over the other. This is where the differences come in.

Print Speed

A large factor that makes CoreXY printers so appealing is the raw speed that the motion system offers. Faster print speeds mean your prints will take less time to complete. The Bambu Lab X1C was one of the first 3D printers released to the public marketed with a maximum print speed of 500 mm/s. This was largely unheard of at the time and still makes the X1C one of the fastest 3D printers available.

The Creality K1C, using largely the same motion system as the X1C, is capable of reaching print speeds of 600 mm/s, 100 mm/s faster than the X1C. It is important to remember that, when comparing maximum print speeds, the average user will almost never reach the marketed maximum speed when using these machines, especially if they are trying to maintain decent quality in their prints. You will more realistically be using a print speed of around 300 mm/s on the K1C and 250 mm/s on the X1C. This does still give the K1C an edge over the X1C, though only slightly.

If you like to draft many different 3D designs and need a printer that can churn out test prints as fast as possible, the K1C will give you slightly better performance than the X1C. For the average user, the difference in speed is largely negligible.

Build Volume and Size

Build volume is an important feature on 3D printers, especially if you like to print larger props and costume pieces. The Creality K1C has a build volume of 220 x 220 x 250 mm(8.6” x 8.6” x 9.8”), which is standard for many of Creality’s 3D printers. This gives you plenty of space for the average print and enough space to fit multiple models on the print bed at a time. You may feel pressed for space when trying to fit large models on the printer such as helmets. The printer itself is about 428 x 428 x 527 mm (16.8” x 16.8” x 20.7”) in size. Fairly bulky, even for a CoreXY machine.

The Bambu Lab X1C has a build volume of 256 x 256 x 256 mm (10” x 10” x 10”). This is much more sizeable than the K1C and will allow you to print larger files with no issues. The size of the X1C totals to 389 x 389 x 457 mm(15.3” x 15.3” x 17.9”), two inches shorter than the K1C while managing a larger build volume. If you do not have a lot of space on your shelf or desk and want a printer that efficiently makes use of this space, the X1C is the clear winner here.

Print Surface

The Creality K1C comes with a textured PEI print surface. This is our favorite type of print surface as the textured face gives prints something to cling to for additional adhesion. The print surface is flexible, making it very easy to pop prints off of the bed once the surface has cooled down. This print surface requires very little maintenance when compared to the alternatives. Be sure to clean the bed with isopropyl alcohol to remove dust and oils and you are good to go.

The Bambu Lab X1C comes with either a textured PEI print surface or a smooth PEI print surface. Which one you receive with your printer is random according to their website. The smooth PEI print surface will give your prints a glass-like finish, though you will need to use a glue stick for optimal print adhesion, resulting in regular cleaning of the bed to remove residual adhesive. We much prefer the textured print surface over the smooth PEI sheet

Nozzle

Both the Creality K1C and the Bambu Lab X1C come with hardened steel nozzles that are resistant to abrasive materials and will last much longer than stainless steel or brass nozzles.

The major difference between these two machines is the design of their nozzles. The Creality K1C uses Creality’s tri-metal Unicorn nozzle, with a combination of copper, aluminum, and steel to efficiently melt and cool filament. The nozzle is quick-swappable, only requiring the removal of two screws to get the front cover off of the print head before removing the heat sock in order to unscrew the nozzle and replace it. This is a proprietary nozzle that is only found on Creality’s website.

The Bambu Lab X1C also uses a proprietary hotend assembly, with the nozzle, heat break, fan, and heating element in a single unit. This type of nozzle is far from hot-swappable. When swapping to a different nozzle, you will need to first remove the front cover of the print head that is held down by two magnets. From here, you will need to disconnect the cables running from the hotend to the breakout board before unscrewing two screws that hold the nozzle and heat break in place. You will need to reattach the cooling fan and heating elements to the new nozzle before reassembling the whole thing. This is not a beginner-friendly process at all. Luckily, Bambu Labs offers a fully-assembled hotend replacement on their website for a higher cost than the single nozzle. This gives inexperienced users a way to simply replace their nozzles without having to disassemble the entire hotend.

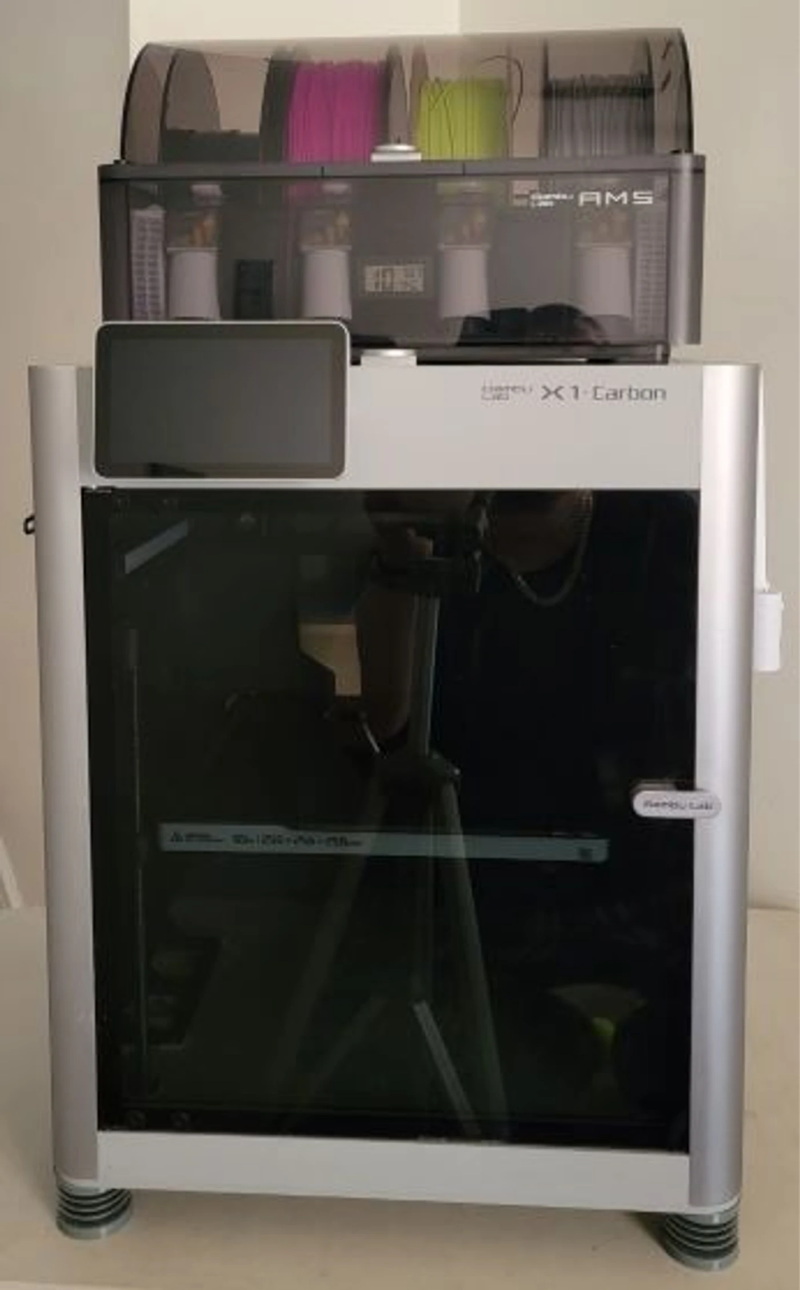

Multi-Color Printing

Bambu Lab was one of the first companies to make multi-color printing widely available for inexperienced users. The release of their Automatic Material System to accompany X1C made it the go-to 3D printer for multi-color printing up until Bambu Lab released more budget-friendly printers in the P1P and P1S, which are also compatible with the AMS unit. The AMS unit allows you to print with up to four different materials or colors of filament at a time. You can use multiple spools of the same filament and have your X1C swap between them when one spool runs out of material to ensure your print finishes with no issues. Alternatively, you can use multiple colors of filament and have your X1C swap between these colors mid-print to create seamless multi-color prints. The AMS unit makes multi-color printing very beginner-friendly when using a Bambu Lab printer.

The Creality K1C is not compatible with Bambu Lab’s AMS unit. While there are third-party multi-material systems available, they often require a lot of modding and tinkering which makes them not suitable for beginners in the hobby. Creality has yet to create its own multi-material system, leaving the K1C stuck to printing in single colors for now.

If you are very interested in printing multi-color prints, the Bambu Lab X1C with the AMS unit is your only option between these two machines and is by far one of the best options on the market.

Should You Buy The Creality K1C or The Bambu Lab X1C?

While similar in many capacities, the Bambu Lab X1C is one of Bambu Lab’s first 3D printers. It still holds up with many of today’s competitors, though it is slowly beginning to show its age. The Creality K1C provides similar performance in many areas to the X1C and exceeds it in others, being one of Crealtiy’s newer models.

Which of these printers is right for you will depend on what you want from your printer. We believe that the Creality K1C will be a more appealing option to the average user when compared to the Bambu Lab X1C. The K1C offers slightly improved print speeds with similar print quality and convenience features to the X1C at almost half the price of the base X1C. This doesn’t even include the cost of the AMS unit, which will significantly increase the price of the X1C when compared to the K1C. For these reasons, the K1C is our choice printer.

There is a good argument to be made for the X1C, however. It comes with a noticeably larger build volume, an improved AI camera that is great for making quality time-lapses, and, like all of Bambu Lab’s 3D printers, is capable of using the AMS unit for multi-color printing. These are solid points and may be the deciding factors for many. If you are looking for a high-end machine that you can add to your print farm for showing off videos of your prints and need something that can print in multiple colors, the X1C is a very compelling option. If you are looking for one of the most capable 3D printers with a mid-to-high-range budget, you will be more than satisfied with the Crealtiy K1C.

Click here to view the Creality K1C on Amazon.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: