If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Prusa CORE One vs Bambu Lab X1C

Prusa CORE One

(~10 x 8.75 x 10.75 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

Prusa is one of the most enduring names in 3D printing and has earned a reputation for making high-quality, hobbyist-friendly machines, but until recently, almost all of their 3D printers have been the classic “bedslinger” Cartesian design. This has changed with the Prusa CORE One, an enclosed CoreXY machine that seems like it was aimed squarely at the Bambu Lab X1C, one of the most popular 3D printers in the market today.

As a much younger company, Bambu Lab doesn’t have the same long history in 3D printing as Prusa, but their lineup of printers have become a go-to choice for many hobbyists and professional users. Their machines are known to be reliable, fast, and capable of producing very high quality printed models. The Bambu X1C is their flagship machine, and although the design is already a few years old as of this writing, it’s still a class-leading 3D printer. With the CORE One, has Prusa come up with a design that will finally unseat the X1C’s recent dominance?

In this article, we’ll compare the Prusa CORE One to the Bambu Lab X1C to help you determine which of these high-end 3D printers is the best choice for you. We’ll look at the similarities and differences between the machines and explain the key differentiating features, as well as giving you our recommendation for which of these 3D printers may be the better choice for you.

We’ll start by looking at the similarities between the machines.

Prusa CORE One and Bambu Lab X1C Similarities

The Prusa CORE One and Bambu X1C have several similar features. We’ll discuss each one in this section and point out the small differences in how each manufacturer implemented each feature.

Physical Size

The 3D printers have the same approximate physical size:

- Prusa CORE One: 415 x 444 x 555 mm (16.3” x 17.5” x 21.8”)

- Bambu X1C: 389 x 389 x 457 mm (15.3” x 15.3” x 18.0”)

The CORE One is larger than the X1C, but only slightly. This is not a meaningful difference, and both printers are impressively compact compared to older bedslinger designs. If you have a cramped workspace, either of these machines is a great choice due to their small footprint and enclosed design.

The only exception is that if you want to print with multiple colors or materials, Prusa’s MMU3 takes up substantially more space than Bambu Lab’s AMS. We’ll cover this difference in a dedicated section later in this article.

Hotend and Extruder

The Prusa CORE One and Bambu Lab X1C both use a direct-drive extruder paired with a metal hotend, allowing you to print with almost all common 3D printing materials. The hotends can heat up to similar maximum temperatures (300° C for the Bambu and 290° C for the Prusa) and both support a variety of nozzle sizes and types, including hardened steel nozzles suitable for printing with abrasive materials.

The Prusa CORE One uses Prusa’s “Nextruder” design first introduced on the Prusa MK4S. This extruder/hotend has a few welcome improvements, such as a quick-swap hotend design and an improved comprehensive cooling system. In comparison, the hotend on the Bambu X1C requires removing a few screws to swap, but since most users shouldn’t need to swap the hotend very often, we don’t see this as a major difference between the machines.

Cooling-wise, the Prusa CORE One should be slightly more capable of quickly cooling filament as it prints, which should improve overhang quality. In practice, we have rarely noticed any issues with overhang performance on the Bambu X1C and don’t anticipate that the Nextruder’s cooling upgrades will make a notable difference in print quality in regular use, so we feel that the printers are fairly equivalent in this regard.

Print Bed

Both 3D printers use a magnetic flexible print bed surface that can be easily removed from the print bed for cleaning, replacement, and easier part removal. You can easily purchase replacement print bed surfaces for either machine–the CORE One is compatible with Prusa MK4S beds, and the X1C is compatible with almost all of Bambu Lab’s bed offerings. It’s also easy to find aftermarket print bed surfaces for either machine.

The Prusa CORE One includes a smooth PEI bed with the printer, while the Bambu X1C includes a textured PEI bed. We like PEI as a bed surface because it’s easy to clean and offers excellent first-layer adhesion. Between smooth and textured, this mostly comes down to your personal preference for which surface finish you prefer on the bottom of your printed models.

Print Speed

One advantage to the CoreXY motion system on both of these printers is that they’re capable of very high print speeds. This was an area that Bambu Lab really pushed forward in the consumer 3D printer market when they released the X1C, and even today, the X1C’s 600 mm/s maximum print speed is competitive with the fastest consumer 3D printers. Although most 3D printers don’t run at their maximum speed for the entire printing process, the high print speed does result in noticeably less time spent waiting for a part to finish printing.

Prusa doesn’t advertise a maximum print speed for the CORE One, but instead prefers to focus on quoting print times for a few sample parts. Based on their quoted times, we estimate that the Prusa CORE One is roughly as fast as the Bambu X1C. It may be slightly faster or slightly slower depending on the part, but probably not by enough for you to notice. This is a welcome improvement over some of Prusa’s older machines, which offered excellent print quality but were noticeably slower than Bambu’s printers.

Print Quality

Both the Prusa CORE One and Bambu Lab X1C are capable of producing excellent-quality 3D prints due to a combination of hardware and software features. On the hardware side, these printers are built with sturdy frames and use the CoreXY motion system, which results in less vibration during printing. They also include sensors to measure resonance and other mechanical properties of the machine, enabling them to compensate for any vibration during printing.

On the software side, both companies have developed firmware features such as input shaping and pressure advance, which tweak the motion of the print head and the flow of melted filament to further improve print quality. We’ve noticed a marked improvement in print quality with many newer 3D printers since these features have become more widely used, and Prusa and Bambu are both known for excellent print quality across the board in their machines.

Controls and Display

Both printers include a color touchscreen controller, which is a modern feature we appreciate seeing on these premium machines. The Bambu X1C’s display is larger–it’s a 5” display compared to the 3.5” display on the Prusa CORE One. The Prusa also has the option of controlling the printer with a dial controller, but we find the touchscreen to be a preferable control method.

Connectivity and Wireless Printing

Both printers include WiFi connectivity and allow you to remotely control and monitor the printer from a computer or smartphone, although the Prusa offers a bit more flexibility with the network connectivity features.

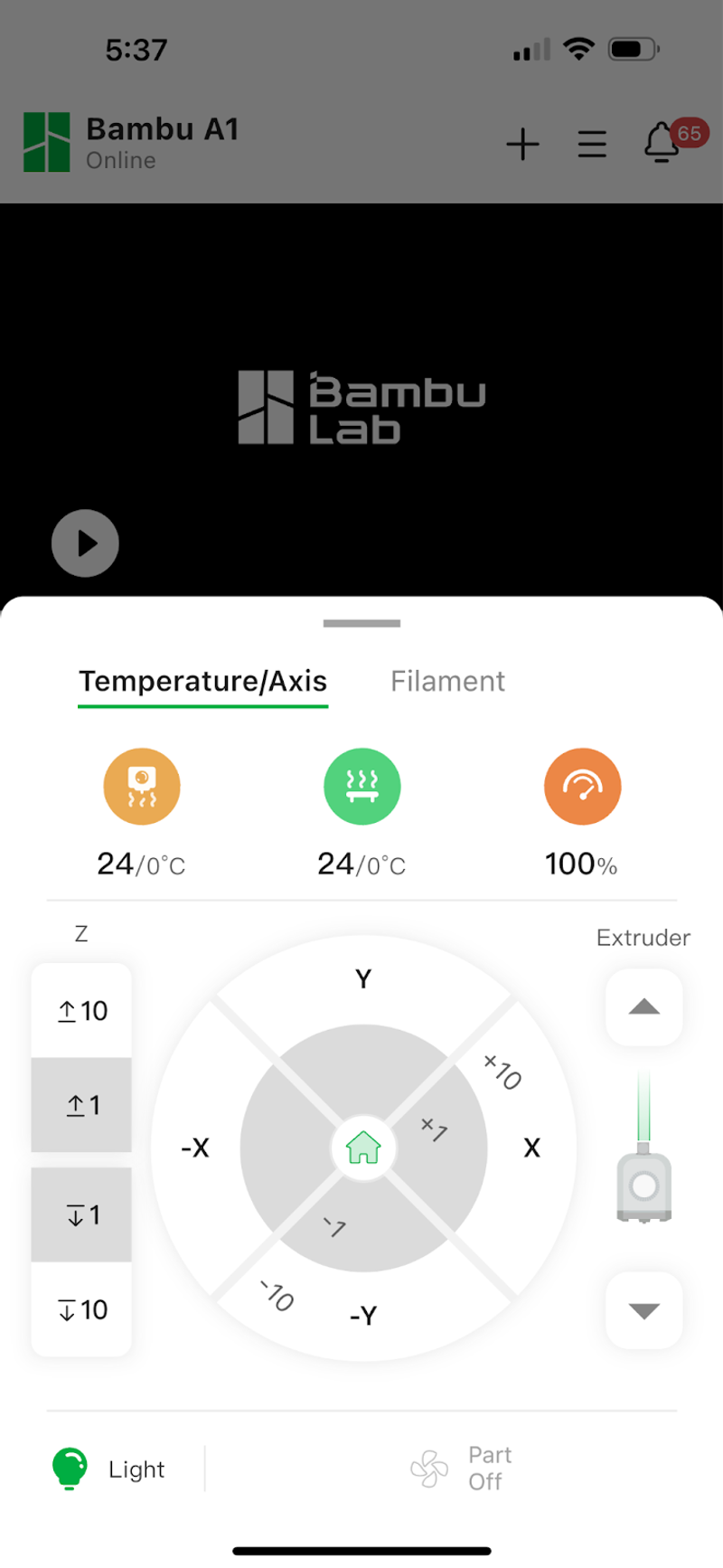

On the Bambu X1C, you can use the Bambu Studio application on a computer to slice 3D models and upload the gcode to the printer. You can also use the Bambu Handy smartphone app to monitor prints and control the printer, in addition to selecting and printing models from Bambu’s online library. Both apps also let you view the camera in the X1C’s build chamber to visually monitor your prints.

On the Prusa CORE One, you can use the Prusa Connect cloud app on either a phone or computer to control and monitor the printer. This web-based application also works with the PrusaSlicer slicing software, allowing you to slice 3D models and directly upload the gcode to your printer. The CORE One supports Ethernet in addition to WiFi, allowing you to hardwire the printer to your network if desired. The X1C only has WiFi.

For users who are in a security-conscious environment, the CORE One might be an attractive choice due to the Ethernet connectivity as well as the ability to completely remove the WiFi module.

On either printer, you can load gcode files directly onto the machine for printing if you don’t want to use the wireless connectivity. The Bambu X1C supports a microSD card, similar to many older 3D printers, while the Prusa CORE One has a USB-A port for USB flash drives.

Setup Experience

Both 3D printers ship fully assembled and include automated calibration and bed leveling systems, making them extremely easy to set up and start using. Gone are the days of having to spend hours building a 3D printer and even more hours calibrating it, which we’re very thankful for.

With either printer, you can expect to need to carefully remove some packing material, zip ties, and a few screws which secure the moving parts for transport. But once you’ve done that, you can simply plug the machine in, turn it on, and follow the onscreen instructions to calibrate it and run your first print.

Although both manufacturers provide a fully-assembled option and that’s our preferred approach, Prusa does intend to offer a kit version of the CORE One at a slight discount. From what we’ve seen on other Prusa 3D printers, you can expect the assembly process to be fairly involved, but with clear instructions to guide you through the process. This can be a good way to get to know the inner workings of your 3D printer, so if you’re mechanically-inclined and interested to learn more about the details of how the printer works, this could be a good option to consider.

Prusa CORE One and Bambu Lab X1C Differences

The Prusa CORE One and Bambu X1C do have some important differences which may affect which of these 3D printers is a better choice for you. We’ll cover the differences in this section and explain how it might impact your experience with each machine.

Build Volume

The two machines have fairly similar build volumes:

- Prusa CORE One: 250 x 220 x 270 mm (9.84” x 8.66” x 10.63”)

- Bambu X1C: 256 x 256 x 256 mm (10.07” x 10.07” x 10.07”)

The Prusa CORE One has a slightly larger Z axis, but the Bambu X1C is larger in the X and Y axes. We consider both of these 3D printers to be in the same basic size class – a build volume of 220-250 mm in each dimension is common among consumer 3D printers.

There may be some users who want to push the limits of the build volume, and if that’s you, you’ll want to pay attention to these sizes. The Prusa machine can print slightly taller objects, but we often find the X and Y dimensions to be more of a limiting factor for prints, and the Bambu printer wins in that regard.

Spool Placement

The standard way to use either of these printers is with a single spool of filament mounted on the printer’s spool holder. On the Bambu X1C, the spool holder is located on the back of the machine, which means you have to reach behind the machine (and leave some available working space) to change filament spools. This design looks clean from the front, but depending on your setup, it can be a bit annoying to work with.

The Prusa CORE One’s spool holder is mounted in a recessed area on the right side of the printer. This is much more accessible from the front and will probably be easier for most users to work with.

Enclosure

The Prusa CORE One and Bambu X1C both have a fully-enclosed design, which enables the use of filament types such as ASA and ABS, as well as keeping curious children and pets away from the moving parts of the printer. Both printers also include a temperature sensor for the ambient air in the chamber, and can run a cooling fan to maintain a specific temperature within the chamber. However, there are some key differences in how each printer’s enclosure works.

First, the Prusa’s enclosure door has a few improvements compared to the Bambu’s. It can open to a full 180 degrees and the hinges can also be flipped to either side, allowing you to decide which way the door opens. These features make it easier to accommodate the CORE One’s enclosure door to your workspace. And although both 3D printers have a door sensor, only Prusa has actually demonstrated a use of that sensor–it can pause a running print when you open the door. The X1C has the sensor, but it doesn’t do anything in the current firmware for the printer.

Prusa also advertises that the Core ONE can print PLA and PETG with the enclosure door closed, thanks to a small air vent you can open to introduce room-temperature air into the enclosure. Many Bambu users have found that they get better print quality with these materials by propping open the top of the X1C’s enclosure or by opening the door during printing. It remains to be seen whether the CORE One’s air vent actually addresses this concern with PLA and PETG, but Prusa seems confident that they’ve solved this common issue.

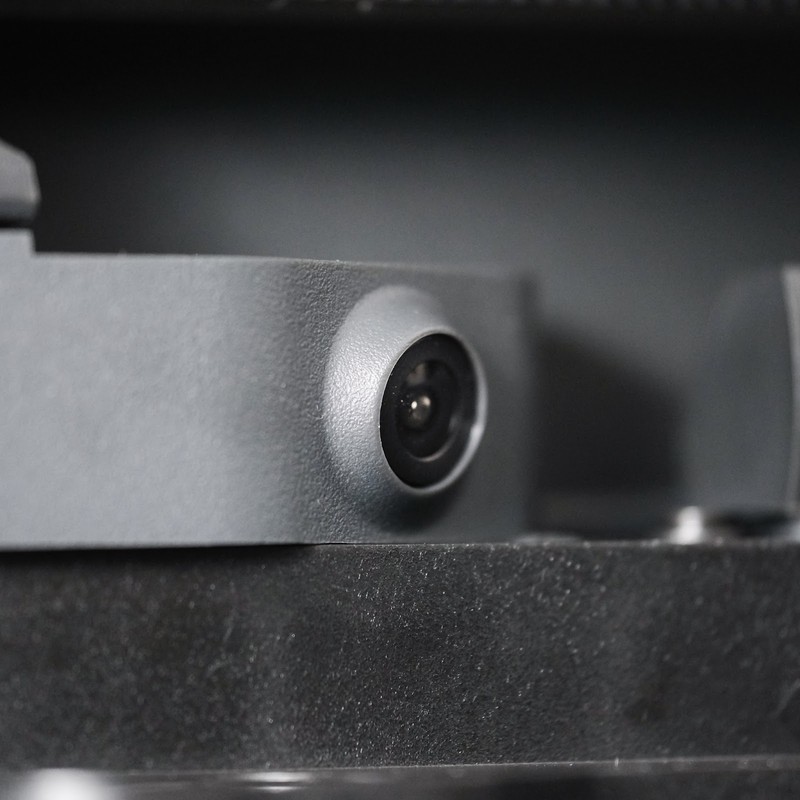

Camera

The Bambu X1C has a built-in camera, which allows you to monitor ongoing prints, create timelapse videos of prints, and automatically detect certain types of printing failures. Unlike most of Bambu’s other printers, the camera in the X1C is higher quality and can stream video to the app at a reasonable framerate, making it more useful for monitor prints. This is a great feature that we’re happy to see included with the printer.

Prusa doesn’t include a camera with the CORE One, but will be releasing a compatible camera add-on through their new “Buddy3D” brand of accessories. We don’t have any details on this camera or its capabilities, but it’s likely to be reasonably priced and Prusa seems to have designed the CORE One to have this camera installed, so we expect it to be a clean installation. However, it’s a part you would have to buy separately for the CORE One rather than being included with the printer.

Multicolor 3D Printing

One of the most significant differences between the two printers is their support for multicolor (or multi-material) 3D printing. Both machines do support multicolor, but their systems are quite different.

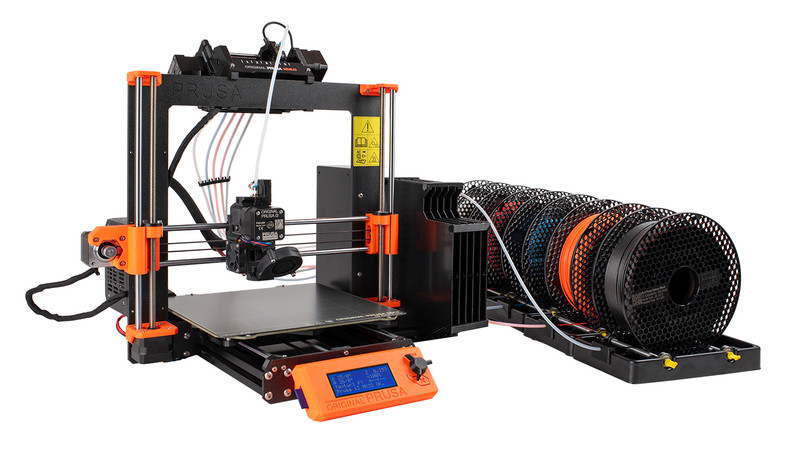

The Bambu X1C supports Bambu Lab’s Automatic Material System (AMS), which is an add-on that allows you to feed up to four different types or colors of filament during a print. This enables you to print in multiple colors, as well as switch over to a new spool when one runs out of plastic, or print with soluble support material to make post-processing easier. However, to use the AMS you’ll need to use the Bambu Studio slicer software or the open-source OrcaSlicer software, as it’s not supported with other third-party slicer applications. If you want to use more than 4 colors or materials at a time, you can chain up to 4 AMS units together for a total of 16 available colors for a single print.

Bambu Lab sells the AMS separately on their site, or you can buy a combo kit that includes the X1 Carbon and the AMS.

The Prusa CORE One supports the Multi-Material Unit 3, or MMU3, which supports up to five different types or colors of filament. It functions similarly to the Bambu AMS, but one difference is that while the AMS is self-contained and can sit on top of the printer, the Prusa MMU3 separates the filament spool holders from the filament feeder, requiring you to mount the spools separately or store them on the desk next to the printer. Similar to the Bambu AMS, you’ll need to use Prusa’s own PrusaSlicer software to slice models when using the MMU3.

Prusa sells the MMU3 on their site, but you’ll have to buy it separately–at the time of this writing, they do not offer a combo kit of the CORE One and MMU3.

The AMS and MMU3 provide similar capabilities and are priced similarly. The MMU3 does offer an additional color in the base unit, and some users have reported that it wastes less filament than the AMS during color changes. However, the MMU3 is far less compact than the AMS unit, and particularly with these enclosed printers, it takes up substantially more desk space than the AMS. You also do not have the option to chain multiple MMU3 units together, so you’re limited to 5 colors or materials.

Repair and Upgrade Potential

One of the most significant differences between the Bambu X1C and Prusa CORE One is their repair and upgrade potential. In short, Bambu Lab requires you to use their parts and isn’t very open to hardware upgrades, while Prusa is compatible with many third-party parts and has more upgrade potential.

Bambu Lab’s approach to 3D printers is to provide a machine that is fully assembled and calibrated, and that handles almost all of the complexity of 3D printing for you. However, the trade-off is that their firmware is closed-source and only works with the specific hardware configuration that they’ve defined for each of their printers. This means you can’t meaningfully change the hardware or electronics on the X1C, and you’ll need to use Bambu Lab’s own parts for most repairs. Bambu Lab does sell a full range of repair parts on their site, so the machine is still user-serviceable.

On the other hand, Prusa fully embraces the open-source roots of 3D printing and the CORE One is much more accessible for upgrades than the Bambu X1C. The firmware for the CORE One is open-source, which means you can update the printer firmware to support any hardware or electronics upgrades you choose to add. The CORE One is also compatible with many third-party repair parts, giving you more options for buying any parts you may need. Prusa even sells a GPIO Hackerboard add-on, which lets you easily power and control third-party or custom-built electronics for your printer.

Whether this difference matters to you comes down to whether you want to deeply understand the hardware of your 3D printer and upgrade your machine. If you enjoy working on electronics and mechanical systems, and like the idea of continually improving your printer, the Prusa CORE One offers much more potential and flexibility than the Bambu X1C. But if you don’t have the desire to modify the printer hardware, and want to focus only on 3D printing models, you can still easily maintain and repair the Bambu X1C using Bambu Lab’s selection of repair parts.

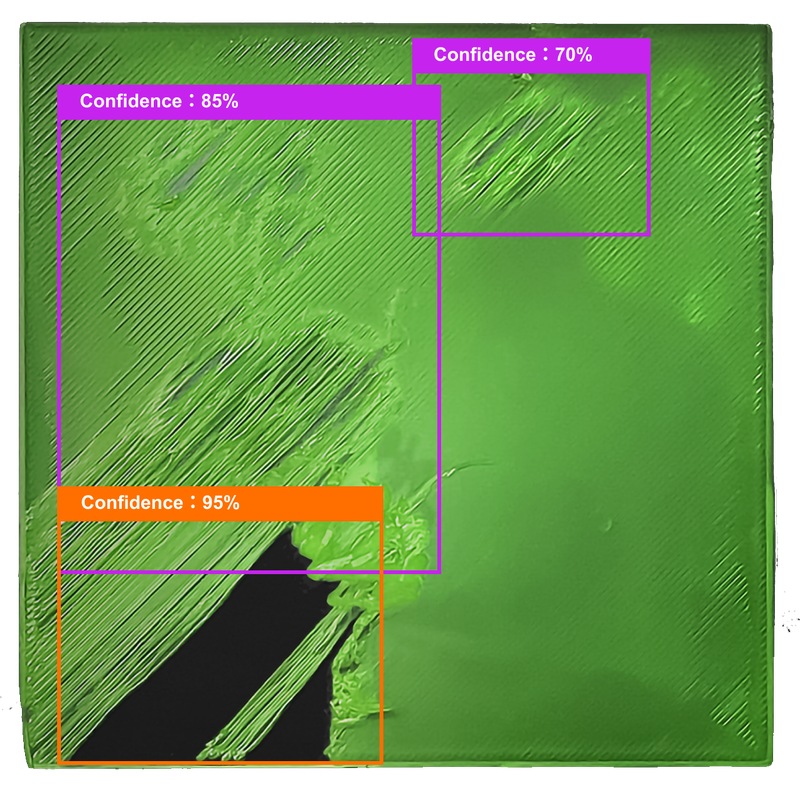

Lidar Sensor

The Bambu Lab X1C includes an optical Lidar sensor, which it uses in a few ways to improve the printer’s automatic calibration and fault detection.

As the first layer prints, the Lidar sensor scans the extruded filament and precisely measures its height and width. The X1C is able to use this information to calculate the flow rate of the filament, which allows it to automatically configure the flow rate. Since this is normally a calibration setting you’d have to set yourself for new brands or types of filament, the sensor makes things easier. It can also detect some issues with the first layer, such as peeling or inconsistent extrusion, potentially stopping a failed print early.

Additionally, the Lidar sensor measures the bed height during bed leveling, acting as a second check for the X1C’s strain-based automatic leveling system. We’ve seen very consistent results from Bambu’s strain-based leveling system, but this is an added measurement that can help the machine level its bed more precisely.

While these features aren’t necessary, they fit in well with the X1C’s promise of a more automated 3D printing experience. The Prusa CORE One doesn’t have this sensor.

Should You Buy the Prusa CORE One or the Bambu Lab X1C?

As you can see, in many ways the Prusa CORE One and Bambu Lab X1C are similar 3D printers. They both offer excellent print quality, fast print speeds, and modern connectivity and app control features. They’re both enclosed and use the CoreXY motion system, giving them the ability to print almost any 3D printing material at a high level of detail. And both manufacturers have a high reputation for making reliable machines, so we feel that you can trust either of these 3D printers to perform well.

If your priority is a simple user experience or if you want to do multicolor 3D printing without taking over an entire desk, the Bambu Lab X1C is probably the right choice for you. Bambu Lab has made 3D printing more approachable than it has ever been before, and in many cases their machines truly are hands-off as far as calibration and maintenance. We’ve been very pleased with the print quality and speed of our Bambu printers, and the X1C’s feature set makes it well-suited for almost any kind of 3D printing.

The AMS add-on for multicolor printing is a game-changer, making it simple to print multicolor objects or simply select a single color on-demand at the beginning of a print. In comparison to the Prusa CORE One with the MMU3, we appreciate the compact design of the AMS. The Bambu X1C with an AMS on top fits nicely into a reasonably-sized workspace and has a clean, modern look. This is a 3D printer that you can have fun with or use for work without needing to become an expert in 3D printing.

If you’re interested in the customization and tinkering aspects of 3D printing, as well as the open-source origins of the hobby, the Prusa CORE One will give you more of what you’re looking for. Prusa continues to embrace the 3D printing community, providing open-source firmware and significant customization potential with the CORE One. While you can easily find repair parts for either of these printers, the CORE One has much more support for third-party or custom-built upgrades.

But with the CORE One, Prusa also appears to have closed the gap substantially with Bambu in terms of the physical design and ease of use of their machines. As Prusa’s first fully-enclosed printer, the CORE One has a similarly clean and compact appearance as the Bambu X1C, and its automatic calibration procedures match the X1C, allowing you to easily get up and running with your first 3D prints. This is the first Prusa 3D printer we’ve seen that feels truly approachable for a user who doesn’t want to tinker with their printer, although the CORE One certainly gives you that opportunity if you want it.

Overall, it’s hard to go wrong with either of these 3D printers. They both sit on the higher end of their respective lineups, but you generally do get what you pay for in terms of design, ease of use, and overall capability.

If you’d like to check out these 3D printers in more detail, you can use the links below to view them on the manufacturers’ websites, or continue down to see a side-by-side spec comparison.

Click here to view the Prusa CORE One.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: