If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Prusa MK4S vs Bambu Lab A1

Prusa MK4S

(~10 x 8.25 x 8.75 in)

Vs.

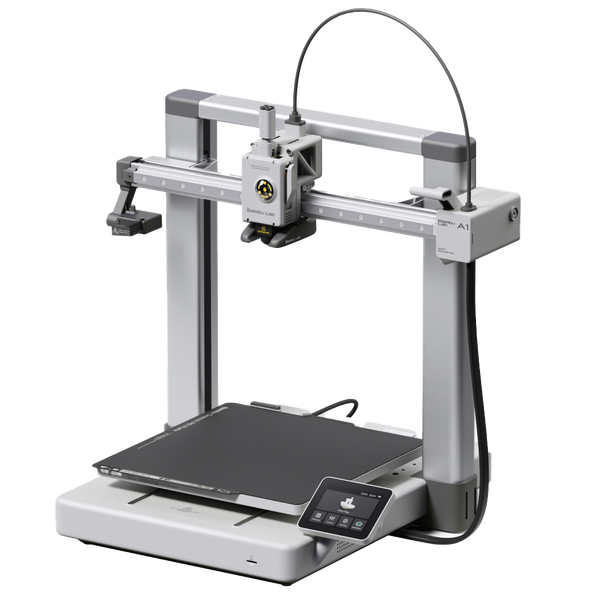

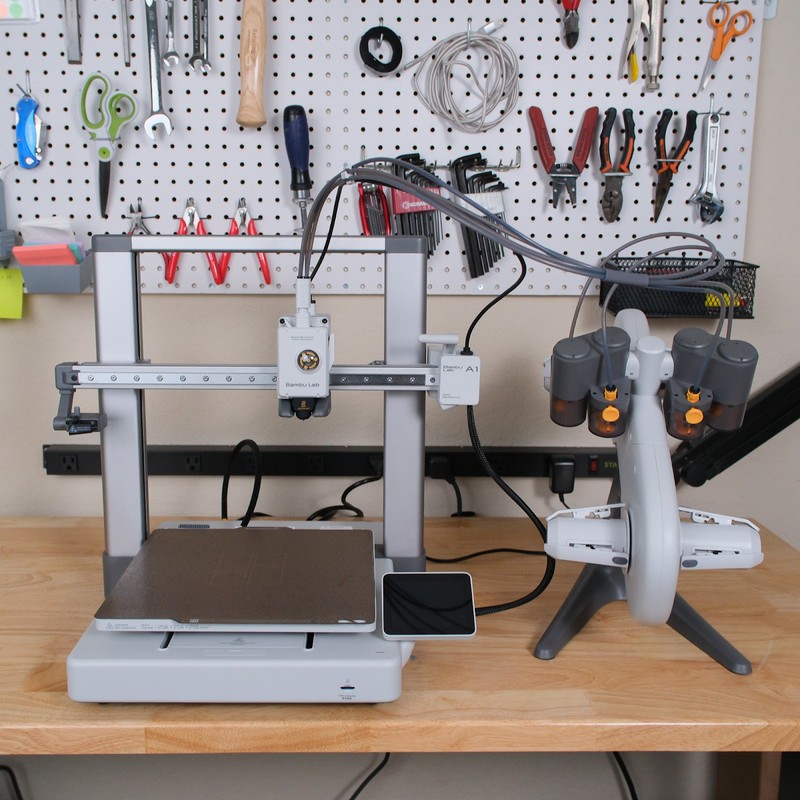

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

In the current 3D printing market, Prusa and Bambu Lab are certainly two of the leading brands for high-end consumer printers. To be honest, we’d started to feel like Prusa wasn’t keeping up with the modern features that companies like Bambu Lab have been introducing recently, but in August 2024 Prusa released the new Prusa MK4S which seems to address some of those shortcomings.

On the other hand, the Bambu Lab A1, which came out at the end of 2023, has proven to be an excellent machine, especially considering its affordable price. The question is, how does the A1 stack up against the newer and more expensive Prusa MK4S? We decided to compare these printers head-to-head to find out.

In this article, we’ll look at the similarities and differences between these two 3D printers. For each feature, we’ll explain how each printer implements the feature and why it may or may not matter to you. We’ll also give you our recommendations for how you should decide between the two machines.

Similarities Between the Prusa MK4S and the Bambu Lab A1

The Prusa MK4S and Bambu Lab A1 share several similar features. For each of these, we’ll point out the small ways in which the two printers differ.

Filament Compatibility

The MK4S and A1 are both compatible with the same set of 3D printing filament types, and can print almost all filament types. Both printers use 1.75mm diameter filament, which is by far the most common size. Both printers can heat the hotend to around 300 degrees C (the MK4S advertises 290 degrees C) which is sufficient for printing many standard materials such as PLA, PETG, and TPU. Neither printer will be able to print high-temperature materials such as nylon, which can require temperatures well in excess of 300 degrees C.

Although both printers are technically capable of printing ABS and ASA, we wouldn’t recommend doing so without an enclosure. These materials are sensitive to air drafts, and can tend to warp during printing if an enclosure is not used. Those materials also tend to give off an unpleasant odor during printing, which may bother you if you’re sensitive to smells in your work area. Although neither printer includes an enclosure by default, Prusa does sell a rather expensive enclosure that fits the MK4S. On the A1, you’d need to rig up an aftermarket enclosure to print with ABS or ASA.

Both printers use a direct-drive extruder, so they can easily print flexible filament such as TPU.

Print Speed

We believe the MK4S and A1 to have similar maximum print speed in most situations. Prusa doesn’t advertise the maximum speed and acceleration of the MK4S, which prevents us from giving a direct numeric comparison, but they’ve clearly made improvements in print speed with the MK4S compared to their previous models. From what we have seen, it’s competitive with the A1, which we know to be a very fast 3D printer.

It’s worth pointing out that 3D printers tend to spend very little time at their maximum speed. Due to model geometry and the quality settings you choose, the printer will typically print most of the model at a slower speed. For that reason, we think it’s best to not pay too much attention to the maximum speed figures as they tend to not represent the reality of how long a print will take. Both the MK4S and A1 are very fast machines that are capable of printing models much more quickly than the 3D printers of a few years ago.

Print Quality

Both the Prusa MK4S and the Bambu A1 are capable of producing excellent-quality 3D prints. The MK4S has a few features that may give it a slight edge over the A1, especially for overhangs, but in our opinion these differences are small enough to not be a major decision factor.

Both printers include advanced firmware features to improve print quality, such as pressure advance and input shaping. In our experience, these features do provide a noticeable benefit and result in cleaner prints. The two printers are running different firmware, so the exact implementation of each feature is likely to be slightly different, but both companies have extensive experience with these types of optimizations and both machines seem to implement the features well.

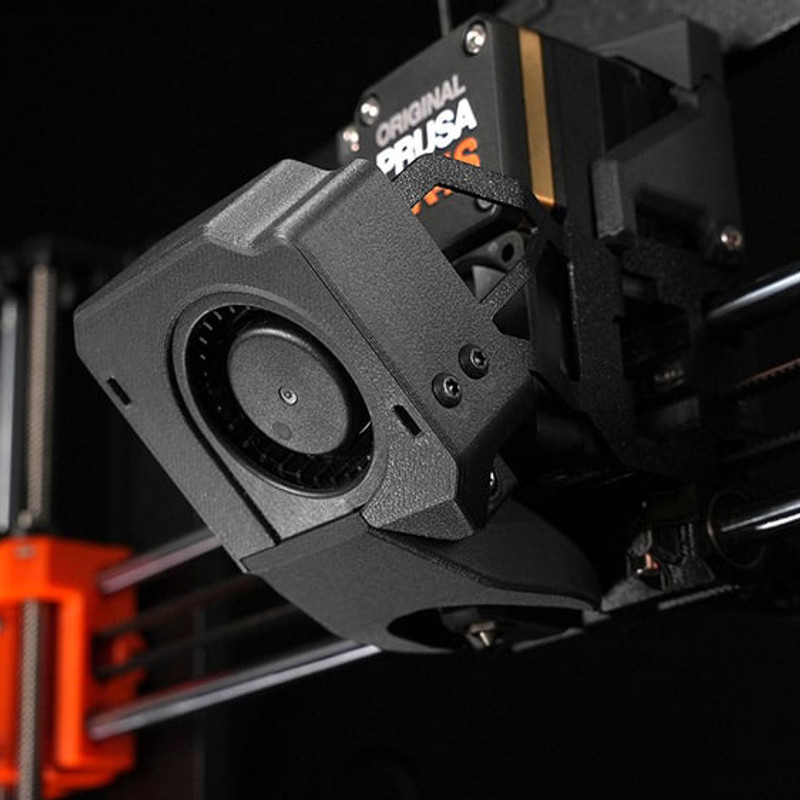

One of the big improvements in the Prusa MK4S is an improved part cooling system which provides more complete coverage all around the nozzle rather than just blowing on the part in one direction. We’ve certainly seen issues on other printers that cooled only from one side, so this is a welcome change that should improve the MK4S’s ability to print overhangs. However, the A1 also has a well-engineered cooling fan duct that provides fairly even coverage around the print, so it’s no slouch in this area.

Overall, we don’t think you should buy one of these printers over the other based on print quality—both machines are well above average for consumer 3D printers in this regard, and produce very high-quality prints.

Screen and Controls

The MK4S and A1 both include a full-color LCD display for viewing the status of the printer and navigating menus, which is a modern feature that we’re happy to see on both machines. The screen on the MK4S is a bit larger, but this isn’t a meaningful difference in usability.

As far as controls, the printers do differ slightly. The MK4S uses a physical control knob, while the A1’s screen is also a touchscreen controller that you can directly interact with. Both systems are usable, but we prefer the touchscreen on the A1. It’s a capacitive touchscreen and is very responsive, and we find it a bit more intuitive than the knob controller on the MK4S.

WiFi Connectivity and App

Both the MK4S and A1 include WiFi connectivity and both brands have a smartphone app and computer application that you can use to wirelessly control and send prints to their respective printers. This is a feature we’ve grown to really enjoy on modern 3D printers, and with the MK4S, Prusa has started to catch up to Bambu Lab and other manufacturers in this area.

Both machines do include a way to load GCode files for printing without using the app—the MK4S has a USB port, and the A1 has a microSD card slot. Additionally, both printers are able to be used without being connected to the Internet, which is an important consideration for some customers. However, between the two, the Prusa MK4S seems to treat the app as more of an optional way of interacting with the printer, while on the other hand the Bambu A1 treats the app as the primary way of interacting with the printer, with the physical controls being a secondary method.

With either company’s app, you can browse their model repositories (Printables for the MK4S and MakerWorld for the A1) and print a model directly from the app if the model includes print settings. We love the ability to do this and find that it makes 3D printing much more accessible for new users.

Automatic Bed Leveling

Both printers include automatic bed leveling using a strain gauge based system in which the nozzle touches the bed surface in a grid pattern across the bed, allowing the printer to precisely compensate for variations in bed height during the print. This is a great feature of modern machines that has removed one of the major frustrations of 3D printing, and it performs consistently and accurately on both the MK4S and A1.

Physical Design

The Prusa MK4S and Bambu Lab A1 both use a standard Cartesian “bedslinger” design, where the print bed moves back and forth in the Y axis. The print head runs along an X axis gantry which raises in the Z axis during the print. This is a simple, well-tested design that is very common for FDM 3D printers.

Both printers include a spool mount which fits onto the top of the printer. We prefer this design because it minimizes desk footprint, but if your workspace has low vertical clearance, you can easily print a freestanding spool holder to mount the spool next to either printer instead of on top.

Differences Between the Prusa MK4S and Bambu Lab A1

Although the MK4S and A1 have several features in common, the two machines certainly have some important differences. We’ll cover each one in this section and explain how it may factor into your decision between the two 3D printers.

Build Volume

The Prusa MK4S and Bambu Lab A1 have similar build volumes, but for some users, even small differences in maximum build volume can be a make or break decision between 3D printers.

- Prusa MK4S: 250 x 210 x 220 mm (9.84” x 8.27” x 8.66”)

- Bambu Lab A1: 256 x 256 x 256 mm (10.08” x 10.08” x 10.08”)

For many 3D prints, there is no functional difference between the build volume of the two printers. But if you need to print especially large models, the Bambu A1 does have slightly more capability in this area.

Assembly Required

The Prusa MK4S is sold in two configurations, a kit which requires assembly, and a fully-assembled 3D printer that you can pull out of the box and immediately start using. The kit is a few hundred dollars cheaper, but the assembly process is fairly involved and will take 8-10 hours to complete. Prusa does provide clear instructions for the assembly and includes all the tools you will need.

On the other hand, the Bambu Lab A1 requires a small amount of assembly. The printer is shipped in a few major pieces that must be bolted together, and you’ll need to plug in a few cables. The process only takes around 20 minutes and is clear and easy to follow.

If the idea of assembling a 3D printer intimidates you, we’d steer you away from the kit version of the Prusa MK4S. However, the assembly process of the A1 is simple enough that we think any user will be able to easily complete it without frustration. The fully-assembled version of the Prusa MK4S is the easiest option, but it’s also by far the most expensive.

Multicolor Printing

The Prusa MK4S and Bambu Lab A1 both support multicolor or multi-material 3D printing, but the way they implement this optional feature has some major differences that are worth discussing.

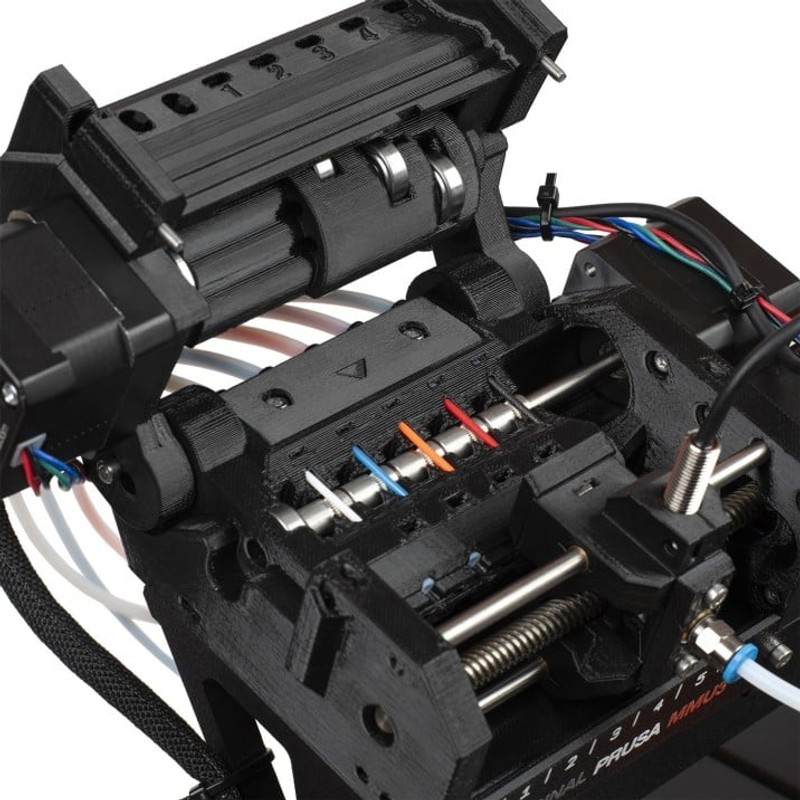

The Prusa MK4S supports Prusa’s MMU3 (Multi-Material Unit 3) add-on, which allows you to use up to 5 different filament spools during the print. The MMU3 is shipped as a kit and must be assembled, and it takes up quite a bit of desk space because it requires a fairly large filament buffer unit and all 5 spools to be sitting on the desk next to the machine. The MMU3 is also more expensive than Bambu’s add-on.

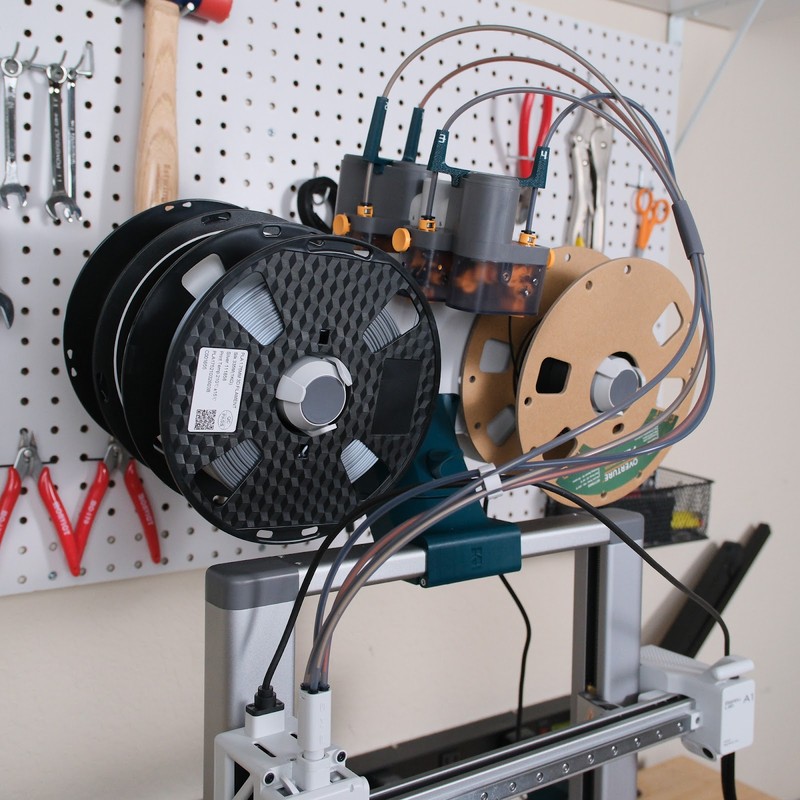

The Bambu Lab A1 supports the Bambu AMS Lite, which allows you to use up to 4 different filament spools during the print. The AMS Lite is shipped as a nearly-assembled unit with only a few parts that need to be pressed together to begin use. By default, it sits on the desk next to the printer, but Bambu Lab provides 3D model files for a printable mount to put the AMS Lite on top of the A1. We prefer this option for a more compact setup.

When you print with the MMU3 on the MK4S, the printer will print a “wipe tower” next to the model you are printing, which it uses as a way to purge the old color of filament when you switch to a new color. This makes multi-color prints slower than single-color prints, but it does avoid purging filament waste off to the side of the printer.

On the other hand, the A1 includes a filament cutter and purge area, which allows the printer to purge some waste filament off to the side of the printer when you change colors. Annoyingly, the A1 doesn’t include a container to catch this waste filament, so most users end up printing a small purge bucket to put next to the printer to catch the waste. Even with this system, most multi-color prints on the A1 will benefit from a wipe tower to help prime the nozzle for the next color, although that wipe tower can typically be smaller than the Prusa version since it doesn’t have to purge the old color.

Overall, it’s hard for us to say that either of these systems is better than the other, but they are certainly different. The Prusa system is much more expensive and must be assembled, which are downsides. It also takes up more desk space than the Bambu system. On the other hand, it doesn’t require a purge bucket and supports one extra filament spool than the Bambu system. We personally have more experience with the Bambu AMS Lite and are very pleased with its performance, but the Prusa MMU3 seems like a solid system as well.

Upgrade Potential

Perhaps the most substantial difference between the Prusa MK4S and Bambu Lab A1 is their upgrade potential. This is an area where the MK4S provides many more options than the A1.

First, the Bambu A1 doesn’t really have many upgrade options. You can switch to different nozzle sizes and change the print bed surface, and can purchase the AMS Lite multi-material add-on for multicolor 3D printing. But beyond that, the A1 doesn’t offer much support for aftermarket upgrades. It’s important to note, though, that Bambu does sell a wide range of repair parts for the A1. Lack of support for upgrades does not mean lack of support for repairs.

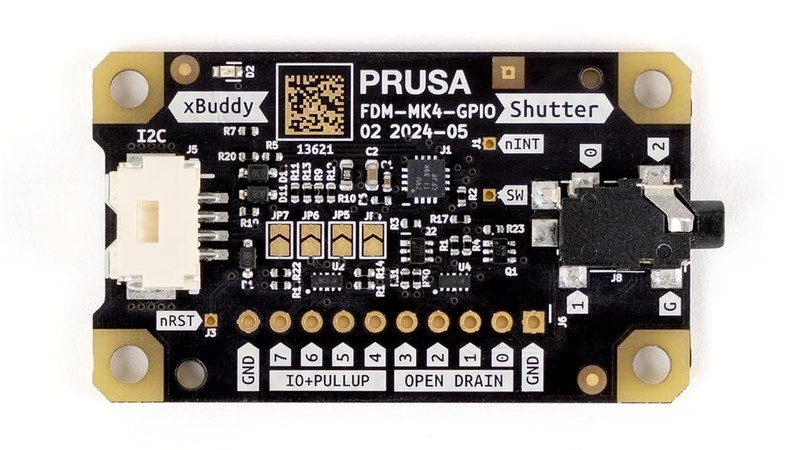

The Prusa MK4S is much more upgradable than the Bambu A1. It supports a wide range of aftermarket upgrade parts, and the printer design is open-source to make it easy for other manufacturers to design compatible parts. For the MK4S, Prusa even created a “Hackerboard” add-on which plugs into the printer and gives you access to some general-purpose I/O pins for controlling custom accessories such as LED light strips. The overall support that Prusa provides to the hobbyist community for modifying their printers is beyond almost all other 3D printer manufacturers.

The fundamental difference here between the MK4S and A1 is this: if you want to set up your 3D printer and use it without thinking about upgrades or customizations, the Bambu A1 provides everything you need out of the box and is an excellent 3D printer, but doesn’t offer much support for using it outside its default configuration. On the other hand, if the idea of upgrading your 3D printer excites you, the Prusa MK4S is going to offer way more for you in that area.

Camera

The Bambu A1 includes a built-in camera which allows you to monitor ongoing prints using the Bambu Handy smartphone app or Bambu Studio computer application. The camera quality is lacking, especially in terms of framerate. The camera feed looks more like a slideshow than a smooth video. But it does give you the ability to easily check on the print if you aren’t right next to the machine.

The MK4S doesn’t include a camera, so if you want to monitor your prints remotely on that machine, you’d need to use an external webcam.

Price

The Prusa MK4S is much more expensive than the Bambu Lab A1. At the time of this writing, the MK4S is sold as either a $799 kit or a $1099 fully-assembled printer, and as we discussed previously, the kit requires a rather involved assembly process. If you want to use the MMU3 multi-material add-on, that’s currently an additional $300.

On the other hand, the Bambu Lab A1 is regularly $400, and can be purchased in a combo kit with the AMS Lite multi-material add-on for a total price of $560, making it a much more cost-effective option.

It’s up to you to decide whether the price is a factor for you in your decision, but we don’t feel that the Prusa MK4S is twice as good of a 3D printer than the A1. In our opinion, it’s a case where the MK4S is probably a bit more expensive than it should be, and the A1 is surprisingly affordable. That combination of factors makes the price a stark contrast in this comparison.

—-

Which 3D Printer Should You Choose?

The Prusa MK4S and Bambu Lab A1 are made by two of the most well-known manufacturers in the 3D printing market, and both are excellent machines. They share a surprising number of features, which can make it hard to decide which printer is a better choice.

The Prusa MK4S is the most capable standard-size 3D printer Prusa has ever released, and they’ve brought their design into the modern age with features such as app connectivity. It’s a fast, reliable printer that is capable of producing excellent-quality 3D prints. It also offers good multicolor printing support through the MMU3 add-on. Most distinctively, Prusa embraces the open-source community and you can upgrade the MK4S in a wide variety of ways, making it a great choice if you find the idea of tinkering with your printer appealing.

The Bambu Lab A1 is one of the best deals in 3D printing right now. It’s an extremely capable printer, with essentially the same speed, reliability, and quality of the Prusa MK4S. Bambu Lab’s software experience is second to none, so it’s also one of the easiest-to-use 3D printers we’ve tested. The AMS Lite add-on allows you to add multicolor 3D printing capability for a low cost. But with the A1, you’re essentially buying a completed 3D printer that doesn’t have significant upgrade potential. For some users, that makes it an even more appealing option, while for others, it might be a detractor.

Ultimately, the choice is up to you, but the points we’ve covered in this article encompass the important differences between the two 3D printers. You can use the links below to view both of them on their respective online stores:

Click here to view the Prusa MK4S.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: