TPU Filament Detailed Guide

TPU filament is a common choice for 3D printing due to its high temperature resistance and ability to flex without breaking. However, TPU can be a challenging filament type to 3D print due to its demanding temperature requirements and potential for warping during the printing process. In this guide, we’ll cover the appearance and properties of TPU filament, our suggested settings for 3D printing TPU, and the filament brands we recommend.

TPU Appearance

- Usually somewhat glossy

TPU has an appearance similar to most other 3D printing filaments. Most colors are somewhat glossy, although it’s possible to find matte colors in some cases. Most TPU is opaque, although there are a few translucent color choices. Although TPU is stretchy, the color of the printed model doesn’t tend to change when stretched.

TPU Strengths

- Very flexible, like rubber

- Fairly high temperature resistance

TPU is the most popular flexible filament type, and is frequently used for applications that require the printed model to flex or stretch. TPU’s rubbery consistency makes it perfect for phone cases, drone parts, and other applications that need a high degree of flexibility. Although TPU prints are not indestructible, it’s typically difficult to rip or break a properly-printed TPU model. Of course, this flexibility means that TPU isn’t a good choice for structural brackets or other prints that need to reliably hold shape.

TPU also has a fairly high temperature resistance of 175-210° F (80-100° C), or even higher for some special variants. This makes it an appropriate choice for prints that will be exposed to high ambient temperatures, such as inside a car on a hot day.

In terms of flexible filament options, TPU offers a lot of advantages and is a good default choice for any application that needs a flexible, stretchy material.

TPU Weaknesses

- Difficult to 3D print

- Must be printed slowly, and is prone to jams on Bowden extruders

- Typically requires cleanup after printing due to strings

The main weakness of TPU is that it is a challenging filament type to 3D print. It must be printed slowly to avoid jamming in the extruder or hot end, since it’s harder for the extruder to push flexible filament than rigid filament. For the same reason, retraction isn’t as effective when printing TPU, which means you may have to trim strings from the completed print. Even when printing slowly, it’s difficult to print TPU without getting any stringing.

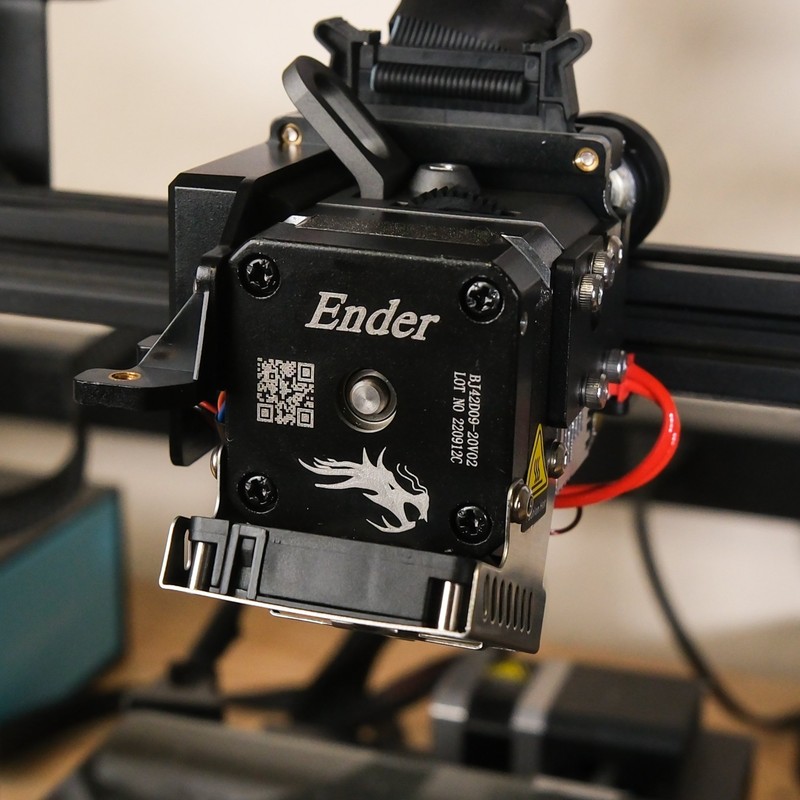

TPU is significantly more difficult to print with a Bowden extruder due to the long tube between the extruder and hot end. The increased filament travel distance causes the flexible TPU to bind up or stretch if it’s printed or retracted too quickly, which leads to the issues described above. Therefore, we highly recommend a direct-drive extruder for printing TPU. Many 3D printers that come standard with a Bowden extruder can be upgraded to direct-drive—for example, this Sprite extruder [Amazon link] from Creality allows you to convert popular Creality 3D printers to use direct-drive.

If your 3D printer has a Bowden extruder, you can still print TPU, but you’ll need to print it very slowly and will likely need to spend more time trimming strings on the completed model.

How To 3D Print TPU

To 3D print TPU, you will need to print slowly, and preferably with a direct-drive extruder.

To avoid jams, you should print slowly—as low as 10-15 mm/s if you’re using a Bowden extruder. On a direct-drive extruder you can print a bit faster, but we recommend starting slow for your first TPU prints to judge whether the extruder and hot end can handle more speed. Although the print may take longer, you’ll make up the time by having less cleanup and a lower chance of print failures.

One way to reduce the difficulty of printing with TPU is to use a more firm variant. The flexibility of TPU filament is measured in shore hardness. The lower the shore hardness number, the more flexible the filament. The difficulty of printing TPU increases with the amount of flexibility, so lower shore hardness TPU is more difficult to print. For this reason, we recommend choosing the highest shore hardness value that will work with your application. Here are some examples of common shore hardness values you may see when shopping for filament:

- Shore 100A: Most rigid form of TPU, and most useful if impact resistance is the priority. Not very flexible.

- Shore 95A: Most common for TPU. Similar hardness to a skateboard wheel.

- Shore 85A : Softest TPU normally available. Similar hardness to a shoe heel.

TPU requires a hotend temperature higher than that of PLA, but well within the range of almost all 3D printer hotends. The bed temperature should be 55-60° C, which matches PLA. TPU doesn’t typically have issues sticking to the print bed while printing, especially at the slow print speeds we recommend.

Our recommended slicer settings for printing TPU are:

- Hotend temperature: 220° C

- Bed temperature: 55° C

- Print speed: 15-25 mm/s

- Retraction amount: Disabled completely

- Part cooling fan: Disabled

Recommended TPU Filament Brands

There are several brands of TPU available, and we’ve generally had good experiences with the ones we have used. TPU tends to be a bit more expensive than other filament types, but you can sometimes offset the increased cost by purchasing a smaller spool—unlike other filament types, TPU is often available in smaller quantities, such as 500g (1.1 lb) spools.

These are a few of the brands we recommend for TPU filament:

- Overture TPU [Amazon]: Overture is a filament brand we trust, and their TPU filament has printed reliably for us.

- Matterhackers Build Series TPU [Matterhackers]: Matterhackers is another reliable choice for filament, and their MH Build Series TPU is a great value, especially if you buy multiple spools at once.