If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

The Evolution of the Sovol SV06

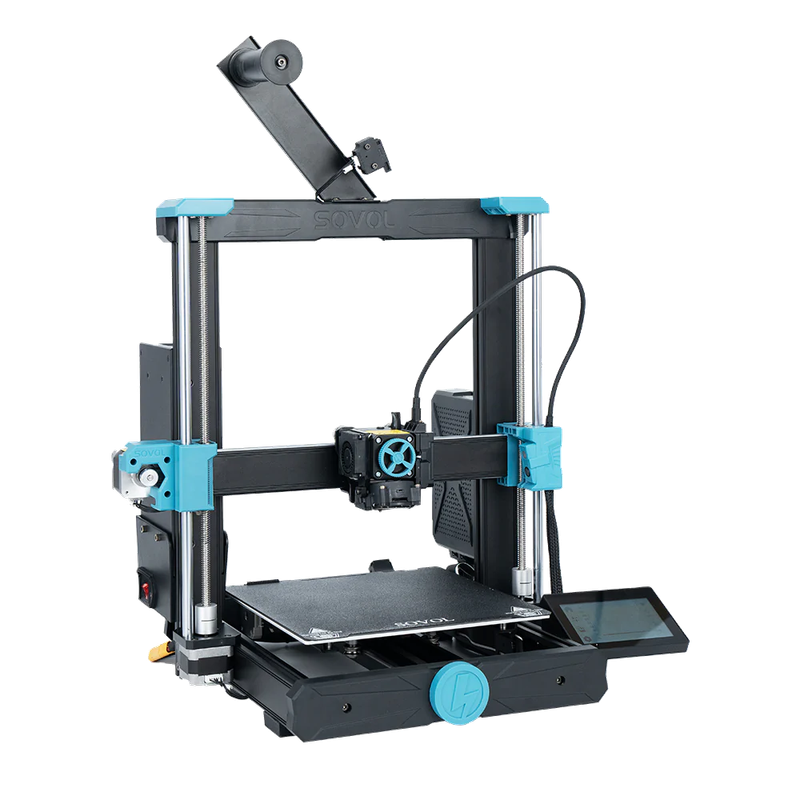

The Sovol SV06 is an interesting 3D printer. It was released in October 2022 when the industry was in the end stages of reacting to the success of the Creality Ender 3 and making clones. But it went in a different direction and was a clone of the Prusa i3 MK3S+. The Prusa MK3S+ was a far more expensive printer than the Creality Ender 3 because it used expensive components - linear rods and bearings on all axes and a direct extruder.

The linear rods are very stiff and deflect very little as components move on the axes, leading to excellent print quality. They offer excellent support to the heavy direct extruder and the bearings don’t wear nearly as much as V-slot wheels do. The direct extruder was only available in high-end printers when the SV06 was first released. Early direct extruders were very heavy, limiting speeds, limiting acceleration and causing ringing artifacts on the print as the extruder is accelerated or decelerated and it “bounces” on the drive belt.

Sovol equipped the SV06 with linear rods on all axes. There are two rods on the X axis, supporting the extruder from the top and the bottom. Each side of the Z axis rides up and down on linear rods. There are also two rods with wide spacing on the Y axis to give the bed a wide stance and increase stability. They also developed a new dual steel gear all-metal direct extruder with a very innovative design that keeps weight and size down yet exerts high torque on the filament using a planetary gear drive. Sovol’s planetary gear drive is at a 6.5:1 gear ratio, which means a small, light stepper motor can exert considerable torque on the filament. The gear drive itself is quite compact.

In another innovation which keeps weight, size, complexity and cost down, the entire body of the extruder forms the heatsink. This means heat is absorbed and dissipated over a very large area with a lot of metal as compared to a conventional extruder. The back of the extruder body - the side closest to the nozzle heatbreak - has fins cast into it. The heatsink fan is directed here to dissipate most of the heat and prevent the heat from softening the incoming cold filament. In operation, the extruder body gets only warm to the touch.

All electrical components and sensors are connected to a breakout board on the back of the extruder and only one multi conductor cable runs back to the mainboard. Many other 3D printers at the time had one cable for each component, leading to a thick cable bundle and difficult replacement of components.

This design was so successful that Sovol has reused it ever since, on the SV06 Plus, the SV07, the SV07 Plus and the SV08.

The SV06 has a few shortcomings:

- no automatic Z offset. This is because it uses a non-contact induction probe to detect the bed - like the Prusa MK3S+. Because the probe activates well before the nozzle tip touches the bed, and because this distance can vary unit to unit, it can’t be used to set Z offset. It’s just not accurate enough for this use. No other budget machines had this at the time though.

- no bed height adjustment wheels. While this eliminates a source of frustration for many users, it means the user is entirely dependent on the bed leveling system. Since no bed is perfectly flat, the bed leveling has to work perfectly. Any deficiency will result in first layer issues that will be difficult to address since the user has no control over the bed level.

- no filament sensor. Typical of budget machines at the time.

- monochrome LCD screen with knob. It’s functional but was getting a bit dated when it was released. Many competitors had full color touch screens by that point.

- low speed, 60mm/s. This was average for budget machines when the SV06 was released but it didn’t take long before even budget machines could print at 200mm/s or 500mm/s and made the SV06 uncompetitive in terms of speed, despite its good fundamentals.

The SV06 Plus

The SV06 Plus, released in February 2023, wasn’t just larger, it gave Sovol a chance to update the SV06 hardware. Sovol increased the diameter of the linear rods from 8mm to 10mm, greatly increasing rigidity. This was necessary for the greater distances the rods had to span, but the difference was out of proportion to the size difference of the printer. It meant that sagging and bending was virtually eliminated.

The SV06 Plus is equipped with a full color touch screen and a filament sensor. It prints at a higher speed than the SV06 due to a longer “volcano” style nozzle which has a longer melting zone, allowing a higher molten filament flow. Sovol accommodated this by cleverly reorienting the heating block to vertical. This speeds it up to 150mm/s.

There’s still no automatic Z offset - the SV06 Plus uses the same non-contact induction sensor. And there are still no bed adjustment wheels.

Did Development Stop?

Sovol then did what the rest of the industry was doing in 2023 - they developed and released a high-speed (500mm/s) 3D printer to compete with the high speed Bambu Lab printers. This is the Sovol SV07, released in May 2023.

The SV07 had a few scratching their heads. The SV06 was a brilliant, expandable design - couldn’t Sovol just equip the SV06 with Klipper and maybe an accelerometer (for resonance compensation and input shaping), speed it up to 500mm/s and call it a day? No, the SV07 goes back to V-slot wheels on all axes. This worried some people, V-slot wheels may wear very quickly at high speed - though there have not been widespread reports of prematurely wearing wheels.

Sovol equipped the SV07 with a Klipper pad (similar to a full-blown Raspberry Pi) with Klipper screen, manufactured for them by a 3rd party, MKS. This is an expensive component. Sovol may have had to cut costs on the rest of the printer and speculation was that they had to eliminate the expensive linear rods.

Wisely, Sovol kept the extruder - dressing it up with a cosmetic cover, a functional wraparound nozzle LED light, the long SV06 Plus high flow nozzle and a gigantic rear mounted part cooling fan. But it’s fundamentally the same extruder.

The SV07 performs very well, but some think that it may have been rushed to market, with a Klipper pad “bolted on” to an older, more economical design.

Was this the end of the SV06? Was it obsoleted by the SV07?

A Sleeper Software Lifeline

Very quietly, Sovol introduced new firmware for the SV06 in June 2024, along with a new SV06 printer profile for OrcaSlicer. This increases the speed of the SV06 to 150mm/s.

Well - that was easy. Just a software change and this “old” printer became more relevant. It’s free for users as well.

Surprise - the SV06 ACE

Seemingly from out of nowhere, Sovol announced the SV06 ACE in November 2024 - a fully updated and revamped SV06. The SV06 ACE speeds the SV06 up to 600mm/s using Klipper.

The SV06 ACE fully modernizes the SV06 design and catches up to the competition:

- full color touch screen

- full contact, strain-based auto leveling

- auto Z offset

- filament sensor

And it goes beyond the original SV06 design:

- 10mm Z axis guide rods, as seen on the SV06 Plus, which are much stronger and much more rigid

- metal guide rails and metal U-shaped wheels on the X and Y axes - these are very smooth and do not wear like the rubberized V-slot wheels on the SV07. They’re even more rigid than the 10mm linear rods.

- resonance compensation

- pressure advance

- built-in camera

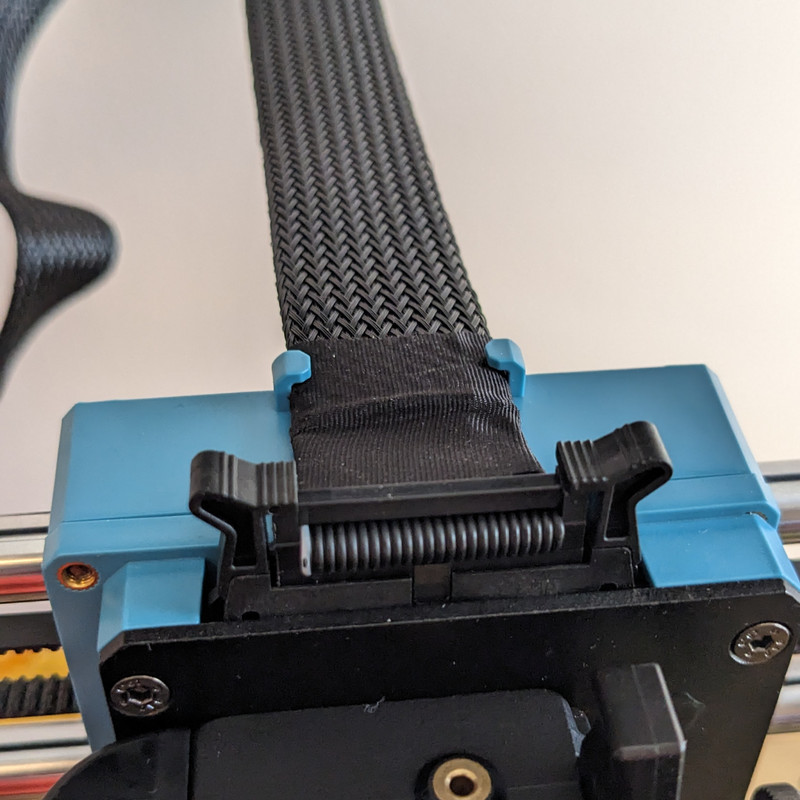

- connection of the extruder by a thin, light USB-C cable rather than a stiff, flat ribbon cable

- more powerful 4020 part cooling fan rather than a much weaker, smaller 4010 fan

- dual-sided PEI print sheet

- fast ceramic plate nozzle heater

So it seems the design had good fundamentals after all! It was able to be fully updated and Sovol added new features to make it even more competitive.

There may even be an SV06 Plus ACE (SV06 ACE Plus?) which would take all this to a larger size and give another update to the design.