If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Flashforge AD5X

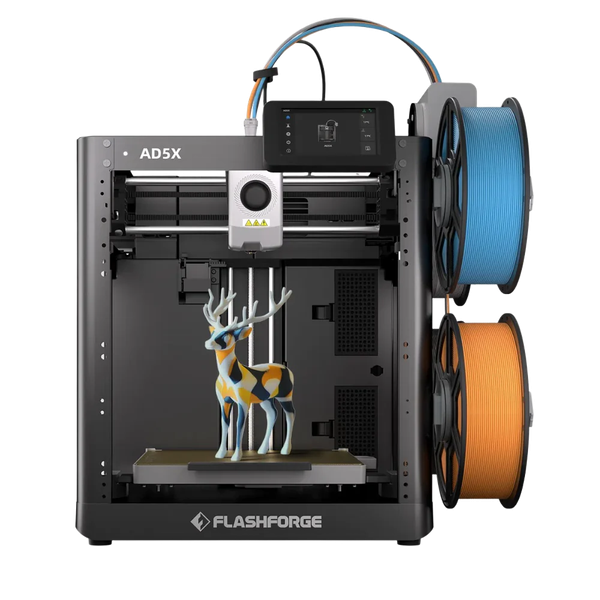

About the Flashforge AD5X

The Flashforge AD5X is a CoreXY 4-filament 3D printer. Its print volume is 220 X 220 X 220mm. It uses a very compact 4-filament feeder attached to the right side of the printer. The spool holders are mounted directly to the side of the printer in a side-by-side, 2 X 2 arrangement, feeding a 4-filament drive control module with 4 separate tubes leading to a hub on top of the extruder. The all-metal direct extruder has a maximum nozzle temperature of 300°C and the PEI coated flexible removable magnetic spring steel bed can be heated up to 110°C. Its peak maximum speed is 600mm/s with 20,000 mm/s^2 acceleration. The direct extruder is equipped with a large single high speed part cooling fan and has a quick swap nozzle. The printer uses a nozzle strain sensor and contact with the bed for auto leveling and auto Z offset. The printer interfaces to the network by WiFi or Ethernet but also has a USB port. It uses OrcaSlicer for slicing and doesn't have a phone app, an online model repository, or allow online remote control. opting instead for local control only.

Benefits of the Flashforge AD5X

Modern mainboard features - Many 3D printer features relate to the version of the mainboard and firmware, including features like resuming prints after a power failure and support for silent stepper motor drivers for quieter printing. Newer boards also include safety features like thermal runaway protection which shuts the printer down if it detects issues with overheating.

Auto bed leveling - auto bed leveling will ensure your prints have perfect first layers every time and greatly reduce issues with bed adhesion. When using an auto-leveling system, the probe allows better tolerances for slightly warped print beds by measuring and compensating for any inconsistencies. Without this feature, you'll need to adjust the bed level manually using nuts on each corner of the print bed.

Has touch screen - having a touch screen isn't a deal-maker or breaker, but it is a convenient feature that makes it easier to navigate the interface when you are printing files and configuring 3D printing settings.

Easy to assemble - This 3D printer is shipped with most of the parts pre-assembled, and you will only need to attach a few components and connect a couple cables in order to get the machine ready to print.

Direct drive extruder - Direct drive extruders are mounted right above the hot end, and push the filament directly into it, as opposed to a side mounted bowden extruder setup. We prefer direct drive extruders to bowden since they are less prone to jamming and typically require less maintenance. they also are much easier to use with flexible materials

PEI build surface has good balance of adhesion and part removal - PEI beds are one of the more premium build surface options, and for good reason. They offer great first layer adhesion with no spraysor other treatments, and can be flexed to quickly remove parts. You'll need to clean the bed with a solvent like acetone or IPA every so often to maintain the bed's adhesion.

Wireless printing - In addition to the standard USB and SD card connections, you can connect wirelessly to this printer to print from your computer or mobile device.

Linear rail motion system - Linear rails provide added stability to the moving parts of the printer, allowing higher printing speeds without sacrificing quality. Keep in mind that the most important factor to consider when optimizing for print speed is the flow rate of filament, which depends on the hot end and nozzle size moreso than the motion system.

All-metal hot end - An all-metal hot end allows for printing at high temperatures up to 300C, while standard hot ends are capped at 260C before the PTFE material begins to degrade. All-metal hot ends are also less susceptible to jamming, and do not degrade as fast.

CoreXY Kinematic System - A CoreXY 3D printer kinematic system uses two stationary motors to move the print head in the X and Y directions, resulting in faster and more precise movements compared to traditional printers. By separating the movement of the print head from the movement of the build plate, the CoreXY system is able to avoid the added weight and momentum of a moving build plate. This results in less vibration and better control of the print head, allowing for faster and more precise movements. Additionally, the CoreXY system can print at higher speeds compared to H-bot systems because it only needs to move one motor for each axis of movement, reducing the overall weight and inertia of the system.

Dual gear extruder - A dual gear extruder grips filament from both sides and can exert much more force on the filament before slipping. It helps with all filaments but especially with flexible, slippery TPU.

Where to buy the Flashforge AD5X

Brand Summary: FlashForge

Flashforge has established itself as a key player in the 3D printing industry, particularly known for its mid-priced and high-priced 3D printers that cater to a diverse range of users, from beginners to professionals. Founded in 2011, Flashforge, the first Chinese manufacturer of 3D printers, has continually expanded its offerings to include not only consumer-level printers but also models suited for educational, professional, and industrial purposes. Their products are characterized by fully enclosed designs that deviate from the typical open-frame models seen in some competitors. The brand has made a name for itself with its focus on user-friendly features such as automatic filament feeding, dual extrusion capabilities, WiFi connectivity, large touchscreens, and cloud printing. These advanced features, combined with their fully enclosed structures, position Flashforge printers as more than just tools, but as integral, user-friendly appliances in the home or professional setting. Despite their broad appeal, Flashforge faces criticism for not fully embracing the open-source movement, resulting in proprietary parts that can limit compatibility with generic components. This aspect can be a drawback for users who seek to upgrade their printers with third-party parts or who require standard-sized filament spools, as Flashforge's automatic filament feeder system is designed for narrower, brand-specific spools. However, the company offsets these limitations by offering lifetime technical support and maintaining a robust online presence, including a substantial following on social media platforms like Facebook. This support, coupled with their focus on producing printers that are quiet, enclosed, and automated, cements Flashforge’s status as a brand dedicated to creating accessible, high-quality 3D printing experiences, especially for those new to the field.

Printer Comparisons

You can compare the FlashForge Flashforge AD5X to other 3D printers using our Compare tool.