If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Creality K1 Max

About the Creality K1 Max

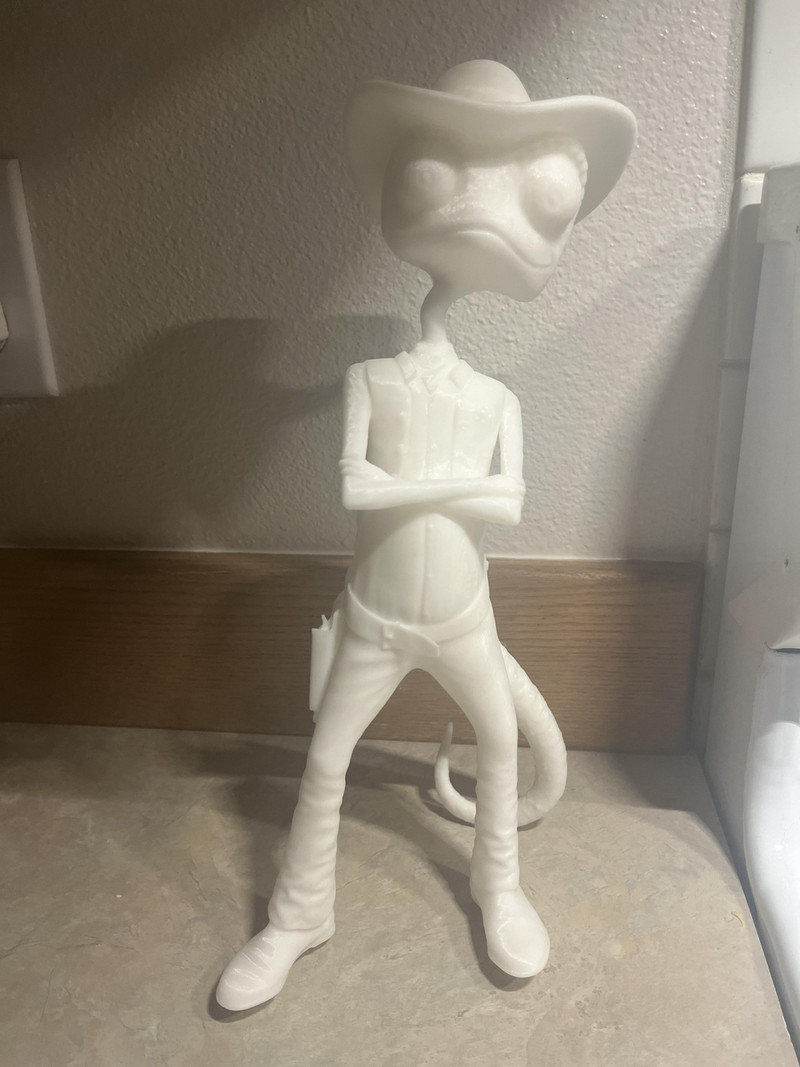

The K1 Max is the upgraded version of Creality’s K1 3D printer. It features a larger build volume of 300x300x300mm, a direct drive extruder, and high-flow hot-end design. The CoreXY motion system allows for fast print speeds of up to 600mm/s. The K1 Max is compatible with a variety of materials, from standard PLA to advanced carbon fiber-reinforced nylon. The K1 Max includes an improved extruder and hotend assembly to provide address the largest shortcomings of the K1. It improves on many of the issues seen in the K1, such as clogging issues, defective extruder motors, and frequent filament jamming. However, some issues remain on the K1 Max, such as the nozzle being difficult to change, bed adhesion problems with certain materials, and deviations in its strain-based automatic leveling.

The K1 Max comes with WiFi connectivity and an integrated camera for remote monitoring and control. AI LiDAR technology guarantees consistent and high-quality prints, and particularly improves the initial printed layers. With a modified version of Klipper firmware, the K1 Max efficiently processes gcode and optimizes its motion for more precise printing and higher quality results.

The Creality K1 series offers significantly more features than other Creality printers, targeting the high-end 3D printing market. It features user-friendly software and a touchscreen interface for a modern and easy-to-use experience. Although priced higher than other Creality printers, the K1 Max’s added features and performance capabilities make it a worthwhile investment for professionals and dedicated hobbyists, as long as you can afford it.

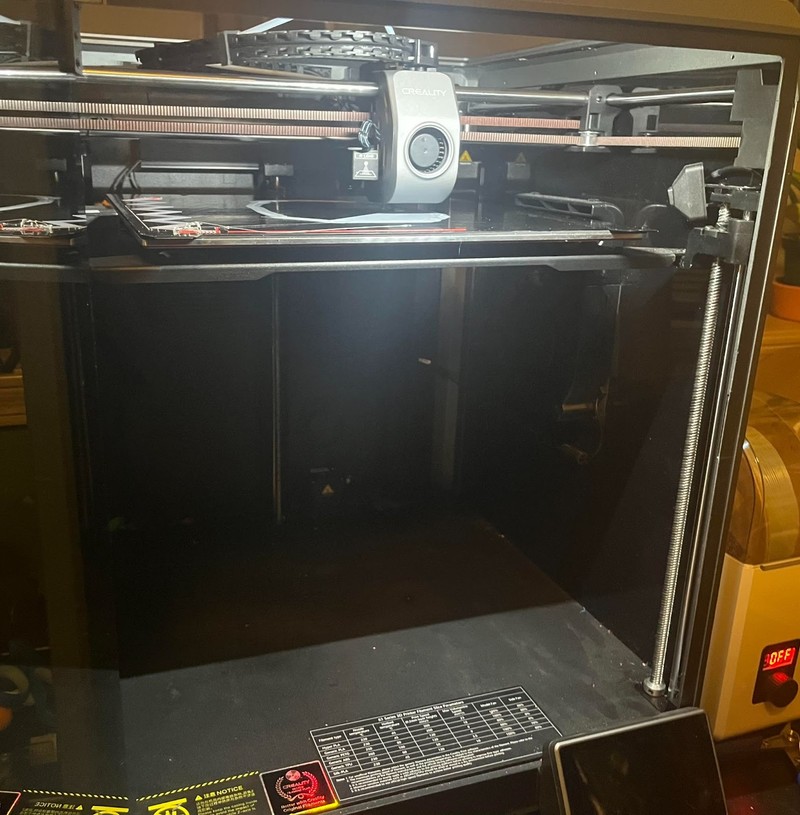

Build Volume

This printer can handle big and detailed 3D prints thanks to its roomy 300 x 300 x 300 mm (11.81” x 11.81” x 11.81”) build volume. At about 17 inches deep, it should fit fine on a regular desk, but it tends to shake a lot when printing at high speeds. With the overall volume being only a bit larger than the build volume, it’s pretty efficient with its space usage.

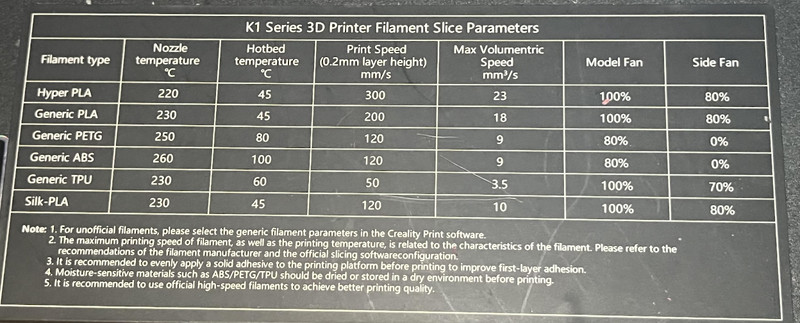

Supported Materials

The K1 Max comes equipped with advanced components like a ceramic heating block, dual gear direct drive extruder, titanium alloy heatbreak, and hardened steel nozzle, allowing for a diverse range of material options such as ABS, PLA, PETG, PET, PA, ASA, PC, TPU, PLA-CF, PA-CF, and PET-CF. Having an enclosure proves especially advantageous when working with materials like ABS, ASA, and PC, since the increased ambient heat prevents parts from warping as the plastic cools. This flexibility opens up opportunities to experiment with material properties. In our experience, we have found that optimizing printing results for different materials requires some tweaking and profile editing, but once the slicer settings are fine tuned, errors are rare, making the printer reliable for varied projects and applications.

Swapping out the nozzle can be a bit of a hassle. You’ll need to unscrew four screws, remove the hot-end sock, keep the hot-end steady with a wrench, and then carefully remove the nozzle using a socket wrench. It only takes a few minutes however, and all of the tools needed are provided.

Hands-free Auto Leveling

The K1 Max incorporates strain sensors in the heatbed that create a precise leveling mesh for automatic compensation. This strain-based automatic bed leveling (ABL) offers an advantage over probe-based leveling by eliminating the need for z offset calibration. This technology allows the 3D printer to autonomously level itself with precision, guaranteeing that each print initiates from a perfectly even surface. By utilizing strain sensors to create a leveling mesh, the K1 Max streamlines the printing process and eliminates the need for manual leveling adjustments, resulting in consistently high-quality prints. This automated leveling system simplifies the 3D printing workflow, making it easier for you to achieve optimal print results without the hassle of manual calibration.

We have dealt with some minor issues with the auto-leveling feature on the printer, which may be addressed in future software updates. One large concern we encountered is the inconsistency in bed leveling, with the deviation between high and low measurements ranging from .8 to nearly 1 mm. While there are online resources suggesting manual adjustments of lead screws based on the mesh to resolve this issue, we have found this process to be quite technical and challenging. This deviation doesn’t significantly impact print quality, but it may result in some inconsistency in the bottom layer of your prints.

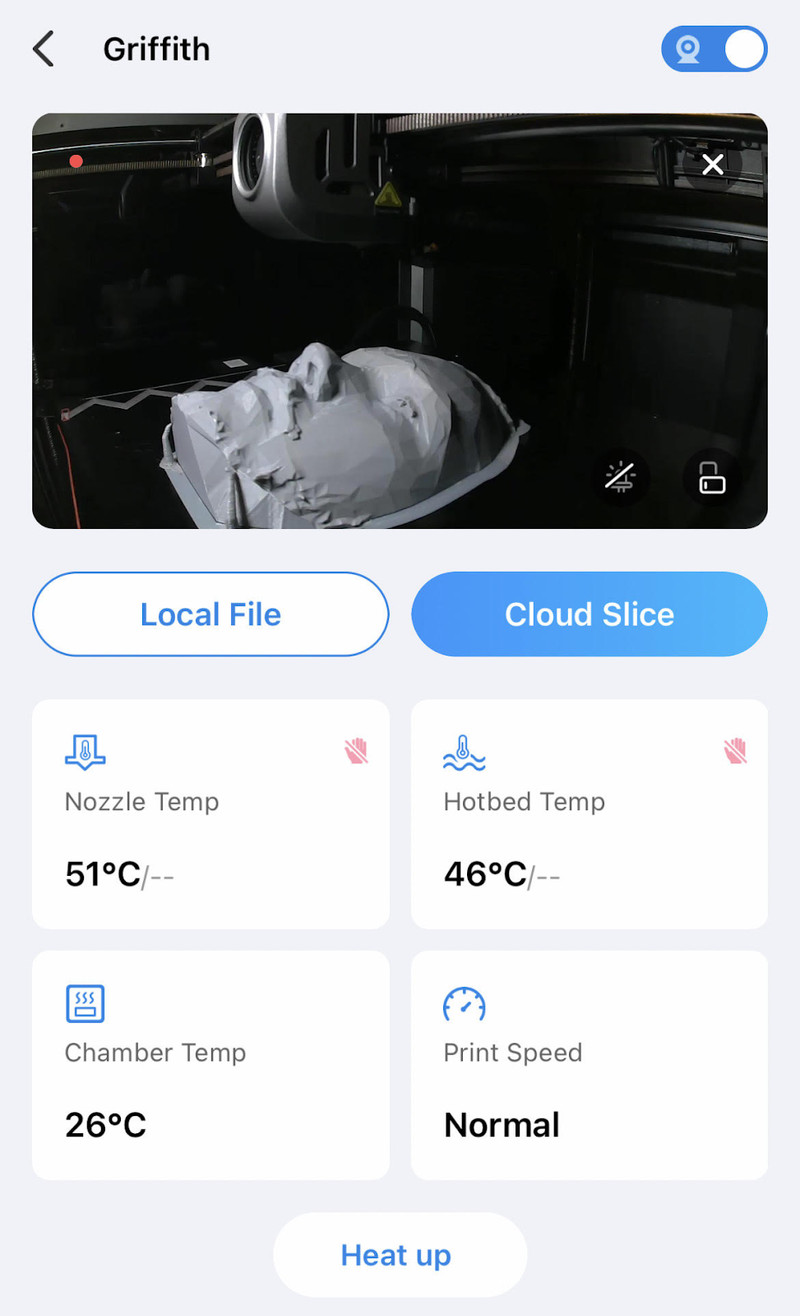

Connectivity and Software

With WiFi connectivity, the K1 Max is compatible with the Creality computer and phone apps, enabling you to access online models, slice them, and start remote printing. You can even remotely check the camera feed of the printer, allowing you to adjust settings like temperature, fan speed, and LED lights from afar. This convenient feature offers flexibility in managing the 3D printing process. We’ve frequently used the camera and mobile app to showcase the printer in action to friends and family, adding an element of excitement to the printing experience. Sometimes when the camera is connecting to the app, there can be a bit of a delay, but only a few minutes maximum.

AI Integrated Camera and AI Lidar

The integrated camera in the K1 Max offers the convenience of remote visual monitoring during ongoing prints, allowing you to check for quality, defects, and simply observe the progress. This feature is particularly useful when combined with the remote control capabilities.

In addition to live monitoring, the camera on the K1 Max includes advanced features like failure detection, in which the print pauses automatically if a quality issue is detected or a foreign object is detected in the build area. Time-lapse filming is also supported, allowing you to create time-lapse videos of your prints. As of February 2024, it’s worth noting that the failure detection feature is temporarily disabled in the default firmware because it had a significant false positive rate. However, there are potential options to utilize this feature through custom software. From our personal experience, the foreign object detection and time-lapse filming features function smoothly and add to the printer’s capabilities.

We appreciate the added functionality of the AI Lidar camera located on the printhead. Its impressive high resolution of 1 μm enables it to autonomously scan the initial layer. This feature is particularly handy as it promptly halts printing if any irregularities are detected, ensuring precision and reliable outcomes. Personally, we’ve found this to be especially beneficial when initiating remote prints, as we typically don’t monitor the app closely after starting the printing process.

Design and Motion System

The K1 Max comes with a CoreXY kinematic motion system, featuring two stationary motors that are responsible for moving the print head along the X and Y axes. This unique design separates the movement of the print head from the build plate, eliminating the additional weight and momentum usually associated with a moving build plate. As a result, the CoreXY system allows for faster and more precise printing, with speeds of up to 600mm/s.

Additionally, the firmware of the K1 Max incorporates input shaping technology, which further enhances the printing experience. A g-sensor integrated into the printhead detects resonance frequencies that occur during high-speed printing and adjusts the input signals to counteract these vibrations. This advanced feature ensures smoother and more precise printing, ultimately contributing to the overall printing quality of the K1 Max. With its input shaping technology, you won’t encounter much ghosting or quality issues when printing at high speeds. However, it is worth noting that the printer tends to shake quite a lot, potentially causing minor disturbances to objects on the table it is placed on.

Additional Mechanical Features

In addition to its impressive functional capabilities, the K1 Max also offers several notable design features. The printer is designed with a full enclosure that includes a removable top glass plate, allowing for easy access to the print bed. Inside the enclosure, powerful fans work to maintain optimal temperature control during printing, and they can be adjusted for added convenience.

Furthermore, the K1 Max is equipped with built-in air filters that effectively purify the air of harmful compounds that may be emitted during printing with certain materials. This not only enhances the overall printing experience but also promotes a safer and healthier work environment.

Some design aspects of the printer can prove to be inconvenient and lead to minor frustrations. While the rubber dampening feet help reduce vibrations, they are not securely attached to the printer and tend to come off easily when moving the device, requiring some effort to keep the printer balanced while reattaching them. Additionally, the limited movement range of the door hinges, which only open at about 45 degrees, has been a common obstacle in our experience. Fortunately, there are free printable models available online to address these issues by modifying the hinges to permit a full 270-degree rotation or fixing the feet semi-permanently to the printer.

We’ve encountered some bed adhesion challenges with certain materials like PA-CF on the smooth PEI build plate that comes with the printer. A simple fix we found was using a glue stick. Alternatively, switching to a textured PEI build plate, which Creality offers, has proven to be a more effective, permanent solution.

The printer’s overall design is a blend of style and practicality, with smooth edges and no potential hazards to be concerned about. The K1 Max features a sleek, cubic design with minimal external features apart from the screen, wires, and optional filament holder. This results in a streamlined and visually appealing printer that is easy to manage.

Summary

The Creality K1 Max 3D printer stands out for its versatility and user-friendly features. This machine offers exceptional print quality, a large print volume, and advanced technologies like error detection and input shaping for smooth and precise printing. With its CoreXY kinematic motion system, versatility with materials,and built-in air filters, the K1 Max is a competitive player in the 3D printing market. While it has a few quirks, it is overall a top-tier option for 3D printing enthusiasts looking for a quality, low maintenance, and modern 3D printer.

Brand Summary: Creality

Creality is a well-known brand that offers a wide range of consumer 3D printers across all price points, from budget to higher end models. The Ender 3 is credited with originating the budget 3D printer market. While other brands now produce lower cost clones of the Ender 3, Creality remains the most established Chinese manufacturer of 3D printers. Creality uses off-the-shelf components and standardized aluminum extrusions on many of their printers to reduce costs, making their printers easy to repair and upgrade. Their official online community forums and manufacturer support are limited, but support can be found on communities on Reddit and Discord.

Pros

- Modern mainboard features

- Auto bed leveling

- Large online community

- Has touch screen

- Premium components

- Fully assembled

- Direct drive extruder

- PEI build surface has good balance of adhesion and part removal

- Wireless printing

- All-metal hot end

- CoreXY Kinematic System

- Enclosure

- Dual gear extruder

Cons

- High price tag

Printer Comparisons

The articles below provide in depth comparisons of the Creality K1 Max to other similar printers on the market.

Comparing the Creality K1 Max vs the Bambu Lab X1 Carbon

Vs

You can compare the Creality K1 Max to other 3D printers using our Compare tool.