If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab P1S vs the Bambu Lab X1-Carbon

In this article, we’ll be comparing the Bambu Lab P1S to the Bambu Lab X1-Carbon (or X1C for short). These two 3D printers share a lot of key similarities, but they do have a few differences, and they come in at very different price points. We’ll take a look at the features in common between the two machines, as well as the differences, and give you our opinion about which ones are most important to consider when you choose between these printers.

Bambu Lab P1S

(~10.25 x 10.25 x 10.25 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

Bambu Lab’s 3D printers have quickly become a top choice in the consumer 3D printing market, with a lineup of machines that offer fast print speeds, excellent print quality, and easy-to-use software. But although Bambu Lab only makes a few different models, it can be hard to determine which of their 3D printers is the best choice for your needs. We’re here to help you understand the differences between some of their most popular models so you can choose the best one for you.

We’ll start by looking at the similarities between the machines.

Bambu P1S and X1C Similarities

The P1S and X1C have several features in common. We’ll cover each one in this section.

Build Volume

The Bambu P1S and X1C both have a 256 x 256 x 256 mm (10” x 10” x 10”) build volume, which is slightly larger than average for an FDM 3D printer. In our experience, this build volume strikes a good balance of allowing you to print decently large objects without the machine needing to be too bulky. We’ve rarely felt limited by this size, but there are other 3D printers with larger build volumes if you need to print very large parts.

Print Speed

Both the P1S and X1C advertise a maximum print speed of 500 mm/s and a maximum acceleration of 20,000 mm/s, which make them some of the fastest 3D printers available. It’s a bit of a surprise that Bambu didn’t reserve its fastest speeds for the higher-end X1C, but the printers are evenly matched on this spec.

We always like to make a note that 3D printers don’t maintain their top speed for an entire print, and the speed of any individual print is dependent on the model geometry and the quality settings you’ve selected. But regardless, either of these machines will be able to 3D print parts faster than most other printers.

Connectivity and Software

Both 3D printers support Bambu Lab’s software suite, including the Bambu Handy smartphone app and Bambu Studio computer application. Combined with the WiFi connectivity in both printers, this allows you to control all aspects of the printer from your phone or computer, including starting prints and monitoring ongoing prints.

In our experience, the software has proven to be easy to use while still giving you the ability to customize slicer settings for different models. One of the easiest ways to get started with either printer is to browse MakerWorld, which is Bambu Lab’s own 3D model website, for a model to print. The users who upload models to MakerWorld typically include preset printing profiles for Bambu’s machines, allowing you to start printing without needing to configure any settings. This allows you to select and print models from your smartphone without ever needing to adjust settings, which is a great feature.

If you don’t want to use WiFi, you can interact with both printers directly using their built-in controls and display, and both machines have a microSD card slot for loading files manually. However, the two printers do differ in their manual controls, which we’ll discuss later in this article.

Enclosure

The Bambu P1S and X1C both have a fully enclosed build chamber, which offers a few key benefits for printing. First, the enclosure allows these machines to print temperature-sensitive materials such as ABS and ASA. These materials tend to warp and delaminate if printed in an open-air environment, because air drafts can cause different parts of the model to cool at different rates.

The enclosure also helps contain the odors and chemicals released during 3D printing. While most materials don’t have a strong smell, certain materials such as ABS do exhibit an odor during printing. The P1S and X1C both have an activated carbon filter on the exhaust vent, which helps to address this issue.

Finally, the enclosure provides a small degree of noise reduction, as well as keeping dust and debris off of the print bed. In our experience, we haven’t found the enclosure to provide too much noise reduction, but every bit helps.

The enclosure on both printers is similar, with a solid bottom, back, and sides, and a glass top and door. The only difference is that the X1C advertises that it has a door sensor, but the current printer firmware does not take advantage of it. This is an improvement we’d like to see in the future, perhaps to pause the print if the door is opened.

AMS Compatibility

The P1S and X1C both support the Bambu Lab Automatic Material System (AMS), a multi-material add-on that allows you to print with up to four filament types or colors at once. The AMS is a unique add-on for Bambu printers, and in our experience it adds substantial capability to these machines. The AMS allows you to produce multi-color 3D prints, as well use multiple materials at once for more complex printing needs. It also has the ability to swap to a new spool when the current spool is depleted, allowing you to use the last bit of filament from every spool.

Bambu currently has two versions of the AMS, the original AMS and the AMS Lite. Both the P1S and X1C are compatible with the original AMS, so they have identical capabilities in this area. You can actually purchase either printer in a combo kit with the AMS to save money, as well—see the P1S Combo or X1C Combo on Bambu Lab’s online store.

Next, we’ll look at the differences between the two printers.

Bambu P1S and X1C Differences

The P1S and X1C have a lot of similarities, but there are a few important differences that may affect your decision between these two machines. We’ll discuss each difference in this section to help you determine which ones may be a factor for you.

Display and Controls

One of the most immediately noticeable differences between the two printers is their integrated display and controls. The Bambu P1S uses a monochrome screen that can only display text and small icons, with a set of physical buttons for controlling the printer. We don’t have any concerns about the buttons, but the screen feels quite lacking for a modern 3D printer, and has some real usability issues–for example, you’re unable to see a preview of any gcode files you have saved on the machine, requiring you to remember how you named each file to know which one you want to print. On the P1S, we find ourselves pulling out our smartphones to control the printer from Bambu’s app, rather than using the integrated display.

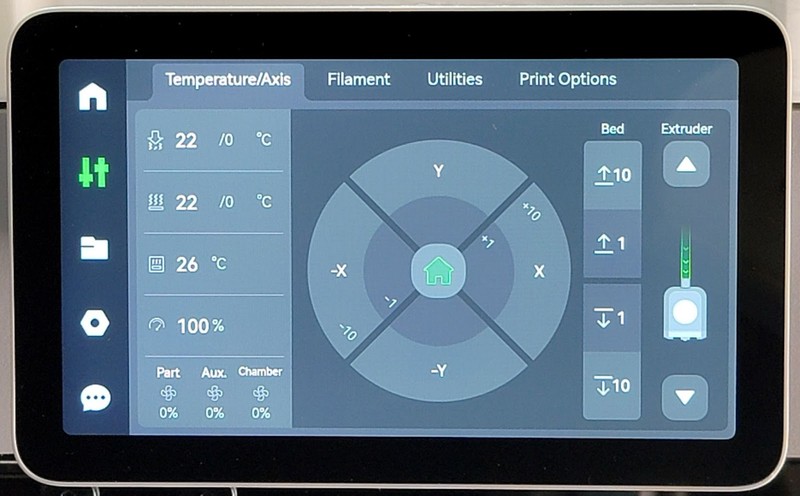

On the other hand, the Bambu X1C includes a 5” color LCD touchscreen display. This graphical interface is much easier to use than the comparatively archaic interface on the P1S, and has more functionality. For example, the X1C allows you to configure colors and material types for the filament spools you load into the AMS, while the P1S’s display doesn’t offer this functionality at all. The X1C’s interface feels modern and easy to use, and we prefer having the ability to intuitively control the printer with its built-in controls.

The X1C clearly wins in this area, and for us, this would be a factor when deciding between the two machines. However, we do want to note that you can easily control the P1S using the smartphone app, and we’ve found the app to be reliable and responsive. There are also third-party options for adding a graphical touchscreen to the P1S, such as the Bigtreetech Panda Touch, which we’ve tested and been pleased with.

Lidar Sensor

The X1C includes a Lidar sensor on the print head, which is a unique feature that isn’t found on the P1S. The Lidar sensor allows the X1C to precisely measure the first layer of filament as it is printed onto the build plate, allowing the printer to automatically calibrate the flow rate of the filament for maximum print quality. This capability also allows the X1C to detect an improperly-printed first layer, which can happen if the print bed is not leveled properly. Because first layer consistency is a critical part of a successful 3D print, the Lidar sensor should help improve the reliability and print quality of the X1C.

In our opinion, this sensor is a nice-to-have, but not a critical feature. The X1C is one of the only 3D printers with a Lidar sensor, and we haven’t felt its absence on the P1S. You can certainly get great prints and high reliability without the sensor. However, it should make the X1C capable of detecting some failures that other printer such as the P1S won’t catch automatically.

Camera

While the Bambu P1S and X1C both include a camera in the build chamber, the X1C’s camera is much better. It’s both higher resolution (1080p vs 720p) and has a much higher frame rate of 30 frames per second compared to 0.5 frames per second on the P1S.

The camera is used mainly for monitoring ongoing prints from the computer or smartphone app, which is a useful feature that allows you to keep an eye on the printer even when you’re in another room. In practice, the P1S’s camera essentially just updates a still image every few seconds, which is fine for making sure the print is still proceeding, but isn’t very satisfying to watch. The X1C’s higher frame rate camera allows the live view to show movement, as if you were watching the print in person.

The X1C’s camera also uses AI analysis to detect “spaghetti”, which is a complete failure of a 3D print that typically results in a mess and wasted filament. In our experience, the X1C doesn’t always detect these failures, and seems to have better success with lighter colors of filament, but we have seen it catch some of these issues and stop the print rather than wasting filament.

Material Compatibility

The P1S and X1C are both technically capable of using all common 3D printing material types, including standard materials such as PLA, PETG, and TPU, as well as less common materials such as PA and PC. Both printers are capable of heating the hotend to 300 degrees C and the bed to 100 degrees C or more, which is sufficient for all 3D printable materials.

However, in the P1S’s stock configuration, Bambu Lab doesn’t recommend printing carbon-fiber reinforced materials, or any abrasive material, while the X1C has no issues with these materials. This is because the X1C includes a hardened steel nozzle and hardened steel extruder gears, while the P1S uses standard stainless steel for both parts.

We don’t consider this to be a major difference between the two printers because you can easily upgrade the nozzle and extruder gears on the P1S using parts available on Bambu Lab’s online store.

Build Plate

The P1S and X1C come with different build plate surfaces by default. Between the two, we prefer the build plate that comes with the P1S.

The P1S comes with a textured PEI surface, which is one of our favorite build plate materials. It offers excellent first-layer adhesion, but easily releases prints once it cools down. It’s also a durable material that tends to have a long life, and is easy to clean. It leaves an orange peel-like texture on the bottom of 3D prints.

The X1C comes with two build plates, a “cool plate” and an “engineering plate”. The cool plate is designed for printing PLA, TPU, and PVA filament at a low bed temperature of 35-45℃, while the engineering plate is designed for filament types that require a higher bed temperature. Both of these build plates have a smooth surface that will result in a glass-like surface finish on the bottom of the printed model, but both plates require you to coat the plate with a glue stick to aid in part adhesion. We don’t enjoy having to do this extra step, and don’t find these build plates to be worth it over the textured PEI plate.

Fortunately, both printers are compatible with Bambu Lab’s full set of build plate options, and are also compatible with a number of third-party build plates. The build plate simply attaches magnetically to the print bed, so it’s extremely easy to change out if you prefer to use a different surface than the one your printer comes with. Therefore, this isn’t a difference that should influence your decision between the printers, but you may want to buy an extra PEI build plate from Bambu Lab if you purchase the Bambu X1C.

Appearance And Build

The two printers share a very similar physical design, and are the exact same dimensions, but there are some small differences in their appearance and construction. The Bambu X1C has a silver finish and the solid enclosure pieces are made of aluminum, making for a solid and premium-looking machine. On the other hand, the Bambu P1S has a black finish but the solid enclosure pieces are made of plastic, which is a decidedly less sturdy and premium-feeling material.

This is a minor difference between the machines, and doesn’t functionally affect performance. Both printers have a welded steel frame, so in terms of vibrations and overall strength, they have similar durability. We also actually prefer the black of the P1S over the silver of the X1C. But there’s no doubt that the aluminum enclosure on the X1C looks and feels more premium, and is likely more durable than the plastic enclosure pieces on the P1S.

Which 3D Printer Should You Choose?

The Bambu P1S and X1C are surprisingly similar 3D printers considering their relatively large price disparity. Both machines offer the same high print speeds, print quality, and software support, and also share important features such as an enclosed build chamber and compatibility with Bambu’s AMS unit. But they do have a few differences that may be important to you.

If you’re looking for a 3D printer that has advanced features for detecting print failures, offers compatibility with carbon fiber filament out of the box, and the simplest set of integrated controls, the Bambu Lab X1C is the right choice for you. It comes at a substantially higher price than the P1S, but includes some sensors and features that are rare among FDM 3D printers, such as its Lidar sensor. We also think the touchscreen display is a major reason to prefer the X1C over the P1S. Although it was Bambu’s first model, the X1C has stood the test of time and is still a dominant 3D printer in the current market, making it an easy printer to recommend.

However, if you want the key benefits of a Bambu 3D printer but are willing to accept a few compromises on integrated controls and lack of the advanced sensors, the Bambu Lab P1S offers an unmatched value. The P1S matches almost all of the key capabilities of the X1C and is only missing a few of its nice-to-have features. For almost all users, we think this printer is an excellent choice and more than capable of handling day-to-day 3D printing, and does so at a price that is much lower than the X1C. While we can’t deny the X1C is a higher-end 3D printer with more features, our clear recommendation between these two machines is the P1S simply because it offers much more value per dollar.

You can view both 3D printers on Bambu Lab’s website using the links below:

Click here to view the Bambu Lab P1S on the Bambu Lab website.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: