ABS Filament Detailed Guide

ABS filament is a common choice for 3D printing due to its high temperature resistance and ability to flex without breaking. However, ABS can be a challenging filament type to 3D print due to its demanding temperature requirements and potential for warping during the printing process. In this guide, we’ll cover the appearance and properties of ABS filament, our suggested settings for 3D printing ABS, and the filament brands we recommend.

ABS Appearance

- Opaque with a matte finish

- Can be sanded to remove layer lines

ABS filament is typically opaque and has a matte finish. Because it is a popular filament type, you can find it in a variety of colors from several different manufacturers. It’s not usually translucent, but some translucent color options are available.

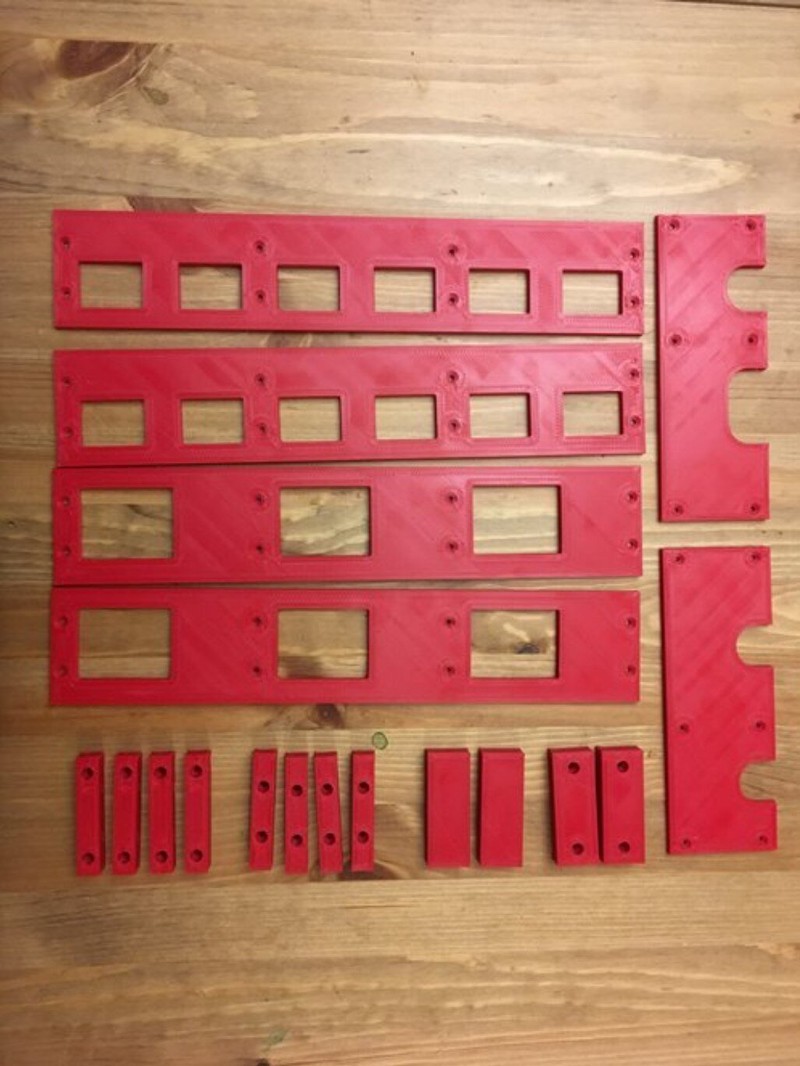

ABS is one of the best filament types to use if you’re interested in post-processing your 3D prints to improve their appearance. It can be sanded more easily than other filaments, which allows you to remove visible layer lines from the print. For a shiny and very smooth appearance, you can even use acetone vapor to chemically smooth the surface of ABS prints. It takes paint well, and is generally a good choice if you want to put in extra work to get the best possible appearance from your prints.

ABS Strengths

- Can flex without breaking

- High temperature resistance

One key difference between ABS and other filaments such as PLA is that ABS prints can flex and bend slightly without breaking. ABS isn’t an inherently flexible or stretchy material—you’d want TPU for that—but its ability to flex makes it a great choice for models with pieces that need to snap into place. It can also be a good option for brackets and other functional pieces that need to resist cracking when exposed to bending forces.

The other key strength of ABS is its temperature resistance. It won’t deform until it reaches a temperature of 210° F (99° C), which puts it far above PLA in terms of resisting high heat. This means you can use ABS for 3D prints that will need to survive inside a hot car or in direct outdoor sunlight and trust that the part won’t warp or deform. If you ever 3D print upgrade or repair parts for your 3D printer, you may want to use ABS if those parts will be near a stepper motor or the hotend—the temperature resistance of ABS will make the parts perform much better than if you printed them from another material such as PLA.

ABS Weaknesses

- Difficult to 3D print

- Slight smell during printing

As a material, ABS doesn’t have many notable weaknesses. It’s not as well-suited to reproducing fine details as PLA, and it’s slightly less strong than other filament types when exposed to tensile (pulling) forces, but these are relatively minor deficiences. The main issues with ABS are in the 3D printing process itself.

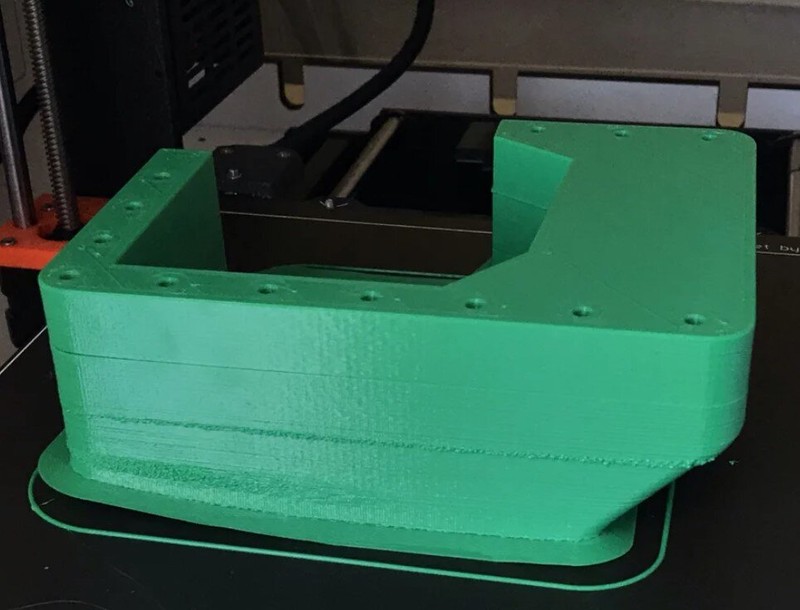

ABS is challenging to 3D print primarily because models are at risk of warping and delaminating during the printing process. These issues are more likely to happen when printing larger parts, but can happen with parts of any size. To reduce the likelihood of these printing issues, you’ll need to heat your bed to a high temperature, which may require a longer heating time before the print and will increase the ambient temperature in the room. Additionally, you may need to construct or purchase an enclosure for your 3D printer to effectively print ABS. We’ve found enclosures to dramatically reduce the risk of warping.

Some users also report that ABS generates a slightly unpleasant smell during the printing process. This smell has never bothered us, but if you’re particularly sensitive to odors, ABS may be a less favorable choice for you. It’s important to note, though, that this smell only occurs during the printing process. Once the print is complete, ABS prints don’t exhibit any more of a smell than any other plastic or 3D printed piece.

How To 3D Print ABS

ABS can be 3D printed at a similar speed to PLA, and with similar retraction settings. Our recommended hotend temperature of 240° C is on the high end of what PTFE-lined hotends can handle, but it’s within the allowed temperature range for most hotends.

The main considerations you should keep in mind while printing ABS is that it’s important to keep the printed model from cooling too quickly. ABS’s tendency to warp and delaminate is more likely to occur if different parts of the model cool at different rates, so maintaining a consistent ambient temperature with no air drafts is important. Typically, the best way to print ABS is with a 3D printer enclosure, which is a box or tent that encloses your 3D printer. The enclosure will trap heat and eliminate air drafts, which addresses these major contributors to ABS print failures. You can buy premade enclosures [Amazon link] for most common sizes of 3D printers, but you also have the option of constructing one yourself from rigid foam insulation, plexiglass, or even wood.

The other notable print setting for ABS is the bed temperature of 100° C. This is substantially higher than what we recommend for PLA or most other materials, but the increased temperature helps prevent ABS prints from warping upward off of the bed surface. Most modern 3D printers will be able to handle this bed temperature, although you may notice the bed takes longer to heat up than you’re used to. Some older 3D printers, especially models with large print beds, may be unable to reach 100° C or may take an extremely long time to reach that temperature.

Finally, you should ensure your printer’s part cooling fan is disabled in the slicer settings when printing ABS. Air drafts and uneven cooling are the enemy of ABS prints, and the part cooling fan is designed to purposely generate an air draft to quickly cool the print.

Our recommended slicer settings for printing ABS are:

- Hotend temperature: 240° C

- Bed temperature: 100° C

- Print speed: 45-55 mm/s

- Retraction amount: 0.8mm for direct-drive extruders, or 7.5mm for Bowden extruders

- Part cooling fan: Disabled

Recommended ABS Filament Brands

Although we typically like to recommend several filament brands for each type of filament, there’s one brand of ABS filament that we trust above all other options.

- Hatchbox ABS [Amazon]: In our experience, Hatchbox ABS is substantially more resistant to warping than other filament brands. We’ve found it to be consistent and high-quality, and printed parts are clean and reproduce details well.