If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Bambu AMS vs AMS Lite

Published: 2024-07-21

The Bambu Lab AMS and AMS Lite are two different multi-material 3D printing accessories that Bambu Lab makes for their printers. Although the two versions of the AMS have several similar features, they have very different designs which makes each one better at certain things. In this article, we’ll compare the Bambu AMS and AMS Lite to help you understand the differences between the systems and what to expect from each one.

3D Printer Compatibility

Perhaps the most important difference between the AMS and AMS Lite is that each accessory is compatible with a different set of Bambu Lab’s 3D printers:

- Bambu AMS: Compatible with Bambu Lab X1 Carbon, X1E, P1S, and P1P

- Bambu AMS Lite: Compatible with Bambu Lab A1 and A1 Mini

This difference alone may cause you to choose one unit over the other, because Bambu’s A1 series is quite different from the P1 and X1 series. But for the rest of this article, we’ll focus on the differences between the AMS and AMS Lite, rather than the printers they’re used with. If you do want to learn more about the difference between the printers, we have comparison articles for almost all of them.

Physical Design and Mounting Options

The two units have rather different physical designs, which affects both their appearance as well as your options for placing them in your workspace.

The Bambu AMS is a box-like design with all four filament spools resting side-by-side inside the unit. It has a large lid that is secured by two twist latches; after opening the latches, you can swing the lid upward to allow you to insert or remove the filament spools.

The AMS can sit on the table surface next to the 3D printer, but because its compatible printer models are all enclosed CoreXY designs, you can also set the AMS on top of the printer itself for a more compact setup. The only except is the Bambu P1P; since that printer is not enclosed and doesn’t have a solid top plate, you’ll need to 3D print a bracket for the AMS to rest on. For us, desk space is at a premium but we have plenty of vertical room above our printers, so we appreciate the ability to set the AMS on top of the printer.

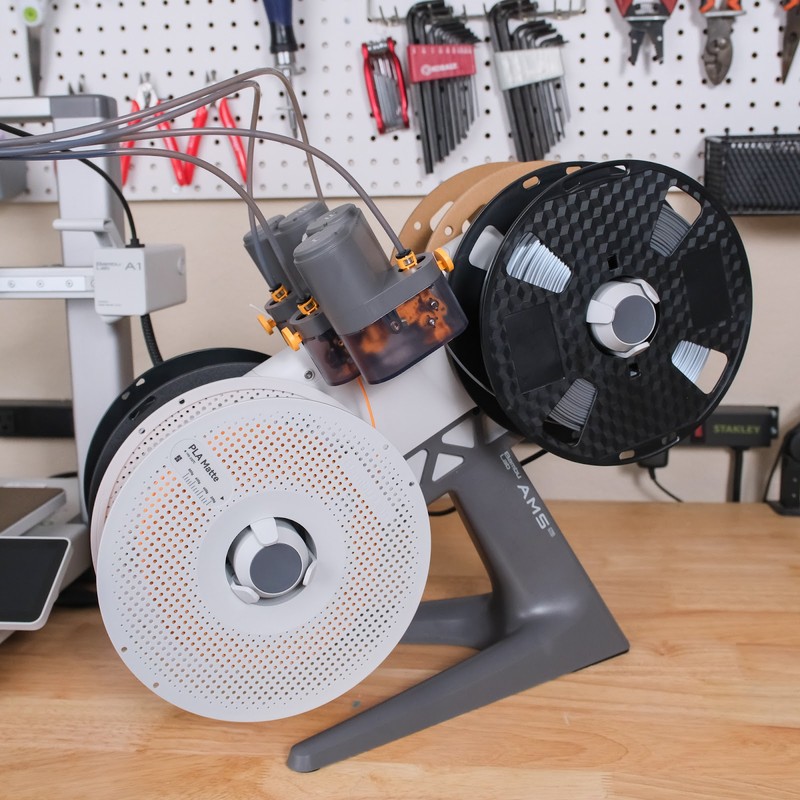

On the other hand, the AMS Lite is a more exposed design. The unit has four pegs that the filament spools rest on, in a configuration that looks similar to the four wheels on a car. By default, it includes a desk stand to allow the unit to sit on the table next to the 3D printer. However, for the Bambu A1 only, Bambu Lab does provide a 3D model that you can print to mount the AMS Lite on the top of the machine. We found this to be a little less appealing than top-mounting the AMS on one of the enclosed printers, both because we needed to 3D print the mount and because it overall feels a bit less stable, but it does result in a setup that takes up a similar amount of desk space.

Filament Spool Compatibility

Because the AMS and AMS Lite hold their filament spools in different ways, there are some differences in which filament spools will work best with them. This also affects the experience of loading filament, which we’ll briefly discuss in this section.

The Bambu AMS has each filament spool resting on motorized rollers, which allow the unit to spin the spool in either direction—forward to assist in feeding filament, and backward to wind the filament back onto the spool when it is retracted. This isn’t the AMS’s primary way of pulling the filament for feeding (it has motors similar to extruder motors which grip the filament itself) but it’s an important part of the AMS’s function.

Because the AMS spins the spool with the rollers, it’s unlikely to work at all with filament spools that aren’t a standard size, and can also have trouble with cardboard spools, which are becoming more and more common. On the cardboard spools, the edges can start to fray, which can cause the spool to not spin smoothly on the rollers. It’s also possible for the cardboard to generate dust, which could eventually clog up the AMS’s mechanical systems, although we haven’t seen this happen ourselves.

There are a few solutions to these issues on the AMS. For cardboard spools, some users 3D print thin plastic rings that press-fit onto the edge of the spool, preventing the fraying and giving the rollers a smooth surface to grab onto. We found these to generally work, but they can make the spool too thick, which causes it to rub on the AMS body and cause a feed error. Users have also designed intricate “respooler” mechanisms, which allow you to quickly transfer filament from a problematic spool onto a reusable Bambu spool for use in the AMS. We haven’t tried one of these ourselves, but our impression is that while they solve the problem, it’s an annoying step that we wouldn’t want to have to take every time we use a new spool.

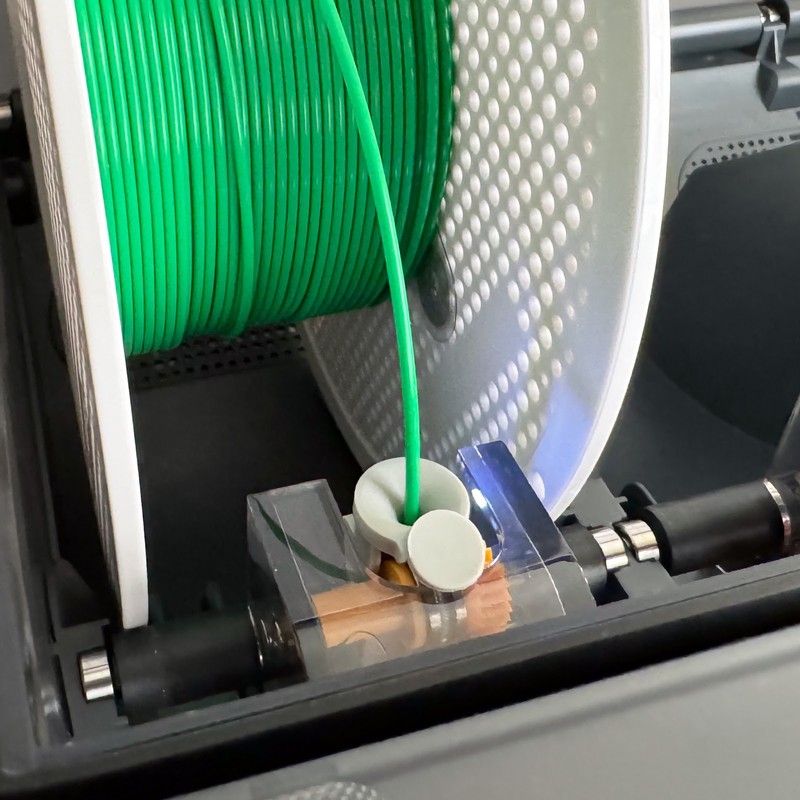

The AMS Lite is generally more compatible with filament spools, although it does have a few issues of its own. It grips spools from the center hole, using a spring-loaded peg to hold onto the spool. We’ve had reliable performance with almost all standard spools on the AMS Lite, including cardboard spools. The only incompatibility you may encounter is that some spools do not have a standard-sized center hole, and therefore won’t work with the AMS Lite. Some Sunlu spools have this issue. Fortunately, you can 3D print an insert for those spools to shrink the center hole such that it will work on the AMS Lite.

One other note is that neither the AMS or AMS Lite are compatible with flexible filament such as TPU. Some users have been able to make TPU work for single color prints, but we don’t recommend it. Flexible filament doesn’t retract as reliably, especially through long Bowden tubes, and both the AMS and AMS Lite require a very long Bowden tube run from the unit to the printer.

3D Printing Performance

The Bambu AMS and AMS Lite both provide the same core 3D printing capabilities: both units allow you to print with multiple colors or materials, and include the ability to automatically switch to a different spool of the same color and material when one runs out. They have similar sensors to detect jams or other issues that can occur during printing, although we’ve found these issues to be rare on both units.

During the print, the AMS and AMS Lite have similar behavior for switching materials. The printer will pause and cut the filament near the extruder. Then, the AMS or AMS Lite will retract that filament spool and feed the new spool until it reaches the hot end. The printer will then extrude some filament into a special purge area to clear out the old material, wipe the nozzle, and resume printing.

One difference between the units is that the Bambu AMS merges the four filament paths into a single tube inside the AMS unit, so that there is a single tube running from the AMS to the printer’s extruder. This means that to change colors, the AMS has to retract the filament all the way back to the AMS unit, which takes a few seconds and is fairly loud. Then, it pushes the new filament to the extruder in the same way.

On the other hand, the AMS Lite has all four filament tubes running almost the entire distance to the extruder, with a splitter directly before the extruder to merge the four tubes into one. This means that the AMS Lite doesn’t have to retract the filament nearly as far, which makes its filament switches both quieter and faster than the AMS. We didn’t find this to make a meaningful difference in print time—the time it takes the printer to purge the old filament is the bulk of the time for material changes—but it does make the entire operation quieter.

There is one other major difference between the capabilities of the two units: The Bambu AMS allows you to daisy-chain up to four units for a total of 16 color/material options, while the AMS Lite is limited to a single unit with only four colors/materials. This seems like a software limitation rather than a hardware one, so it’s possible Bambu Lab may change this in the future. But right now, if you want to use more than 4 colors for a single print, you’ll want to use a 3D printer which supports the Bambu AMS.

Reliability and Repair

We’ve found both the AMS and AMS Lite to be generally reliable, with very few issues during printing. For how complicated these devices are, it’s impressive that they perform as consistently as they do. When we have had issues, they’re generally due to using old, brittle filament, which can tend to break in the long Bowden tubes that both units use.

Clearing jams is a different experience with each unit. With the Bambu AMS, since it merges all four filament paths into one tube inside the AMS itself, some jams can require you to open up the AMS to access the tubing. Bambu has made this about as easy as they can, and it’s much better than other units such as the Anycubic ACE Pro, but this is still a pain. You’ll have to unload and remove the four filament spools, disconnect the tube from the back of the AMS, and remove two bolts from inside the AMS. Then, you can lift out a tray and unplug a small cable to fully remove the AMS’s internals from the outer shell. This should be sufficient to clear almost any jam or blockage in the tubing.

The Bambu AMS Lite is much better in this regard because the filament path is completely exposed. You can clear any jam by disconnecting one of the tubes from the unit, and you won’t need to remove the filament spools to do so. The only unique issue you can encounter on the AMS Lite is that you may need to remove the splitter on the top of the extruder, which has a plastic tab that can be a little difficult to attach and detach. But overall, the experience of clearing a jam on the AMS Lite is much easier than on the AMS.

Bambu AMS vs AMS Lite: Which is Better?

Ultimately, it’s hard to say whether the Bambu AMS or AMS Lite is better. In terms of 3D printing capabilities, they offer almost all of the same features, so there is no situation where one unit will allow you to print objects that you can’t print with the other unit. And both units include features such as automatic filament switching when a spool runs out and the ability to read Bambu Lab’s RFID spools.

The AMS Lite has a couple of advantages over the AMS: it’s a bit more compatible with filament spool types, especially cardboard spools, and it’s more accessible for clearing jams. However, the AMS has a cleaner appearance and can sit on top of a Bambu X1C or P1S without needing any 3D printed accessories. The AMS also has a sealed box design which can act as an (unheated) dry box for filament, which could be a plus depending on your workspace.

As far as price, at the time of this writing the AMS is approximately $100 more than the AMS Lite. This is certainly a notable price difference, especially considering the printers the AMS Lite works with are cheaper than Bambu’s other machines. The overall cost of purchasing a Bambu Lab 3D printer with the AMS Lite is a fair bit lower than the cost of a printer with the AMS.

As we mentioned at the beginning of this article, in most cases your choice between the AMS and AMS Lite will be made for you by which Bambu Lab 3D printer you choose. We think that it’s generally better to consider the features of the printer over the features of the multi-material addon, since these two units are so similar. But there are a few differences between the two units as we’ve described here, so you may wish to consider those differences as part of your decision.

Click here to view the Bambu AMS on Bambu Lab’s online store.

Click here to view the Bambu AMS Lite on Bambu Lab’s online store.