If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Creality K1

About the Creality K1

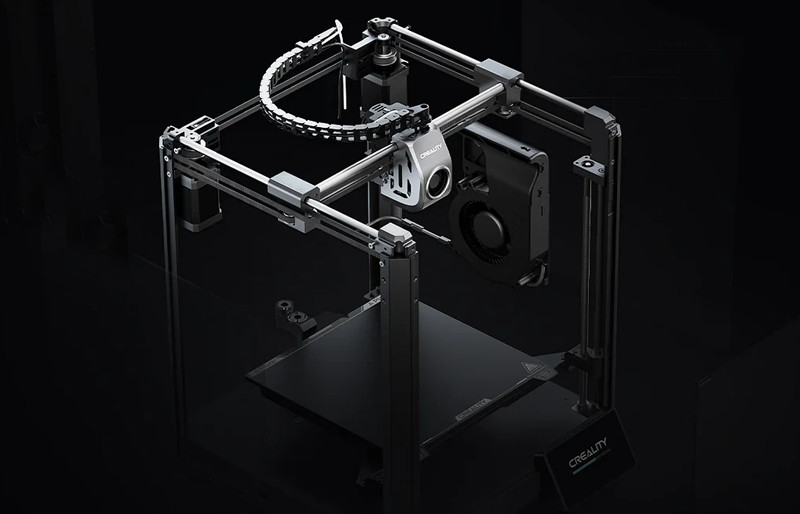

The K1 3D printer represents Creality’s entry into the high-end segment of 3D printing. Featuring a 220x220x250mm build volume and an impressive print speed of up to 600mm/s, it offers advanced features such as strain-based automatic leveling and a high-flow hot-end design, catering to users seeking enhanced functionality. However, it’s important to note that the printer has encountered challenges in the past, particularly with its extruder. Users have reported issues such as clogging, filament jams, and difficulties with nozzle swapping. Creality has addressed these concerns by providing replacement parts or upgraded extruders under warranty, with the printer now shipping with a higher quality nozzle similar to the K1 Max. While efforts have been made to resolve these issues, there is still room for improvement.

- Advanced Hardware Features:

The K1 incorporates a direct drive extruder, ceramic heating block, full enclosure, and CoreXY motion system

- Material Compatibility:

Compatible with various 3D printing materials, including flexible filaments like TPU and fiber-reinforced options

- WiFi Connectivity and Integrated Camera:

With WiFi connectivity and an integrated camera, the K1 allows for remote monitoring and control

- High-Quality Prints:

The printer ensures reliable and high-quality prints, supported by a modified version of Klipper firmware known for efficient processing of gcode

Build Volume

With its modest build chamber measuring 220 x 220 x 250 mm (8.66” x 8.66” x 9.84”), this printer provides sufficient space for decent-sized prints. Its dimensions, roughly 14 inches in depth, make it suitable for placement on a standard desk. However, its high-speed printing capabilities may result in desk vibrations. With its relatively compact overall volume, which is not significantly larger than its build volume, the printer utilizes its space efficiently.

Supported Materials

The K1 now incorporates high-quality components in its hotend assembly, including a ceramic heating block enveloping the entire hotend, a dual gear direct extruder, a hotend featuring a titanium alloy heat break, and a hardened steel nozzle. These components enable printing with a diverse range of materials, encompassing ABS, PLA, PETG, PET, PA, ASA, PC, TPU, PLA-CF, PA-CF, and PET-CF. Equipped with a full enclosure, the printer allows for ambient temperature control, which proves particularly useful when working with materials like ABS, ASA, and PC. This feature prevents parts from warping as the plastic cools due to the increased ambient heat. The versatility in filament options facilitates experimentation with different material properties for various applications. While some users have noted the need for adjustments and profile editing in slicer settings, particularly with more challenging filaments, once the settings are fine-tuned, the printer demonstrates reliability across a range of applications.

Changing out the nozzle on the K1 can be somewhat challenging due to the design of the hotend assembly. The process involves removing a few screws, the hotend sock, holding the hotend steady with a wrench, and then removing the nozzle with a socket wrench. While this procedure typically takes only a few minutes, it does require slightly more time compared to most other 3D printers. However, it’s worth noting that all the necessary tools are provided for this task, ensuring a straightforward nozzle replacement process.

Hands-free Auto Leveling

The K1 employs an advanced system by integrating strain sensors into the heatbed to establish a precise leveling mesh for automatic compensation. Unlike traditional probe-based leveling systems, this strain-based automatic bed leveling (ABL) eliminates the need for z offset calibration. This technology enables the 3D printer to autonomously level itself with precision, ensuring that each print starts from a perfectly even surface. By utilizing strain sensors to create a leveling mesh, the K1 simplifies the printing process and removes the requirement for manual leveling adjustments, resulting in consistently high-quality prints. This automated leveling system streamlines the 3D printing workflow, providing users with the ease of achieving optimal print results without the complexities of manual calibration.

We’ve encountered minor challenges with the auto-leveling feature of the printer, which may be addressed in future software updates. A notable concern is the inconsistency in bed leveling, with variations between high and low measurements ranging from .8 to nearly 1 mm. While online recommendations suggest manual adjustments of lead screws based on the mesh to address this issue, users have found this process to be intricate and daunting. Although this deviation does not significantly affect print quality, it may result in some inconsistencies in the bottom layer of prints.

Furthermore, the printer includes additional automatic features. In addition to the Automatic Strain-based Leveling (ABL), when toggled on the print screen, the printer will also automatically retest input shaping—a process that adjusts the printer’s response to vibrations during high-speed printing to improve print quality—and clean the nozzle. These functionalities aim to ensure higher quality prints and prevent defects.

Connectivity and Software

The K1 integrates with the Creality computer and phone apps via WiFi, allowing you to access online models, slice them, and start remote printing. Utilizing the app, we’ve showcased the printer in action to friends and family, enhancing the printing experience. Additionally, the app enables remote adjustments to temperature, fan speed, and LED lights. While occasional delays in connecting—especially to the camera—may occur, they typically last only a few minutes at most.

Design and Motion System

The K1 employs a CoreXY kinematic motion system, incorporating two stationary motors to guide the print head along the X and Y axes. This design choice effectively separates the movement of the print head from that of the build plate, minimizing the extra weight and momentum usually associated with a moving build plate. As a result, the CoreXY system facilitates faster and more precise printing, achieving speeds of up to 600mm/s.

Additional Mechanical Features

Moreover, the firmware of the K1 incorporates input shaping technology to improve the printing process. A g-sensor integrated into the printhead detects resonance frequencies during high-speed printing and adjusts input signals to reduce vibrations. This advanced feature ensures smoother and more accurate printing, enhancing the overall print quality of the K1. With input shaping technology, you can expect fewer issues like ghosting when printing at higher speeds. It’s worth noting, however, that the printer may experience noticeable shaking from high-printing speeds, potentially causing minor disturbances to nearby objects on the table.

Another premium feature of the K1 is built-in air filters, designed to effectively purify the air from potentially harmful compounds that may be emitted during printing with certain materials.

Minor inconveniences and frustrations can arise from certain design aspects of the printer. We’ve found that the door hinges, with their limited movement range of only about 45 degrees, present a common obstacle in our experience. Moreover, while the rubber dampening feet effectively reduce vibrations, they tend to detach easily when moving the device, requiring effort to maintain printer balance. Thankfully, there are freely available printable models online that tackle these issues. These models allow for hinge modifications, enabling a full 270-degree rotation, or provide solutions for semi-permanently securing the feet to the printer.

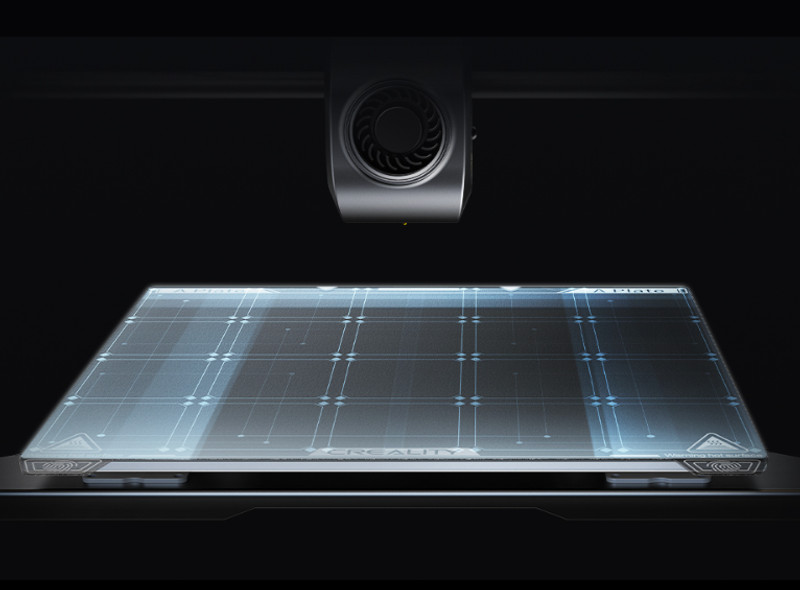

Bed adhesion issues have been reported with certain materials like PA-CF on the smooth PEI build plate provided with the printer. To resolve this, users have found success using a glue stick as a temporary fix. However, for a more effective and permanent solution, switching to a textured PEI build plate, available from Creality, has proven to be more reliable in the long term.

The K1 Max features a design that seamlessly merges style with practicality. Its smooth edges and absence of potential hazards ensure user safety. Featuring a sleek, cubic design, the printer minimizes external features, comprising only the screen, wires, and optional filament holder. This minimalist aesthetic contributes to a visually appealing and easily manageable printer.

Summary

The K1 represents a significant advancement in Creality’s printer lineup, offering an array of features not present in their previous models, albeit at a moderately higher price point than most of Creality’s printers. With strain-based leveling, exceptional print quality, very fast printing speeds, a full enclosure useful for certain filaments, a CoreXY kinematic system, versatility with materials, and built-in filtering fans, it stands out as a versatile option for enthusiasts. With an overall sleek design and a strong physical-size-to-build volume ratio, it positions itself as a high-tier option within its price range and features. This printer is an excellent choice for printing enthusiasts seeking a quality, low-maintenance, and modern 3D printer within a reasonable budget for its features.

Brand Summary: Creality

Creality is a well-known brand that offers a wide range of consumer 3D printers across all price points, from budget to higher end models. The Ender 3 is credited with originating the budget 3D printer market. While other brands now produce lower cost clones of the Ender 3, Creality remains the most established Chinese manufacturer of 3D printers. Creality uses off-the-shelf components and standardized aluminum extrusions on many of their printers to reduce costs, making their printers easy to repair and upgrade. Their official online community forums and manufacturer support are limited, but support can be found on communities on Reddit and Discord.

Pros

- Modern mainboard features

- Auto bed leveling

- Large online community

- Has touch screen

- Premium components

- Fully assembled

- Direct drive extruder

- PEI build surface has good balance of adhesion and part removal

- Wireless printing

- All-metal hot end

- CoreXY Kinematic System

- Enclosure

- Dual gear extruder

Cons

- High price tag

Printer Comparisons

The articles below provide in depth comparisons of the Creality K1 to other similar printers on the market.

Comparing the Bambu Lab P1P vs the Creality K1

Vs

Creality K1 vs Creality Ender 3 V3 KE

Vs

You can compare the Creality K1 to other 3D printers using our Compare tool.