If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Prusa CORE One

About the Prusa CORE One

The Prusa CORE One is Prusa’s first fully enclosed CoreXY high speed 3D printer. It’s not their first CoreXY printer - that would be the Prusa XL. It’s not their first fully enclosed 3D printer - that would be their delta Prusa Pro HT90. But it is their first fully enclosed CoreXY 3D printer.

Due to the CoreXY kinematics, it’s 15-20% faster than their MK4S, and the MK4S is competitive with the 500-600mm/s printers on the market. Since it’s CoreXY and not a “bed slinger”, its footprint is not as deep as the MK4S - it’s 30% smaller than the MK4S and 50% smaller than the MK4S in an enclosure, yet it’s taller and has a 30% greater print volume. The CORE One’s print volume is 250 X 220 X 270mm versus the MK4S’s print volume of 250 X 210 X 220mm.

Design

A conventional fully enclosed printer consists of an open frame printer surrounded by an enclosure or an open frame printer with enclosure panels mounted into the frame sides. But the Prusa CORE One does not have a frame at all. It uses steel panels mounted from the outside with screws to secure the internal parts. Prusa refers to this as an exoskeleton - an external support structure instead of an internal support structure (a frame). This allows the printer to be fully disassembled and easily repairable, but it also allows it to be supplied as a kit.

The transparent door and top cover are not glass but high performance polymer. There have been enough instances of glass doors shattering with other printers that Prusa wanted to avoid glass entirely. The door opens up to 180 degrees to avoid projecting out in front of the printer in a print farm setting. The door hinges can be switched from the right to the left if this will be more convenient for the space.

Inside the enclosure, there are two ventilation fans which are critical to the active temperature control. The enclosure can be heated up to 55°C, which will greatly assist printing ABS and PA (nylon). A vent can let in cool air and the fans can be used to keep the enclosure cool in order to print PLA and PETG. PLA and PETG can then be printed with the door closed and top lid in place.

Another innovative design feature is the inset side panels. On the right side, the inset accommodates the filament spool. The left side is left up to the user. Since this is all steel, Prusa suggests custom 3D printed accessory holders attached using magnets. These insets provide space for the filament spool and add storage space without adding to the width of the printer.

The bed on the CORE One is the same as on the MK4 and MK4S even though the print volumes are a little different - the CORE One uses more of the margin area. You can reuse your MK4/MK4S bed plates on the CORE One. The supplied bed is a smooth PEI coated magnetic bed sheet. Optional sheets are textured PEI or satin PEI.

There’s full lighting, both on the top and on the bottom. The bottom lighting is a new idea - enclosures often don’t have enough light at the bottom of the enclosure which makes seeing the bottom of a tall print difficult.

Extruder

The extruder is the same as the MK4S - the Nextruder. This is an all-metal direct extruder with 10:1 planetary gearing. The planetary gear arrangement increases torque while allowing the use of a smaller, lighter stepper motor. The quick change integrated heatbreak and high flow nozzle is inherited from the MK4S. The high flow nozzle is critical to the high speed performance.

Leveling is by strain gauge built into the extruder and nozzle assembly. This handles automatic bed leveling and automatic Z offset.

The cooling fan is the same as the MK4S - a powerful 5020 fan coupled to a 360 degree cooling duct. The printer is able to achieve 75 degree overhangs with this powerful cooling.

Controls and Electronics

The controls and electronics are identical to the MK4S. The onboard control consists of a 3.5” 65K color touchscreen. This made its first appearance on the MK4 which was knob controlled - touchscreen functionality was added to the MK4S but the knob was retained and can still be used on the MK4S and CORE One.

This is connected to a 32 bit xBuddy mainboard used in the MK4 and MK4S.

Connectivity is by Ethernet or (optional, removable) WiFi. This connects to Prusa Connect, Prusa’s cloud printing platform. The WiFi module has NFC functionality first introduced in the MK4S which allows a phone running the Prusa App to connect the printer to the network with a single tap.

The CORE One also uses the special no-VFA stepper motors as seen in the MK4S. These have finer step increments than standard stepper motors, reducing or eliminating wavy vertical fine artifacts that can be produced between the steps of standard stepper motors on X and Y axes.

Accessories

There’s a custom USB-C camera specifically designed for the CORE One made by a 3rd party at Prusa’s direction under their new Buddy3D brand. Prusa also makes an advanced filtration system which reduces fumes from ABS and ASA and filters out particles discharged from the enclosure fans.

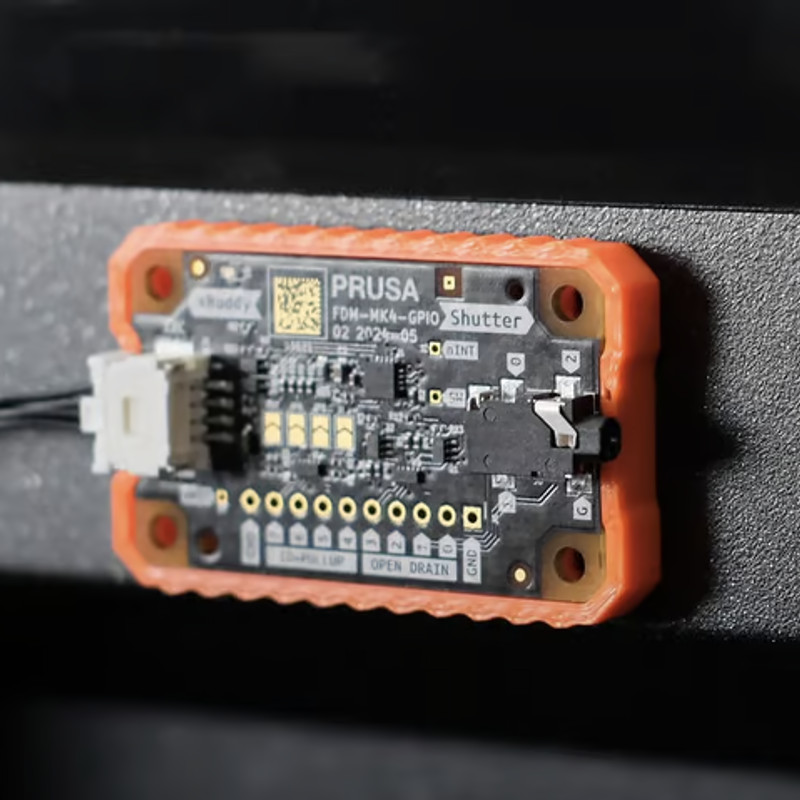

You can also use the GPIO Hackerboard, first introduced with the MK4S, to trigger and take input from external devices. It’s connected to the I2C port on the mainboard and users can interact with it using custom G code.

There’s even a drybox for the filament which fits into the right inset panel.

The printer is compatible with the 5-filament MMU3 multimaterial unit, allowing multicolor or multimaterial printing.

Upgrading from an MK4S

Prusa’s printers almost always have an upgrade path, and the MK4S is no exception. Users will be able to upgrade an MK4S to a CORE One. This upgrade process is a little more involved than with Prusa’s open frame printers because it will have to be entirely rebuilt, but the CORE One does reuse the MK4S’ extruder, bed, mainboard and touchscreen.

Prusa has made it clear that the MK4S is not being discontinued and the CORE One is a parallel printer, not a replacement. Development of the i3-style MK printers will continue while development of the fully enclosed CORE series will continue simultaneously.

Kit Option

Due to its exoskeleton construction, the CORE One is offered as a kit - it can be completely broken down into individual parts. No fully enclosed printer has ever been offered as a kit before.

Summary

The CORE One is an interesting development from Prusa. They’re late to the fully enclosed CoreXY printer game but have used their unparalleled experience to get it right with no compromises.

Prusa is doing the most they can with the enclosure - it is actively temperature controlled and ventilated. It can even accommodate PLA and PETG with the door closed with the use of the unusual intake vent.

They’ve also firmly resolved the speed issue - the CORE One can print as fast or faster than any other 3D printer on the market.

Its repairable, upgradable design should be adaptable for years to come and its very name implies that more printers like this are coming.

Brand Summary: Prusa

Prusa Research is a well-known manufacturer of high-end 3D printers that are known for their top-performing and innovative designs. The brand is mostly recognized for its impeccable documentation, high quality parts, and excellent customer support. Prusa printers are beginner-friendly once assembled, but the assembly process can be time-consuming, even though the firmware has extensive calibration and troubleshooting routines built-in. The Prusa community is large and active, with many technical experts among the veteran 3D printing hobbyists. Prusa's focus is on a few models at a time, and they are known for their well-made printers. However, competitors are rapidly catching up to Prusa, offering similar features at a lower price.

Printer Comparisons

The articles below provide in depth comparisons of the Prusa CORE One to other similar printers on the market.

Prusa CORE One vs Bambu Lab X1C

Vs

You can compare the Prusa CORE One to other 3D printers using our Compare tool.