If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Top pick

Prusa MK4S

About the Prusa MK4S

History

Prusa Research does not produce many models of 3D printers. Instead of introducing new models, they usually update their main model, the i3. They also offer upgrade kits so that owners of older models can update to the very latest. The current i3 is a direct descendent of one of the first 3D printers available to consumers. The i3 evolved into the i3 MK1, the i3 MK2, the i3 MK2S, the i3 MK3, the i3 MK3S, then the i3 MK3S+.

In 2023, Prusa released the MK4 (formally, the i3 MK4), after several years of development. It featured a replacement of the outdated 8-bit controller board with a new 32-bit controller board. Its other standout feature is the Nextruder, a Prusa-designed planetary geared direct extruder with a nozzle strain-based leveling system, controlled by its own advanced controller board. This extruder also featured a nozzle system with the heatbreak integrated, allowing quick nozzle changes.

The MK4 was well-received. It is very well built, with high quality components, and is extremely reliable and accurate. However, its price was still very high compared to its many competitors. But most importantly, Prusa’s competitors were competing with each other for speed and could offer faster printers that cost far less. Prusa famously does not disclose speeds like the 500mm/s or 600mm/s print speeds touted by its competitors, instead wisely insisting that there’s more to making a 3D print than just the printing speed. There’s preparation, heating, leveling, first layer, acceleration, deceleration, slowdowns for cooling small layers, etc. While this is all true, the MK4 was still substantially slower than its cheaper competition.

Now Prusa has leveled the playing field with the introduction of the much faster MK4S, announced on August 13, 2024.

New Features of the MK4S

High Flow CHT Nozzle

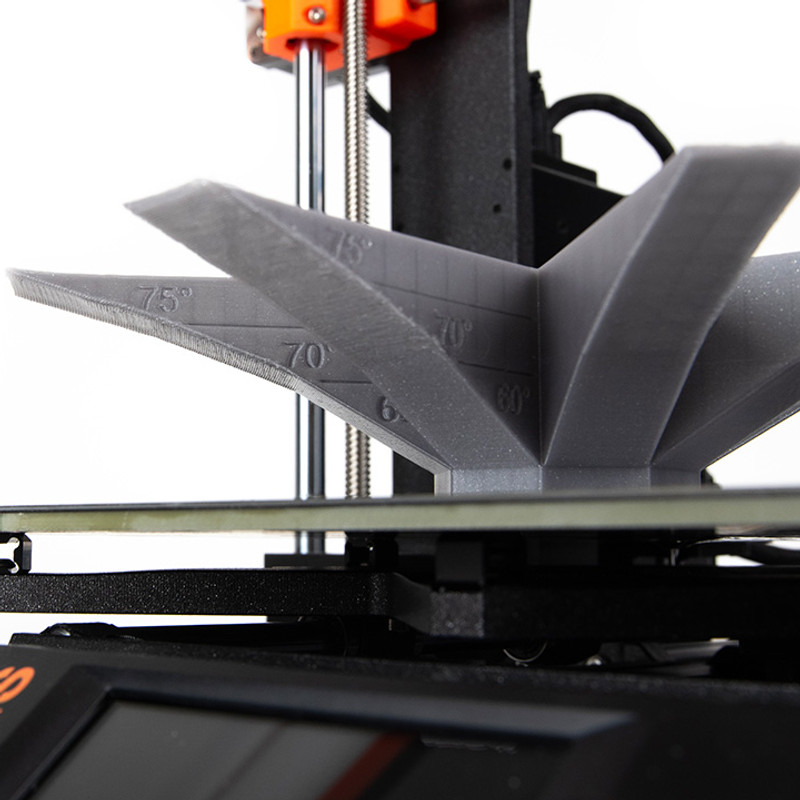

Prusa have addressed the speed issue in a unique way: by increasing the flow. Most manufacturers speed up their printers by modifying the motion system - using a CoreXY kinematic system, increasing acceleration and speeding up control actions and calculations with faster CPUs and improved firmware such as Klipper. Prusa’s approach is simpler and just as effective yet it does not require a substantial redesign of the printer - allowing a rapid changeover in production and an easy upgrade for MK4 owners.

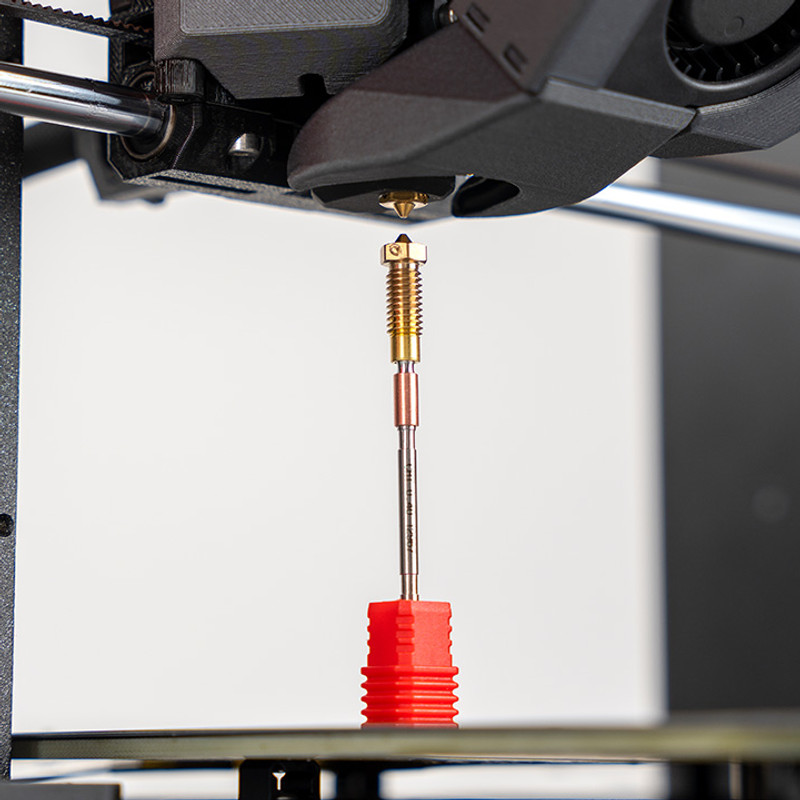

Prusa has increased the melt flow on the MK4S by using a high flow nozzle designed in collaboration with CHT and integrated into their all-in-one nozzle and heatbreak assembly. A CHT high flow nozzle has 3 small tubes leading to the nozzle tip rather than one large diameter tube. The surface area for heat transfer is increased, allowing more filament to be melted.

This nozzle can melt up to 26mm3/s of filament. Prusa’s own figures show their previous printers have a maximum melt flow of 18mm3/s. The flow for various filaments increases from 44% to 71% for 0.4mm nozzles, and 50% to 114% for 0.6mm nozzles. This increases speed without any other changes, allowing Prusa to catch up to their competitors.

Prusa advertises that the MK4S will be able to print a Benchy in 8 minutes, which is comparable to the competition’s 500mm/s or 600mm/s printers.

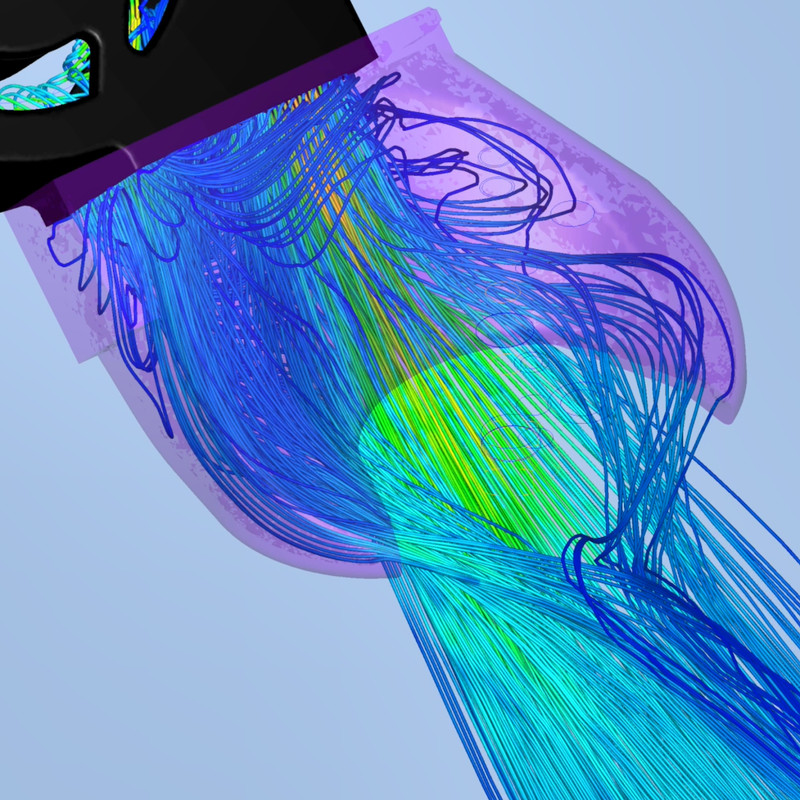

360 Degree Wraparound Part Cooling Fan Duct

The other major upgrade is a 360 degree wraparound part cooling duct. This ensures cooling air flow around all sides of the nozzle.

Other Upgrades

Other upgrades include:

- an NFC (near field communication) module, which allows the new Prusa App running on a phone to quickly connect to the printer just by tapping it, and to connect the printer to the wireless network

- injection molded rather than 3D printed parts such as the LCD touchscreen cover

- polycarbonate carbon fiber (PCCF) 3D printed parts for high strength where required

Features Carried Over from the MK4

The rest of the printer was introduced with the MK4, which is still quite new.

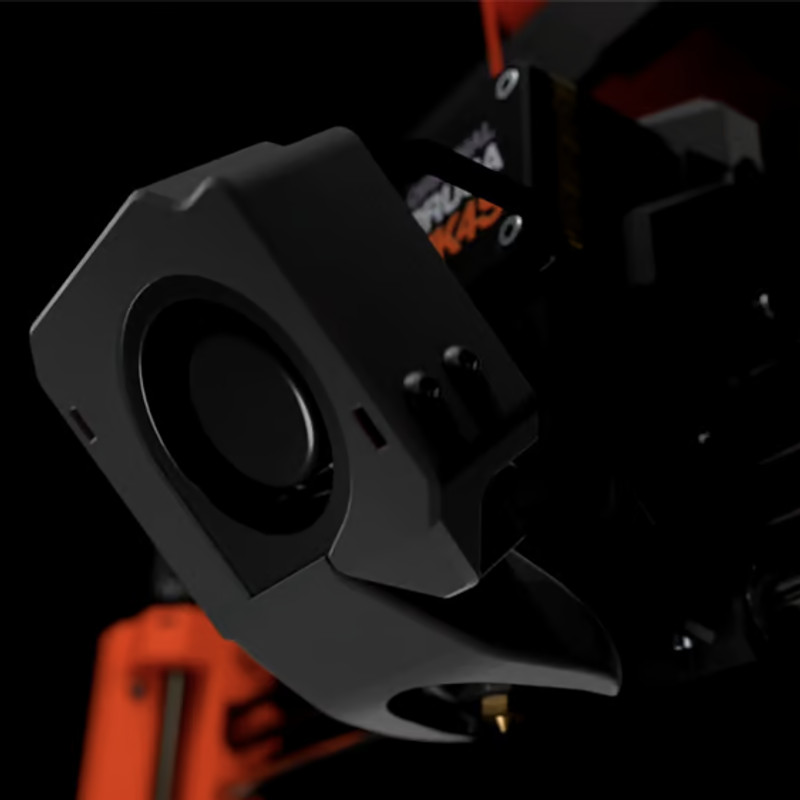

Nextruder and Quick Swap Nozzle Assembly

The standout feature is the advanced extruder, the Nextruder. This is a lightweight all-metal direct extruder with a high torque planetary gear drive. The quick swap nozzle has a heatbreak integrated.

Automatic leveling and Z offset is by a strain sensor activated by the nozzle assembly.

The build volume was established by the MK4 at 250 X 210 X 220mm. This is similar to all the Prusa i3s since at least the MK2 - it is considerably wider than it is deep and it’s moderately tall. The height has been slightly increased since the MK3, and that was slightly increased over the MK2, so there’s been continuous improvement. The bed material is PEI coated spring steel on a removable magnetically-attached sheet.

Electronics and Controls

The MK4 upgraded the controller board from the old 8-bit board used in the MK3 to a much more up-to-date 32-bit board which has much greater capabilities. The monochrome display in the MK3 has been replaced with a color touchscreen. Print files can be loaded by USB, Ethernet or WiFi. The printer runs PrusaLink, a local web-based network control program. The printer can optionally connect to Prusa Connect, a cloud-based service.

“No VFA” Stepper Motors

The MK4 and MK4S use upgraded stepper motors designed to reduce VFAs - vertical fine artifacts. VFAs are small vertically-oriented waves or ripples in the print that are formed as the X or Y axis stepper motors move between steps in a discrete fashion.

The no-VFA stepper motors have 400 steps in 0.9 degree increments, as opposed to previous motors which have 200 steps in 1.8 degree increments. These upgraded motors reduce or eliminate VFAs.

Upgrading from an MK4

An MK4 can also be upgraded to an MK4S. The package includes the high flow CHT nozzle, the 3D printed PCCF cooling fan duct, a WiFi module with NFC, a revised cover for the LCD and Nextruder, and an updated silicone cover for the heatblock.

Summary

The MK4S continues the tradition of Prusa Research incrementally upgrading the same printer and offering an opportunity for existing customers to upgrade their machines to the most current specifications. These upgrades finally speed up the main Prusa printer to the level of their competitors.

Brand Summary: Prusa

Prusa Research is a well-known manufacturer of high-end 3D printers that are known for their top-performing and innovative designs. The brand is mostly recognized for its impeccable documentation, high quality parts, and excellent customer support. Prusa printers are beginner-friendly once assembled, but the assembly process can be time-consuming, even though the firmware has extensive calibration and troubleshooting routines built-in. The Prusa community is large and active, with many technical experts among the veteran 3D printing hobbyists. Prusa's focus is on a few models at a time, and they are known for their well-made printers. However, competitors are rapidly catching up to Prusa, offering similar features at a lower price.

Printer Comparisons

The articles below provide in depth comparisons of the Prusa MK4S to other similar printers on the market.

Prusa MK4S vs Bambu Lab A1

Vs

You can compare the Prusa MK4S to other 3D printers using our Compare tool.