If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

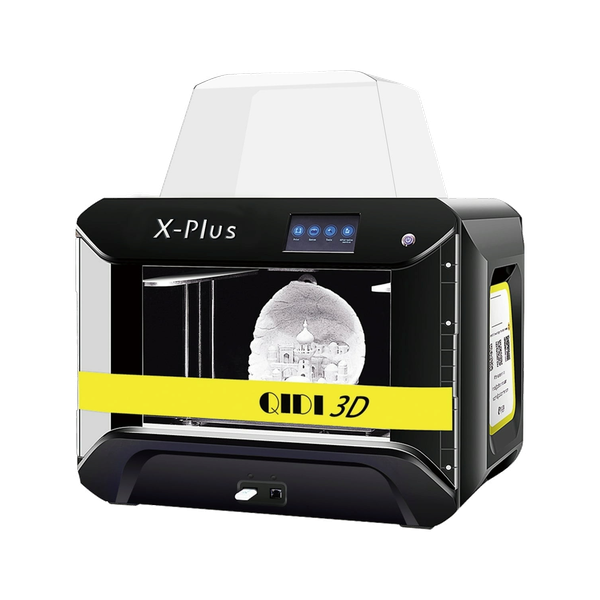

Qidi Tech X-Plus

About the Qidi Tech X-Plus

This is a midsize, fully enclosed printer capable of printing many filament types. The filament spool can be located inside the enclosure for especially sensitive materials. The print volume is 270 X 200 X 200mm and the CoreXY motion system uses dual Z rods. It is equipped with two interchangeable dual gear direct extruders: one for regular materials like PLA, PETG, TPU and ABS, and another all-metal abrasion-resistant extruder capable of printing carbon fiber, nylon and polycarbonate. It is one of the first printers to be equipped with a double-sided removeable PEI build plate. This printer is equipped with reliable, high quality components and constructed very rigidly. It is intended for advanced home hobbyist or light industrial or commercial use.

Benefits of the Qidi Tech X-Plus

Has touch screen - having a touch screen isn't a deal-maker or breaker, but it is a convenient feature that makes it easier to navigate the interface when you are printing files and configuring 3D printing settings.

Premium components - This printer is known for using the highest quality components, and prioritizes this over providing a lower price point on their printers.

Fully assembled - This 3D printer is shipped completely assembled, and is ready to plug in and start using as soon as you unbox it. You will still need to follow the included calibration procedures, but this will not take a significant amount of time.

Direct drive extruder - Direct drive extruders are mounted right above the hot end, and push the filament directly into it, as opposed to a side mounted bowden extruder setup. We prefer direct drive extruders to bowden since they are less prone to jamming and typically require less maintenance. they also are much easier to use with flexible materials

PEI build surface has good balance of adhesion and part removal - PEI beds are one of the more premium build surface options, and for good reason. They offer great first layer adhesion with no spraysor other treatments, and can be flexed to quickly remove parts. You'll need to clean the bed with a solvent like acetone or IPA every so often to maintain the bed's adhesion.

Wireless printing - In addition to the standard USB and SD card connections, you can connect wirelessly to this printer to print from your computer or mobile device.

All-metal hot end - An all-metal hot end allows for printing at high temperatures up to 300C, while standard hot ends are capped at 260C before the PTFE material begins to degrade. All-metal hot ends are also less susceptible to jamming, and do not degrade as fast.

CoreXY Kinematic System - A CoreXY 3D printer kinematic system uses two stationary motors to move the print head in the X and Y directions, resulting in faster and more precise movements compared to traditional printers. By separating the movement of the print head from the movement of the build plate, the CoreXY system is able to avoid the added weight and momentum of a moving build plate. This results in less vibration and better control of the print head, allowing for faster and more precise movements. Additionally, the CoreXY system can print at higher speeds compared to H-bot systems because it only needs to move one motor for each axis of movement, reducing the overall weight and inertia of the system.

Enclosure - An enclosure seals air around the print area. This holds warm, still air around the print area and is essential for printing temperature-sensitive materials like ABS. Enclosures also prevent particulates and gasses from being emitted into the surrounding area, increasing safety. They also greatly reduce printer noise.

Dual gear extruder - A dual gear extruder grips filament from both sides and can exert much more force on the filament before slipping. It helps with all filaments but especially with flexible, slippery TPU.

Disadvantages to consider

Manual bed levelling - This printer requires you to to adjust the bed level manually using nuts on each corner of the print bed. Once you have calibrated the bed leveling, you may need to adjust the levelling knobs periodically to ensure good first layer adhesion to the print bed.

High price tag - While this printer includes a lot of premium features, they come with a price. This printer is one of the more expensive consumer printers, and may not be worth the cost if you are willing to sacrifice some of the high end features.

Where to buy the Qidi Tech X-Plus

Brand Summary: Qidi

Qidi Technologies, often referred to as Qidi Tech or just as Qidi, offers a range of mid-priced to high-priced printers. These devices are considered "prosumer" level, striking a balance between high-end consumer devices and professional-grade printers. Qidi's offerings are particularly appealing to users who seek quality and performance beyond basic printers but aren't ready for the investment required for industrial-grade equipment. Qidi printers are known for their beginner-friendly nature. They come enclosed, which helps in reducing noise and fumes, making them safer and more comfortable for various environments. The printers feature easy-to-use touchscreens and come supplied with user-friendly slicing software, adding to their appeal for beginners.

Pros

- Has touch screen

- Premium components

- Fully assembled

- Direct drive extruder

- PEI build surface has good balance of adhesion and part removal

- Wireless printing

- All-metal hot end

- CoreXY Kinematic System

- Enclosure

- Dual gear extruder

Cons

- Manual bed levelling

- High price tag

Printer Comparisons

You can compare the Qidi Tech X-Plus to other 3D printers using our Compare tool.