If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Sovol SV08

About the Sovol SV08

Sovol has made some unusual 3D printers. Their first printer, the SV01, was released in 2020 and is just an Ender 3 clone like many other manufacturers were building at the time. But their next printer, the SV02, is an independent dual extrusion (IDEX) Ender 3 clone. The SV03 was a large Ender 3 clone with a direct extruder, which was only in much more expensive printers at the time. The SV04 is a large SV02, a large IDEX Ender 3 clone. In another unusual move, the SV05 was a box-style CoreXY Ender 5 clone.

Bucking the trend yet again, the SV06 is a Prusa i3 clone. They are the only major manufacturer to clone an i3. The SV07 is a Klipper-equipped fast Ender 3 clone like all manufacturers were releasing in 2023 to catch up to Bambu Lab.

Now the company has made probably their most unusual printer to date by releasing the SV08, based on the Voron 2.4. Since 2015, Voron has released a series of advanced, no-compromise open-source printer designs. The Voron 2.4 is one of their fastest, largest, most advanced designs. Since it is open source, Sovol can legally use the design either in parts or in its entirety.

So this is the industry’s first mass-produced Voron 2.4. It’s available at a small fraction of the cost of a self-sourced Voron 2.4, either from components or from a kit.

Design

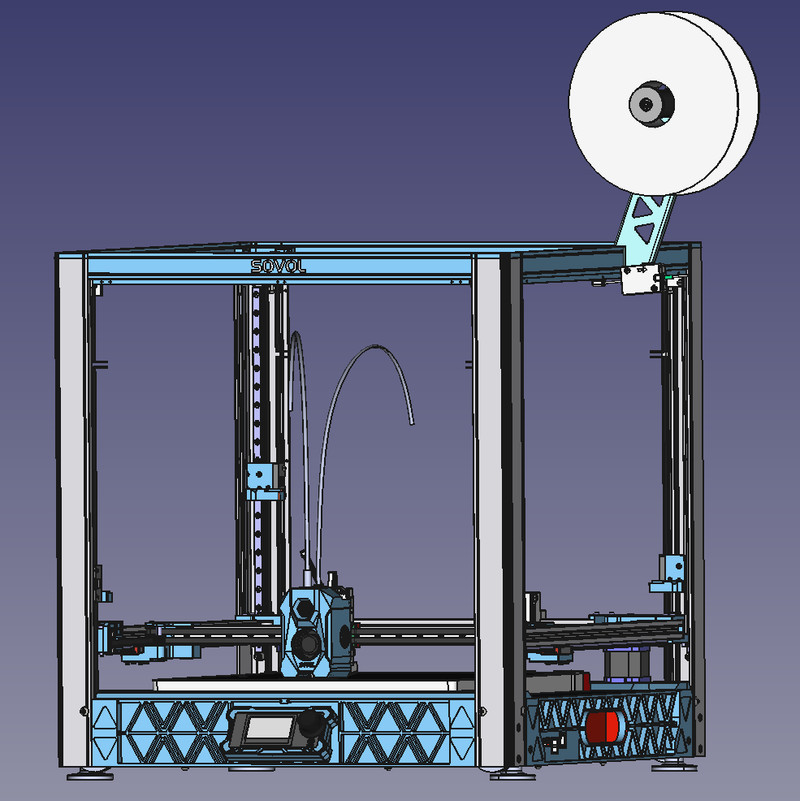

A Voron 2.4 can take over 40 hours to assemble, But Sovol has preassembled most of the SV08, cutting assembly time down to about an hour. It is a box frame printer constructed of CNC machined aluminum frame components and cast plastic parts - a Voron 2.4 requires cut aluminum extrusions and many 3D printed parts, printed with precision using ABS or better on another 3D printer. On the SV08, the base and gantry are preassembled. The main assembly activity is installing the 4 gantry support uprights, which come complete with stepper motors and belts.

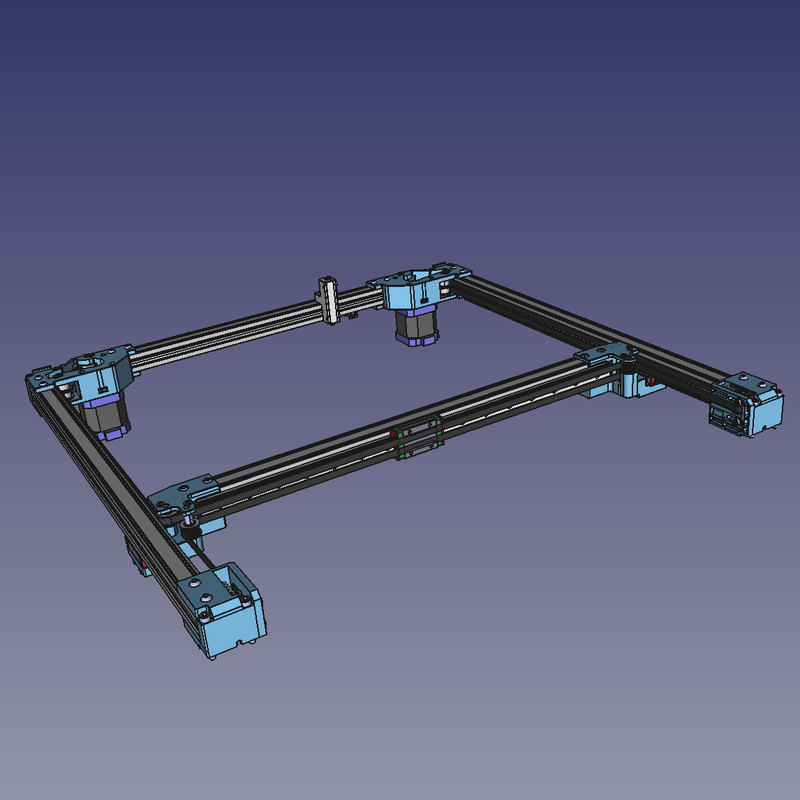

The large 350mm X 350mm PEI bed is aligned with guides at the rear corners, assuring perfect placement. It remains stationary at the bottom of the frame, while the “flying gantry” CoreXY design means the gantry handles all X and Y movement. The entire gantry assembly is raised and lowered above the bed by belts on 4 stepper motors. This keeps the center of gravity low, increasing stability. And motors powering belts operate much more quickly than leadscrews. These stepper motors are dampened, preventing the gantry from falling, and the 4 of them are more than strong enough to raise the entire flying gantry assembly. All axes move on 7 linear rails: 4 for the Z axis uprights, 2 for the Y axis and 1 for the X axis.

CAD drawing of the flying gantry

The SV08 is equipped with a very small knob-controlled monochrome LCD screen, showing only a few lines and a few characters at a time. This is the same screen used on the Voron 2.4 design. But this is only a rudimentary, secondary method of control - it’s been stripped down to the bare essentials. For complete control, the user relies on the printer’s wired and wireless network connections which give access to various interfaces running on the Klipper mainboard, controlling the printer and storing print files. An HDMI port allows you to connect a touchscreen of nearly any size - meaning you don’t need to pay for a fancy on-printer user interface unless it’s important to you, and if you do, you have many choices.

Powered by Klipper, the printer uses both pressure advance and input shaping to maintain quality during fast printing.

Wiring is greatly simplified by sending all sensor and control signals over the same wires using CAN bus. This is an advanced technique used in very expensive 3D printers and is never seen in printers in this price range.

Bed Leveling

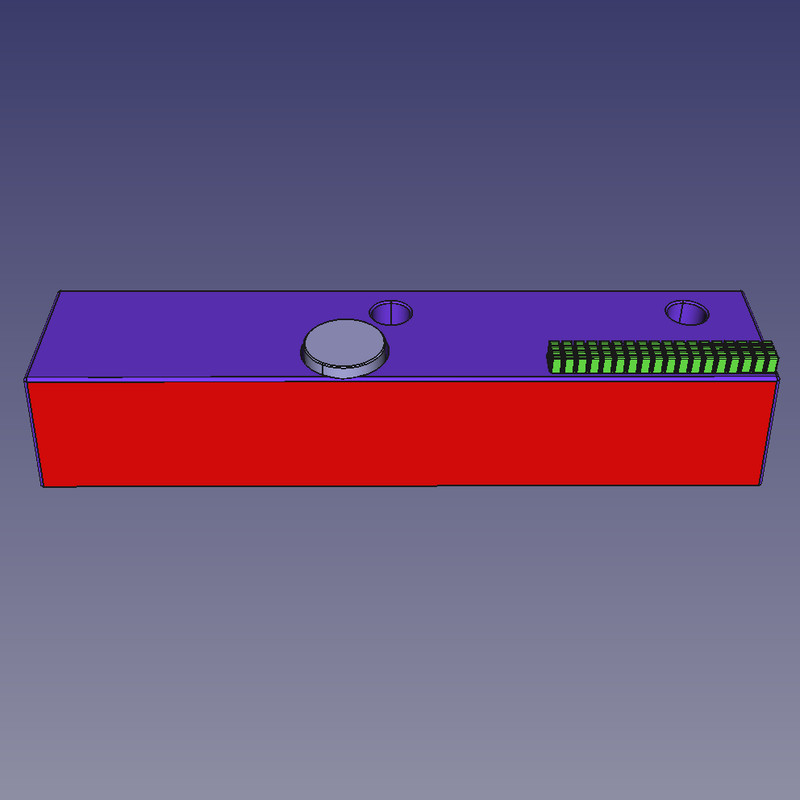

The SV08 uses a non-contact induction sensor for bed leveling, the same sensor used in the Sovol SV06 and SV07. There is also a pressure sensor behind the bed that the nozzle will tap for automatically setting Z offset, but this is not implemented yet in the firmware.

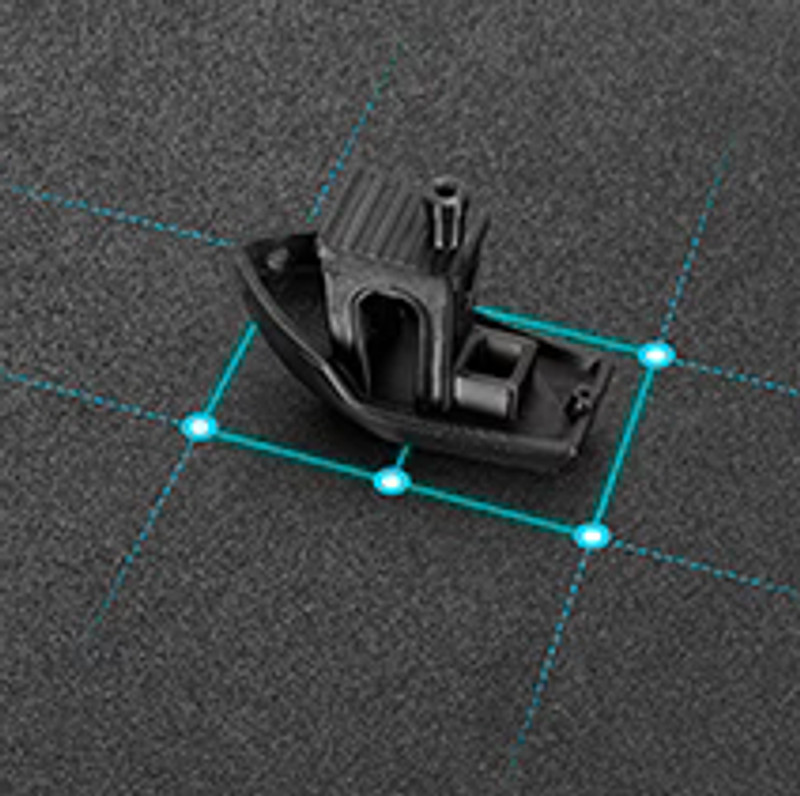

This printer uses KAMP - Klipper Adaptive Meshing and Purging. This measures a bed level mesh only in the area where the part will be printed, which is quite a time saver for such a large bed. It also prints the purge right next to that area.

All 4 Z axis motors are used to keep the gantry level to the bed in two dimensions based on the measured bed level mesh in a process known as Quad Gantry Leveling (QGL).

Fast Heaters

The bed heater is AC powered which is the fastest method - heating such a large bed with conventional DC power from the power supply would be quite slow. The nozzle is heated by a fast ceramic heater.

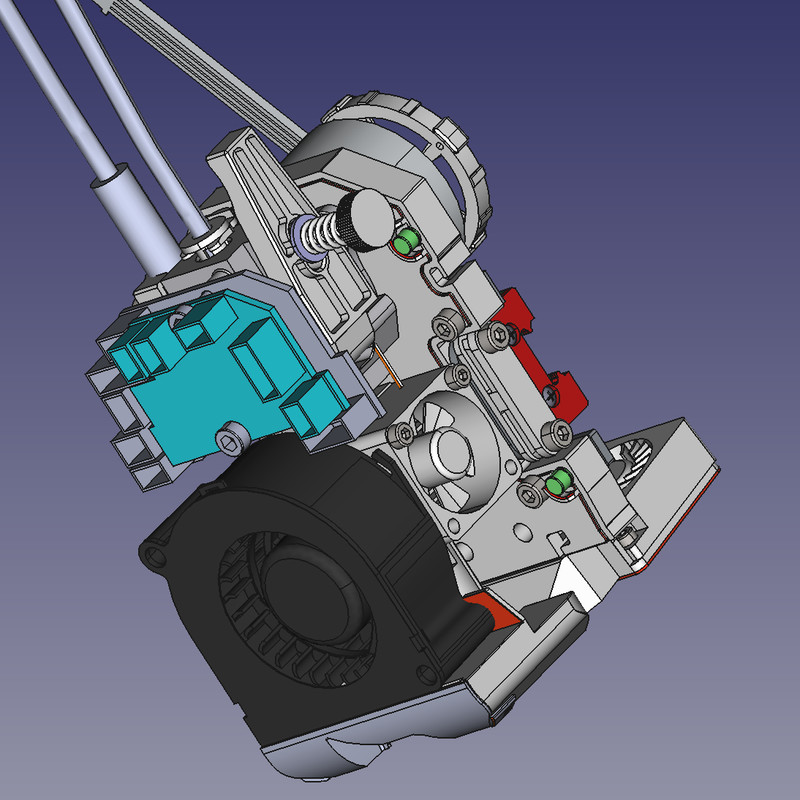

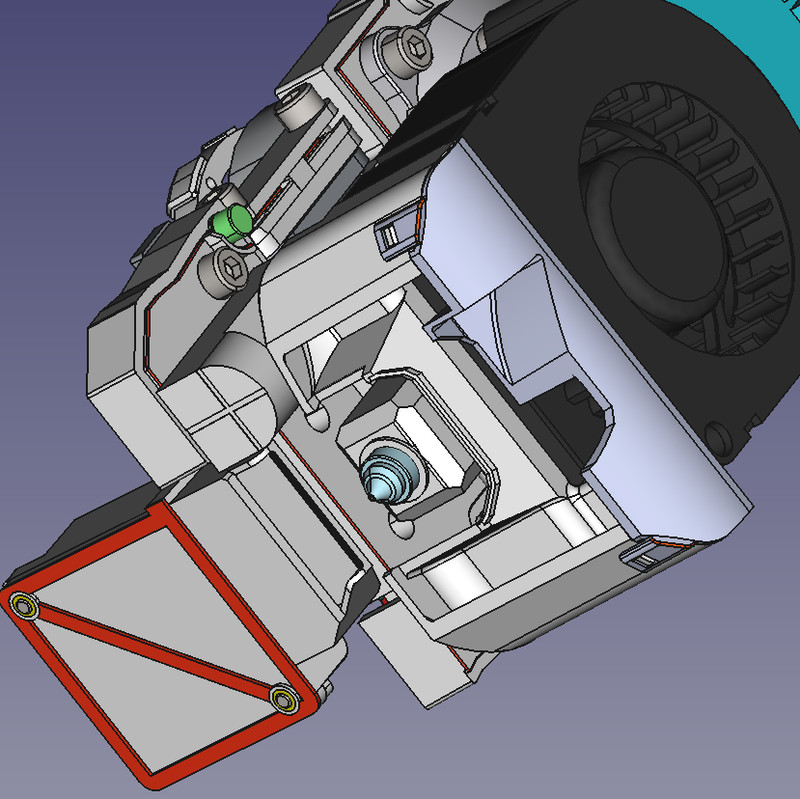

Part Cooling Fans

A printer with a peak print speed of 700mm/s needs a lot of cooling, so there is a massive 5020 (50mm diameter, 20mm thick) blower fan as a primary cooler with a duct that directs cooling air to the front and sides of the print. An auxiliary 4010 blower fan cools the back of the print - note the 4010 acts as the only cooling fan on printers like the Ender 3 and the Sovol SV06, so this is a huge upgrade.

The SV08 uses an all-metal direct extruder with dual steel gears driven by a planetary gear drive. This design has been used since the SV06 and provides high torque in a small size with minimal weight.

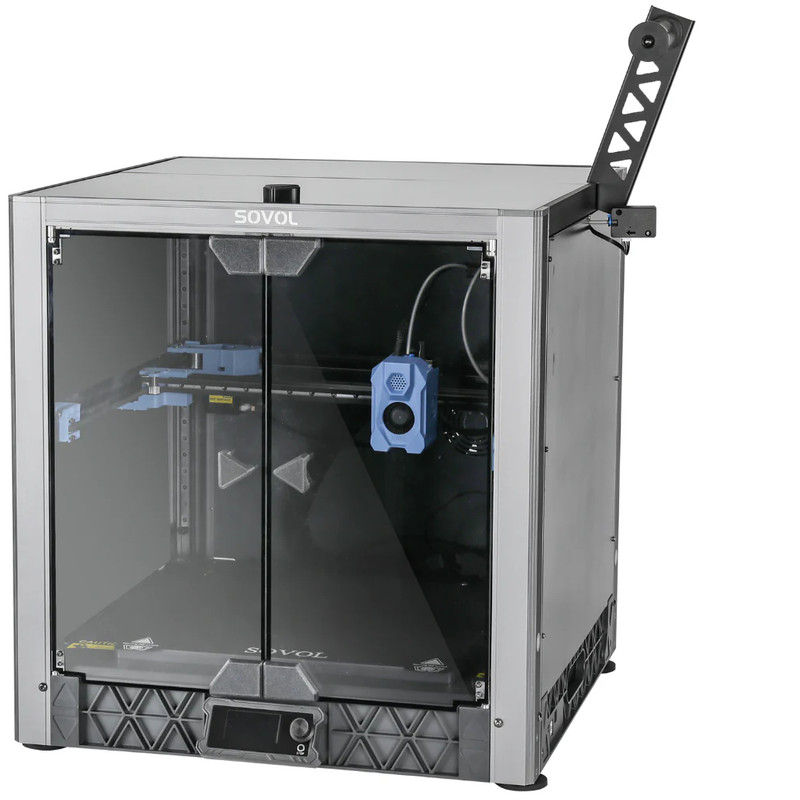

Enclosure

Stepped faces in the frame rails hold enclosure panels. The enclosure kit will be available later and will include a door, panels for both sides and the back as well as a top. This will allow the printing of temperature sensitive filaments like ABS.

Other Features

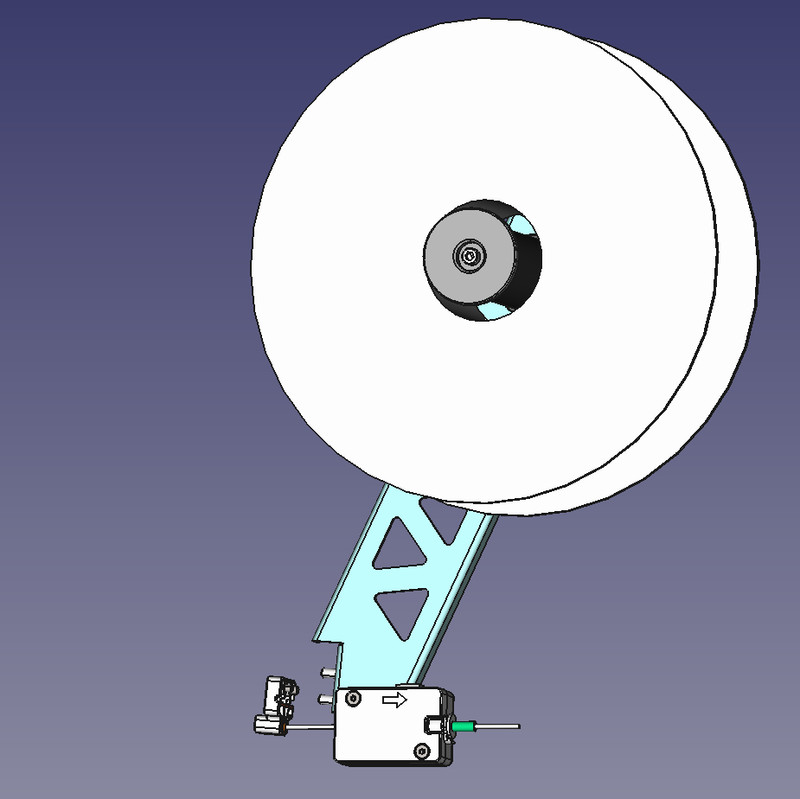

The SV08 is equipped with a camera, lighting, a nozzle wiper (not yet activated) and a filament runout sensor.

The filament runout sensor might not seem all that unusual, but Voron 2.4 kits do not come with one - the design doesn’t even have a spot for it.

Open Source

The printer is derived from an open source project and, in turn, Sovol has made the entire printer open source. They have released all mechanical and electrical designs on their GitHub repository along with the Klipper configuration.

This allows the community to design modifications using accurate dimensions right from the manufacturer. As well, the firmware can be easily modified to allow adjustments and incorporate new features.

Sovol will be giving $2 from every printer sold to Voron Design. This gives back to the community and should advance development. To a small non-profit design team comprised of a few individuals this could be a significant contribution - these printers may be sold by the thousands given the low price for the significant size, high speed and advanced features.

Specifications

Print volume: 350mm X 350mm X 345mm

Printer size: 550mm X 537mm X 575mm

Printer weight: 17.7kg (39 lb)

Printing speed: 700mm/s (peak)

Acceleration: 40,000 mm/s2

Extruder flowrate: ≤30mm3/s

Nozzle temperature: ≤300°C

Heatbed temperature: ≤100°C

Connectivity: WiFi, Ethernet, USB

Stepper motor drivers: TMC2209

CPU: Allwinner H616 (Quad core ARM Cortex-A53)

RAM: 1 GB (512 MB + 512 MB)

Flash memory: 8 GB eMMC

Issues

This is a noisy printer. The large part cooling fans are required for high speed printing but are not quiet. The mainboard fan is loud and its noise reflects in the underside of the printer and onto the table surface, creating a sound reverberation chamber. This mainboard fan runs at 100% speed as long as the printer is on - there is no thermal control.

The printer is large and heavy. This is good for stability and indicates it’s solidly built out of metal parts, and it’s necessary given the print volume, but it will be difficult to fit into many areas of a typical home. Given the size, weight and noise, it will not fit into many residential or office areas.

Early reviewers note that the Z offset does not get saved between reboots of the printer, but this is something that will probably be solved in one of the first firmware updates. As well, the automated strain-based Z offset module and nozzle wiper is not active on early units. This will be fixed in due time.

Who Is This For?

This is definitely not a beginner’s printer. It does have some nice quality of life features as we’ve seen, but it is not fully automated. And although assembly is vastly shortened over the extensive project that is assembling a Voron 2.4, it is still a lengthier process than almost every other recently introduced printer - some are even fully assembled.

The released drawings and firmware code will be welcomed by advanced users and tinkerers looking to customize and improve their printer with modifications and upgraded parts, but are not of much value to beginners. The assembly of a Voron is the ultimate achievement for many experienced hobbyists and the Sovol SV08 is a shortcut to this goal, providing an easy to achieve starting point for future modification.

We would definitely not recommend this to a beginner, but it does put the advanced Voron design within reach for many, many more experienced users. This is the largest, fastest printer available at this price and is unlike anything on the market at the moment.

Brand Summary: Sovol

Sovol is a 3D printer brand known for producing innovative printers with more features than their competitors at a lower price. Their printers are beginner-friendly and have good build quality, but their entry-level printer, the SV01, lacks a bed leveling probe. While Sovol's community is still establishing itself, the company's support is well-regarded, and they have over 80,000 users. Sovol has experimented with complex dual extrusion features, which led to clogging problems and quality issues in some of their previous models. However, their current printers, such as the SV06 Plus, offer impressive features like 25-point auto bed leveling and a 500W bed heater. Sovol's varied printers appeal to different users, from new users to advanced users.

Printer Comparisons

You can compare the Sovol SV08 to other 3D printers using our Compare tool.