Layer Height for 3D Printed Parts

What Is Layer Height?

Filament 3D printers create parts as a series of layers, starting from the bottom of the part and working upwards. Layer height is the setting that controls the thickness of each individual layer of the printed part, typically measured in millimeter or microns (thousandths of a millimeter).

The standard layer height for filament 3D printers typically ranges from 50 microns (.05 mm) to 400 microns (0.4 mm). Adjusting the layer height affects the part’s detail and resolution, print speed, and the amount of post-processing required.

Layer height significantly impacts the print speed because it affects the total number of layers in a print. With a smaller layer height, more individual layers are needed to complete the object, increasing print time. Because each layer will take approximately the same time to complete regardless of the layer height, doubling the layer height will roughly half the print time.

Layer height also impacts the level of detail and the amount of post-processing work required. A smaller layer height provides finer details and a smoother finish, often reducing the amount of post-processing needed to get a smooth finish with no visible layer lines. However, it’s important to note that the material also affects your ability to get a smooth surface finish through post-processing—filaments like ABS are naturally easier to sand and smooth than PLA.

Smaller layer heights also tend to print overhangs better, since smaller layers mean that each layer is not as far from the edge of the layer below it. With large layers, much of the outer shell will be printed onto air for a severe overhang, so you’ll often see more drooping on overhanging parts with larger layer heights.

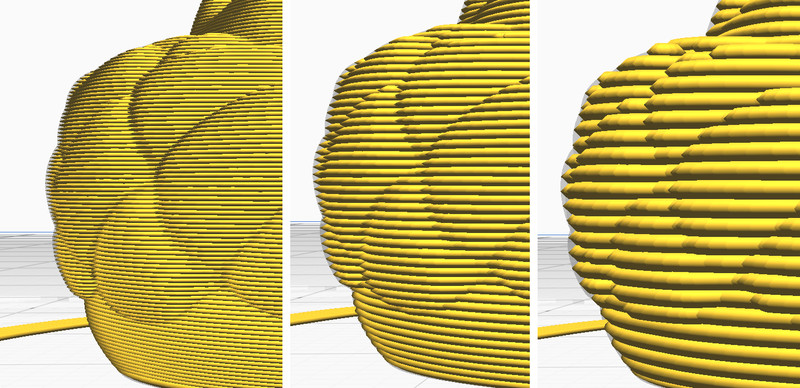

The image below illustrates the visual differences between prints with varying layer heights.

Nozzle Size and Layer Height

The nozzle size of your 3D printer plays a significant role in determining the optimal layer height. As a rule of thumb, the layer height should be between 25% and 75% of the nozzle diameter. Exceeding this range can lead to inconsistent layers at the lower limit of layer height and weak layer bonding at the upper limit.

For instance, if you’re using a standard 0.4 mm nozzle, your maximum layer height should be around 300 microns (0.3 mm) and minimum should be 100 microns (0.1 mm). If you wish to print with larger layer heights for faster prints, you would need to use a nozzle with a larger diameter. On the other hand, smaller nozzles, such as 0.2 or 0.3 mm, can allow even finer details for small models by allowing for smaller layer heights.

Keep in mind that using large nozzles and layer heights will drastically increase the required flow rate of filament through the hotend, which is limited by how fast the hotend can melt the plastic. If the flow rate is too fast, it can cause your extruder to skip since it cannot push the filament through fast enough. If this occurs, try decreasing the print speed until the hotend is able to keep up. You can buy “volcano”, or high flow rate, hotends for many 3D printers to increase the maximum flow rate and increase your printer’s maximum printing speed with larger layer heights.

Recommended Layer Height

The layer height you use will depend on your use case for your 3D prints. We recommend these layer heights:

100 micron (0.1 mm) - High Detail

If you require a high degree of detail, such as for miniatures, sculptures, or parts with intricate features, we recommend a small layer height. These parts are typically not large, so the increased print time will be less of a concern. If you’re using a nozzle smaller than the standard 0.4 mm size, you can achieve even thinner layers like 50 microns, but we recommend using at least 100 microns with a standard 0.4 mm nozzle.

200 micron (0.2 mm) - Balanced

For general purpose 3D printing and parts with less intricate detail, we recommend a layer height of 0.2 mm. It strikes a balance between detail and print speed, and is suitable for a wide range of applications.

300+ micron (0.3 mm)- Functional Parts

When speed is more crucial than detail, such as for prototypes or functional parts, the increased print speed of thicker layers is more beneficial. With nozzles larger than the standard 0.4 mm, you can use larger layer heights, such as using a 0.6 mm nozzle to print 400 micron (0.4 mm) layers.