Origin Story: My Wooden 3D Printer

If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

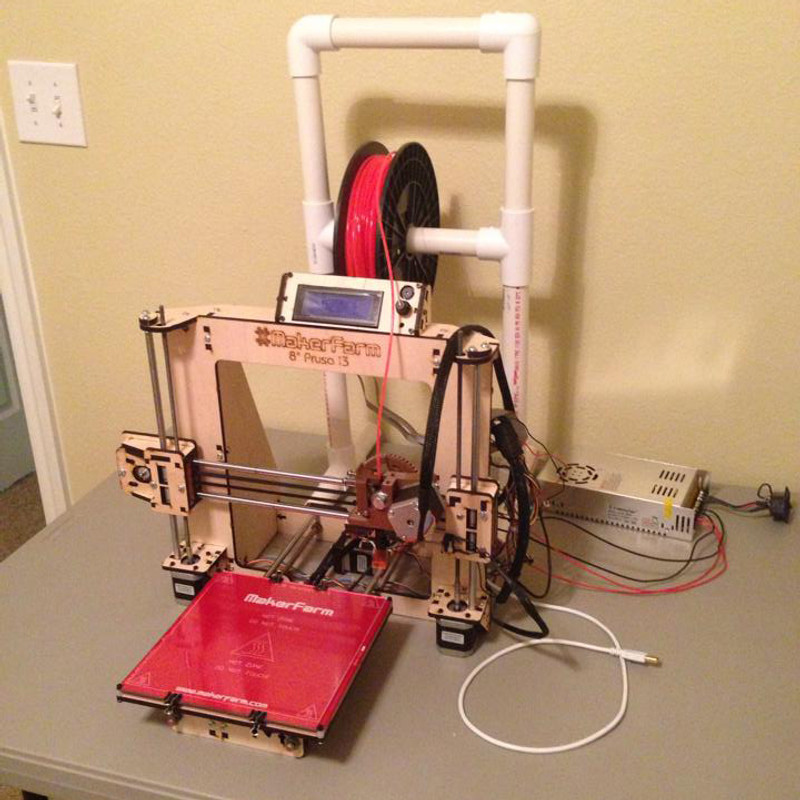

My first 3D printer was made of wood.

This is the type of thing I expect to tell my kids someday to make me sound even older than I am, as though I was somehow playing with 3D printers before the industrial age or indoor plumbing. But the truth is, it’s only been about 11 years since I got into the hobby—it’s come a long way in a surprisingly short time.

Of course, 3D printing itself has been around longer than my personal involvement with it. The RepRap project, one of the first efforts to make 3D printers accessible to hobbyists (and self-replicating, although that aspect has mostly fallen by the wayside), began in 2005. Within a few years, companies like MakerBot started selling kits and prebuilt machines, bringing 3D printers closer to being a consumer product. I remember seeing the MakerBot printers when I was in college and wanting one, but it didn’t quite fit into my college student budget. I’d have to wait a few more years before getting in.

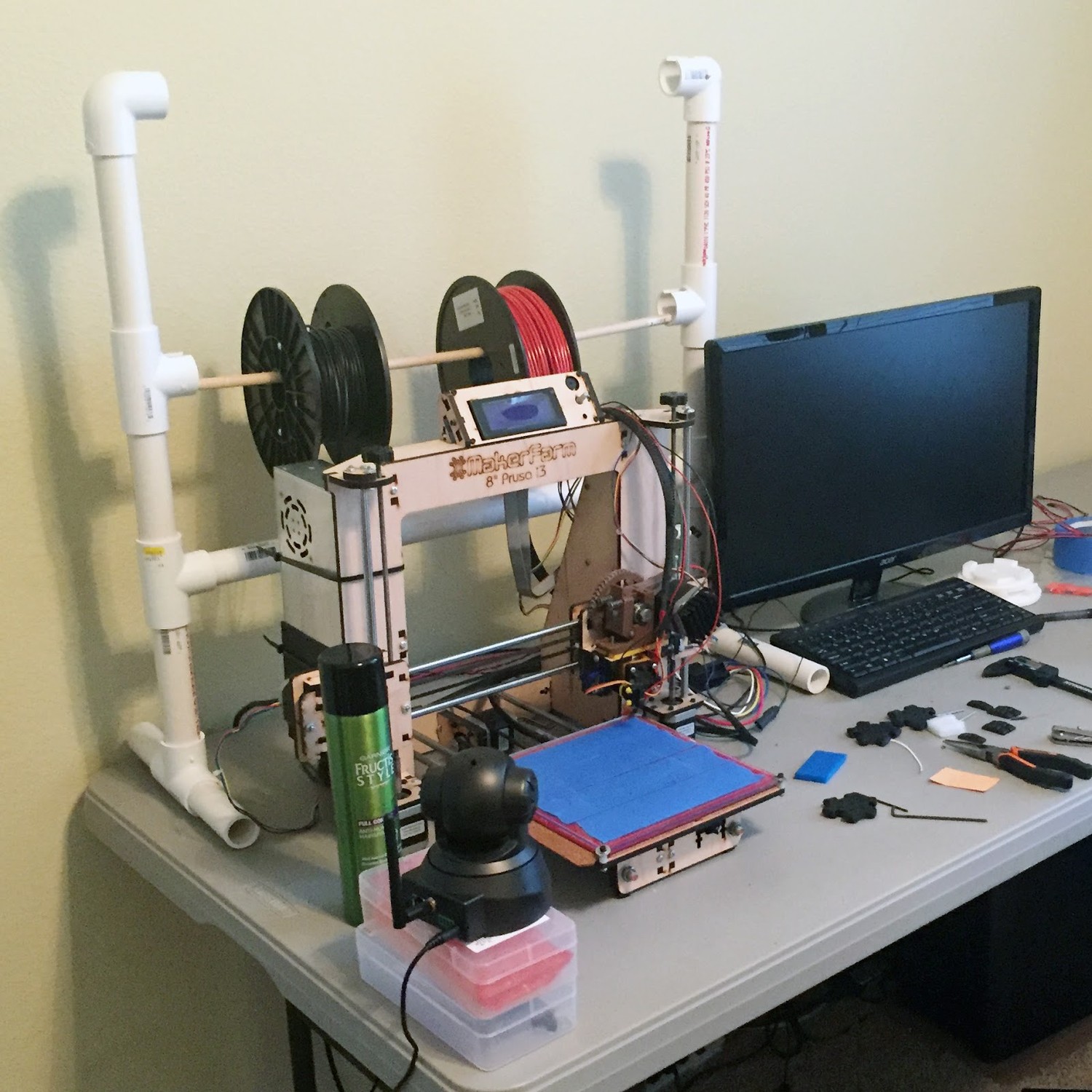

I got my first 3D printer in 2013, as a kit from a company named MakerFarm. The company unfortunately isn’t around anymore, but their printers were some of the most affordable and feature-complete kits I’d seen up to that point. I think the original kit cost somewhere around $550–a bargain at the time. I remember being excited about the idea of getting a 3D printer, but also uncertain. Would I be able to figure out how to put it together? Would I actually use it for anything? And was 3D printing going to stick around, or was this just a short-lived fad? I think I lost some sleep debating the decision, but I did end up pulling the trigger on the purchase. I guess things worked out.

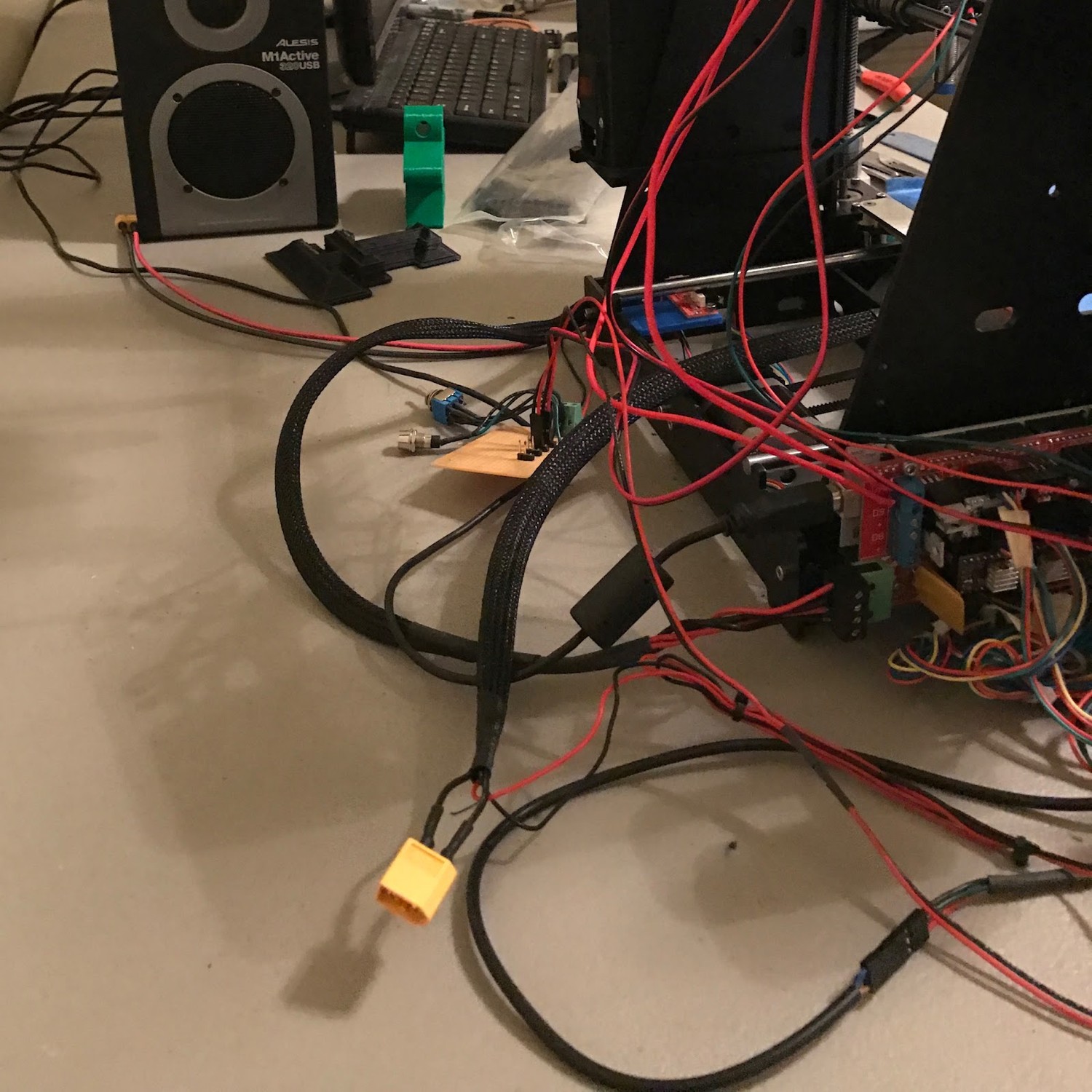

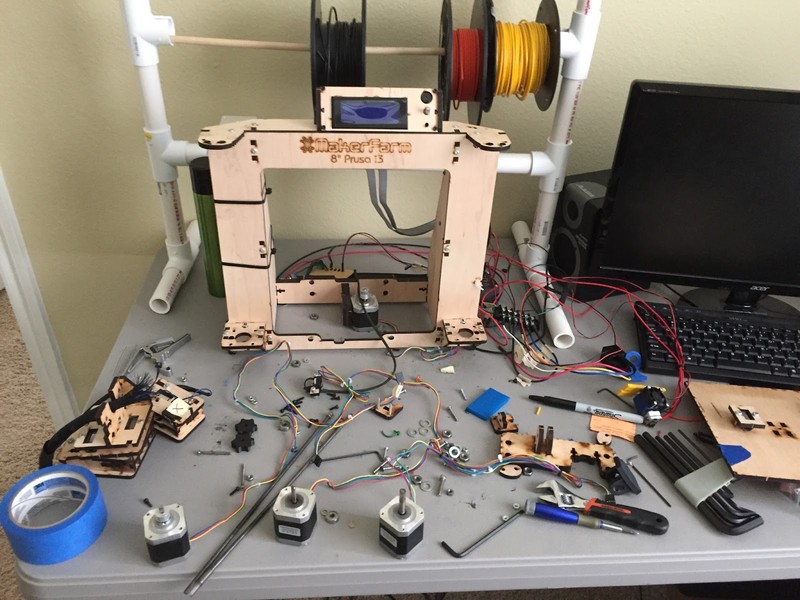

The printer arrived as a box of parts, with laser-cut sheets of wood that I had to carefully punch out and fit together to form the frame and gantry brackets. It was a clever way of designing a 3D printer and is probably part of how they were able to keep the cost down, but was definitely a bit fiddly to assemble. The company (actually, I think it was a one-man operation, another charm of the earlier days of the hobby that has mostly been lost now) did actually have a clear assembly guide and also provided email support, which helped.

One of my friends had also decided to get into 3D printing with the same kit (which I take credit, or responsibility, for…he’s still very much involved in the hobby). We ended up building both of our machines at the same time—sometimes completing steps in parallel, and other times using one kit to try out a complicated step and then repeating it on the second kit after seeing how things were supposed to fit together. I’ve always enjoyed building things and working on electronics projects, so I found it fun, but it was definitely not for the faint of heart.

The two printers took us a full weekend to build, starting on Friday evening after work and continuing well into Sunday. By Sunday evening, we were close to having one of the machines fully completed, and my friend invited a few other guys over to see the historical moment. We worked at an engineering company, so it wasn’t particularly hard to find the kind of people who would drop everything and drive over to see a 3D printer.

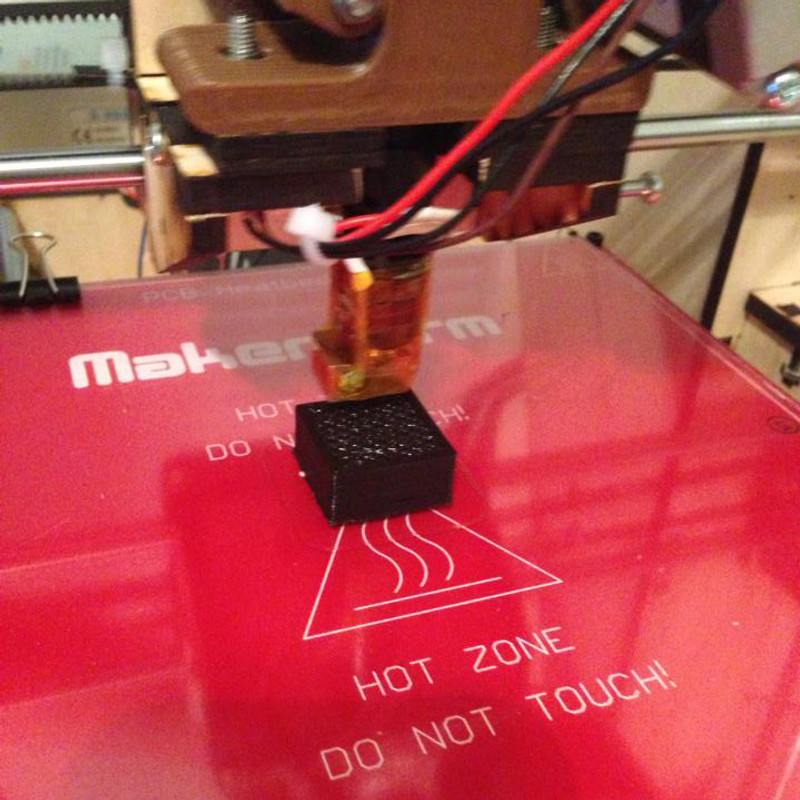

The popular “Benchy” model wouldn’t be released for another two years, so our first 3D print on the MakerFarm printer was a simple 20x20mm calibration cube. If you’ve ever used a 3D printer, you’re familiar with the action of contorting your body to get your head down to the level of the bed so you can see the first layer and details of the print start to appear. Imagine that, but with 4 people all crowding around to watch a suspicious-looking mass of wires and motors slowly produce a small cube. The anticipation was immense, and I think for a while the only sound in the room was the musical sound of the stepper motors. If you’re not sure what I mean, you probably got into 3D printing after 2019 or so—before then, the motors all made weird musical noises while printing.

One of my favorite memories from this experience was that when that first cube was finished, we all went to McDonald’s in celebration, and because we probably skipped a meal or two in our excitement to finish the printer build. Of course, we took the cube with us, and set it in the middle of the table to talk about while we ate. Occasionally one of us would pick it up and turn it around in our hands, admiring its somewhat-straight lines as though it was an artistic masterpiece. I’m sure that made us look completely normal and well-adjusted to everyone else in the restaurant.

That marked the end of a project, but also was only the beginning. In those early days of 3D printing, assembling the machine was really only the first step, and it took me weeks to calibrate my printer to a reasonable degree of accuracy and print quality. A combination of manual adjustments, rudimentary slicer software, and fewer online guides made calibration a time-consuming and frustrating process. I’m sure the material properties of the wood frame didn’t do me any favors, either—wood isn’t exactly the most rigid and consistent material.

I did eventually get things calibrated, and I used that printer for tons of functional parts and fun models over the next few years. It was never as reliable as modern machines, and I spent plenty of time fixing or modifying parts of it, some of which I’ll probably cover in future posts here. It was also never capable of the quality and speed that we’re used to these days—I frequently ran 24 hour prints, but not because I was printing anything particularly large or impressive. Everything just took longer.

Even still, that first MakerFarm 3D printer cemented my interest in 3D printing and got me into a hobby that has become a substantial part of my life. The 3DPros company and this website ultimately trace back to that first wooden 3D printer, and I still personally enjoy building and testing 3D printers. It’s an impact I never could have imagined from making that first purchase. I’m glad printers now are a bit easier to use, but I’ll always have great memories from that first machine.

Read more from the History of 3D Printing series

The Electronics of Early 3D Printers

June 5, 2024

June 10, 2024