If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Bambu Lab H2D

About the Bambu Lab H2D

Bambu Lab revolutionized the 3D printing industry in 2022 with the release of the X1C, a 500mm/s CoreXY fully enclosed printer with extensive automation capabilities and a multifilament system, the AMS (Automatic Material System). The industry has been trying to catch up ever since, first by introducing new 500mm/s printers, then by introducing their own fully enclosed high-speed CoreXY printers. Creality took a while to respond, but finally met and exceeded the X1C’s capabilities in the K1 at 600mm/s. Later, they took it further with the K2 Plus, a 600mm/s fully enclosed 3D printer with an actively heated chamber and the CFS (Creality Filament System) multifilament feeder, sealed and heated to dry filament.

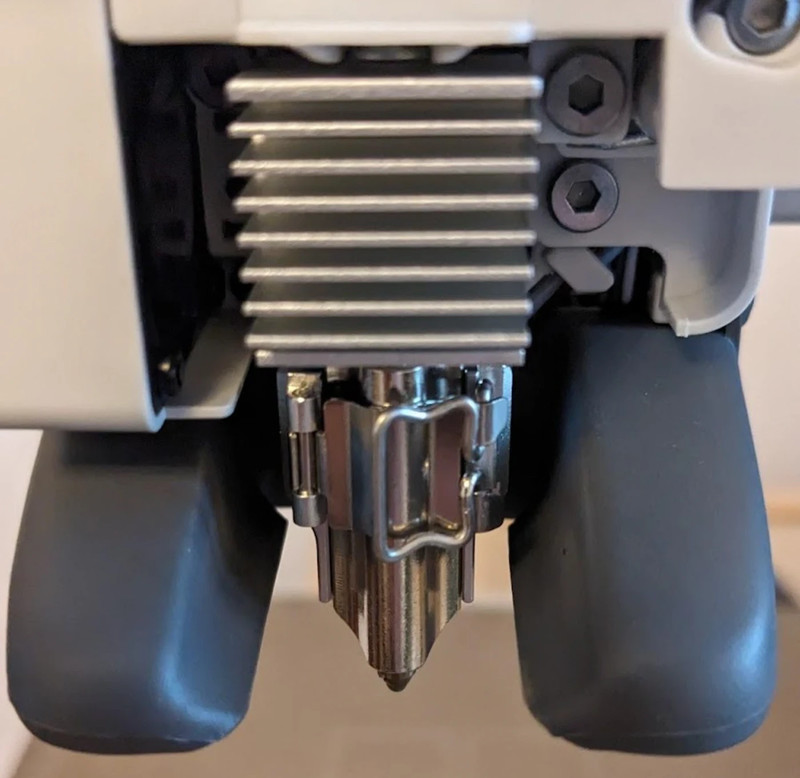

Bambu Lab has been under pressure to enlarge their 256 X 256 X 256mm X1C, starting shortly after the X1C’s introduction (and the follow-up, less capable P1 series). They may have disappointed some fans when they announced the downmarket open-frame A1 mini and later the A1, but the A1 series introduced a few new technologies which were more advanced than the older X1 and P1 printers. The first was a tool-less quick swap nozzle assembly, which comprises the heatsink and nozzle. This is held into the extruder by a magnet and retained by a clip mechanism. The second technology is the friendly-looking, informative touchscreen.

On March 25, 2025, Bambu Lab introduced the H2D. It is a fully enclosed, larger CoreXY X1C follow-up. Bambu Lab customers have been asking for something like this, but it goes beyond the X1C in that it is a dual extrusion printer and is also capable of laser engraving, laser cutting, bladed cutting, and pen plotting.

Key Features of the Bambu Lab H2D

Build Volume

The print volume is complicated, like all dual extrusion printers. Since the two nozzles are mounted side-by-side, the rightmost nozzle can’t print on the extreme left of the bed with the extruder positioned at its limit on the left, and the same situation occurs with the leftmost nozzle on the right of the bed with the extruder at its limits on the right. So, although the bed is 350mm wide, the effective print volume with only one nozzle printing is 325 X 320 X 325mm - that nozzle just can’t reach all the way on one side. With two nozzles printing, the print volume drops to 300 X 320 X 325mm since neither nozzle can reach the edge.

Speed

The speed has been increased to 600mm/s, probably to compete with Creality’s K1 series. To enable this, the H2D uses high flow nozzles capable of 40mm3/s flow. It’s more likely that only the optional very high flow 65mm3/s nozzles would permit this speed continuously.

The toolhead is capable of 1000mm/s movement, but for 3D printing it’s limited to 600mm/s. It has 20,000mm/s2 acceleration, just like the X1C.

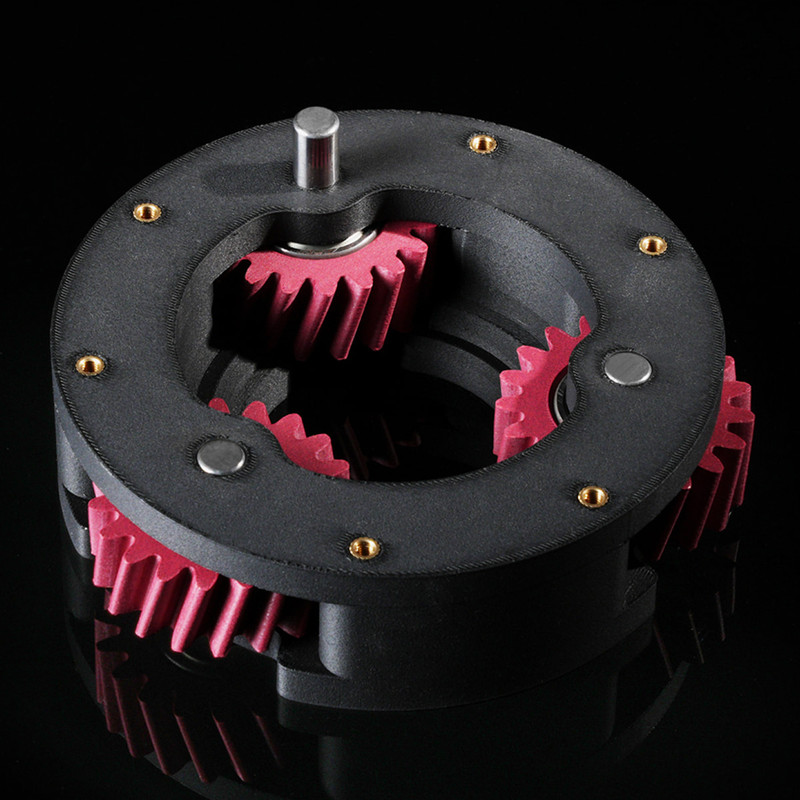

Extruder

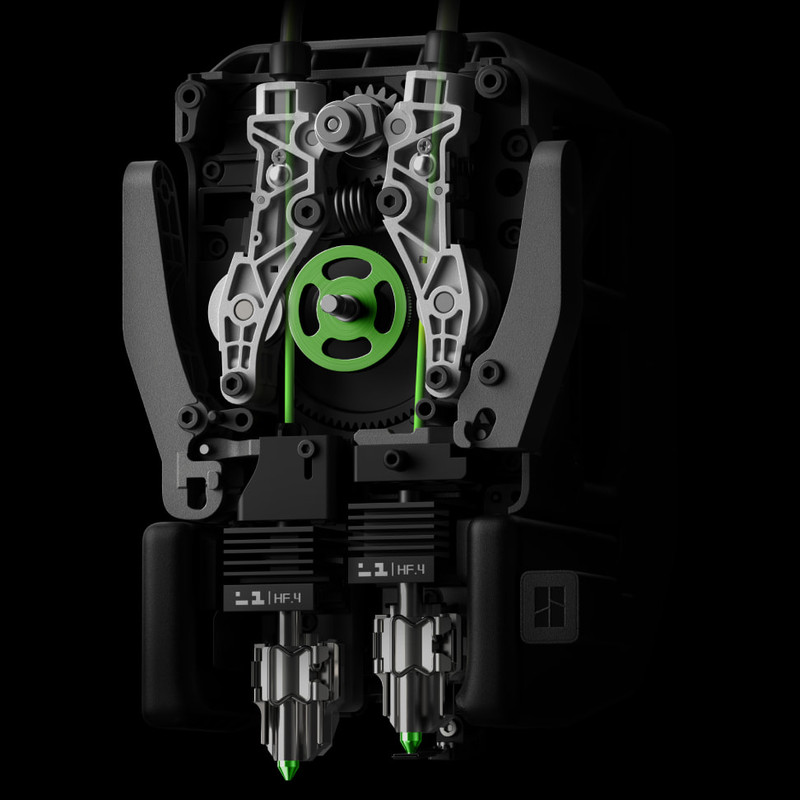

The H2D’s dual extruder is the first new dual extruder on the market in many years. Dual extruders allow quick filament changes without filament waste. They present some unique problems though. Each nozzle must be individually leveled, and each nozzle must be precisely aligned with the other. Also, there’s a high probability of the idle nozzle colliding with the print the active nozzle has just printed. And special care must be taken to ensure the idle nozzle does not ooze filament onto the print.

Bambu Lab has considered all these concerns with their new design.

A cam mechanism lowers the left nozzle when it’s active, and raises it higher than the right nozzle when it’s idle. The right nozzle remains in place. This means the active nozzle is always lower than the idle nozzle, preventing nozzle collisions with the print. This cam mechanism also disengages the extruder drive gear from the idle nozzle and flips a nozzle stopper under the idle nozzle, preventing oozing.

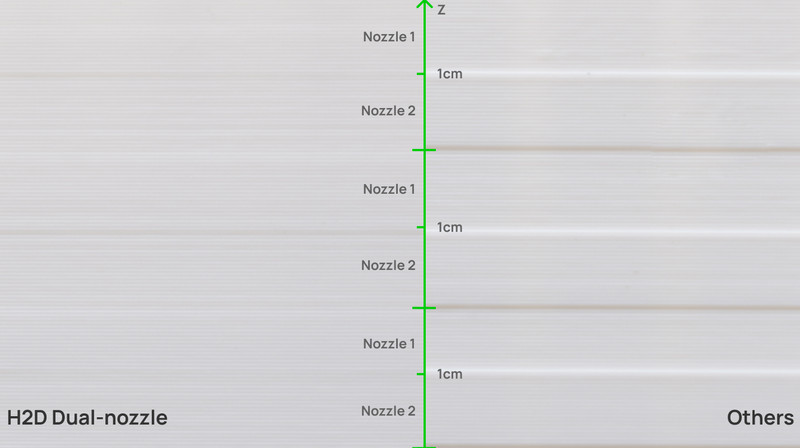

A calibration sensor keeps both nozzles leveled and aligned with each other to within 25µm (0.025mm). This reduces artifacts when the printer changes from one nozzle to the other.

Bambu Lab paid special attention to the extruder motor since it’s critical to ensuring even, consistent flow to the nozzle. Almost all high-speed printers have linear advance, which adjusts extrusion flow as the nozzle approaches corners in the print. If the extruder motor is able to respond more quickly, linear advance becomes more effective. Fine control over the extruder motor also means the motor can adjust better to different filament flow properties and changes within the filament. Motor position feedback leads to the detection and correction of transient conditions like filament grinding and nozzle clogging. Bambu Lab calls this motor the DynaSense extruder motor, and it’s not the usual stepper motor - it is a PMSM (permanent magnet synchronous servo motor) design which samples torque, resistance, and position 20,000 times per second, adjusting the electromagnetic force to compensate and ensure smooth control.

X Axis Linear Rails

Bambu Lab has changed from linear rods to linear rails on the X axis. Linear rods are used on all of Bambu Labs’ previous CoreXY printers as well as competitors’ CoreXY printers. But Bambu Lab uses linear rails on the A1 series, and they’re used on most of the competition’s modern open frame printers as well. Though they’re heavier and more expensive, they’re extremely rigid and may be necessary to support the higher weight of the dual extruder without deflection.

Machine Vision

The Bambu Lab H2D has three 1920 X 1080 cameras: a live view camera of the chamber, a nozzle view camera (focused on the nozzle with a macro lens), and a toolhead camera in the extruder. The live view camera is used for the usual purpose of remotely monitoring the print, but AI also uses it for a “pre-flight checklist”. Many components have optical codes on them, which resemble components of QR codes. AI examines these codes on the build plate and the nozzles and stops the print if these items don’t match the chosen print parameters. It also checks for items left on the build plate - tools, previous printed items, or debris.

AI also checks the nozzle view camera for nozzle clumping, air printing (extrusion failure), and spaghetti (filament that did not adhere to the bed or to the rest of the print).

Vision Encoder

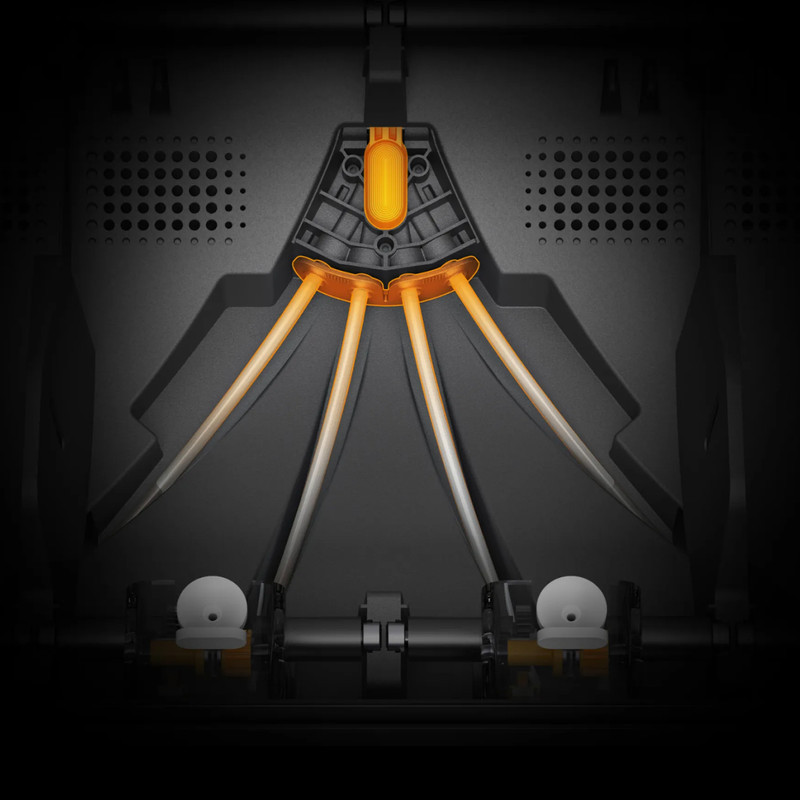

The H2D makes extensive use of machine vision, and a new application of this technology is what Bambu Lab calls a vision encoder. A special vision encoder plate has a surface covered in optical codes and an optional vision encoder sensor reads the position of these codes to within 5µm. This feedback corrects movement to within 50µm (0.05mm), which is 10 times better than typical 3D printer accuracy. It means that mechanical components like gears and axles fit together tightly with virtually no provision required for inaccuracy.

Filament Sensors

While most 3D printers have one filament sensor to detect filament run-out or breakage, the Bambu Lab H2D has 15 sensors in the filament path, going from each AMS multifilament feeder port to the 4-to-1 filament tube hub, to the connection to the printer, to the extruder. These sensors monitor not only filament presence/absense but also velocity, tension, filament tip location, extruder thermal conditions and extrusion pressure.

Controls and Connectivity

Bambu Lab’s A1 series touchscreens have friendly prompts, icons and an “assistant”, with a happy green “OK” face when there are no errors and a frowny red face when there are errors.

The H2D’s large 5” touchscreen carries over the A1 font, friendly prompts, and assistant. It even quotes pithy catchphrases like “I would print 500 layers, and I would print 500 more”. Maybe this is too much for some users, but it’s definitely an improvement in user friendliness over the X1C.

The printer connects to the network by dual-band Wi-Fi and is controlled by the touchscreen, Bambu Studio slicing software or the Bambu Handy app running from anywhere.

Chamber Heating and Ventilation

The chamber is actively heated to 65°C. Based on the set temperature, the printer opens an air inlet and directs outlet air as appropriate. It’s designed to keep the chamber cool enough for printing PLA with the door closed, or warm enough for printing ABS, with the exhaust air directed through an activated carbon filter to reduce hazardous gases and particulates.

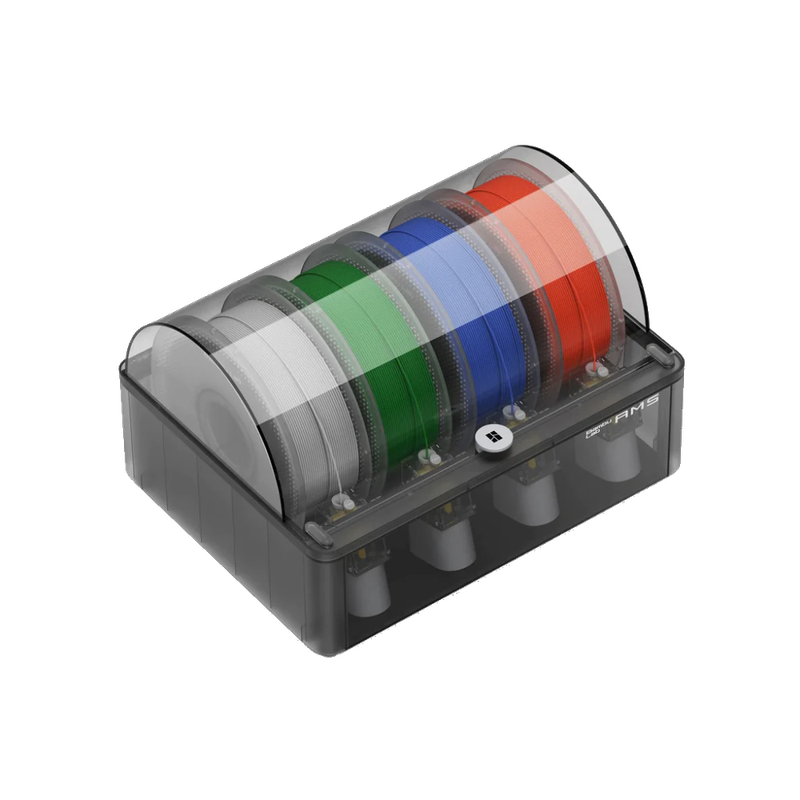

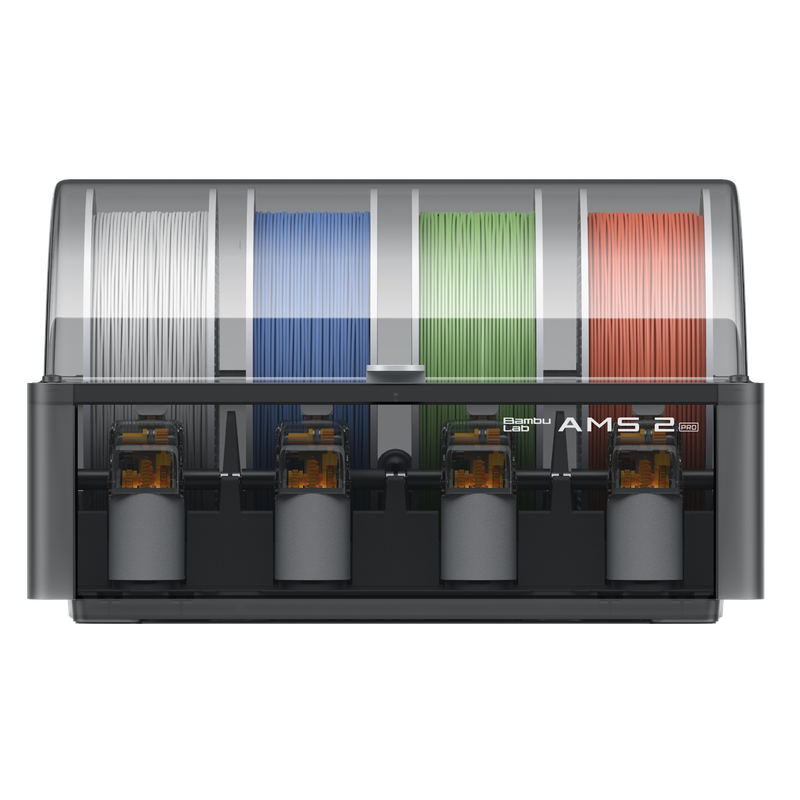

AMS 2 Pro and AMS HT

Bambu Lab has revised the original AMS (Automatic Material System) multifilament feeder introduced with the X1C and also used in the P1 series. This revision is called the AMS 2 Pro. It looks similar to the AMS - it’s a four-filament side-by-side feeder. It has an RFID reader which passes Bambu Lab filament data to the printer and a hub which brings the four filaments together to one feeder tube to the printer.

The AMS 2 Pro adds filament drying capability, similar to the earlier Creality CFS. The enclosure is sealed and heated up to 65°C, with the temperature and time set by the filament parameters read off the RFID tag. Each filament spool is rotated in place to ensure even drying. Desiccant absorbs moisture, and active moisture is vented out of the chamber by an electromagnetically-controlled vent.

The filament port entrances are ceramic, which greatly increases wear resistance.

In order to remove broken filament from the first-generation AMS, all the filament spools had to be removed and the AMS had to be disassembled to access the filament hub. In the AMS 2 Pro, the filament hub is accessible from the top without tools.

Filament feeding is sped up by 60% using a brushless motor. This reduces time for filament changes. Bambu Lab states that this will save 10 minutes for every 100 filament changes.

The AMS 2 Pro supports PLA, PETG, support for PLA/PETG and PP. Other filaments cannot be dried completely, although the AMS 2 Pro will function as a regular filament feeder for those.

Bambu Lab also introduced the AMS HT. The AMS HT has the same features as the AMS 2 Pro, but it is a single filament feeder and is capable of heating up to 85°C for more temperature sensitive filaments like ABS, ASA, PET, PA, PC, PVA, BVOH, POM, HIPS, Bambu PLA-CF/PAHT-CF/PETG-CF and Bambu TPU for AMS. It has a display showing temperature, humidity, and drying time. There’s also a bypass port for flexible or brittle filaments that can’t be fed through the regular filament port.

The H2D can accommodate four AMS 2 Pro units plus eight AMS HT units for a total of 24 filaments. The H2D can also control older AMS units mixed in with AMS 2 Pro units. After firmware updates, the AMS 2 Pro and AMS HT will be compatible with the older Bambu Lab X1 and P1 series and even the A1 series.

Summary

The Bambu Lab H2D is the larger, more evolved version of the X1C that users have been waiting for, but it’s more than that. It has dual extrusion, an advanced extruder motor, a heated, ventilated, filtered chamber, advanced machine vision, a redesigned multifilament feeder, the AMS 2 Pro, and a new filament feeder, the AMS HT. The AMS 2 Pro and AMS HT will be compatible with all other Bambu Lab printers, and these represent good value because they replace a filament dryer as well.

Add to this the fact that the H2D can also act as a laser engraver, laser cutter, bladed cutter, and pen plotter, and you can see that this is one of Bambu Lab’s most significant product introductions since the original X1C.

Brand Summary: Bambu Lab

Bambu Lab, founded by ex-DJI engineers in Shenzhen, has made waves in the 3D printing industry with its focus on speed, innovation, and user-friendliness. While it began its journey through a successful Kickstarter campaign, raising $7 million in a month, the brand has since had its share of growing pains, including shipping issues and firmware bugs. The company's commitment to creating intuitive, precalibrated 3D printers like the X1-Carbon and P1P is commendable, but some users have found limitations with the proprietary components and software. Despite these challenges, Bambu Lab boasts a large community of dedicated users across various platforms and continues to evolve in its offerings and customer service.

Compatible Accessories and Upgrades

- Bambu AMS HT

The Bambu Lab Automatic Material System High Temp, or AMS HT, is an accessory for Bambu Lab 3D printers that allows you to heat and dry filaments that are particularly sensitive to humidity. The AMS HT can heat up to 85° C and includes a display to monitor settings. You can attach up to 8 AMS HT units and 4 AMS 2 Pro units to a single Bambu 3D printer, enabling you to use the AMS HT as part of a multi-material 3D print with up to 24 colors or materials.

- Bambu AMS 2 Pro

The Bambu Lab Automatic Material System 2 Pro, or AMS 2 Pro, is an accessory for Bambu Lab 3D printers which allows the printer to use up to four filament spools during a print, allowing for multi-color and multi-material 3D printing. The AMS 2 Pro improves on the original AMS by adding heating/drying functionality, faster speed, and physical design changes to improve usability. You can attach up to 4 AMS 2 Pro units and 8 AMS HT units to a single Bambu 3D printer, enabling 24-color 3D prints.

- Bambu AMS

The Bambu Lab Automatic Material System, or AMS, is an accessory for Bambu Lab 3D printers which allows the printer to use up to four filament spools during a print, allowing for multi-color and multi-material 3D printing. Additionally, you can attach up to four AMS units to a single Bambu 3D printer, enabling 16-color 3D prints.

Printer Comparisons

The articles below provide in depth comparisons of the Bambu Lab H2D to other similar printers on the market.

Comparing the Bambu Lab H2D vs the Bambu Lab X1C

Vs

You can compare the Bambu Lab H2D to other 3D printers using our Compare tool.