If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Creality Ender 3 V3

About the Creality Ender 3 V3

The Creality Ender 3 V3 was released in January of 2024 as Creality’s ultimate rendition of their V3 lineup. It comes with many of the traits you can expect from a K1 series printer, such as WiFi capabilities, Klipper firmware, and a direct drive extruder, along with a unique CoreXZ motion system paired with linear rods for added precision and maneuverability while printing. Just how much does this new type of motion system affect print quality? Let’s find out.

Key Features of the Creality Ender 3 V3

Physical Design and Motion System

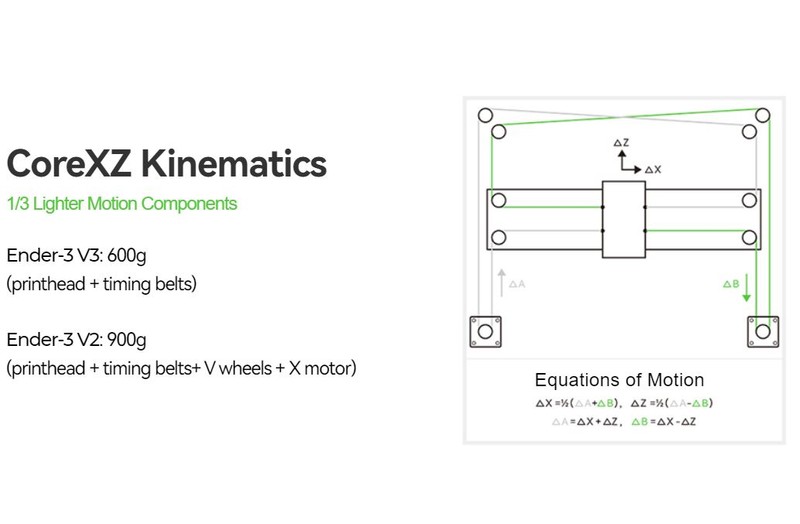

While the Ender 3 V3 is still a bedslinger 3D printer, it innovates with its inclusion of a CoreXZ motion system, similar to that found on the Creality K1. Rather than the more common CoreXY design, created to reduce print head weight and increase print speeds, Creality has chosen to link both the X-axis and Z-axis together using linear rods and timing belts. This creates a much smaller footprint than any other Ender 3 V3 variant. The X-axis and Z-axis are both controlled by two high-torque stepper motors positioned at the base of the printer. This design reduces the overall weight of the gantry, allowing for faster movement of the print head compared to standard i3-style printers. While the gantry is also able to make faster movements in the Z-axis with this design, we do not see this as a needed improvement for the average 3D printer user. The timing belts are automatically tensioned using a spring system hidden inside the frame.

As the Z-axis no longer requires lead screws for movement, the Ender 3 V3 uses linear rods for added stability and reduced Z-banding. This will also lead to more precise movements along the Z-axis. The use of linear rods provides a more durable design than Creality’s V-wheel systems and is quickly becoming the standard for 3D printers going forward. The use of Die-cast aluminum parts for the frame provides a rigid base, which is required as the timing belts will constantly be moving throughout the frame. The aluminum frame provides a sleek appearance for the machine, far from the tinker’s machine that many other Creality printers follow.

The power supply and mainboard are both stored inside the base of the printer, completely out of sight. A spool holder clips onto the right side of the 3D printer, further increasing its footprint. You do have the option of mounting the filament spool on top of the printer, should you choose to. The touchscreen display is mounted on the front of the machine for easy access.

The Ender 3 V3 is designed to hide many of the stepper motor connections behind the frame. From the front, this creates a very clean appearance that has been a common theme in the V3 lineup. All wires leading to the hot end assembly are run through a single cable that attaches securely to the top of the hot end with plenty of stress relief to keep the cable protected during use.

Print Speed and Quality

The Ender 3 V3 is rated for speeds of up to 600mm/s, 100mm/s faster than any other Ender 3 V3 variant. Though this is a theroetical maximum, this is still an impressive improvement over ther other printers in the Ender 3 V3 series. The removal of stepper motors from the gantry creates a very lightweight hot end that should make it much easier for the motion system to move at high speeds. This reduction in weight also affects the speed at which the Z-axis can safely operate, allowing for faster movements during calibration and homing, however speed in the Z axis is not important while printing, since Z moves only occur when changing to a new layer, and are very small motions.

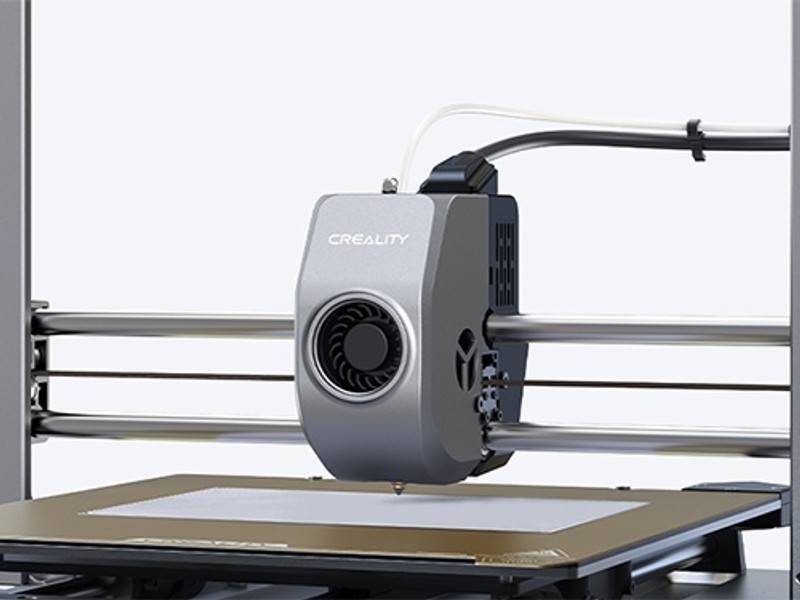

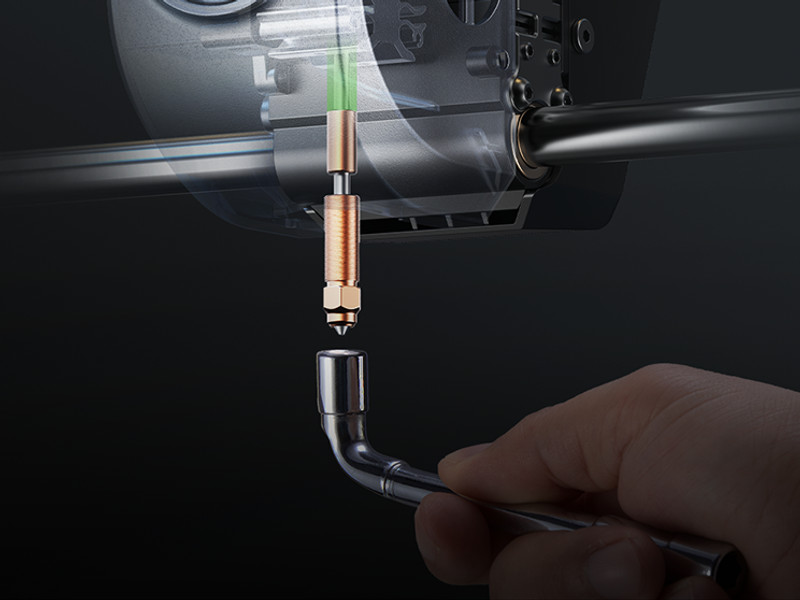

The hot end is assembled using Creality’s tri-metal Unicorn nozzle, which is composed of a copper alloy as well as a titanium alloy for controlled heating and cooling, leading to the hardened steel nozzle. This Unicorn nozzle is capable of achieving temperatures of 300C and is designed for high-speed printing. You will find that the hot end itself is very similar to the K1 printer, with the same quick-swappable capabilities. Unlike the K1, the V3 has separated the electronics in the hot end, making it much easier for you to disassemble and make necessary repairs when needed.

The hot end is designed with a dual-fan part cooling system that will quickly cool down prints. This is mandatory for high-speed printing and leads to improved overhangs on tricky prints.

The V3 uses a direct-drive extruder with Bowden tubing to help guide filament. The Bowden tubing is run along the print head cable with a loop that feeds into the extruder. This design allows you to mount your filament spool off to the side of the printer, rather than on top of it. Many 3D printers with top-mounted filament spools suffer from print quality issues with all of the added weight of the spool. The V3 has smartly avoided this common flaw.

The Ender 3 V3 is capable of printing all of the most common hobby-grade filaments, including PLA, PETG, TPU, and even a few tougher filaments such as Polycarbonate blends. Do note that an enclosure is recommended should you want to print any filaments that require much higher temperatures than PLA or PETG.

Display and Connectivity

The full-color HD display on the Ender 3 V3 is a direct upgrade from the KE or S1 variants. Though it is the same size, the high definition is definitely noticeable, very similar to the screen found on the K1. The touchscreen navigation gives the V3 a very modern feel, as many 3D printers are moving away from analog control systems.

The Ender 3 V3 comes with WiFi connectivity, allowing you to connect to your printer on your home network and send files wirelessly for the machine to print. You will also have access to the Creality Cloud, where you can send ready-to-print models straight to your 3D printer. Lastly, you will be able to use the included USB thumb drive for offline printing should you prefer it. This USB slot also makes the V3 compatible with Creality’s AI Camera to create time-lapses and monitor prints for potential failures.

Advanced Firmware Features

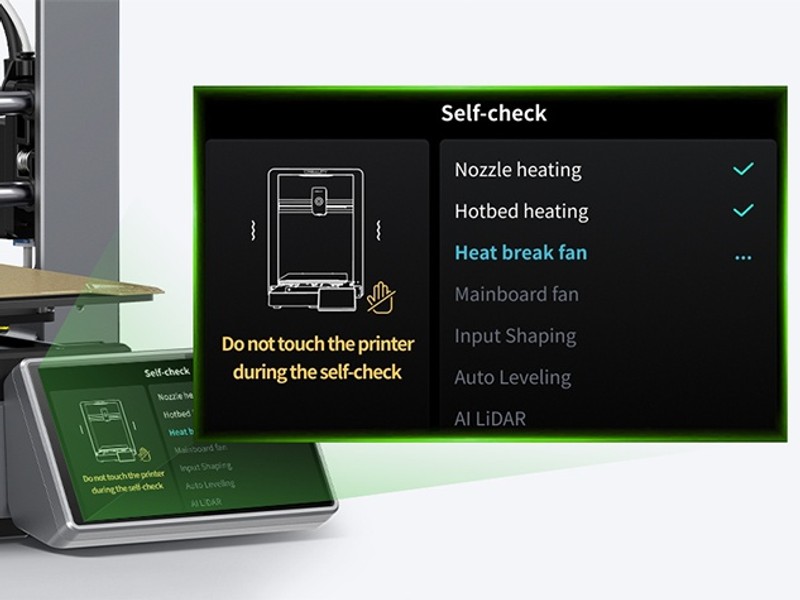

The Ender 3 V3 uses a Klipper derivative firmware, giving it all of the advanced features found on modern Klipper printers, such as vibration compensation, pressure advance, and input shaping to give you a better overall printing experience.

One-Touch Automatic Leveling

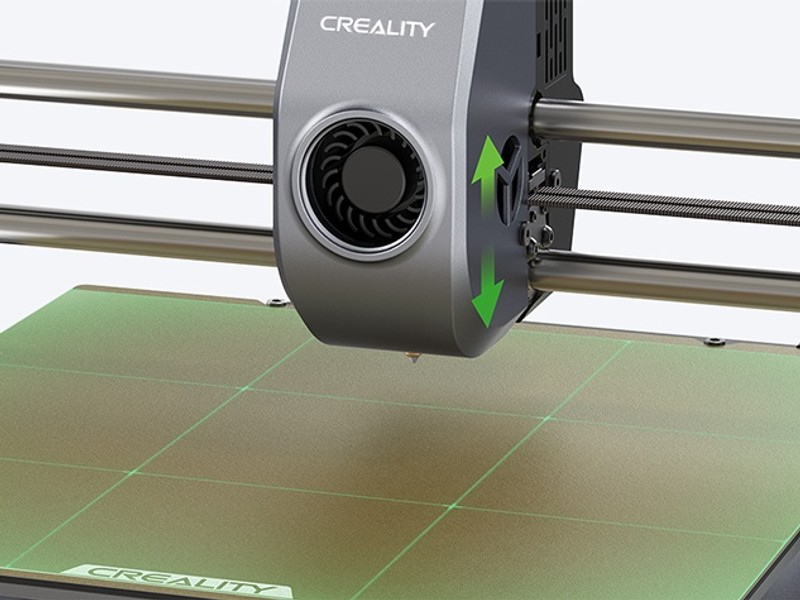

The Ender 3 V3 uses all of the latest leveling sensors, similar to the ones found on Creality’s K1 printers. With a single press of a button, the machine will go through all of the steps necessary to level every axis in preparation for your prints, utilizing load cells placed on all four corners of the print bed for the initial leveling process. This is a very nice feature, especially if this is your first 3D printer, as new users will often have trouble with machines that use manual Z-offset.

Print Bed Surface

The Ender 3 V3 comes with a flexible PEI print surface, the standard for many 3D printers today. The PEI print surface provides great first-layer adhesion while automatically popping prints off of the bed once cooled. The PEI sheet magnetically attaches to the print bed, no clips are needed. PEI is still one of our favorite print surfaces due to the minimal amount of upkeep needed and the long-lasting service life. You will need isopropyl alcohol in order to clean off any oils left behind from your hands after handling the print surface.

Ease of Assembly and Maintenance

While the Ender 3 V3 requires some assembly, it is one of the simplest Ender 3 variants to assemble. The machine is split into two halves, with the top frame acting as a single piece while the bottom half is composed of the print bed and electronics. Simply attach the two halves together, plug in the screen, and ensure that all of the motor wires are properly connected and you are good to begin your first calibration test. The whole assembly process shouldn’t take you more than 10 minutes. As with any Creality 3D printer, you should have no issues finding replacement parts, print surfaces, and PTFE tubing. However, the nozzle on the Ender 3 V3 is non-standard, meaning you will have to purchase additional nozzles directly from Creality’s website.

Maintenance of the Ender 3 V3 will be tougher for new users, as this type of motion system isn’t common. Troubleshooting any sort of timing issues with the belts, as well as finding replacement parts for the motion system outside of Creality’s store, will be a challenge.

Summary

The Ender 3 V3 is Creality’s step closer to creating an appliance-like 3D printer, something that just works out of the box. While it is interesting to see the innovation they have made with their CoreXZ system, it has yet to prove whether it is a necessary change or a novelty. The Ender 3 V3 CoreXZ has a higher price than any other V3 variant. The noticeable differences come in the form of a slim Die-cast aluminum design and faster print speeds.

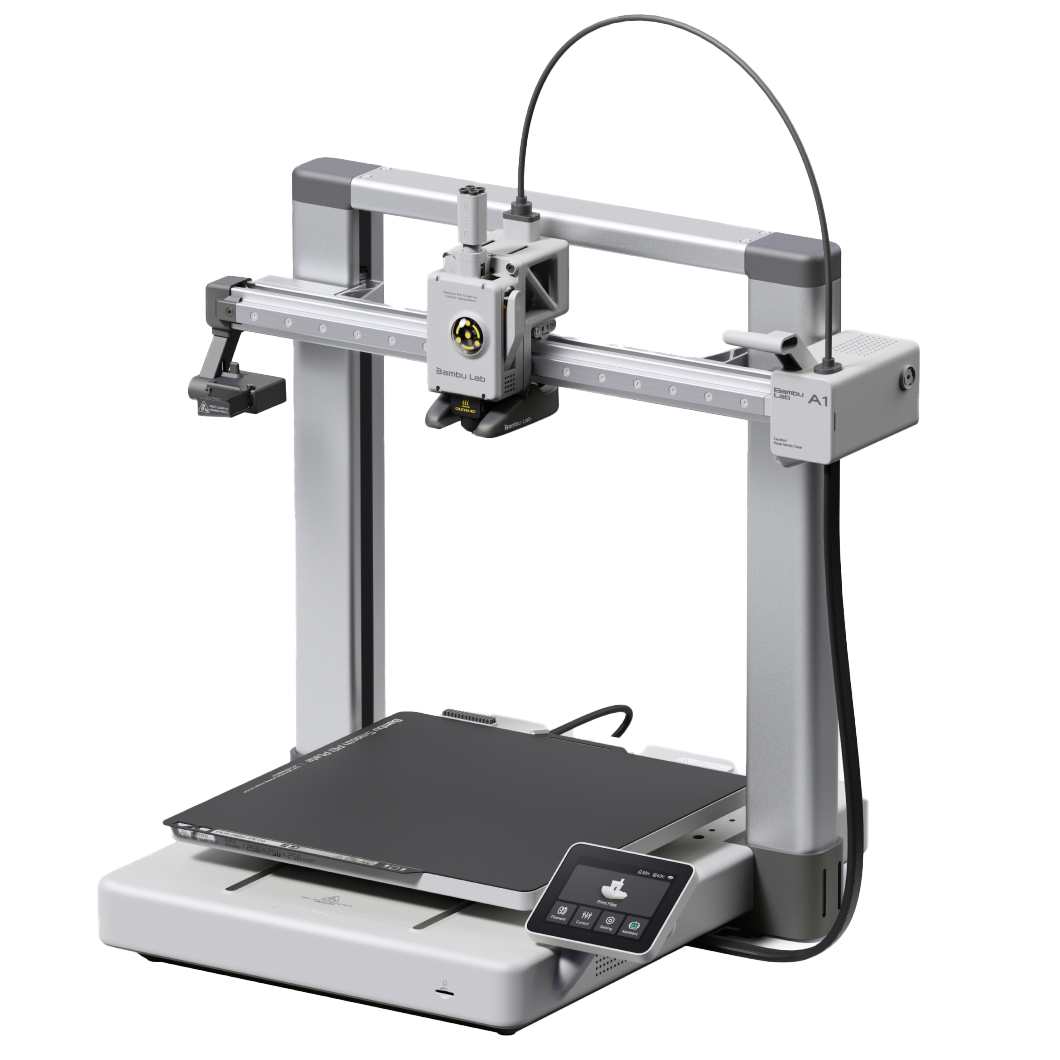

We see the V3 similar to a Creality K1, minus the enclosure. This is a bonus for those who want a high-speed 3D printer that doesn’t take up a ton of space in their home. You could also compare it to the Bambu Lab A1 series of printers, both in size and performance. If you are not fond of the closed ecosystem that comes with the Bambu Lab printers, the Ender 3 V3 is a good alternative at a similar price point. We think that the V3 CoreXZ is a great improvement in terms of speed and durability over the other V3 series printers Creality has released. While the printer itself is very beginner-friendly, the increased price may be a turn-off for anyone looking to purchase their very first 3D printer.

Brand Summary: Creality

Creality is a well-known brand that offers a wide range of consumer 3D printers across all price points, from budget to higher end models. The Ender 3 is credited with originating the budget 3D printer market. While other brands now produce lower cost clones of the Ender 3, Creality remains the most established Chinese manufacturer of 3D printers. Creality uses off-the-shelf components and standardized aluminum extrusions on many of their printers to reduce costs, making their printers easy to repair and upgrade. Their official online community forums and manufacturer support are limited, but support can be found on communities on Reddit and Discord.

Printer Comparisons

The articles below provide in depth comparisons of the Creality Ender 3 V3 to other similar printers on the market.

Comparing the Bambu Lab P1S and Ender 3 V3

Vs

Comparing the Bambu Lab A1 vs the Creality Ender 3 V3

Vs

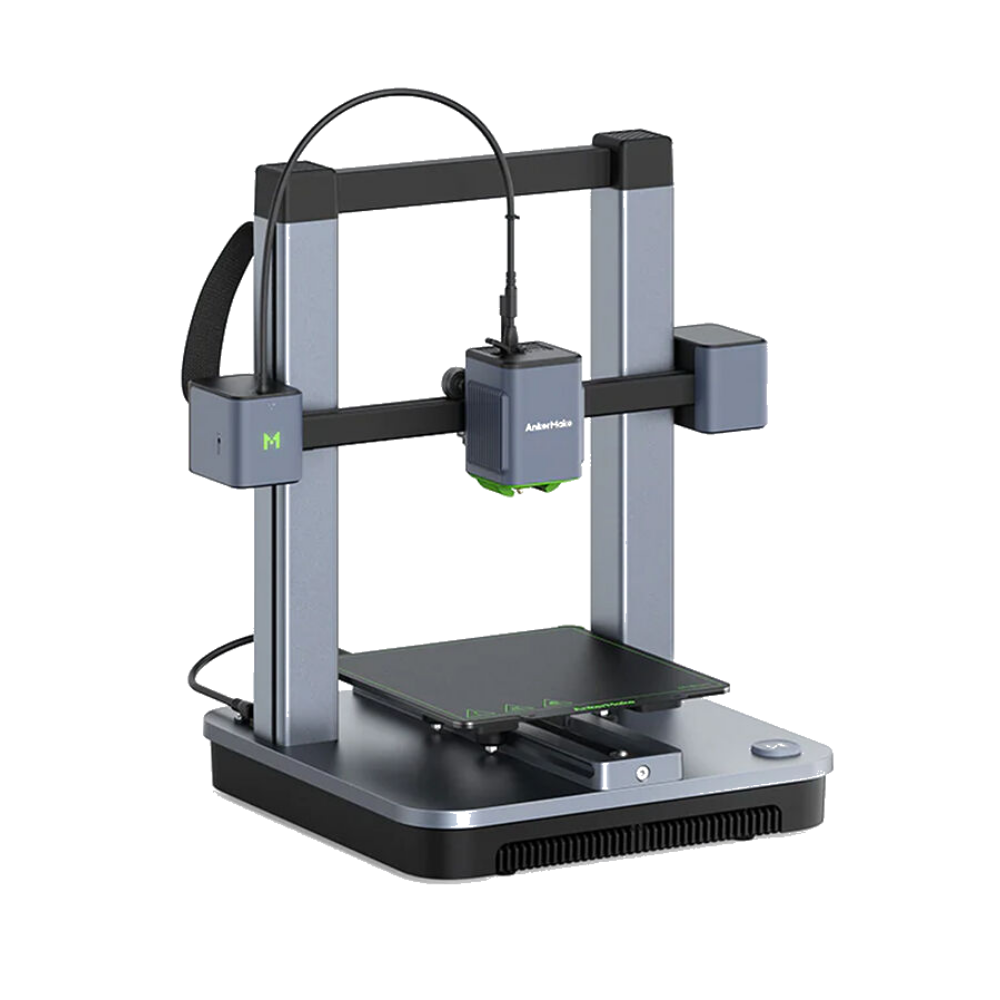

Ender 3 V3 vs AnkerMake M5C

Vs

Ender 3 V3 vs Creality K1C

Vs

Ender 3 V3 vs Prusa MK4

Vs

You can compare the Creality Ender 3 V3 to other 3D printers using our Compare tool.