If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Sovol SV07

About the Sovol SV07

Sovol introduced their SV07 on May 13th, 2023. It follows the Creality Ender 3 clone concept that Sovol had been pursuing with models prior to the SV06 but incorporates some technologies Sovol developed with the SV06. It has been sped up to 500mm/s peak (250 mm/s typical) and is powered by Klipper firmware which uses a fast CPU rather than an underpowered microcontroller to perform rapid calculations. Sovol supersized the SV07 by introducing the larger SV07 Plus on August 29th, 2023. It is identical to the SV07 but has a larger printing volume and a larger power supply.

Design

The SV07 takes Sovol in a different direction than their earlier SV06. It is a conventional Cartesian Creality Ender 3-style printer with an identical printing volume to the Ender 3: 220 X 220 X 250mm. It uses V-slot extrusions and POM wheels on all axes while the SV06 uses linear bearings like the Prusa i3.

There are integrated belt tensioners, a parts drawer incorporated into empty space in the frame, and a magnetic, removable PEI-covered spring steel bed plate.

The key new feature with the SV07 is the touchscreen, which is actually a full-featured Klipper host controlling the printer and enabling printing speeds of up to 500mm/s. It also allows full access via WiFi to any network-connected device.

The SV07 uses a high quality 350W Meanwell power supply. These power supplies are often used in commercial and industrial equipment and many users upgrade lower quality, generic power supplies in other printers to Meanwell power supplies.

Extruder

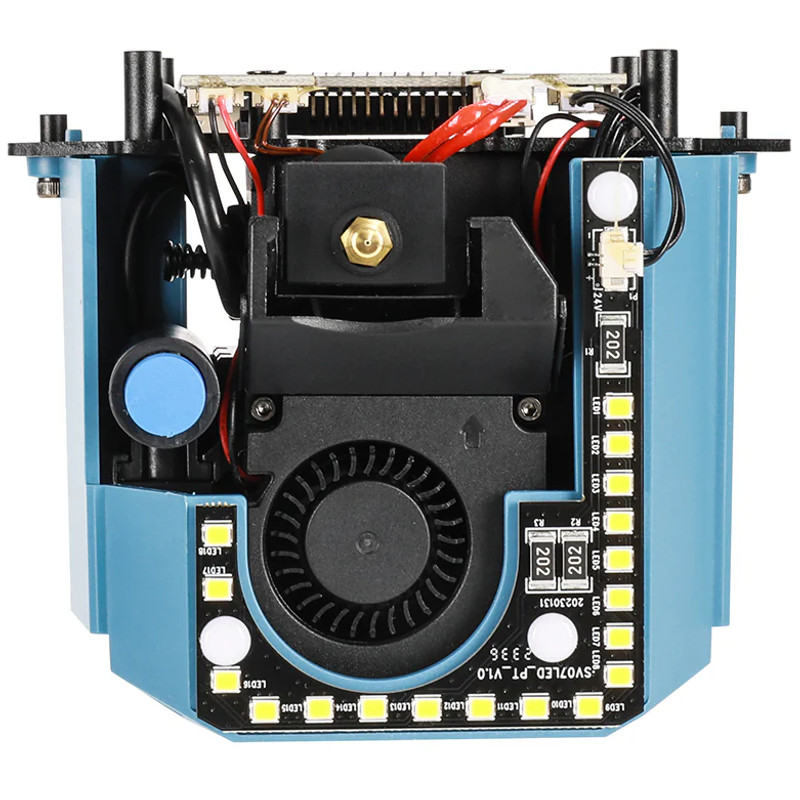

The SV07 reuses the SV06 Plus extruder. This is an all-metal direct extruder with a high flow extended Volcano-style nozzle and a heating block mounted vertically to heat such a long nozzle. The entire metal extruder body forms a very large heatsink. A planetary gear system drives dual steel filament gears. This system increases torque, reduces weight and allows for a smaller, lighter extruder motor. A manual filament advancement and indicator wheel is in front while a gear release lever is on the right. All electrical components are plugged into a breakout board on the rear of the extruder with micro JST connectors. This makes replacing extruder electrical components much easier.

SV07 extruder showing heatsink fan grill on the left

All wires are bundled into a flat cable protected by fabric. Stiff support wires are bundled with the cable so that it holds its shape while still being flexible. It plugs into the breakout board and will stand up so that it will not sag, which might cause it to drag on the heatbed or snag a printed part.

Part Cooling Fans

High speed printers need strong part cooling and the SV07 has had a huge upgrade over the previous SV06. First there’s the standard 4010 (40mm diameter 10mm thick) blower fan with a wraparound duct blowing cooling air on the front and sides of the print. But this draws warm air from over the bed. This is the cooling fan arrangement on the Sovol SV06 and was reused so that the extruder did not need to be redesigned. It’s effective enough for a medium speed printer.

The big upgrade for the SV07 is the inclusion of a 6020 axial fan directing cooling air from behind the extruder onto the rear of the part. It’s very large and is capable of outputting a lot of air.

This fan is so powerful it needs its own cable. It’s mounted to the right of the nozzle as seen from the front so that its airflow does not cool the nozzle.

Bed Leveling

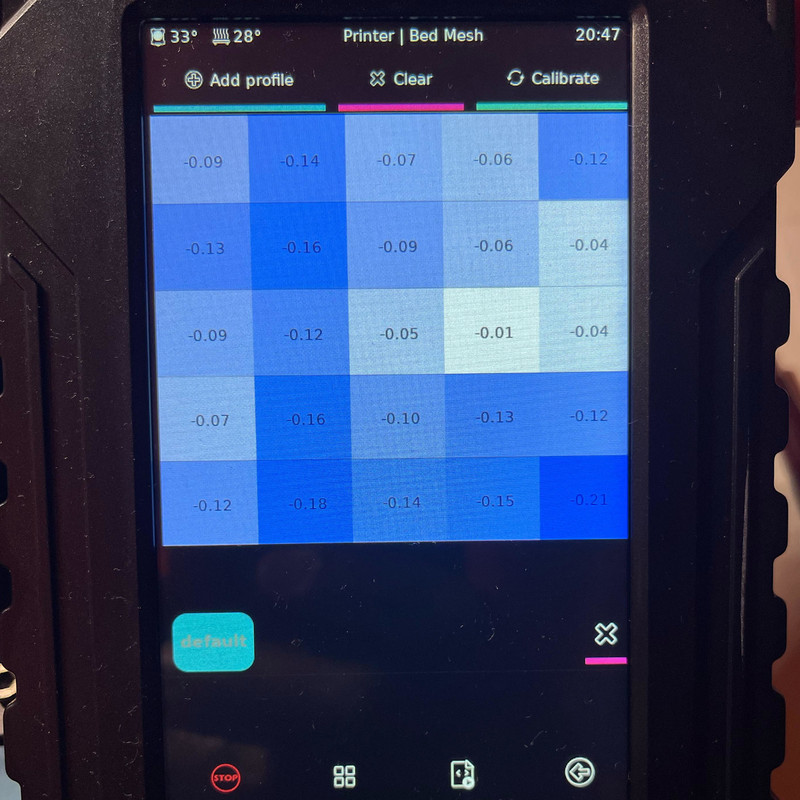

The SV07 uses the same 25-point non-contact inductive leveling system with the same sensor used on the SV06. This system detects the steel of the bed plate, so non-metallic bed types will not work with this system. Unlike the SV06, the SV07 includes bed leveling knobs so that the user may manually correct the bed level. Although the printer automatically corrects the bed level, by adjusting the knobs to get as level a bed as possible, the printer will minimize corrections and the results will improve since this correction isn’t perfect.

Another new feature of the SV07 is that the user can view the results of each tested leveling point on the screen.

_

Touchscreen

The 5” touchscreen is bright and responsive, but not what it appears to be at first glance. It is actually a full-featured KlipperScreen connected to a customized Klipper host - a MakerBase MKS KLIPAD50 V1.0 similar to a retail MakerBase MKS PI. It is like a Raspberry Pi that a user would install to run Klipper on another printer. It has onboard eMMC storage and a WiFi module. There’s also a port which runs KlipperScreen that plugs directly into a 5” touchscreen similar or identical to a MakerBase IPS50. The touchscreen is mounted on top of the board.

Since the display is a full KlipperScreen, it is quite extensive and has complete controls and menus. Advanced users can customize the menus and parameters displayed by altering the Klipper configuration.

The Klipper board connects to a wireless network and allows any network connected device to access the Fluidd web interface, which gives complete remote control of the printer. Mainsail is also enabled as an alternative. The Klipper configuration can be modified for improvements or customization.

A USB port allows a user to connect a webcam.

Input Shaping

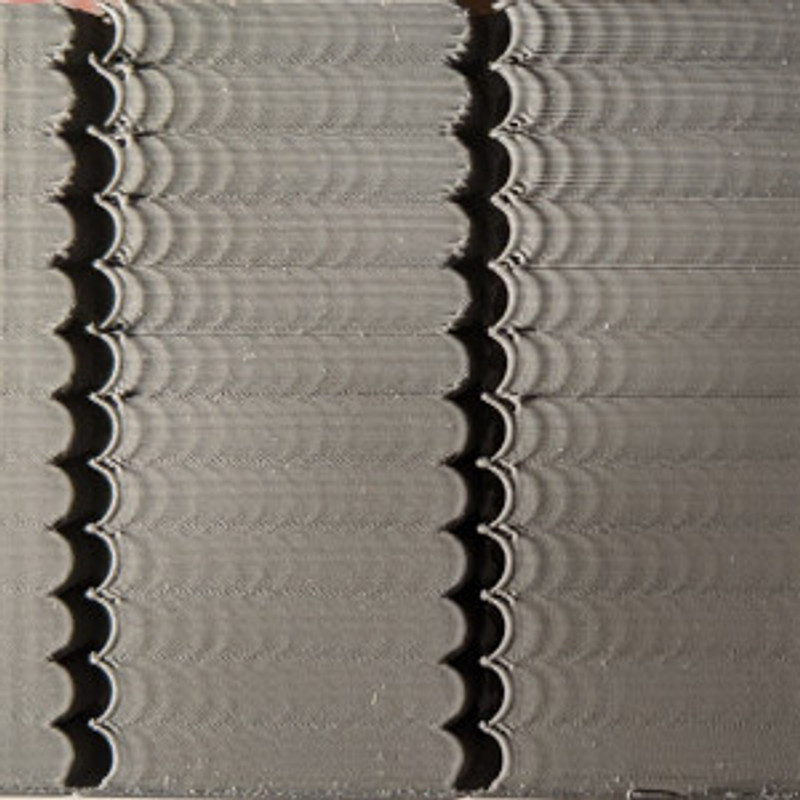

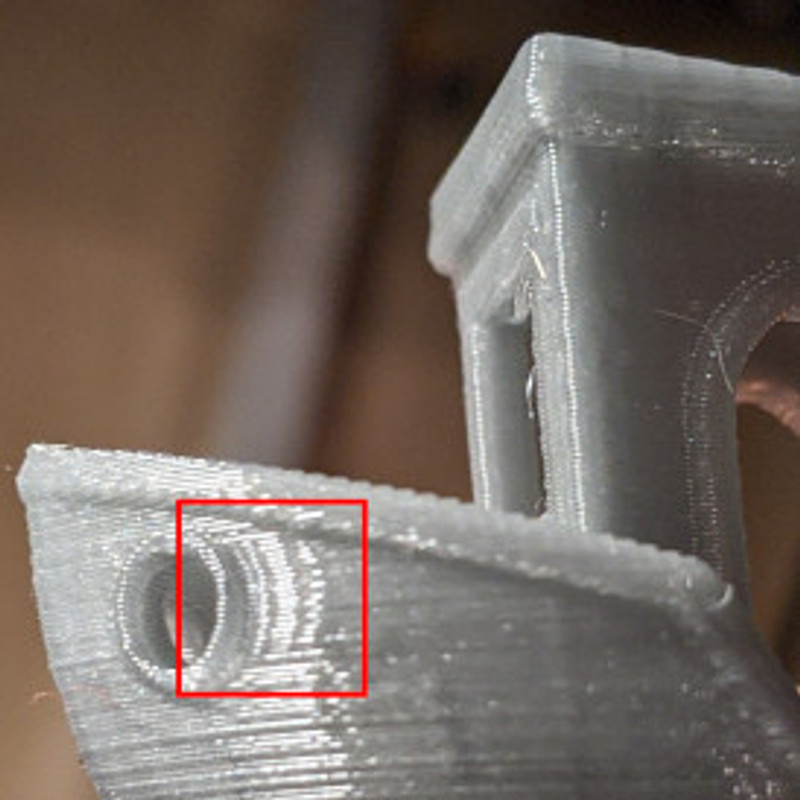

Input shaping or resonance compensation is a routine built into Klipper that minimizes vibrations as the extruder or the bed belt changes direction. This vibration causes ringing in prints, also known as ghosting, echoing or rippling. The defect becomes much worse as speed is increased since the belts are being driven faster.

The SV07 comes with an accelerometer that connects to a special port under the touchscreen. The accelerometer is bolted to the extruder and the user activates an auto calibration routine. The extruder vibrates and the measurements taken from the accelerometer are used to calculate input shaping parameters for the X axis. Next the accelerometer is bolted to the bed strain relief bracket and the bed vibrates. This calibrates the Y axis.

Other Features

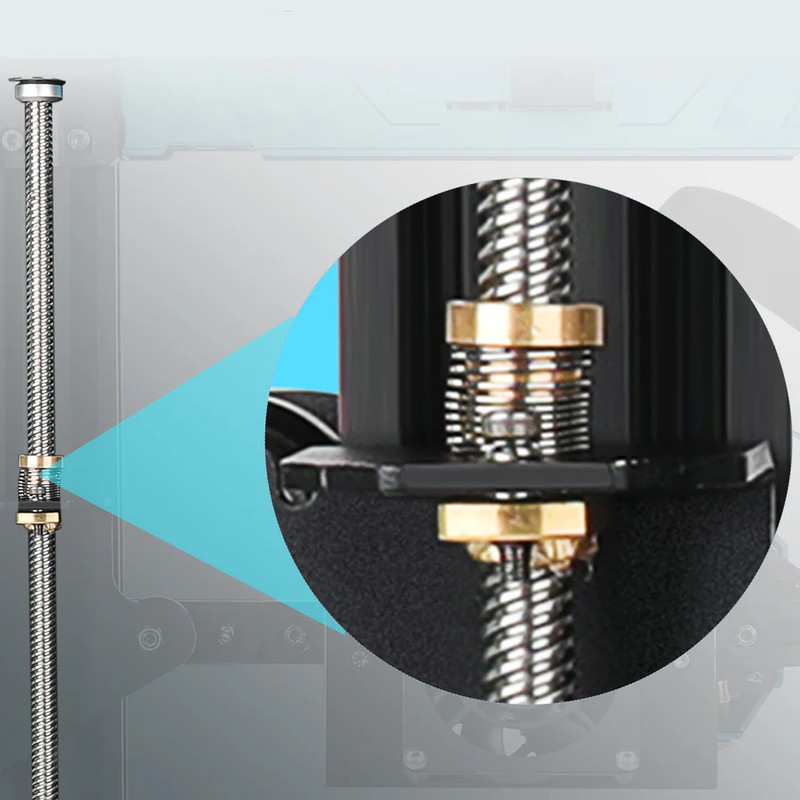

The SV07 is equipped with a filament sensor which will pause the print once it detects filament runout or breakage. This has become fairly standard lately but it is still worth mentioning. The printer also has dual Z axis leadscrews and motors - this is a good feature but what’s more interesting is that the gantry can be leveled using the G34 G-code command. This syncs both Z axis motors, pushing them to the top until the X axis beam hits the gantry and the motors stall, then zeroing the motors from each stall point.

Both Z axis leadscrews are connected to the X axis by anti-backlash nuts. These prevent backlash, which occurs when the leadscrew changes direction but the X axis connection is yet to engage the gear and move. A spring presses the mounting gear up against the leadscrew inclined gear at all times, eliminating any slack. This increases the accuracy of Z axis positioning.

Issues

The return to V-slot wheels surprised many reviewers who saw it as a downgrade from the linear bearings of the SV06. V-slot POM wheels will wear and will need to be replaced. As they wear, they introduce vibration and instability. This wear will be accelerated with such a high speed printer. However, in practice, the wear is not reported to be severe.

The Klipper pad is not well ventilated and the CPU can overheat, causing failures in longer prints. There are many community-designed modifications to mount a fan in order to keep the CPU cool. Here’s one example. This usually solves the problem.

Conclusion

Tests show this is definitely a fast printer, one of the fastest Cartesian 3D printers ever made. The highly capable extruder is accompanied by an extremely impressive part cooling fan, offering powerful cooling. The included Klipper host offers great value - essentially a Raspberry Pi computer included with the printer, with Klipper preinstalled and preconfigured.

Provided you’re aware of the V-slot wheels and are prepared to change them as they wear out, this is an affordable and fast 3D printer with an excellent control system and part cooling serious enough to justify its lofty speed claims.

Brand Summary: Sovol

Sovol is a 3D printer brand known for producing innovative printers with more features than their competitors at a lower price. Their printers are beginner-friendly and have good build quality, but their entry-level printer, the SV01, lacks a bed leveling probe. While Sovol's community is still establishing itself, the company's support is well-regarded, and they have over 80,000 users. Sovol has experimented with complex dual extrusion features, which led to clogging problems and quality issues in some of their previous models. However, their current printers, such as the SV06 Plus, offer impressive features like 25-point auto bed leveling and a 500W bed heater. Sovol's varied printers appeal to different users, from new users to advanced users.

Printer Comparisons

You can compare the Sovol SV07 to other 3D printers using our Compare tool.