3D Printer Filament Types

Filament 3D printers, or FDM printers, are able to print with many different types of filament. Each type of 3D printer filament has different strengths, weaknesses, and material properties, and some filaments are easier to print with than others. In this guide, we’ll cover each of the major types of 3D printer filament available to you. For each filament type, we’ll cover its material properties, typical use cases, 3D printing ease, and any special requirements for printing with the filament.

Standard Filament Types

These are the most common 3D printing filaments and are the first filament types you should consider for general-purpose 3D printing. All of these filament types are readily available for purchase in a variety of colors, and most 3D printers can easily print these materials.

PLA

PLA is by far the most popular 3D printing filament type. It’s the easiest filament to print and is excellent for printing detailed parts with small features. It’s also capable of handling extreme overhangs as long as the 3D printer has a part cooling fan (which almost all modern 3D printers do), making it ideal for printing complex geometries and parts that weren’t designed with 3D printing in mind.

Appearance

- Semi-gloss finish

- Many color options

- Typically opaque, although translucent options are available

PLA is most commonly fully opaque with a semi-gloss finish, although it’s available in a wide range of colors and styles, including translucent and matte options. Out of all of the 3D printing filaments you can buy, PLA offers the largest color selection and the most manufacturer options. It’s most commonly sold in 1 kg (2.2 lb) spools, but you can also purchase larger 5 kg or 10 kg spools if needed.

Material Properties

- Low ability to flex and bend, doesn’t deform

- Good for precise parts where accurate dimensions are critical

- Low temperature resistance

PLA 3D prints are reasonably strong, although it isn’t the strongest 3D printing filament available. It has some ability to flex to a small degree, but also isn’t especially bendable unless printed into a thin shape. PLA does tend to be very dimensionally accurate, and because it doesn’t deform or flex, is ideal for printing detailed models and precisely-fit components. In general, PLA’s material properties are a good reference point from which to compare other 3D printer filaments—it exhibits average strength and flexibility for a 3D printed material, making it a good starting point if you aren’t sure what material properties you’re looking for.

PLA’s weakness is temperature resistance. It can start to deform at temperatures as low as 115° F (46° C) meaning that it is not an appropriate choice for any outdoor or high-heat applications. Even the inside of a car on a sunny day can easily exceed the allowable safe temperature for a PLA print.

3D Printing Ease

- Easy to 3D print

PLA is an especially easy 3D printing filament to work with. It prints at low temperatures, doesn’t require any special printer features, and can be 3D printed reliably even at high speeds. Most default 3D printer slicer software settings will be configured for printing with PLA, and many machines even come with a small sample roll of PLA filament. The bottom line is: PLA is the best 3D printing filament to start with, and one of the most forgiving materials to print.

3D Printer Requirements

- Part cooling fan is optional, but can improve overhangs

Virtually all FDM 3D printers can print with PLA. The only special feature you may consider is a part cooling fan, which blows cold air onto the filament as it extrudes to cool the printed material faster. This allows for printing more extreme overhangs and larger bridged sections. Fortunately, almost all modern 3D printers include a part cooling fan, although the effectiveness of the fan does vary from model to model—pay attention to reviews for this detail if you want to attain maximum performance from printing PLA on your 3D printer.

Recommended Brands

PLA is available from many different manufacturers, but these are a few of the brands we trust most:

For more detailed information about PLA, our advice for printing with it, and more information about the filament brands we’ve tested, see our detailed guide for PLA filament.

ABS

ABS is a common 3D printing filament that is often used for parts that require a higher temperature resistance than PLA or that need to be able to flex slightly without breaking. ABS prints can also be post-processed more effectively than some other filament types, allowing you to create models with a very smooth surface finish if you’re willing to put in extra work after printing. These advantages come at the cost of printing ease—ABS is significantly harder to print with than other filament types such as PLA.

Appearance

- Matte finish

- Opaque

- Can be post-processed more than other filament types

ABS filament is almost always opaque with a matte finish, although some translucent options exist. Since it’s one of the most popular filament types, there many color choices available, although not as many as PLA.

If you’re interested in post-processing your 3D prints, ABS is one of the best filament types to use. It responds well to sanding, allowing you to reduce or eliminate layer lines, and tends to take paint reasonably well. You can also smooth ABS prints to a mirrorlike finish using acetone vapor (although that process is a bit involved and requires caution).

Similar to PLA, ABS filament is typically sold in 1 kg (2.2 lb) spools.

Material Properties

- Strong resistance to bending forces

- High temperature resistance

ABS 3D prints are particularly strong in terms of resisting bending forces, so if your model needs to be able to flex slightly without breaking, ABS is a great choice. It’s less strong that other filaments when subjected to tensile (pulling) forces, and has an average resistance to impact forces. ABS tends to not be a good choice for printing models with many small or thin features, due to both its material properties and its printing difficulty.

ABS does exhibit much more temperature resistance than PLA, and won’t deform until it reaches temperatures of around 210° F (99° C). This makes it a great choice for high-temperature applications.

3D Printing Ease

- Difficult to 3D print

- Large parts are at risk of warping or delaminating during printing

- High bed temperature is required

ABS can be a challenging filament type to 3D print. Although its average printing temperature of 230° C is within the temperature range of most hotends, ABS prints have a tendency to warp during the printing process if the entire print is not kept at a high enough temperature. You will typically need to use a bed temperature of 100° C to print ABS, and some 3D printers will take a long time to heat the bed to this temperature. In the case of some older large 3D printers such as the Creality CR-10 S5, the print bed may not be capable of reaching 100° C.

3D Printer Requirements

- Printer enclosure is strong recommended

ABS requires a 3D printer that can heat the hotend to 230° C and heat the print bed to 100° C. Most modern 3D printers are capable of heating to these temperatures, but you should check the printer specifications to be sure. If you plan to print larger parts, you should also construct or purchase an enclosure for your 3D printer. This increases the ambient temperature and prevents air drafts from cooling part of the model too quickly, which helps prevent the model from warping. You can purchase or construct a 3D printer enclosure that will solve these issues, but the enclosure does increase the required table space for the printer and makes maintenance tasks a bit more difficult.

Recommended Brands

Our most trusted brand for ABS filament is Hatchbox, which we’ve found to perform better than other brands we’ve tested.

For more detailed information about ABS, our advice for printing with it, and more information about the filament brands we’ve tested, see our detailed guide for ABS filament.

PETG

PETG is a popular 3D printer filament type known for its strength, temperature resistance, and watertight capability. It’s fairly easy to print and exhibits very strong layer adhesion, making it ideal for printing thin parts or parts that need to resist tensile (pulling) forces.

Appearance

- Glossy finish

- Translucent and opaque options

PETG filament is glossy in appearance, and is available in many color options from various manufacturers. Unlike most other filament types, PETG is naturally very translucent, and there are many translucent color options available that tend to allow more light to pass through than translucent PLA. It’s most commonly sold in 1 kg (2.2 lb) spools.

In terms of post-processing, PETG is easier to sand than PLA, but not as easy to sand as ABS.

Material Properties

- Very strong, especially with tensile forces

- High temperature resistance

- Can be printed watertight

PETG is one of the strongest 3D printer filament types, especially when subjected to tensile (pulling) forces. It has an average resistance to impact forces, roughly on par with ABS. PETG isn’t particularly resistant to bending forces, but is able to withstand that type of force better than PLA. In general, PETG is an ideal choice for 3D printing strong parts, especially if the part has thin walls.

PETG has a high temperature resistance of 180° F (82° C) which puts it between PLA and ABS. It’s a good choice for parts that need to be able to survive in a hot environment, such as the inside of a car.

One unique property of PETG is that prints tend to be watertight. If water resistance is an important part of your design, PETG should be your first choice of filament.

3D Printing Ease

- Can be challenging to 3D print

- Tends to be stringy, prints may require cleanup

PETG is not the easiest filament type to 3D print, although it’s less challenging than ABS or nylon. It tends to stick to the print bed very well, and doesn’t warp during printing, but sharp corners can peel up from the bed. It must be printed slower than PLA to avoid surface defects. Also, the plastic has a tendency to stick to the nozzle, which can cause printing quality defects or failures. However, it’s generally possible to get great PETG prints as long as you go slow and use a high enough temperature. An enclosure is not required for printing.

You will need to print PETG at a rather high temperature—at least 230° C, and some manufacturers recommend printing their PETG at 245-250° C. This is very close to the maximum temperature of the PTFE-lined hotends that many 3D printers come with, which may cause jams or more required maintenance over time. We’ve been able to successfully print most PETG at 230° C and haven’t experienced any of these issues, but if you want to print at the higher temperatures, you may want a 3D printer with an all-metal hotend that is capable of handling higher temperatures.

PETG tends to generate small strings during the 3D printing process, which you’ll need to clean up with clippers or a knife after the print is complete. While you can reduce this by adjusting hotend temperature and retraction settings, it’s difficult to completely eliminate stringing with PETG.

3D Printer Requirements

- High printing temperature is needed, so you may benefit from an all-metal hotend

PETG requires a 3D printer that can heat the hotend to 230-250° C, which is at the limits of PTFE-lined hotends. If you plan to print PETG often, you may want to use a machine with an all-metal hotend. Otherwise, there no special requirements for printing with this filament.

Recommended Brands

PETG filament is widely available, and we’ve had good experiences with most of the manufacturers for this filament type. Here are a few we recommend:

- Overture PETG [Amazon]

- Hatchbox PETG [Amazon]

- NovaMaker PETG [Amazon]

- Polymaker PolyLite PETG [Amazon]

For more detailed information about PETG, our advice for printing with it, and more information about the filament brands we’ve tested, see our detailed guide for PETG filament.

Specialty Filament Types

These filament types have special material properties that make them particularly well-suited to certain uses, but are not as generally useful as the standard filament types above.

TPU

TPU is a flexible filament type used for 3D printing parts with a rubbery consistency. It can be challenging to 3D print, but is an excellent choice for printing functional parts that can bend and stretch.

Appearance

- Matte or glossy, depending on color and brand

- Typically opaque, although translucent options are available

TPU filament can be matte or glossy in appearance, depending on the color. Some manufacturers do produce translucent color options, although TPU is not a particularly translucent material. As it is one of the more popular filaments for 3D printing, TPU is available in a wide range of colors. Although TPU is available in the standard 1 kg (2.2 lb) spool size, you can also often find smaller sizes, such as 0.5 kg spools.

Material Properties

- Flexible, rubbery material

- High temperature resistance

- Only useful for parts that need to flex and deform without breaking

TPU is a flexible material that can bend and stretch far more than standard 3D printing filament types such as PLA or ABS. It’s more rubber than plastic, making it an ideal choice for any part that needs to flex and bend without breaking. TPU’s flexibility is sometimes measured in shore hardness, which is a standard measure of how resistant a plastic is to identation when a needle is pressed into it. A higher shore hardness indicates that a material is harder and less flexible. You can purchase TPU filament in various shore hardness levels, allowing you to choose how soft and rubbery you want your resulting print to be.

TPU has a fairly high temperature resistance, with most TPU filament being able to withstand temperatures of 175-210° F (80-100° C). Some “high temperature” variants of TPU can handle higher temperatures.

Overall, TPU is ideal for certain use cases but not a general-purpose filament type for 3D printing. Unlike most other filament types, TPU does not exhibit much rigidity and would not be a good choice for many functional parts. It can be difficult to print small features, which makes it less desireable for printing small, detailed models. On the other hand, TPU is unique in that it can stretch and bend, making it extremely useful for items such as phone cases, tool handles, and other similar 3D prints that would typically be made of rubber.

3D Printing Ease

- Difficult to 3D print

- Must be printed slowly

- Greatly benefits from a direct-drive extruder

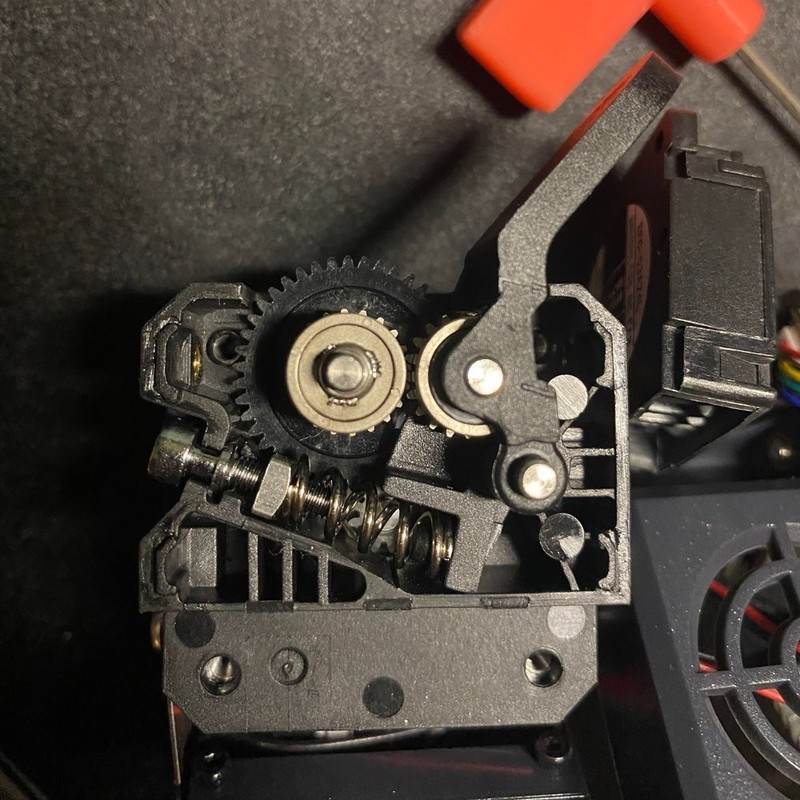

- TPU is sensitive to moisture and humidity

TPU is more challenging to 3D print than most other filament types. Because it is a flexible filament, TPU greatly benefits from a direct-drive extruder. If you’re using a 3D printer with a Bowden extruder, you may still be able to print TPU, but you’ll need to print extremely slowly and may experience more stringing. Even with a direct-drive extruder, TPU must be printed more slowly than rigid filament types.

Even on a well-calibrated 3D printer with correct settings, you are likely to experience some stringing with TPU. You can clean up these strings after the print using a set of wire cutters or by applying heat to the print with a lighter or heat gun, but some amount of print cleanup is unavoidable with this material.

TPU is also more sensitive to moisture and humidity than other 3D printing filament types. If you need to store a partial spool of TPU for an extended period of time, it’s best to store it in a sealed container or bag (some spools come with a resealable plastic bag for this purpose). If you print TPU frequently, you may wish to use a filament spool dryer to remove moisture from the filament before printing.

3D Printer Requirements

- Direct-drive extruder is strongly recommended

A direct-drive extruder is highly recommended for printing with TPU. Although it is possible to print flexible filament with a Bowden extruder, you will need to print more slowly and are likely to see more stringing or other print quality issues.

Recommended Brands

These are a few of the brands we trust most for TPU filament:

For more detailed information about ABS, our advice for printing with it, and more information about the filament brands we’ve tested, see our detailed guide for TPU filament.