How to Buy a FDM 3D Printer

A Comprehensive Guide

Introduction

If you’re ready to buy a filament 3D printer, also known as an FDM 3D printer, you’ve probably discovered that there are an overwhelming number of choices available to you. As 3D printing has grown in popularity, there are more and more brands to choose from. And because 3D printers are fairly complex machines, there are many different specs and features you can compare between different printers. It’s hard to know which things matter and which don’t, and how to make a smart buying decision without many hours of research.

In this guide, we’ll show you which features to pay attention to when buying an FDM 3D printer, and how to choose the printer that fits your needs best. Whether you’re just window shopping or looking to jump into 3D printing immediately, this page should give you the information you need to choose a great FDM 3D printer.

Choosing a Brand

One of the most important decisions you have when buying an FDM 3D printer is which brand, or manufacturer, to choose. Over the past several years, the 3D printing market has greatly expanded and now includes printers from many different manufacturers, each of which offers a different balance of price, features, reliability, and more.

What’s in a Brand?

A budget or entry-level 3D printer brand will offer machines at extremely low prices, but quality of the parts used in those machines won’t match that of a more expensive brand of printer. That may not be a factor for you if you’re just trying out 3D printing or expect to only use your printer on occasion, but if you plan to use your machine frequently, you may end up replacing parts more often on a lower-end 3D printer. Brands such as Anycubic and Sovol fit into this category—their machines are affordable, offering a great value for the price, but lack some of the features found on more premium machines.

Mid-tier brands tend to offer 3D printers with improved specs and more features than what you’ll find in an entry-level machine. For example, you’re more likely to find printers with convenience features such as automatic bed leveling or a full-color LCD screen. Mid-tier brands also often have a full range of product options, from lower-priced entry-level machines to higher-priced machines that compete with premium brands on build quality and features. However, they still lack some of the benefits of truly premium brands, such as higher-grade customer support. Brands such as Creality fit into the mid-tier category.

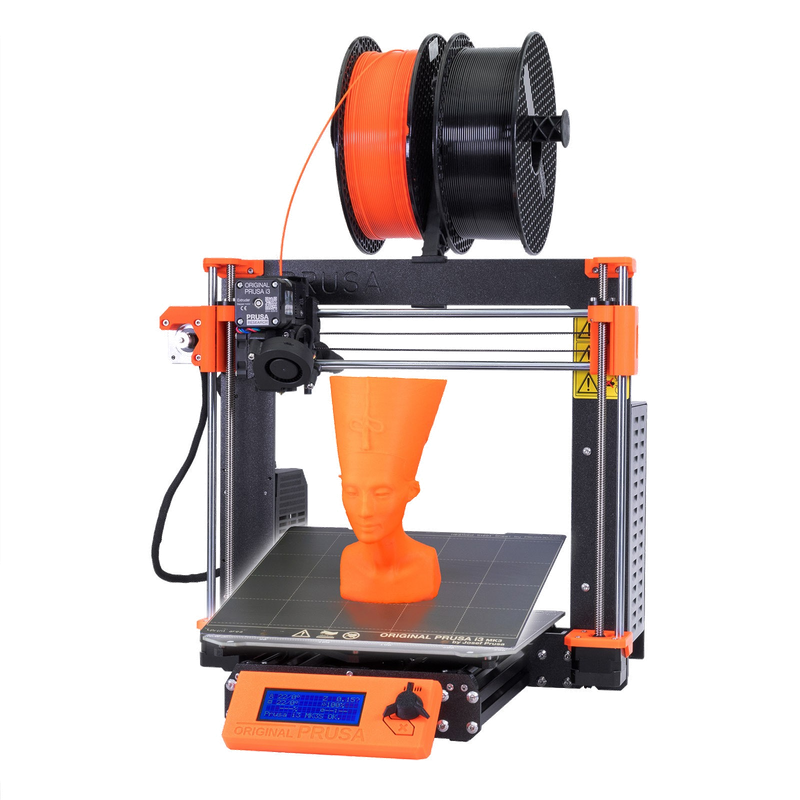

Premium brands produce 3D printers with higher-quality parts, resulting in a machine that tends to be more reliable and longer-lasting. In some cases, premium machines offer capabilities or specs not found on lower-end 3D printers. They’re also more likely to provide hands-on customer support, and you’ll have a smoother getting-started experience in general with a premium 3D printer. If you enjoy tinkering and are adept at troubleshooting problems, you’ll be able to solve issues on your own, but if you prefer to reach out to the manufacturer for guidance, that may be another reason to consider a premium 3D printer brand. Examples of premium brands include Prusa and Bambu Lab.

We should mention that “budget” doesn’t have to mean “low quality”, and in our experience, there are budget 3D printer brands that offer great machines at very affordable prices. It’s also important to note that print quality is not majorly affected by whether you buy a budget or premium machine. You can get great quality prints out of a budget machine, but it will generally take more adjustments and calibration to reach that level of quality as compared with a premium machine.

As with any market, there are brands to look for and brands to avoid. To research 3D printer brands further, check out our brand guide, which contains our detailed analysis of several 3D printer brands.

Community Support

Community support is also likely to be an important factor in your success and enjoyment of your 3D printer. In some cases, even from reliable brands, customer service from the manufacturer can be hit or miss. In those cases, a vibrant online community can be instrumental in helping you troubleshoot problems or get your new 3D printer up and running. Additionally, most 3D printers have significant potential for upgrades and improvements, and if you’re interested in tinkering or want to upgrade your 3D printer, having an online community of owners means you’re more likely to find upgrade guides and parts for your machine. It can also just be fun to chat with other users of your 3D printer model to learn more about how to use your printer to its fullest potential.

We always factor in the online community when evaluating 3D printer brands. Some brands have large communities with thousands of users, while others are less well-known and don’t have the same level of online presence. Unless you have very specific needs that aren’t served by a mainstream brand, we’ll generally recommend you stick with a brand that has a large, healthy community of users. In the brands we cover in our brand guide, we research the community to determine how active it is and how likely you are to be able to find like-minded users to help with any problems you encounter and discuss 3D printing with a given machine.

Key Features

Once you have chosen the type of brand you’d like, you can firther narrow down your options by looking at key features of different models. To help you cut through the long list of specifications advertised with most FDM 3D printers, we’ll cover the most important ones you should focus on when choosing a machine. Some specs aren’t meaningful when deciding between multiple 3D printers (listed at the end of this section) but there are a few key specs that you should pay close attention to when you’re comparing multiple 3D printers to pick the best one for you. We’ll cover each one, explain what it means, and give you our guidance on what to look for.

Build Volume

Perhaps the single most important specification is build volume, which dictates how large of an object you can print. The build volume should be a priority for you because:

- Unlike many other specs of a 3D printer, you can’t typically upgrade it after buying

- If you need to print large functional parts, a single large part will be much stronger than combining multiple smaller parts

- The build volume affects the physical size of the 3D printer, which directly impacts how much space you need to fit the printer in your work area

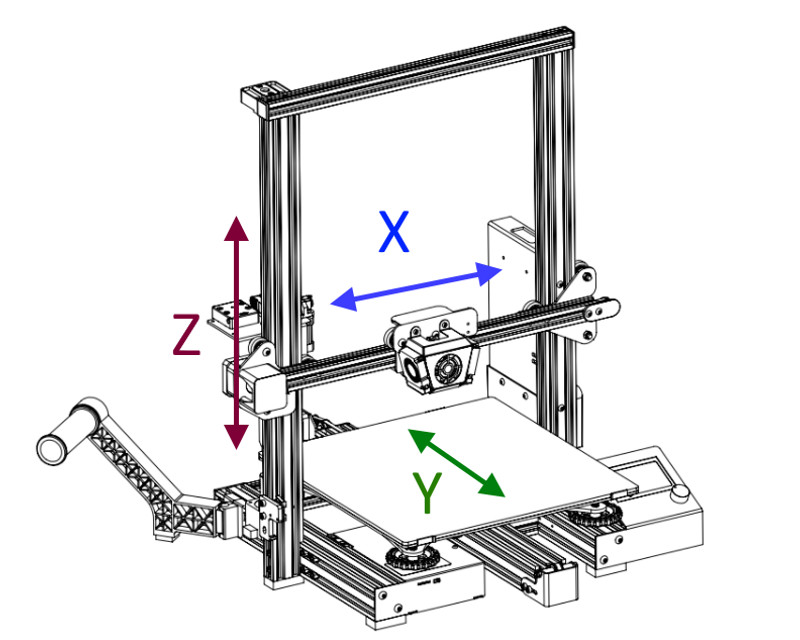

Currently, an average FDM 3D printer can print an object that is approximately 200-300 mm in each dimension (7.9” - 11.8”). Of course, it’s possible to find machines with smaller or larger build volumes. For example, some entry-level 3D printers have a build volume as small as 165 mm, and some large 3D printers are 450 mm or higher. It’s common to find machines where the Z axis is larger than the X and Y axes, because the design of many 3D printers is such that it’s cheap and easy to stretch the frame higher in the Z axis.

However, an important aspect of build volume is that each axis is not created equal. Because FDM 3D printers construct objects layer-by-layer upwards in the Z direction, you may not want to use that added Z height to print objects that are too large for the X and Y dimensions of your printer. FDM 3D prints are weaker along the layer lines, and have a smoother finish on the top and bottom of objects. So as a simple example, imagine you wanted to 3D print a ruler. If you chose to print it vertically along the Z axis, the resulting 3D print would snap in half easily and wouldn’t have a smooth finish on the largest surfaces of the model. You’d be much better off printing that type of object flat on the print bed of the printer, and the maximum size of that 3D print would be dicated by the X and Y dimensions of the build volume on your printer.

To give you an idea of what you can expect from different sized build volumes, here are a few examples of things you can print with different sized 3D printers:

- 200mm^3: Figurines, small toys, small functional enclosures (for example, a Raspberry Pi case)

- 300mm^3: Larger functional parts (for example, a headphone stand), decorative vases or planters

- 400mm^3 or more: Wall-hung art, or a large trophy

It’s also important to note that bigger isn’t always better. A 3D printer with a large build volume will be heavier and take up more desk space (sometimes, substantially more) than a 3D printer with a smaller build volume. The larger machine will also be heavier and often more expensive than a smaller machine. And because the print bed includes a heater that heats the bed surface, a larger print bed will consume more power and generate more ambient heat, which may cause the room your printer is in to heat up.

With the exception of a few machines that allow you to extend the Z axis further with a simple upgrade, the build volume is generally not an upgradeable aspect of a 3D printer, so make sure to buy a printer with the build volume you need.

Extruder

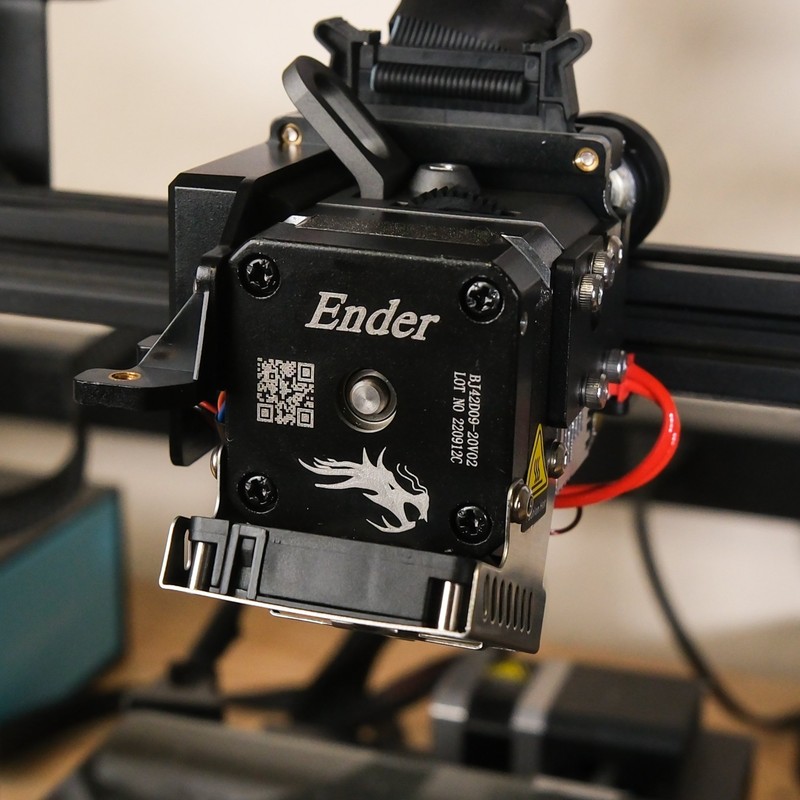

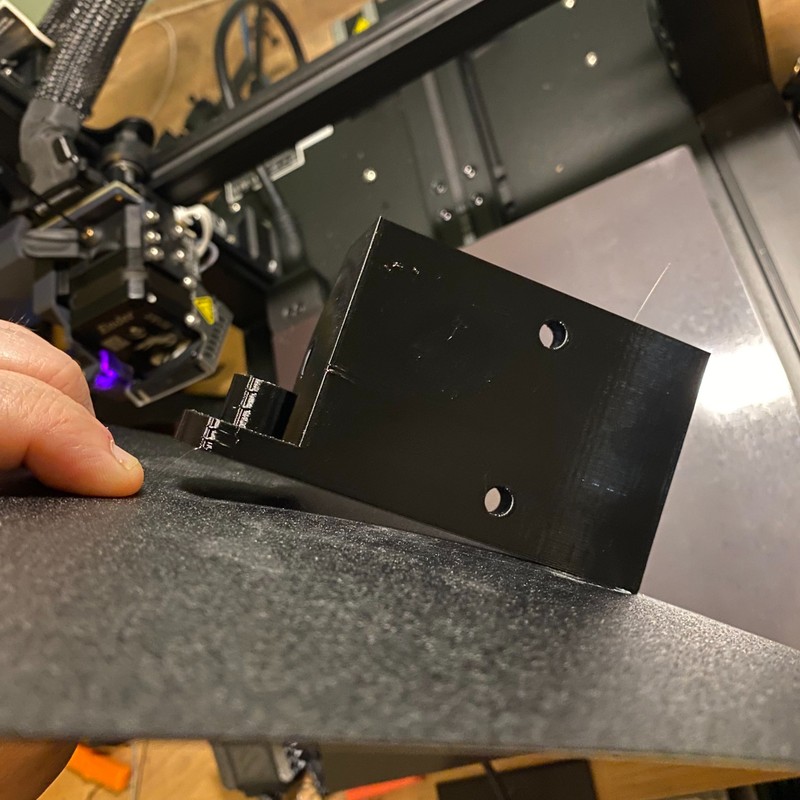

FDM 3D printers use either a direct-drive or Bowden extruder, which affects the reliability of the printer as well as its ability to print with flexible materials such as TPU. The main difference between these extruder types is:

- Direct-drive extruders are mounted directly above the hotend, pushing the filament right into it. The extruder moves with the print head.

- Bowden extruders are positioned separately from the print head, usually on the printer’s side, and use PTFE tubing (also known as the Bowden tube) to guide filament to the hot end.

Between these two types, direct-drive extruders tend to be more reliable and perform better than Bowden extruders. They’re also significantly better suited to printing with flexible filament, such as TPU. Although Bowden extruders are an effective choice for FDM 3D printing (and we own many machines with Bowden extruders), we feel that a direct-drive extruder is a noteworthy feature on 3D printers that include it. Between two otherwise equal options, we’d pick the one with the direct-drive extruder.

And if you’d like to learn more about the differences in the two common extruder types, check out our in-depth extruder reference.

Automatic Bed Leveling

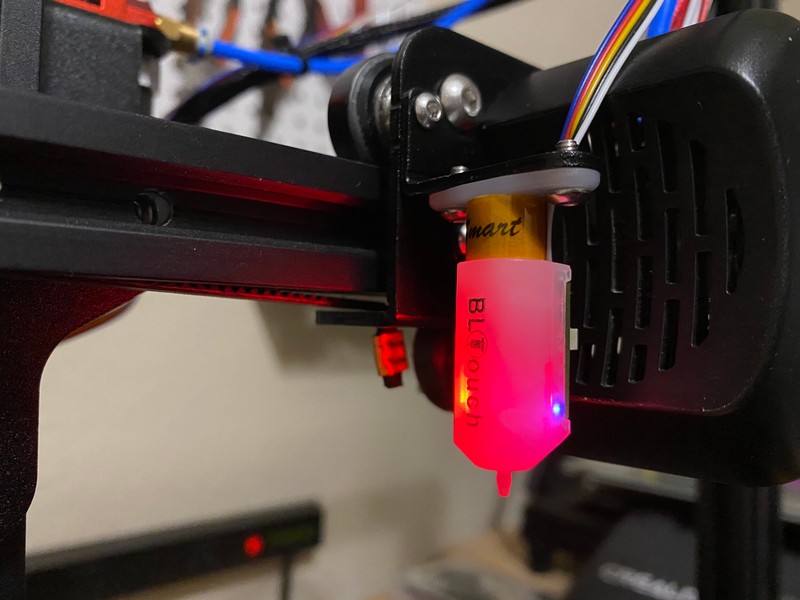

More and more FDM 3D printers are starting to include automatic bed leveling, which is a system that measures the distance between the print nozzle and the bed surface and automatically compensates for any variations. On an FDM machine, it’s critical for the first layer of the print to have a correct and consistent height throughout the entire layer, and automatic bed leveling is extremely helpful in achieving a consistent first layer.

We wouldn’t say that you should completely discount the idea of buying a printer without automatic bed leveling, though. Many 3D printers do not include automatic bed leveling, and instead require you to make small bed leveling adjustments using knobs below the print bed. While this process can be a bit tedious, especially for someone new to printing, it’s still possible to achieve great results with these printers. We also have found that the bed leveling settings don’t need to be adjusted for every print, so you aren’t signing yourself up for any daily effort if you forego automatic bed leveling. However, it’s a nice convenience feature and makes the 3D printer much easier to use.

It’s important to note that not all automatic bed leveling systems are created equal. Some systems use a touch-sensitive probe, such as a BLTouch or CR-Touch, which mechanically extends and touches the bed surface to detect its position. Other systems use no-touch probes that use techniques such as magnetic induction to detect the bed surface. In our experience, the BLTouch and CR-Touch probes are reliable and consistent, but the magnetic induction probes can be hit or miss. If you’re considering a 3D printer with automatic bed leveling, we highly recommend you look into that printer’s specific automatic bed leveling system and make sure it’s known to be reliable.

Bed Surface

There are several print bed surfaces used on different FDM 3D printers, and the bed surface can have a big impact on the reliability and ease of use of the printer. A quality bed surface will cause the first printed layer to stick firmly to the bed, which is necessary for a successful and accurate print, but will also allow the finished part to be removed once the bed has cooled down. The bed surface also must be durable enough to not flake off or break when removing a print. Finally, the bed surface affects the surface finish of the bottom of the printed model, so in some cases you may want to choose a surface based on your desired appearance of the printed parts.

It’s often, but not always, possible to change the bed surface of your 3D printer, so this is a possible upgrade option even if the 3D printer you buy doesn’t have the bed surface you want. The main exception to this is printers that have an automatic bed leveling system that uses magnetic induction—because those systems require the bed to be made of metal, you’re limited in which bed surfaces you can use. You may also run into trouble finding an aftermarket bed surface if your 3D printer has an oddly-shaped bed or a particularly large bed.

Our short list of preferred bed surfaces are these:

- Borosilicate glass, which is durable and gives printed models a shiny, smooth bottom finish. The only downside to glass beds is that you must use an adhesive such as hairspray or a glue stick to allow the first layer to stick to the bed.

- Carborundum, a textured glass-like surface that has exceptionally good layer adhesion with no added adhesive needed, and can be cleaned with water when adhesion starts to suffer.

- PEI spring steel, which gives printed models a shiny, smooth bottom finish. This type of bed surface can be removed from the printer and flexed to aid in part removal, and can be cleaned with isopropyl alcohol as needed.

We also have a comprehensive guide to many common 3D printer bed surface types, if you’d like to learn more about the different available bed surfaces.

Specs That Don’t Matter

In contrast to the specs we covered previously that you should consider when choosing a 3D printer, there are other specs that you can safely disregard. Here are a few examples:

- Minimum layer height, or layer resolution, which is identical for almost all modern FDM 3D printers and is not a meaningful indicator of print quality

- Nozzle diameter, which, while impactful for print characteristics, is easily changed after purchase with a low-cost replacement nozzle

What’s Next?

After reading this guide, you should have a clear idea of which features to look for in a new FDM 3D printer, and you’re ready to start researching all of the options. You can start exploring the wide variety of 3D printers in our 3D printer database, which allows you filter on different specs, as well as view all of the technical details of a particular printer and read our analysis of each machine’s strengths and weaknesses. We also have a comprehensive brand guide, which covers each 3D printer brand in detail.

On the other hand, if you’d prefer to read our advice on specific machines to consider, check out our list of 3D printer recommendations.