If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Bambu Lab P1P

About the Bambu Lab P1P

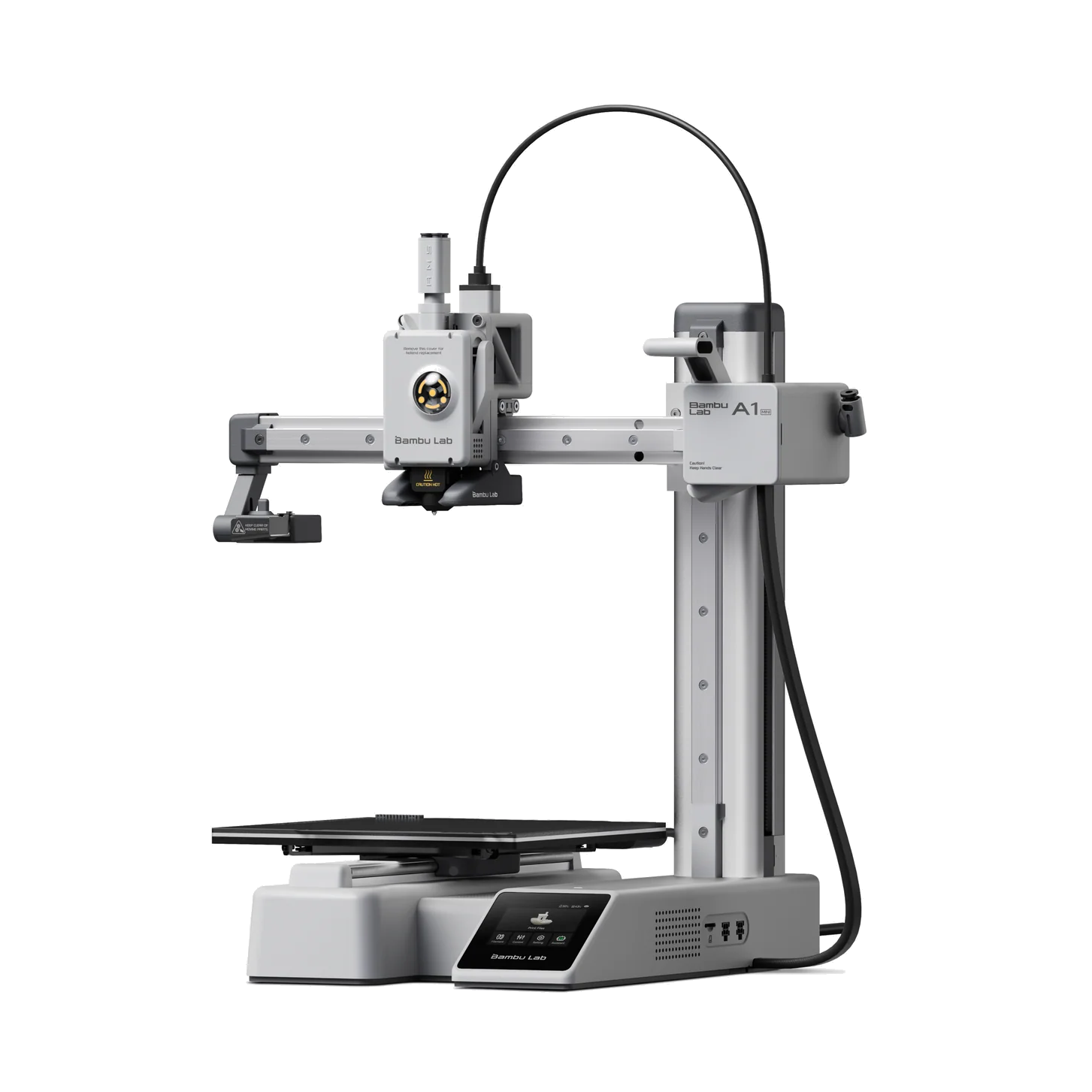

The Bambu Lab P1P, introduced in November 2022, is a well-known 3D printer that brought Bambu Lab’s high-end features to a more affordable price point. With a generous build volume and very fast print speeds, the Bambu P1P is still a noteworthy printer and a solid performer.

Key Features of the Bambu Lab P1P

Design and Build Volume

The P1P is housed in an open metal frame with a CoreXY motion system, offering a build volume of 256 x 256 x 256 mm (10” x 10” x 10”). Despite its above-average build volume, it maintains a compact footprint, measuring approximately 386 x 389 x 458 mm (15.2” x 15.3” x 18”), making it well-suited for home use.

Extruder and Hotend

The P1P is equipped with a direct drive extruder and an all-metal hotend capable of reaching temperatures up to 300°C, enabling it to handle a wide array of filament types, including flexible filaments.

Print Speed

With a maximum print speed of 500 mm/s and acceleration of 20,000 mm/s, the P1P is among the fastest in the consumer FDM 3D printer category. It achieves these speeds through its CoreXY motion system and enhanced firmware features, allowing it to maintain excellent print quality even at high speed.

Bed Surface

The P1P includes a flexible textured PEI build plate, known for strong adhesion and ease of print removal. The printer also supports other build plate options offered by Bambu Lab, such as a smooth PEI build plate that leaves a smooth finish on the bottom of prints.

Connectivity and Monitoring

Featuring Wi-Fi connectivity, the P1P can be controlled remotely via the Bambu Studio computer application or the Bambu Handy app. It includes a 720p camera within the build chamber for monitoring ongoing prints.

Display and Controls

The P1P’s interface includes a small monochrome display and button controls, offering basic functionality for direct printer interactions. This display is smaller and harder to read than the graphical displays found on many other modern 3D printers, which is a downside.

AMS Compatibility

Compatible with Bambu Lab’s Automatic Material System (AMS), the P1P allows for advanced printing capabilities such as multi-color prints and automatic filament switching when one spool runs out. Since most FDM 3D printers are capable of printing with a single color only, the AMS is a unique capability of Bambu Lab’s printers.

Optional Customization and Upgradability

The P1P provides the option to 3D print side panels, adding a degree of customization and some protection from air drafts that can interfere with prints. For users who want a more substantial upgrade, Bambu Lab also offers an upgrade kit to upgrade the P1P to a Bambu P1S, which adds a full enclosure and improved part cooling.

Summary

Our overall take on the Bambu Lab P1P is that its high-end feature set makes it a compelling choice for users who want a capable 3D printer that doesn’t require assembly or extensive calibration. Its print quality and speed are comparable to the Bambu Lab X1-Carbon, but at a much lower price point that is competitive with offerings from other manufacturers. However, the P1P is limited in a few ways—it doesn’t have as many ease-of-use features as the X1-Carbon, and its proprietary hardware and firmare mean you are reliant on Bambu Lab for continued support of the machine. For users who want a 3D printer that feels high-end but want to stay within a budget, the Bambu Lab P1P should be a front-runner choice.

For further information and purchasing options, visit the Bambu Lab website: Bambu Lab P1P.

Brand Summary: Bambu Lab

Bambu Lab, founded by ex-DJI engineers in Shenzhen, has made waves in the 3D printing industry with its focus on speed, innovation, and user-friendliness. While it began its journey through a successful Kickstarter campaign, raising $7 million in a month, the brand has since had its share of growing pains, including shipping issues and firmware bugs. The company's commitment to creating intuitive, precalibrated 3D printers like the X1-Carbon and P1P is commendable, but some users have found limitations with the proprietary components and software. Despite these challenges, Bambu Lab boasts a large community of dedicated users across various platforms and continues to evolve in its offerings and customer service.

Pros

- Modern mainboard features

- Auto bed leveling

- Large online community

- Premium components

- Fully assembled

- Direct drive extruder

- PEI build surface has good balance of adhesion and part removal

- Generous Build volume

- Wireless printing

- Linear rail motion system

- All-metal hot end

- CoreXY Kinematic System

- Dual gear extruder

Cons

- No touch screen

- High price tag

- Dated LCD Screen

Compatible Accessories and Upgrades

- Bambu AMS HT

The Bambu Lab Automatic Material System High Temp, or AMS HT, is an accessory for Bambu Lab 3D printers that allows you to heat and dry filaments that are particularly sensitive to humidity. The AMS HT can heat up to 85° C and includes a display to monitor settings. You can attach up to 8 AMS HT units and 4 AMS 2 Pro units to a single Bambu 3D printer, enabling you to use the AMS HT as part of a multi-material 3D print with up to 24 colors or materials.

- Bambu AMS 2 Pro

The Bambu Lab Automatic Material System 2 Pro, or AMS 2 Pro, is an accessory for Bambu Lab 3D printers which allows the printer to use up to four filament spools during a print, allowing for multi-color and multi-material 3D printing. The AMS 2 Pro improves on the original AMS by adding heating/drying functionality, faster speed, and physical design changes to improve usability. You can attach up to 4 AMS 2 Pro units and 8 AMS HT units to a single Bambu 3D printer, enabling 24-color 3D prints.

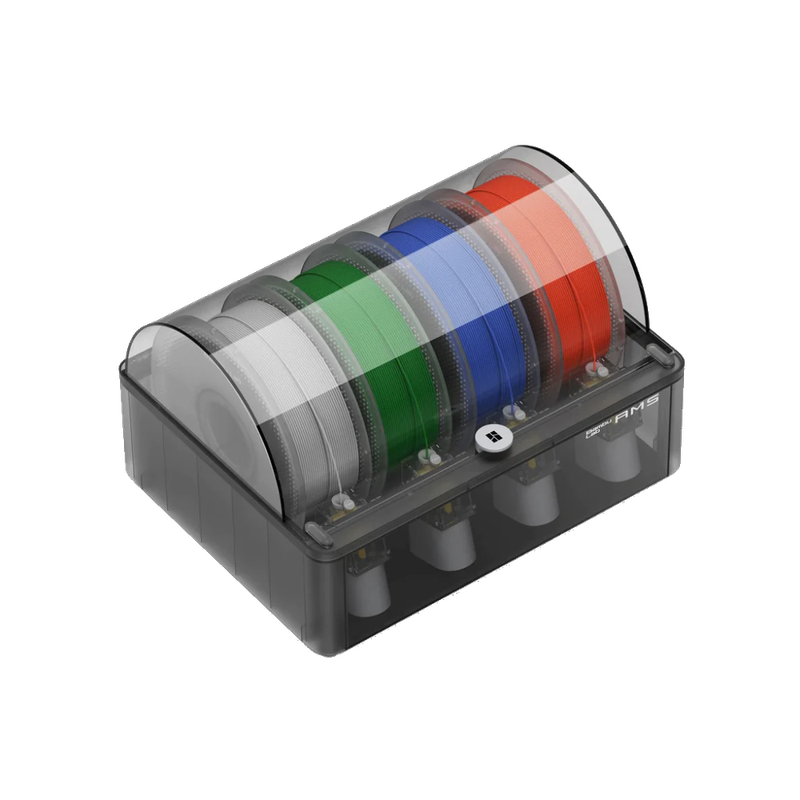

- Bambu AMS

The Bambu Lab Automatic Material System, or AMS, is an accessory for Bambu Lab 3D printers which allows the printer to use up to four filament spools during a print, allowing for multi-color and multi-material 3D printing. Additionally, you can attach up to four AMS units to a single Bambu 3D printer, enabling 16-color 3D prints.

- Bigtreetech Panda Touch

The Panda Touch is a touchscreen controller for Bambu Lab 3D printers made by Bigtreetech, who produces a line of accessories for Bambu Lab's machines. It provides a larger and more functional user interface than the built-in screen on most Bambu 3D printers, and offers additional capabilities for wireless monitoring and print farm management.

More on the Bambu Lab P1P

- Reference - Bambu Lab P1P Printer Overview (Current page)

- 3DPros Articles - Bambu Lab P1P Review

Printer Comparisons

The articles below provide in depth comparisons of the Bambu Lab P1P to other similar printers on the market.

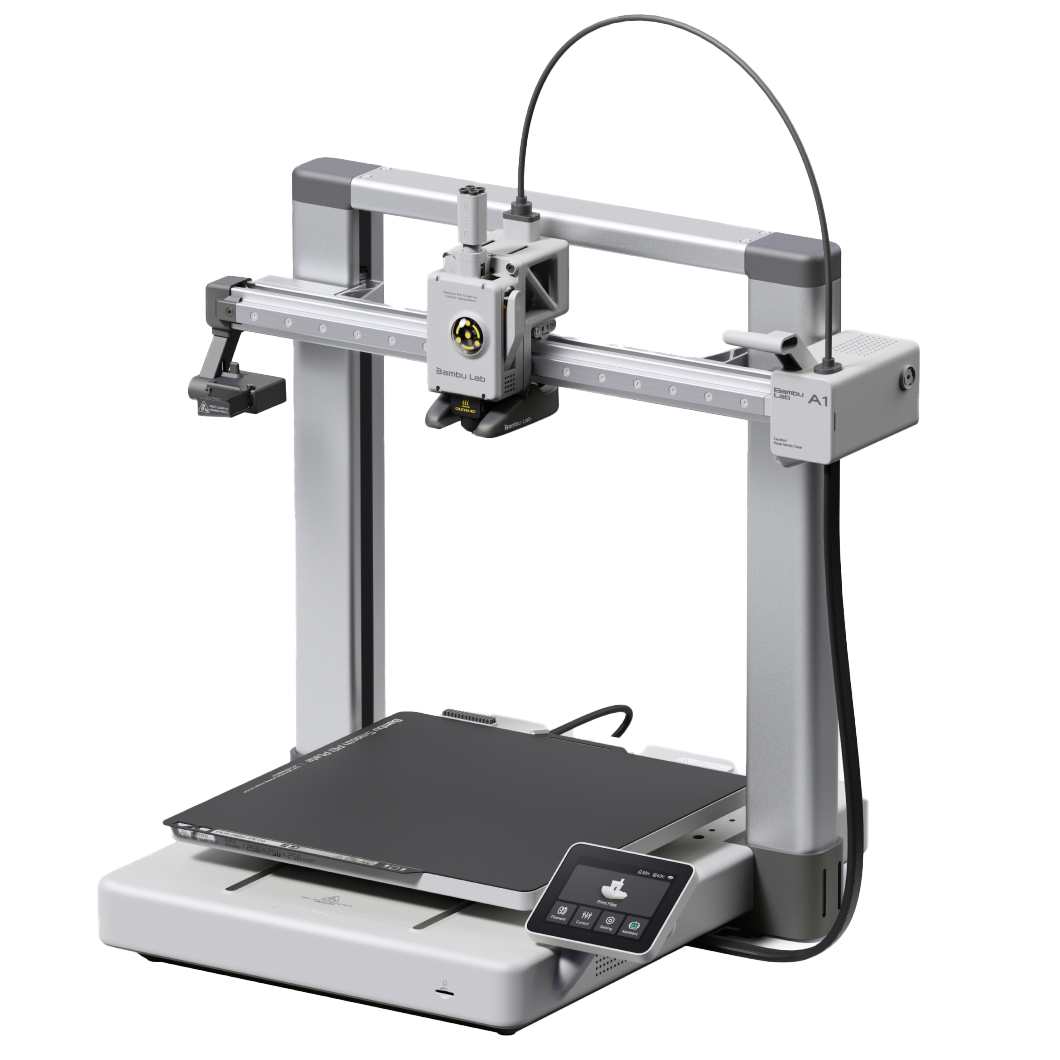

Comparing the Bambu Lab A1 vs the Bambu Lab P1P

Vs

Comparing the Bambu Lab P1P vs the Prusa MK4

Vs

Comparing the Bambu Lab P1P vs the Creality K1

Vs

Comparing the Bambu Lab P1P vs the Bambu Lab A1 Mini

Vs

Comparing the Bambu Lab P1S vs the Bambu Lab P1P

Vs

Comparing the Bambu Lab X1-Carbon vs the Bambu Lab P1P

Vs

You can compare the Bambu Lab P1P to other 3D printers using our Compare tool.