If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Prusa MK4

About the Prusa MK4

The Prusa MK4 was announced by Prusa Research in late March of 2023. It is an iterative design from Prusa’s MK3 line, which had sold 350,000 units worldwide from 2018-2023 and was highly respected by the 3D printing community for its reliability and open-source community. Prusa certainly took their time developing the MK4; the MK3’s features and performance have been met and surpassed by other manufacturers for a few years now. By the time the MK4 finally went on sale, it was one of the last printers of its caliber to be introduced to the market. Nevertheless, Prusa ships several thousands of units of the MK4 each month to customers worldwide. The MK4 debuts a plethora of new features for Prusa, including an extruder design capable of automatic calibration and easy nozzle swapping, rigid structure and high precision motors for increased print quality, and new electronics and firmware for higher speed printing and built-in support for cloud printing.

Key Features of the Prusa MK4

Structural Design and Drive System

For the MK4, Prusa continues to use the popular FDM Standard Cartesian drive system, with the print bed moving in the Y-axis while the extruder moves along the X-axis. The MK4 has a rigid structural design, utilizing cylindrical roller bearings and hardened steel rods to define each axis of motion. The X and Y axes each use 2x-8mm rods, while the Z axis utilizes 2-10mm rods for support. The frame is made of die-cast aluminum and utilizes a honeycomb-style structure for added rigidity in the X and Z directions. The open frame design gives you easy access to all 3D printer components and is capable of a maximum print area of 250 x 210 x 220mm. While the open frame design may be beneficial for accessibility, it lacks the clean, polished look and environmental control that is achieved by brands with a more enclosed configuration. Advanced print enclosures for the MK4 are available from Prusa, but must be purchased separately at significant additional cost.

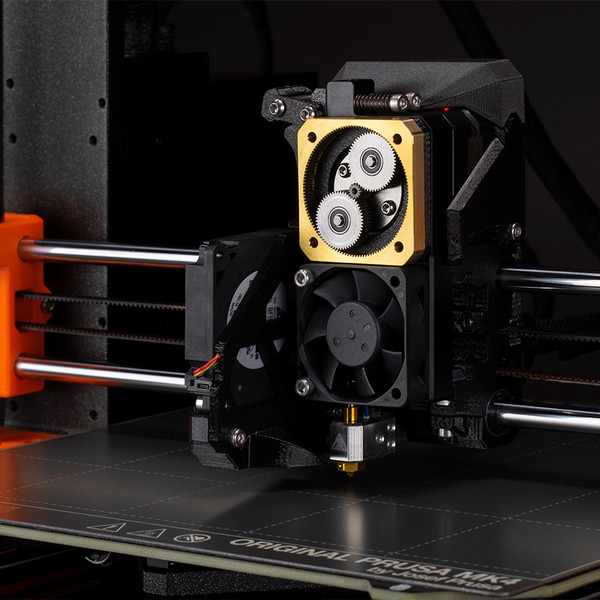

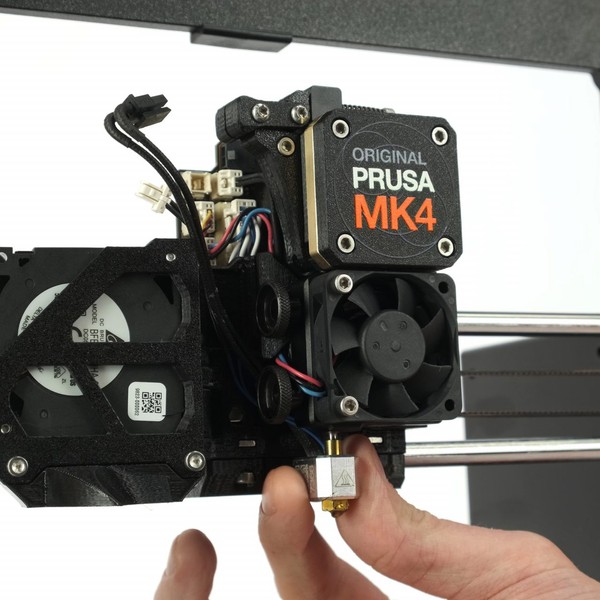

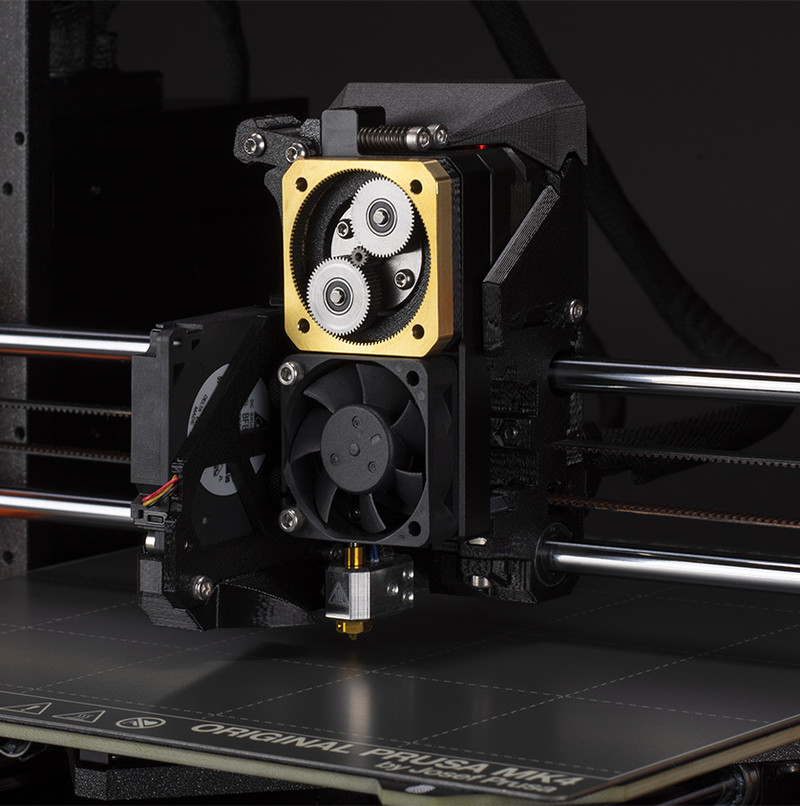

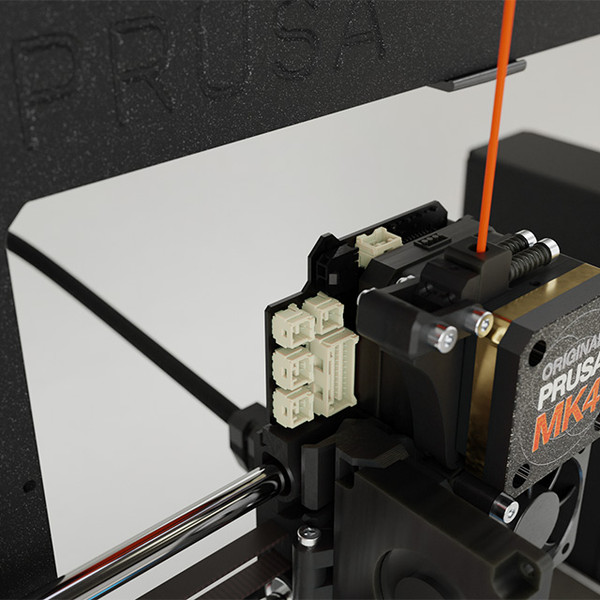

Extruder

The MK4 extruder, dubbed the “Nextruder” by Prusa, has a direct drive filament feeding system and utilizes an all metal hot-end. The hot-end is capable of temperatures up to 290℃ and has an aluminum heatsink. The extruder uses an all-metal filament guide leading into a 0.4mm brass nozzle. This design, along with a break-out board on the extruder itself, allows you to quickly unplug and remove the hot-end. You can then easily replace the nozzle with any other Prusa V6 nozzle of your choosing. The drive system for the extruder utilizes a 10:1 planetary gearbox and a pancake motor; a configuration that keeps the center of mass of the print head close to the X-axis, reducing vibrations induced by movement. A hall sensor in the filament drive detects if the filament has run out and pauses prints until you reload it.

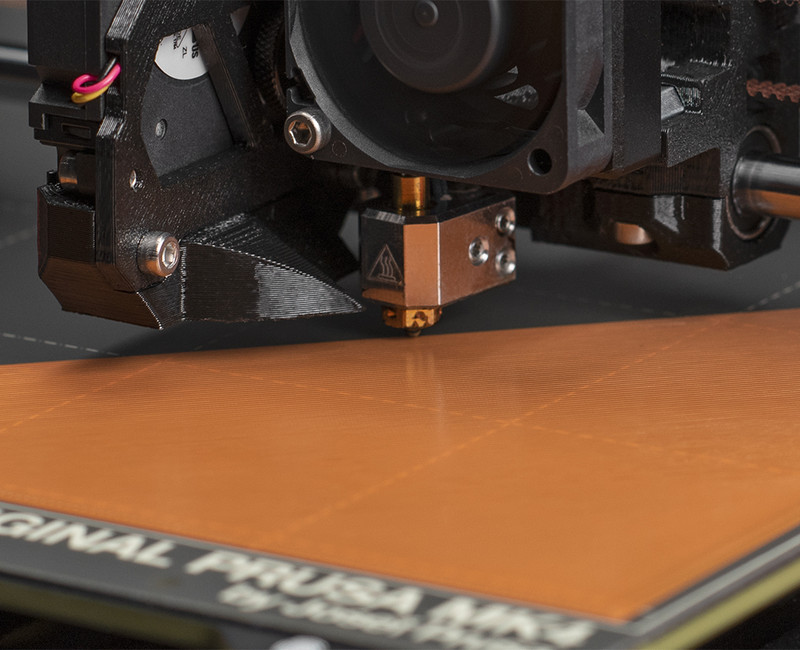

A load cell sensor on the extruder is used to achieve the MK4’s automatic bed leveling and perfect first layer. This sensor is able to accurately measure the distance between the nozzle and print bed. It uses this information to account for slight Z differences in the surface of the print bed and automatically adjust, as well as to choose the Z height for the first layer so that it sticks properly and prints smooth every time.

Print Bed

The MK4 print bed is capable of heating to 120℃ and ships with a smooth PEI steel print sheet. It is magnetic, so the sheet can easily be removed and flexed for safe print retrieval. Satin and textured powder coat sheets are also available from Prusa.

Printing Performance

The MK4 brings Prusa in line with a lot of the competition in the categories of speed and quality. Using a new 32-bit architecture for the MK4, the firmware utilizes two new features: Input Shaping and Pressure Advance. Input Shaping is a built-in process that predicts the vibrations created by moving parts in the printer and is able to actively prevent transfer of these vibrations into the print layers. Pressure Advance is an active means of controlling filament flow through the extruder. It is calibrated to reduce under-extrusion at the beginning of new lines/layers and over-extrusion at the end of a line or in a corner of the print. Together, these active algorithms give the 3D printer enhanced capability to print quickly with a high level of accuracy.

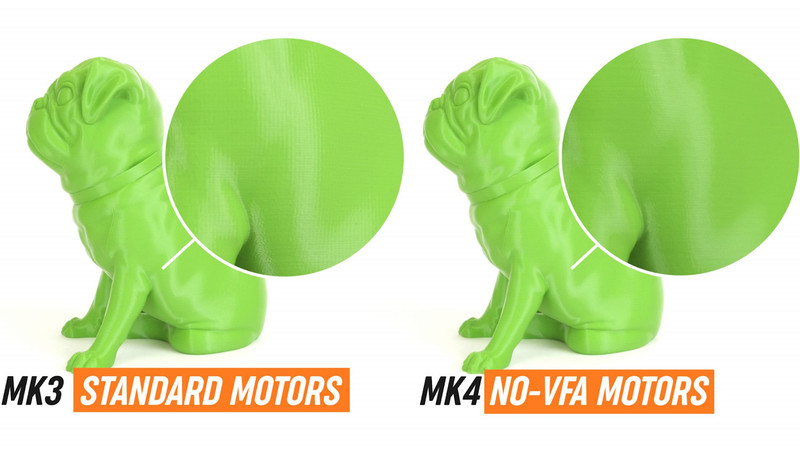

Another aspect of the MK4 that provides higher quality to prints is the use of new stepper motors with a high precision step angle of 0.9°. A lower step angle allows the stepper motor to achieve a more accurate position; this motor can accurately move to 400 unique positions within one full rotation of the motor. These precision motors are able to eliminate small Vertical Fine Artifacts, or VFAs, that can appear with less precise motors.

UI and Display

The MK4 has a 3.5” 65k color LCD that gives status information and allows you to select and execute print options directly on the printer. The screen does not have touch capability and is navigated with a clickable selector dial; while simple and effective, this makes the UI considerably more tedious than one that could be navigated by touch. The printer also includes an RGB status bar under the screen that shows colors to communicate discernable information about print status from afar. Adjacent to the front display is a USB-A port that can use a flash drive to directly load g-code files for printing.

Safety and Monitoring Features

Additional features that come with the MK4’s 32-bit firmware include overcurrent and overheating safety shutoffs for the hot-end and bed, power panic, and temperature monitoring for fan speed control. Power panic refers to the printer’s ability to detect power loss and pause a print so that it can be resumed when power returns. The MK4 actively monitors hot-end, heatbed, and ambient thermistors to control the print and hot-end cooling fans so that performance can remain stable even under varying conditions.

Connectivity and Software

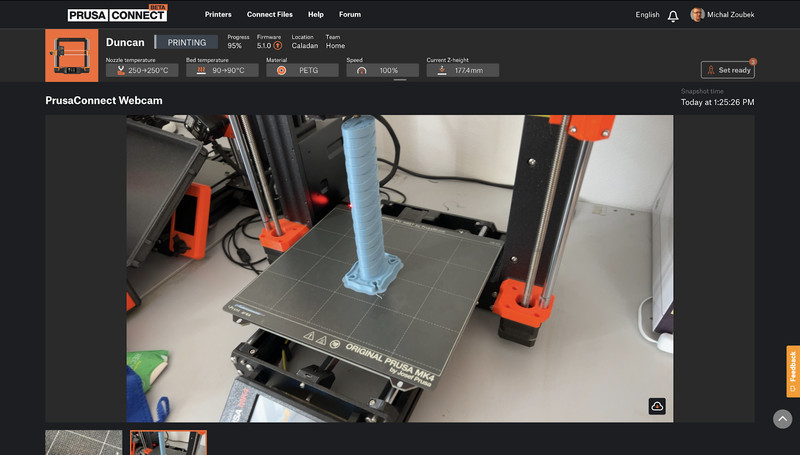

There are several options for connectivity on the MK4: it can connect to a print server over Wi-Fi/Ethernet or directly connect to a computer via USB. It is directly compatible with Prusa’s 3D printer management software, Prusa Connect. Prusa Connect allows you to remotely monitor printer status, upload print files to the cloud printing server, or even control the axes of the printer with specific inputs. It is also capable of tracking stats and metrics for your prints.

Summary

The MK4 offers many of the features that are expected for modern 3D printers. You can expect high quality printing from the rigid structure, high precision motors, and onboard extruder sensors. The extruder is versatile with a design that allows for easy swapping of print nozzles as well as easy access for servicing the extruder head. The firmware and electronics of the MK4 enable high printing speeds using advanced calibration algorithms without making any sacrifices to safety and reliability. Integrated connectivity gives the MK4 access to several ease of use features, including the remote management features of Prusa Connect.

The MK4 is one of the more expensive printers on the market: $1099 fully assembled, and $799 if you opt to put the printer together yourself. You’ll also need to pay for shipping, which can be quite expensive for some locations as Prusa ships all their printers directly from their headquarters in the Czech Republic. At this price point, the MK4 loses a lot of its competitive edge in performance and features, especially since it came to market so late. At total costs nearing $1200 assembled and shipped, you might expect printers to include some premium features such as a touchscreen, built-in print enclosure, or dual filament extrusion. Printers with similar features to the MK4 have been available at a lower cost for some time. Thus, the MK4’s greatest drawback is ultimately cost, even if you purchase it disassembled.

Nevertheless, the MK4 is well suited for people who are new to 3D printing and are interested in gaining a deep understanding of the printer itself; the Prusa community is well-established and has many resources for information, models, and troubleshooting readily available. It also appeals to those who want a reliable printer that takes little effort to calibrate properly and produce high quality prints. Additionally, the remote management and safety features make it a very attractive option for buyers who want to run a print farm of several printers with ease. However, if you are on a tight budget or want something that works out of the box with minimal assembly, there are similar-performing options out there at more competitive price points.

A close up of the hot end shows the convenient breakout board for the hot end components, making replacement much easier than previous models. (Image from prusa3d.com)

Brand Summary: Prusa

Prusa Research is a well-known manufacturer of high-end 3D printers that are known for their top-performing and innovative designs. The brand is mostly recognized for its impeccable documentation, high quality parts, and excellent customer support. Prusa printers are beginner-friendly once assembled, but the assembly process can be time-consuming, even though the firmware has extensive calibration and troubleshooting routines built-in. The Prusa community is large and active, with many technical experts among the veteran 3D printing hobbyists. Prusa's focus is on a few models at a time, and they are known for their well-made printers. However, competitors are rapidly catching up to Prusa, offering similar features at a lower price.

Pros

- Large online community

- Modern mainboard features

- Premium components

- Direct drive extruder

- Wireless printing

Cons

- Difficult to assemble

- High price tag

Printer Comparisons

The articles below provide in depth comparisons of the Prusa MK4 to other similar printers on the market.

Comparing the Bambu Lab P1S vs the Prusa MK4

Vs

Ender 3 V3 vs Prusa MK4

Vs

Comparing the Bambu Lab P1P vs the Prusa MK4

Vs

Comparing the Prusa MK3S+ vs the Prusa MK4

Vs

Comparing the Bambu Lab X1-Carbon vs the Prusa MK4

Vs

Comparing the Bambu Lab X1 Carbon Combo vs the Prusa MK4

Vs

You can compare the Prusa MK4 to other 3D printers using our Compare tool.