If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Bambu Lab A1 Mini

About the Bambu Lab A1 Mini

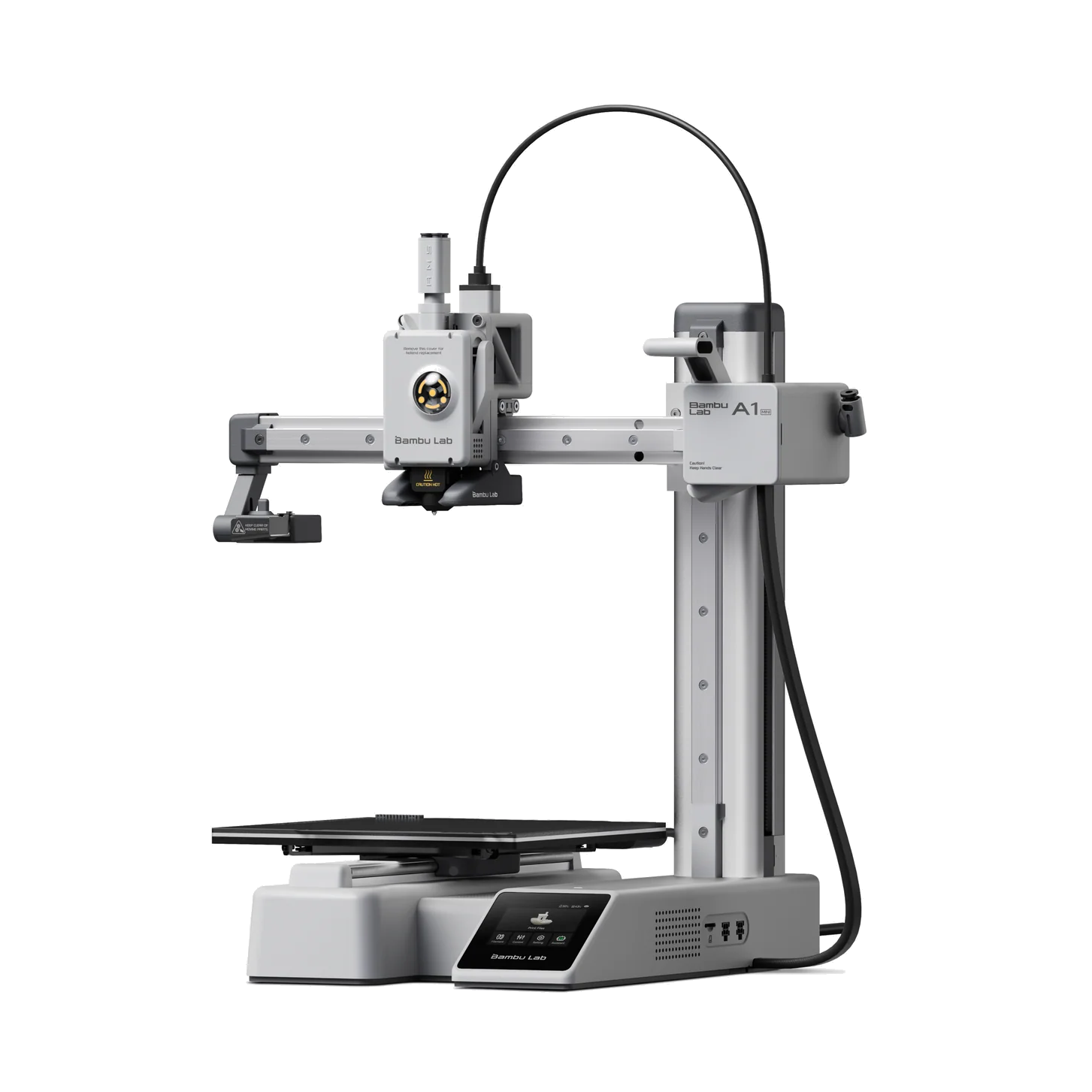

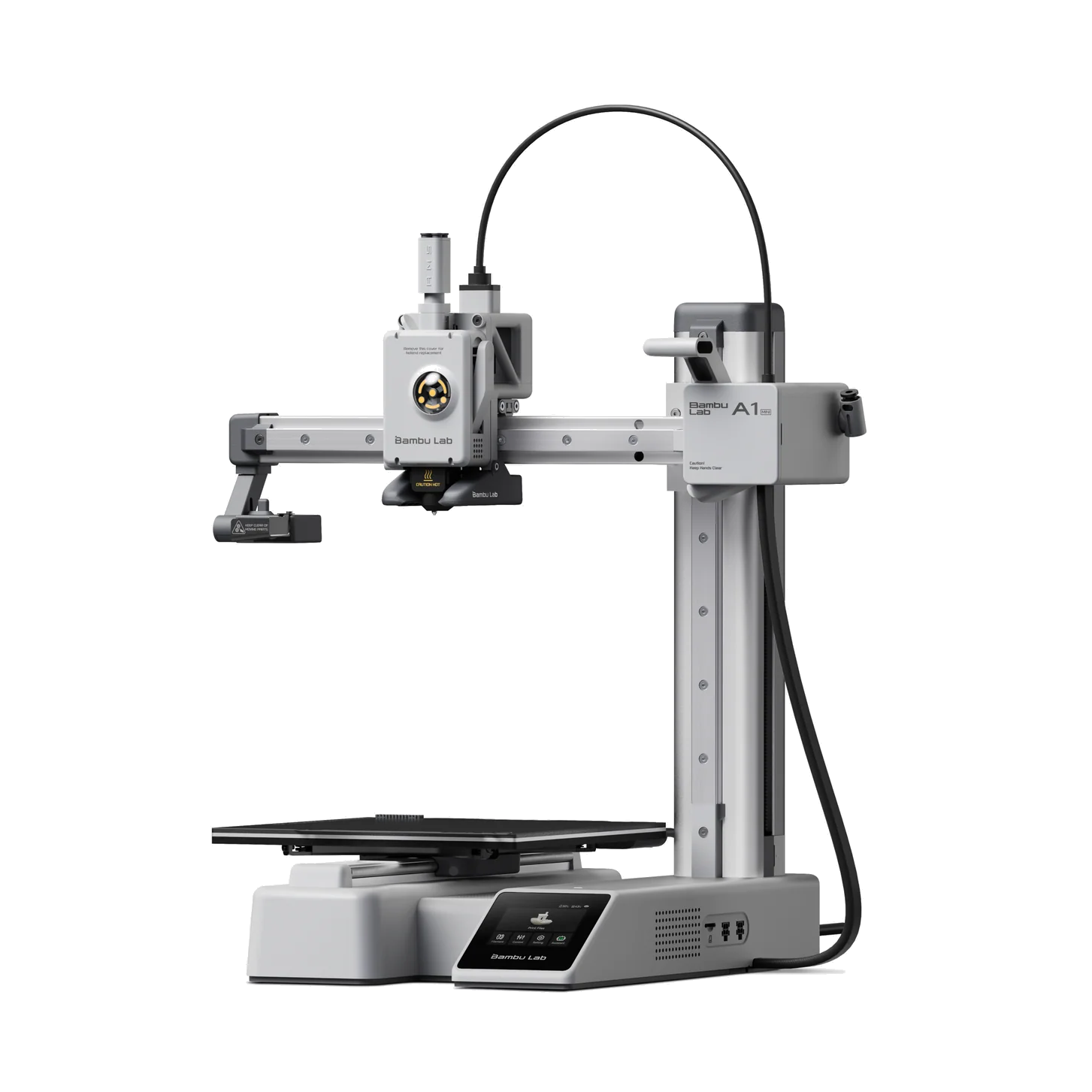

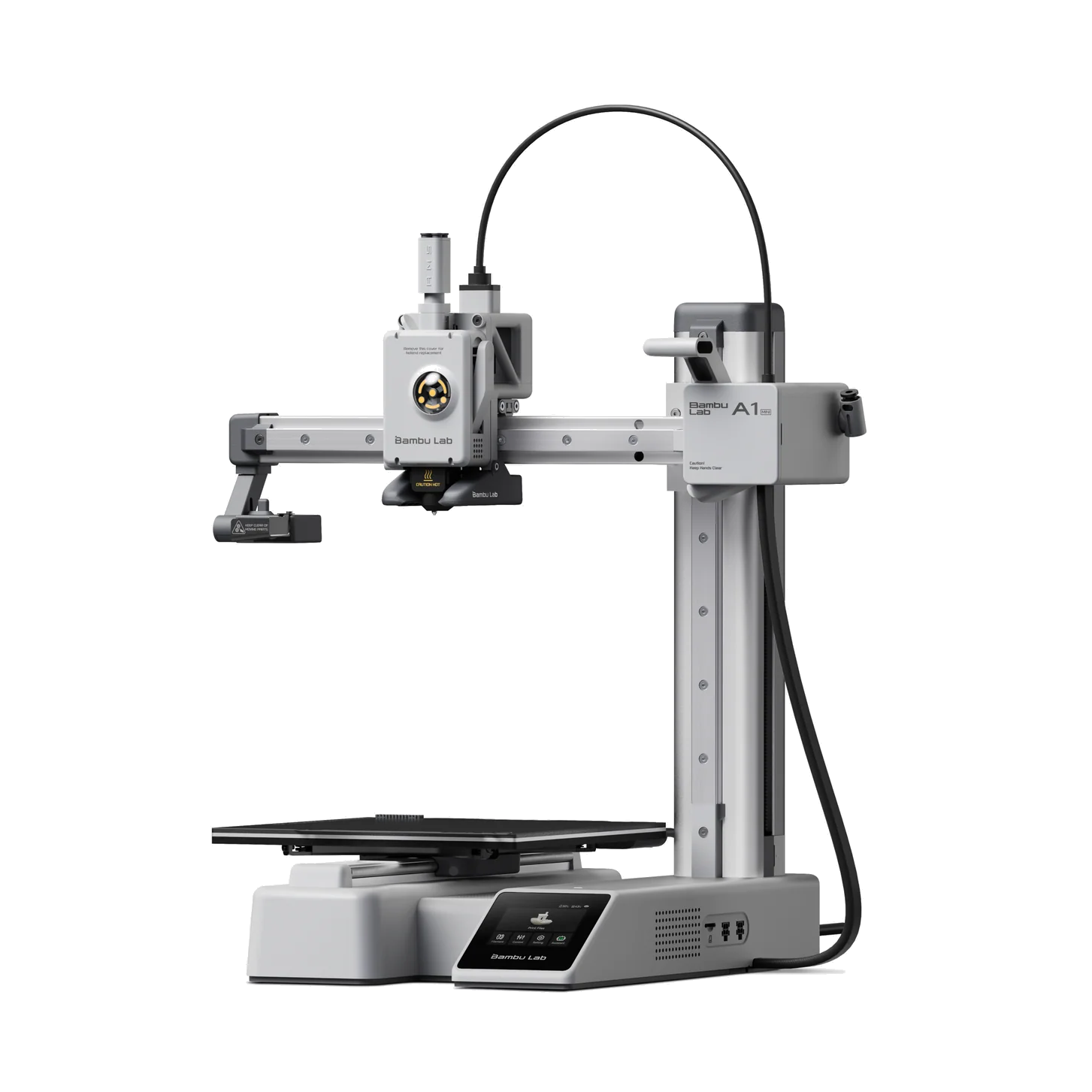

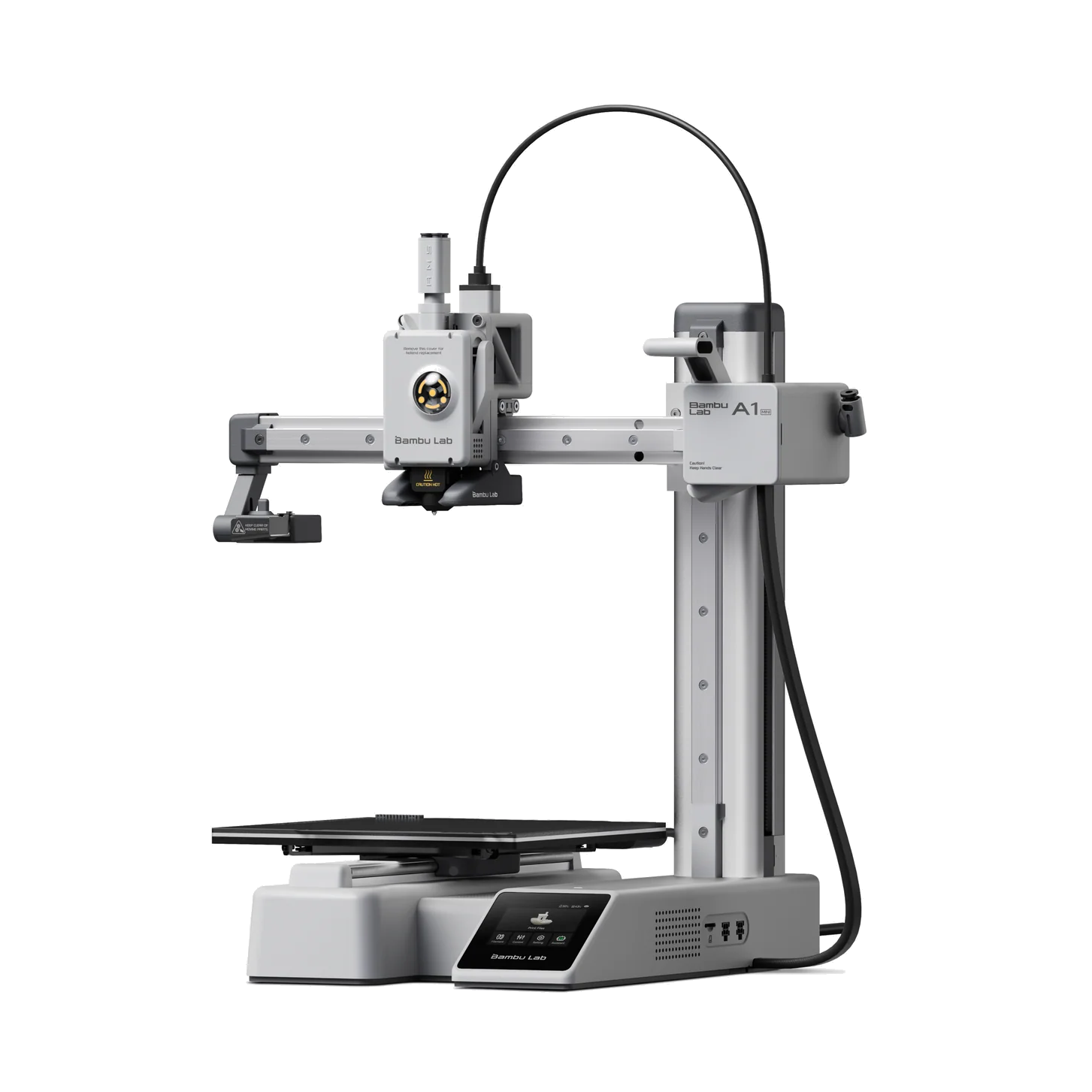

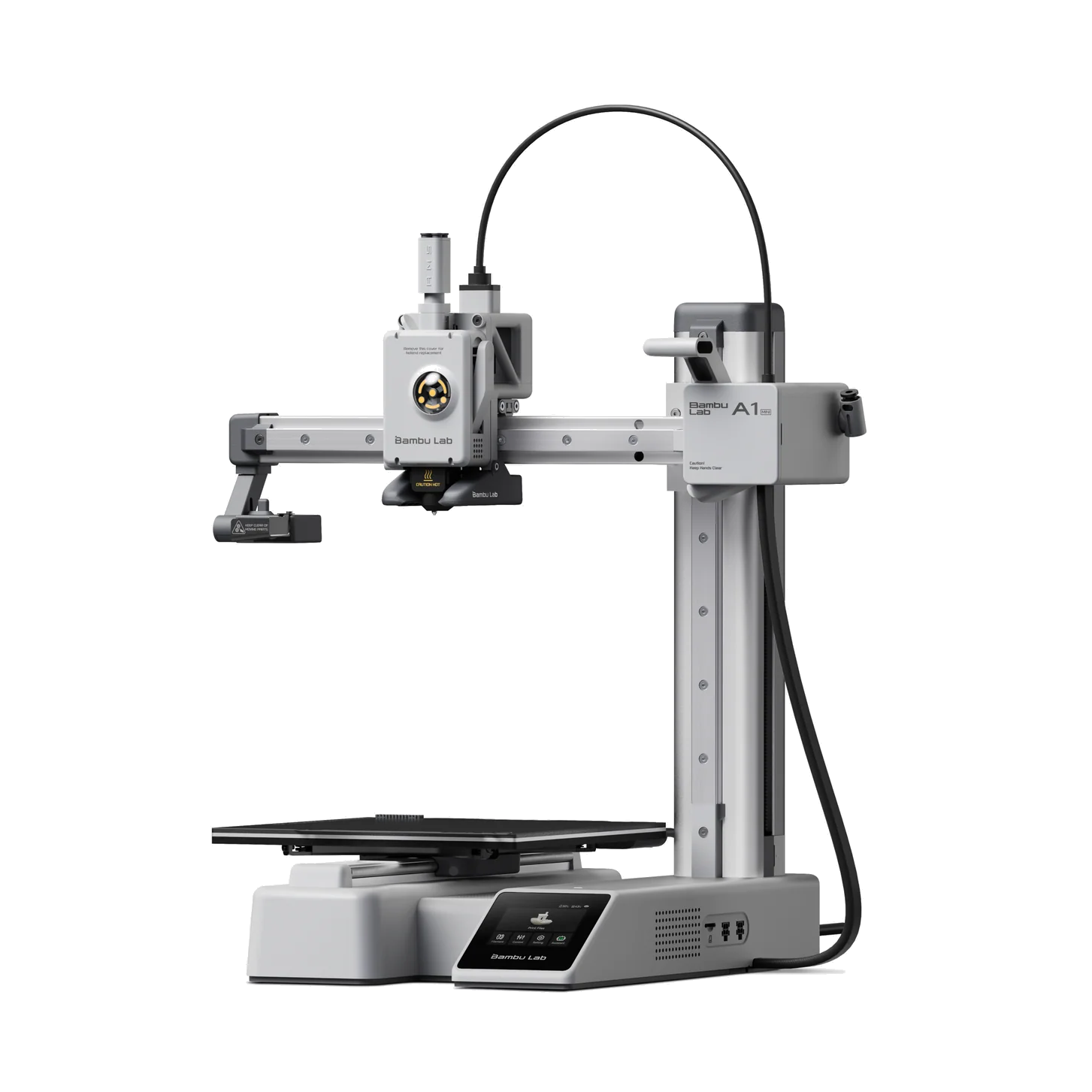

The Bambu Lab A1 Mini, released in the fall of 2023, marks an exciting addition to Bambu Lab’s lineup of 3D printers. With its unique design and a host of performance-driven features, the A1 Mini stands out as an affordable and efficient option for those venturing into the world of 3D printing.

Key Features of the Bambu Lab A1 Mini

Compact Design and Build Volume

The A1 Mini features an unusual cantilever design, breaking away from the traditional 3D printer aesthetics and motion system design. Despite its compact size, the A1 Mini offers a respectable build volume of 180 x 180 x 180 mm (7.1” x 7.1” x 7.1”), providing ample space for a variety of printing projects. However, this is notably smaller than the 220 x 220 x 250 mm (8.6” x 8.6” x 9.8”) build volume found on many other affordable 3D printers.

High Print Speed and Quality

Consistent with Bambu Lab’s reputation for fast printers, the A1 Mini features a maximum print speed of 500 mm/s. While its maximum acceleration of 10,000 mm/s² can’t quite match the speed of the Bambu P1S or X1C, it still delivers impressive print speeds that don’t compromise on quality. The A1 Mini’s firmware features, such as vibration compensation and pressure advance, play a key role in maintaining high-quality prints even at these speeds.

Direct Drive Extruder and Advanced Hotend

The A1 Mini is equipped with a direct drive extruder and an all-metal hotend that can reach temperatures up to 300°C, enabling it to print a wide range of filament types, including flexible materials.

Filament Compatibility

The A1 Mini supports many standard filament types like PLA, PETG, TPU, and PVA. Its heat bed can reach a maximum temperature of 80°C, which is lower than many other printers but still sufficient for printing with most standard materials. While the printer is not enclosed, limiting its effectiveness with materials like ABS and ASA, it excels with more common filament types such as PLA and PETG.

Bed Surface

The A1 Mini comes equipped with a flexible textured PEI build plate, offering excellent first-layer adhesion and ease of print removal. Textured PEI is one of our favorite build surfaces, and doesn’t require any glue, hairspray, or other substances to aid in adhesion.

Connectivity and Software Ecosystem

The A1 Mini includes WiFi support, allowing users to remotely monitor and control their prints through the Bambu Studio computer application or the Bambu Handy smartphone app. The Bambu Studio app also includes integrated slicing software, although third-party slicers can be used if preferred.

Additional Sensors

The A1 Mini stands out with its innovative filament tangle sensor, designed to pause prints if the spool gets tangled. This adds a layer of reliability uncommon in this price range. Additionally, it includes a flow sensor in the nozzle to allow it to automatically calibrate the filament flow rate, a key setting for maximizing print quality. These sensors are not found on most other 3D printers, and give the A1 Mini unique capabilities for preventing failures and improving printed models.

Graphical Touchscreen Controller

The A1 Mini includes an integrated graphical touchscreen controller, which is intuitive and user-friendly. This makes printer interaction and monitoring simple.

Multi-Material System (AMS Lite)

The A1 Mini is compatible with Bambu’s AMS Lite system, an affordable and capable multi-material add-on that supports up to four filament spools. This system enhances the A1 Mini’s versatility, allowing for multi-color and multi-material printing.

Summary

The A1 Mini’s compact size, coupled with its powerful features, makes it an ideal printer for those with limited space who do not want to compromise on functionality and quality. Its design and features make it a strong entry point into 3D printing or an excellent addition for experienced users seeking a reliable, compact printer.

For more details and purchasing options, visit the Bambu Lab website: Bambu Lab A1 Mini.

Brand Summary: Bambu Lab

Bambu Lab, founded by ex-DJI engineers in Shenzhen, has made waves in the 3D printing industry with its focus on speed, innovation, and user-friendliness. While it began its journey through a successful Kickstarter campaign, raising $7 million in a month, the brand has since had its share of growing pains, including shipping issues and firmware bugs. The company's commitment to creating intuitive, precalibrated 3D printers like the X1-Carbon and P1P is commendable, but some users have found limitations with the proprietary components and software. Despite these challenges, Bambu Lab boasts a large community of dedicated users across various platforms and continues to evolve in its offerings and customer service.

Pros

- Modern mainboard features

- Auto bed leveling

- Large online community

- Premium components

- Fully assembled

- Direct drive extruder

- PEI build surface has good balance of adhesion and part removal

- Wireless printing

- Linear rail motion system

- All-metal hot end

- Dual gear extruder

Cons

- Limited build volume

Compatible Accessories and Upgrades

- Bambu AMS HT

The Bambu Lab Automatic Material System High Temp, or AMS HT, is an accessory for Bambu Lab 3D printers that allows you to heat and dry filaments that are particularly sensitive to humidity. The AMS HT can heat up to 85° C and includes a display to monitor settings. You can attach up to 8 AMS HT units and 4 AMS 2 Pro units to a single Bambu 3D printer, enabling you to use the AMS HT as part of a multi-material 3D print with up to 24 colors or materials.

- Bambu AMS Lite

The Bambu Lab AMS (Automatic Material System) Lite upgrades the A1 series Bambu labs 3D printers with multi-color and multi-material printing capabilities. It features automatic filament backup and improved spool compatibility, making it easy to maintain and use. Additionally, it supports RFID filament synchronization.

- Bigtreetech Panda Touch

The Panda Touch is a touchscreen controller for Bambu Lab 3D printers made by Bigtreetech, who produces a line of accessories for Bambu Lab's machines. It provides a larger and more functional user interface than the built-in screen on most Bambu 3D printers, and offers additional capabilities for wireless monitoring and print farm management.

More on the Bambu Lab A1 Mini

- Reference - Bambu Lab A1 Mini Printer Overview (Current page)

- 3DPros Articles - Bambu Lab A1 mini Filament Handling

- 3DPros Articles - Bambu Lab A1 Mini Review: Brush with Perfection

Printer Comparisons

The articles below provide in depth comparisons of the Bambu Lab A1 Mini to other similar printers on the market.

Bambu Lab A1 Mini Vs. Ender 3 V3 KE

Vs

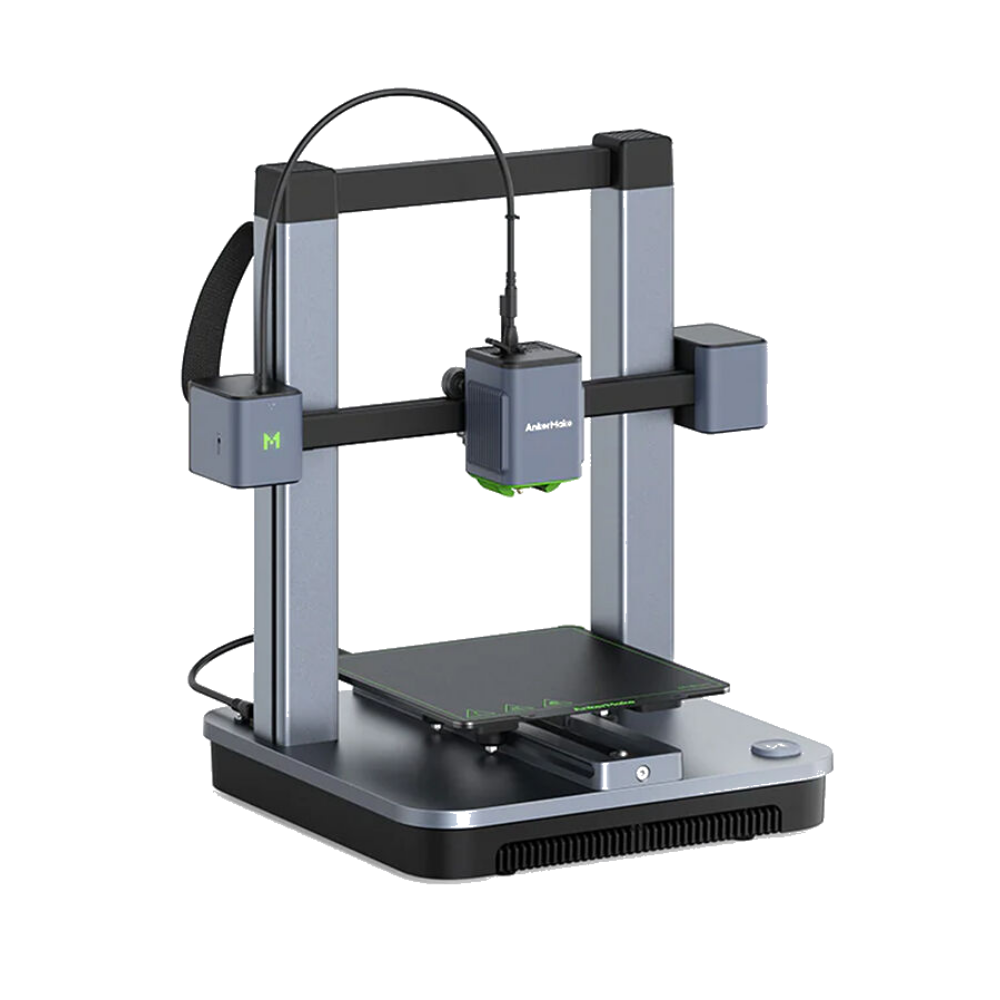

Bambu Lab A1 Mini and AnkerMake M5C

Vs

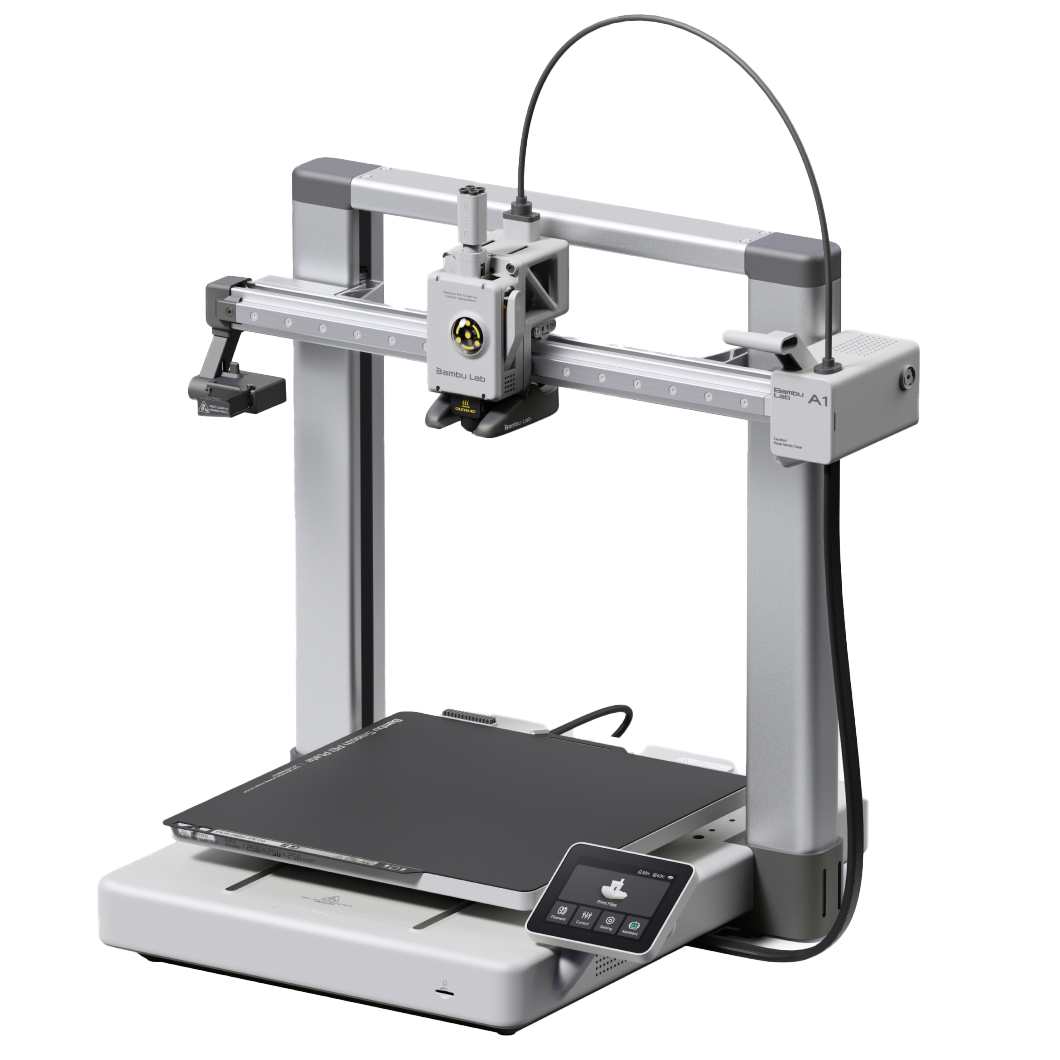

Bambu’s Bedslingers: the Bambu Lab A1 Compared to the Bambu Lab A1 mini

Vs

Clash of the Cantilevers: the Bambu Lab A1 mini vs

Vs

Comparing the Bambu Lab P1P vs the Bambu Lab A1 Mini

Vs

You can compare the Bambu Lab A1 Mini to other 3D printers using our Compare tool.