If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Bambu Lab X1 Carbon

About the Bambu Lab X1 Carbon

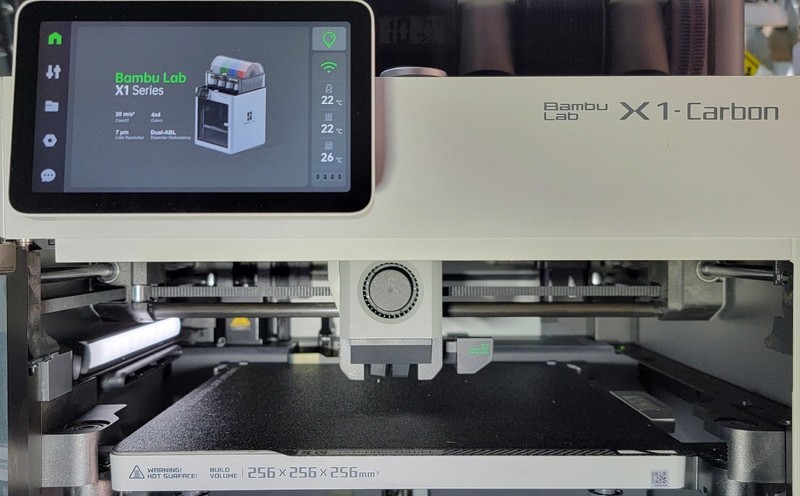

The Bambu Lab X1-Carbon, or X1C, is a premium 3D printer that offers extremely fast print speeds, an enclosed build chamber, and automated calibration and monitoring features enabled by AI vision and Lidar sensors. The X1-Carbon pushes the envelope of both performance and ease of use for consumer FDM 3D printers, making it a compelling choice if you are willing to pay for a higher-end machine.

Design and Build Volume

The Bambu Lab X1C has a fully enclosed build volume of 256 X 256 X 256 mm (10.1” x 10.1” x 10.1”), which is a bit larger than the standard size of 220 x 220 x 220 mm found on many other FDM 3D printers. It is made from a stamped metal frame, injection molded plastic, aluminum side panels, tinted glass door and lid, and a perforated steel back.

Motion System

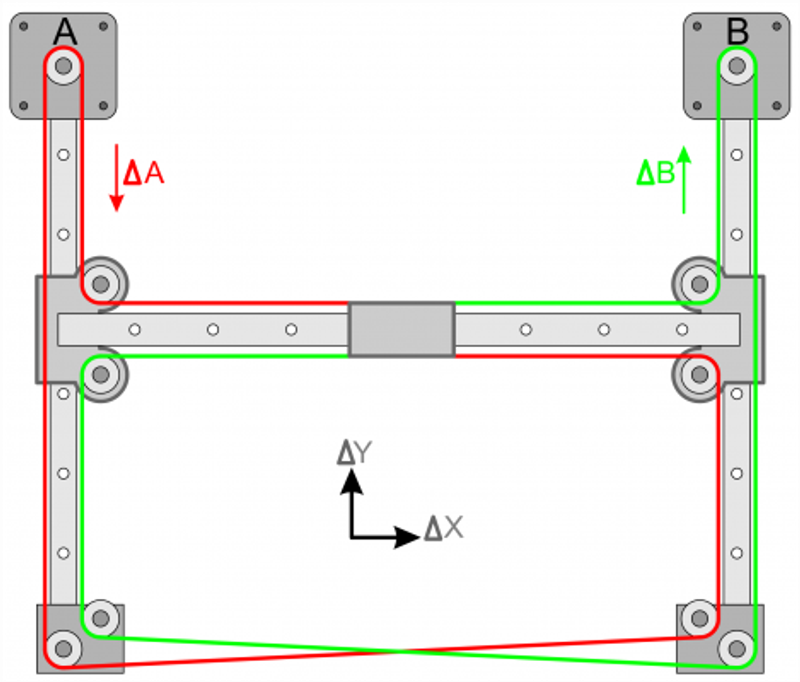

The X1C uses a CoreXY motion system. This uses 2 motors, referred to as A and B which are mounted high in the rear. Each motor drives their own 6mm timing belt, which is routed by pulleys to move the printhead in the X and Y Axis. This design allows for simultaneous movement along both the X and Y axes, resulting in quicker positioning and improved overall printing speeds. The absence of large motors on the moving carriage reduces the overall weight, allowing for better acceleration and deceleration, as well as improved efficiency.

The high precision and low backlash in CoreXY systems contribute to improved print quality. The Y Axis moves on a pair of steel guide rods per side, while the X Axis uses a pair of carbon fiber rods to reduce weight of the moving assembly. The print bed moves in the Z Axis on three steel guide rods via 8mm lead screws. The lead screws are connected by a 6mm timing belt in a loop to a single motor in the base.

Extruder, Printhead, and Heated Bed

The Bambu X1C has a compact direct drive extruder and uses 1.75mm filament. It uses hardened steel drive gear along with a hardened steel 0.4mm nozzle making it capable of printing abrasive filaments, such as carbon fiber and glow in the dark materials. The nozzle can reach a temperature of 300 degrees C, whichallows for a wider range of filament options including Polyamide(Nylon) and Polycarbonate for strong 3D prints from prototyping to functional end-use parts.

The X1 Carbon’s heated bed utilizes mains voltage. This can be 120 or 220 Volts AC depending on where you live, as opposed to the DC voltage many printers use which is typically 24V. This enables rapid heat up times for the bed, and allows it to reach a maximum temperature of 120 degrees C.

User Friendly Interface

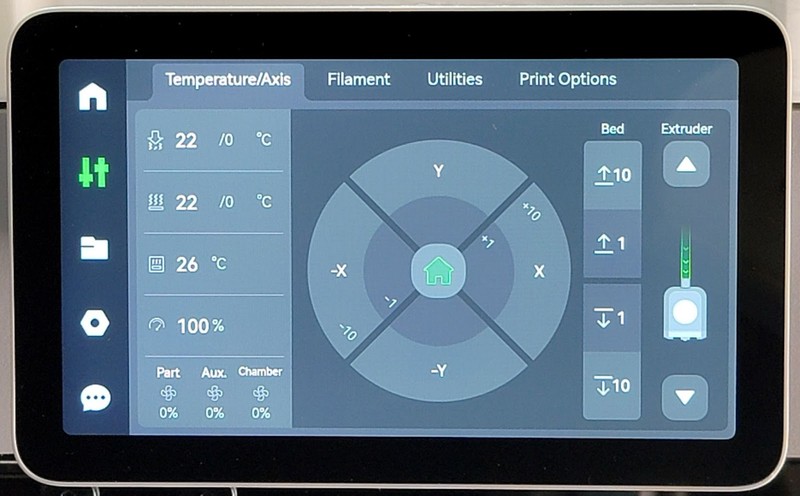

The Bambu Lab X1 Carbon uses a large 5 inch touchscreen interface, which simplifies the printing setup, allowing you to easily navigate through settings, monitor the printing process, and make adjustments on the fly.

The printer also supports a variety of file formats, making it compatible with a wide range of 3D modeling software, however some features are only available through the Bambu slicer, such as wireless printing. This is fairly typical though, since there is no standard yet for wireless printing.

Precision and Speed

The Bambu Lab X1 Carbon incorporates advanced motion control systems and high-resolution sensors, ensuring accurate layers with precision. Piezo sensors in the bed detect the nozzle touching it, and create a digital mesh of the bed’s surface. This and the Micro Lidar sensor mounted on the side of the printhead enables dual bed leveling, where the data from both of these sensors is combined to determine the bed level. The default grid density is 3x3 (9 points). However, if you still experience uneven first layer adhesion, you can increase the density in settings to 7x7 (49 points), at the cost of additional time to complete the levelling. 3x3 is typically plenty to get good first layers.

The Lidar sensor is also responsible for flow calibration and first layer inspection, making sure your prints have a great foundation. The X1 Carbon has a camera located on the top left hand side of the printer for remote monitoring and AI spaghetti detection. This looks for abnormal printing and warns you when something may be going awry.

The speed of the X1C’s printing process is facilitated by rigid, lightweight components and smart electronics, including accelerometers in the printhead to calculate and cancel out the frequencies that can lead to poor print quality and performance.

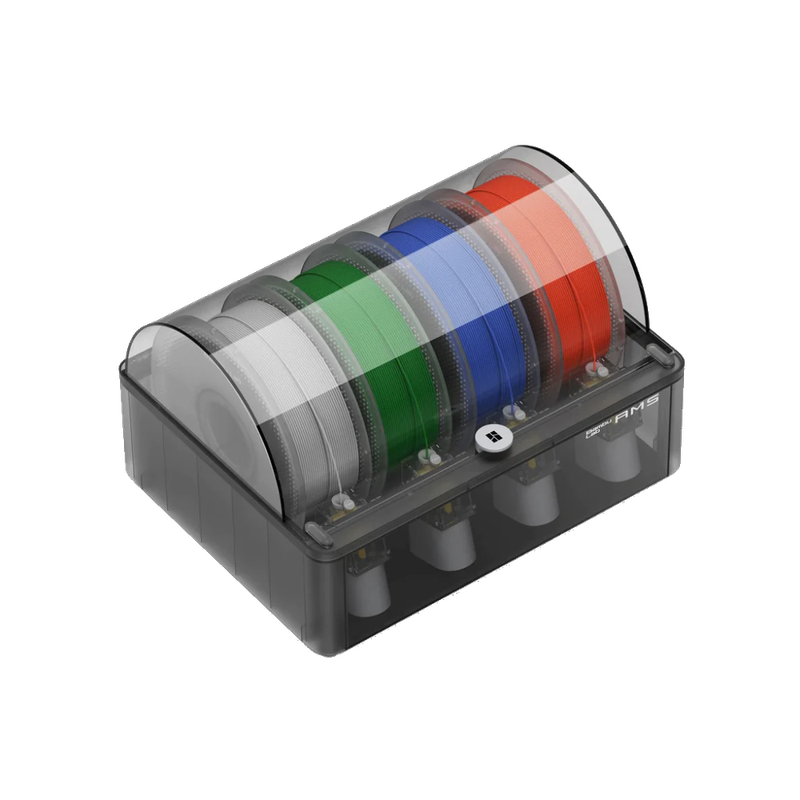

AMS Automated Material System

The AMS unit is an optional accessoy, which sits atop the X1C and allows users to load and print with up to 4 different filaments in the same print. The X1 Carbon can support up to 4 AMS units simultaneously, allowing for 16 different filaments in a single print. To switch filaments mid-print, the currently loaded filament is cut just above the hot-end, and retracted/respooled. The next filament necessary is then fed by the AMS to the hot-end of the X1C. The X1C will then purge the previous filament and get the new filament flowing out of the nozzle, ready to print. This ensures no bleeding of colors The little purge blobs are ejected out the back of the printer and can be collected by a user printable tray.

The Cons

High speed printing along with an automated loading/unloading of filament comes at a cost;nearly $1500 for the X1 Carbon with AMS. We’ve also found that the printer can be louder than others on the market, especially when printing at higher speeds.

Additionally, some filament spools won’t work in the AMS. They can be too wide, and won’t fit in the cradle, or too small - for example, 250 gram, and 500 gram spools are incompatible since they can’t contact the rollers to be rewound. However, this can be addressed by community developed printable modifications. The “Hydra AMS” available on Printables.com resolves these shortcomings by allowing for multiple roller locations for smaller spools and has wider allowances for larger spools.

Another drawback of the AMS is that multi-color or multi-filament prints create a lot of waste from purging the nozzle, especially when switching frequently between light and dark colors as it takes more to completely purge the previous filament.. Depending on the print, the wasted purge material can weigh as much or more than the final object. There is nothing included with the printer to catch these purge blobs coming out of the purge chute located at the back. However, you can download and print a catch tray, or just use a cardboard box.

Conclusion

We like the Bambu Lab X1 Carbon with AMS overall: it’s fast and easy to set up and produces beautiful prints. The AMS makes multi-colored printing easier than ever, though it is wasteful when purging. The X1 Carbon is able to print at high speeds and produces beautiful parts. It is quite loud while printing at high speed, and when the AMS is changing filament. Overall, these are minor inconveniences especially when considering the final products this system produces and the reliability of the machine, and we feel it is well worth the price if it is within your budget.

Brand Summary: Bambu Lab

Bambu Lab, founded by ex-DJI engineers in Shenzhen, has made waves in the 3D printing industry with its focus on speed, innovation, and user-friendliness. While it began its journey through a successful Kickstarter campaign, raising $7 million in a month, the brand has since had its share of growing pains, including shipping issues and firmware bugs. The company's commitment to creating intuitive, precalibrated 3D printers like the X1-Carbon and P1P is commendable, but some users have found limitations with the proprietary components and software. Despite these challenges, Bambu Lab boasts a large community of dedicated users across various platforms and continues to evolve in its offerings and customer service.

Pros

- Modern mainboard features

- Auto bed leveling

- Large online community

- Has touch screen

- Premium components

- Fully assembled

- Direct drive extruder

- PEI build surface has good balance of adhesion and part removal

- Generous Build volume

- Wireless printing

- CoreXY Kinematic System

- Enclosure

- Dual gear extruder

- Linear rail motion system

- All-metal hot end

Cons

- High price tag

- Limited Third-Party Repair Parts

Compatible Accessories and Upgrades

- Bambu AMS HT

The Bambu Lab Automatic Material System High Temp, or AMS HT, is an accessory for Bambu Lab 3D printers that allows you to heat and dry filaments that are particularly sensitive to humidity. The AMS HT can heat up to 85° C and includes a display to monitor settings. You can attach up to 8 AMS HT units and 4 AMS 2 Pro units to a single Bambu 3D printer, enabling you to use the AMS HT as part of a multi-material 3D print with up to 24 colors or materials.

- Bambu AMS 2 Pro

The Bambu Lab Automatic Material System 2 Pro, or AMS 2 Pro, is an accessory for Bambu Lab 3D printers which allows the printer to use up to four filament spools during a print, allowing for multi-color and multi-material 3D printing. The AMS 2 Pro improves on the original AMS by adding heating/drying functionality, faster speed, and physical design changes to improve usability. You can attach up to 4 AMS 2 Pro units and 8 AMS HT units to a single Bambu 3D printer, enabling 24-color 3D prints.

- Bambu AMS

The Bambu Lab Automatic Material System, or AMS, is an accessory for Bambu Lab 3D printers which allows the printer to use up to four filament spools during a print, allowing for multi-color and multi-material 3D printing. Additionally, you can attach up to four AMS units to a single Bambu 3D printer, enabling 16-color 3D prints.

Printer Comparisons

The articles below provide in depth comparisons of the Bambu Lab X1 Carbon to other similar printers on the market.

Comparing the Bambu Lab P1S vs the Bambu Lab X1-Carbon

Vs

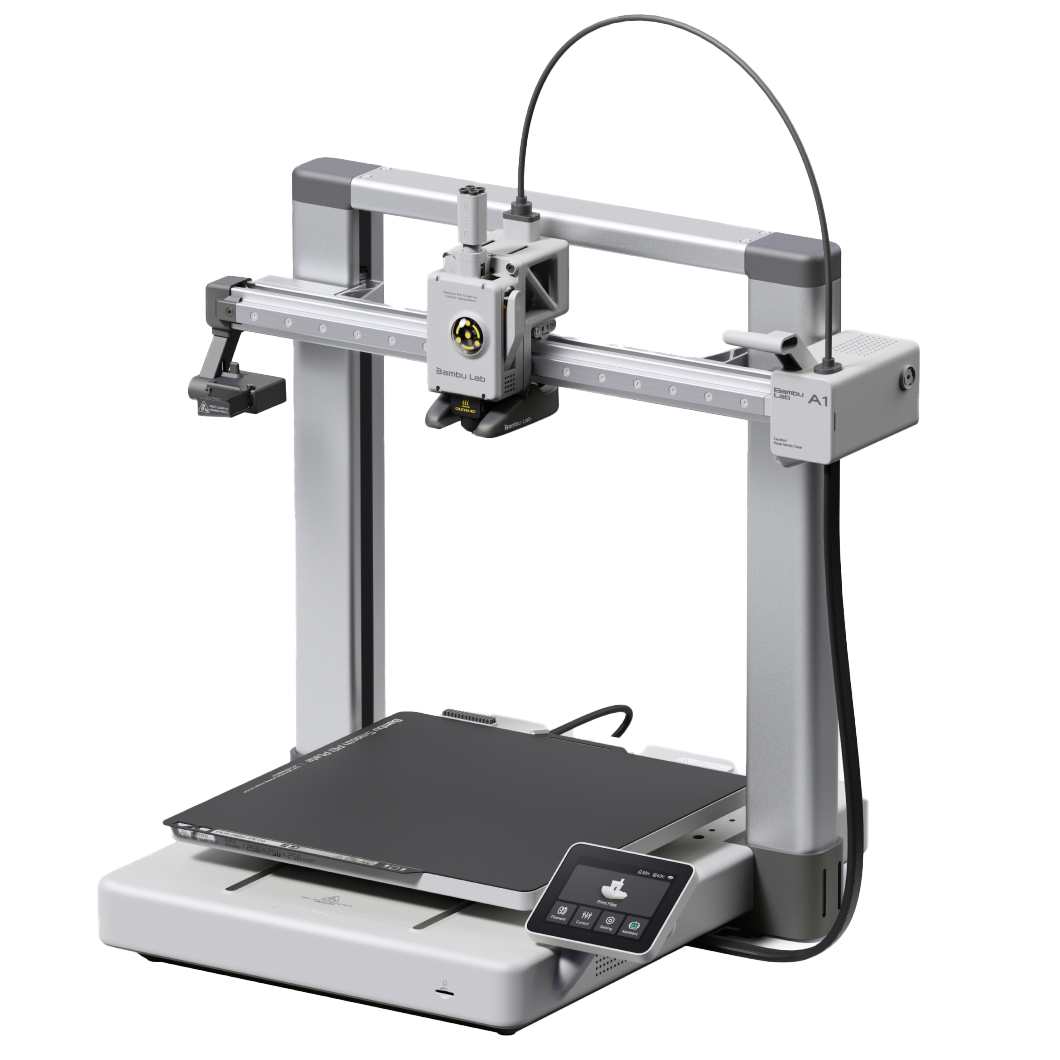

Comparing the Bambu Lab A1 vs the Bambu Lab X1 Carbon

Vs

K1C vs Bambu X1C

Vs

Comparing the Bambu Lab H2D vs the Bambu Lab X1C

Vs

Comparing the Bambu Lab X1-Carbon vs the Prusa MK4

Vs

Comparing the Bambu Lab X1-Carbon vs the Bambu Lab P1P

Vs

Comparing the Creality K2 Plus and the Bambu X1C

Vs

Comparing the Creality K1 Max vs the Bambu Lab X1 Carbon

Vs

Prusa CORE One vs Bambu Lab X1C

Vs

You can compare the Bambu Lab X1 Carbon to other 3D printers using our Compare tool.